Valtek Severe Service Equipment

Valtek Severe Service Equipment

Valtek Severe Service Equipment

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

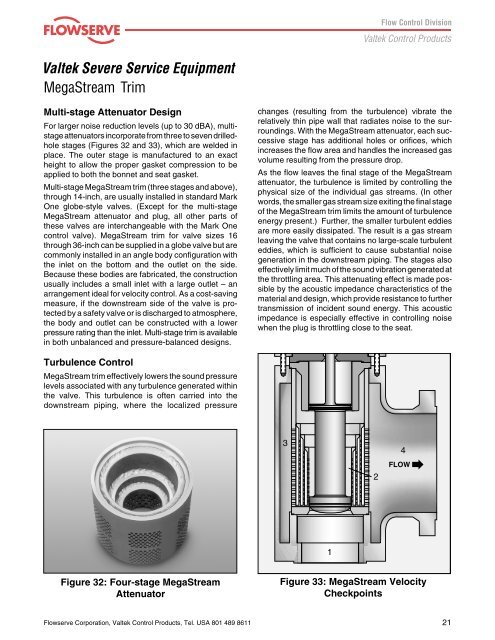

<strong>Valtek</strong> <strong>Severe</strong> <strong>Service</strong> <strong>Equipment</strong>MegaStream TrimMulti-stage Attenuator DesignFor larger noise reduction levels (up to 30 dBA), multistageattenuators incorporate from three to seven drilledholestages (Figures 32 and 33), which are welded inplace. The outer stage is manufactured to an exactheight to allow the proper gasket compression to beapplied to both the bonnet and seat gasket.Multi-stage MegaStream trim (three stages and above),through 14-inch, are usually installed in standard MarkOne globe-style valves. (Except for the multi-stageMegaStream attenuator and plug, all other parts ofthese valves are interchangeable with the Mark Onecontrol valve). MegaStream trim for valve sizes 16through 36-inch can be supplied in a globe valve but arecommonly installed in an angle body configuration withthe inlet on the bottom and the outlet on the side.Because these bodies are fabricated, the constructionusually includes a small inlet with a large outlet – anarrangement ideal for velocity control. As a cost-savingmeasure, if the downstream side of the valve is protectedby a safety valve or is discharged to atmosphere,the body and outlet can be constructed with a lowerpressure rating than the inlet. Multi-stage trim is availablein both unbalanced and pressure-balanced designs.changes (resulting from the turbulence) vibrate therelatively thin pipe wall that radiates noise to the surroundings.With the MegaStream attenuator, each successivestage has additional holes or orifices, whichincreases the flow area and handles the increased gasvolume resulting from the pressure drop.As the flow leaves the final stage of the MegaStreamattenuator, the turbulence is limited by controlling thephysical size of the individual gas streams. (In otherwords, the smaller gas stream size exiting the final stageof the MegaStream trim limits the amount of turbulenceenergy present.) Further, the smaller turbulent eddiesare more easily dissipated. The result is a gas streamleaving the valve that contains no large-scale turbulenteddies, which is sufficient to cause substantial noisegeneration in the downstream piping. The stages alsoeffectively limit much of the sound vibration generated atthe throttling area. This attenuating effect is made possibleby the acoustic impedance characteristics of thematerial and design, which provide resistance to furthertransmission of incident sound energy. This acousticimpedance is especially effective in controlling noisewhen the plug is throttling close to the seat.Turbulence ControlMegaStream trim effectively lowers the sound pressurelevels associated with any turbulence generated withinthe valve. This turbulence is often carried into thedownstream piping, where the localized pressure324FLOW1Figure 32: Four-stage MegaStreamAttenuatorFigure 33: MegaStream VelocityCheckpointsFlowserve Corporation, <strong>Valtek</strong> Control Products, Tel. USA 801 489 861121