Valtek Severe Service Equipment

Valtek Severe Service Equipment

Valtek Severe Service Equipment

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

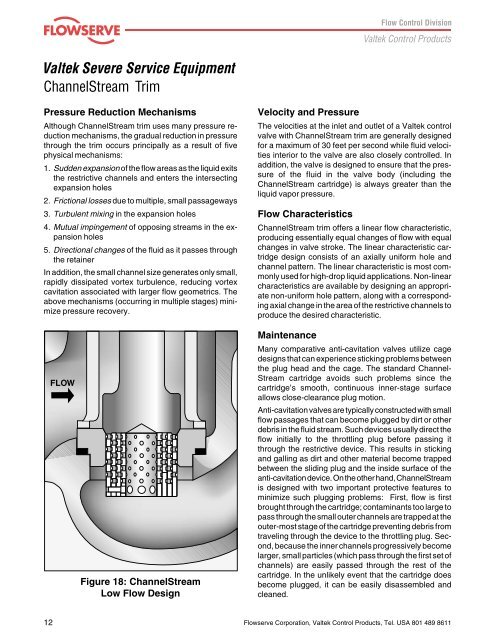

<strong>Valtek</strong> <strong>Severe</strong> <strong>Service</strong> <strong>Equipment</strong>ChannelStream TrimPressure Reduction MechanismsAlthough ChannelStream trim uses many pressure reductionmechanisms, the gradual reduction in pressurethrough the trim occurs principally as a result of fivephysical mechanisms:1. Sudden expansion of the flow areas as the liquid exitsthe restrictive channels and enters the intersectingexpansion holes2. Frictional losses due to multiple, small passageways3. Turbulent mixing in the expansion holes4. Mutual impingement of opposing streams in the expansionholes5. Directional changes of the fluid as it passes throughthe retainerIn addition, the small channel size generates only small,rapidly dissipated vortex turbulence, reducing vortexcavitation associated with larger flow geometrics. Theabove mechanisms (occurring in multiple stages) minimizepressure recovery.Velocity and PressureThe velocities at the inlet and outlet of a <strong>Valtek</strong> controlvalve with ChannelStream trim are generally designedfor a maximum of 30 feet per second while fluid velocitiesinterior to the valve are also closely controlled. Inaddition, the valve is designed to ensure that the pressureof the fluid in the valve body (including theChannelStream cartridge) is always greater than theliquid vapor pressure.Flow CharacteristicsChannelStream trim offers a linear flow characteristic,producing essentially equal changes of flow with equalchanges in valve stroke. The linear characteristic cartridgedesign consists of an axially uniform hole andchannel pattern. The linear characteristic is most commonlyused for high-drop liquid applications. Non-linearcharacteristics are available by designing an appropriatenon-uniform hole pattern, along with a correspondingaxial change in the area of the restrictive channels toproduce the desired characteristic.FLOWFigure 18: ChannelStreamLow Flow DesignMaintenanceMany comparative anti-cavitation valves utilize cagedesigns that can experience sticking problems betweenthe plug head and the cage. The standard Channel-Stream cartridge avoids such problems since thecartridge’s smooth, continuous inner-stage surfaceallows close-clearance plug motion.Anti-cavitation valves are typically constructed with smallflow passages that can become plugged by dirt or otherdebris in the fluid stream. Such devices usually direct theflow initially to the throttling plug before passing itthrough the restrictive device. This results in stickingand galling as dirt and other material become trappedbetween the sliding plug and the inside surface of theanti-cavitation device. On the other hand, ChannelStreamis designed with two important protective features tominimize such plugging problems: First, flow is firstbrought through the cartridge; contaminants too large topass through the small outer channels are trapped at theouter-most stage of the cartridge preventing debris fromtraveling through the device to the throttling plug. Second,because the inner channels progressively becomelarger, small particles (which pass through the first set ofchannels) are easily passed through the rest of thecartridge. In the unlikely event that the cartridge doesbecome plugged, it can be easily disassembled andcleaned.12Flowserve Corporation, <strong>Valtek</strong> Control Products, Tel. USA 801 489 8611