ANALYSIS OF THERMOELASTIC STRESSES IN LAYERED PLATES

ANALYSIS OF THERMOELASTIC STRESSES IN LAYERED PLATES

ANALYSIS OF THERMOELASTIC STRESSES IN LAYERED PLATES

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

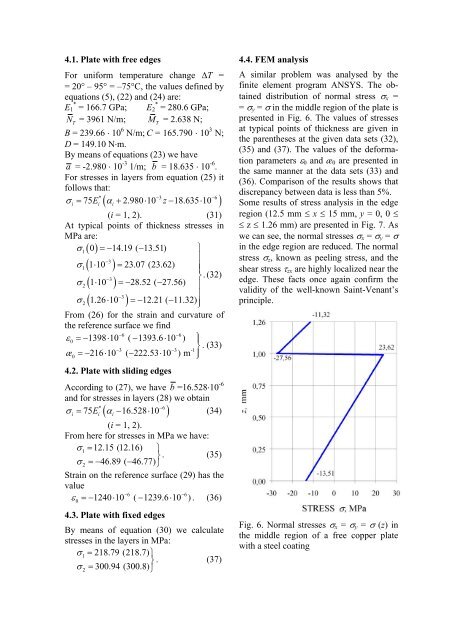

4.1. Plate with free edgesFor uniform temperature change ΔT == 20° – 95° = –75°C, the values defined byequations (5), (22) and (24) are:E * 1 = 166.7 GPa; E * 2 = 280.6 GPa;N = 3961 N/m; M = 2.638 N;TB = 239.66 ⋅ 10 6 N/m; C = 165.790 ⋅ 10 3 N;D = 149.10 N⋅m.By means of equations (23) we havea = -2.980 ⋅ 10 -3 1/m; b = 18.635 ⋅ 10 -6 .For stresses in layers from equation (25) itfollows that:* −3 −6σi = 75Ei ( αi+ 2.980⋅10 z−18.635⋅10)(i = 1, 2). (31)At typical points of thickness stresses inMPa are:σ1( 0)=−14.19 ( −13.51)⎫−3⎪σ1( 1⋅ 10 ) = 23.07 (23.62) ⎪ ⎪⎬. (32)−3σ2 ( 1⋅ 10 ) =−28.52 ( −27.56)⎪−3⎪σ2 ( 1.26⋅ 10 ) =−12.21 ( −11.32)⎪⎭From (26) for the strain and curvature ofthe reference surface we find−6 −6ε0=−1398⋅10 ( −1393.6⋅10 ) ⎫⎪ −3 −3 -1 ⎬ . (33)æ0=−216⋅10 ( −222.53⋅10 ) m ⎪⎭4.2. Plate with sliding edgesAccording to (27), we have b =16.528⋅10 -6and for stresses in layers (28) we obtain* 6σ = 75 ( −16.528⋅10 −iEi αi) (34)(i = 1, 2).From here for stresses in MPa we have:σ1= 12.15 (12.16) ⎫⎬ . (35)σ2=−46.89 ( −46.77)⎭Strain on the reference surface (29) has thevalue−6 −6ε 0=−1240⋅10 ( −1239.6⋅ 10 ) . (36)4.3. Plate with fixed edgesBy means of equation (30) we calculatestresses in the layers in MPa:σ1= 218.79 (218.7) ⎫⎬ . (37)σ2= 300.94 (300.8) ⎭T4.4. FEM analysisA similar problem was analysed by thefinite element program ANSYS. The obtaineddistribution of normal stress σ x == σ y = σ in the middle region of the plate ispresented in Fig. 6. The values of stressesat typical points of thickness are given inthe parentheses at the given data sets (32),(35) and (37). The values of the deformationparameters ε 0 and æ 0 are presented inthe same manner at the data sets (33) and(36). Comparison of the results shows thatdiscrepancy between data is less than 5%.Some results of stress analysis in the edgeregion (12.5 mm ≤ x ≤ 15 mm, y = 0, 0 ≤≤ z ≤ 1.26 mm) are presented in Fig. 7. Aswe can see, the normal stresses σ x = σ y = σin the edge region are reduced. The normalstress σ z , known as peeling stress, and theshear stress τ zx are highly localized near theedge. These facts once again confirm thevalidity of the well-known Saint-Venant’sprinciple.Fig. 6. Normal stresses σ x = σ y = σ (z) inthe middle region of a free copper platewith a steel coating