February - Feedlot Magazine

February - Feedlot Magazine

February - Feedlot Magazine

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Circle No. 100 on Reply

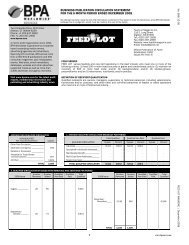

Robert A. StrongPresident, EditorVolume XV Number 1<strong>February</strong> 2007FeaturesKernel Processed Earlage 6Learning to use the “improved” earlageRetail Beef Prices to Hold Steady in 2007 8Strong demand supports higher pricesDetermining “Fair Pay” 10Setting appropriate compensation is difficultGetting a Handle on Grade 12Feeding sector discusses how to hit quality targetsSearching for Yield Signs 14Online Yield Calculator Can HelpUnderstanding Vaccines 16Vaccination ConsiderationsFeeding Efficiency 18Change in the Beef IndustryGreg StrongJill DunkelThe Time Has Come 20DNA technology -- practical for all segments of theindustryTreason, Heresy and Sedition 21The cattle or the beef business?Where Are Corn Prices Headed? 25How high will corn prices go?The “Risks” in High Risk Cattle 26Which cattle are truly high risk?BVD: Why Biotype Matters 28BUD falls into two genotypesWinter Herd Health Problems MayBe Curbed With Good Nutrition 30Cold temperatures are a stress to livestock?Annita LorimorCircle No. 101 on Reply

Editor’s DeskQuality Audit ReportThe National Beef Quality Audit(NBQA) has been conductedevery five years since 1991. Eachaudit report is a “snapshot” of the industriesquality status and evaluateswhat producers have done to improvequality.Lack of uniformity and inconsistencyin quality was ranked by endusers as the most prevalent defectin the U.S. beef industry. Therewere four areas of defects: marbling,tenderness, palatability, andinconsistency among and withinquality grades.The initial results of the 2005 auditwere discussed at the 2006NCBA summer conference inReno, Nevada, in July. The final reportprovides additional insightinto beef quality successes and futurechallenges over which producershave some or total control.The old saying “you can’t makea purse out of a sows ear” fits wellin this case. Regardless of any one’spreference for breed type, the geneticshave to be there before qualitygrade can be realized. Even withthe right genetics, quality grade stillhas to be managed for desired resultswithin a given time frame.Copies of the full audit reportmay be requested by calling GraceWebb at 303-850-3338 or emailgwebb@beef.org.Instrument GradingInstrument grading is coming,said Glen Dolezal, Ph.D, directorof New Technology Applications,Cargill, at the Feeding Quality Forumsat North Platt, Nebraska, andAmarillo, Texas. “Cargill Meat Solutions(CMS) has utilized multipleversions of vision-based instrumentgrading for over 15 years.Early efforts relied upon black andby Bob Strongwhite images to capture the crosssectionalribeye (m.longissimus) atthe 12th and 13th rib interface forsubcutaneous fat thickness andribeye area measurements. Thisprogressed to a full color multiplecamera system for whole side dimensionaldata collection (hotcamera on harvest floor) andcross-sectional ribeye data collection(cold camera on gradingstand). The Research ManagementServices (RMS) vision camera systemwas installed by May of 2000 inall six of our major North Americanfinished steer and heifer plants.“We are confident that we accountfor a majority of the variationin the traits of interest using asingle camera vision-based systemto capture the ribeye cross-sectionalarea (cold camera system) at thetime sides are presented for gradingand sorting.”♦60 ft. Reach, 120 ft. Working DiameterPOND AND LAGOON CLEANINGCONSTRUCTION AND DESIGN• Full line of support equipment including theTrac-Hoe with 60 ft. reach.• Compare. We can load our trucks in 4minutes flat!• 24-Hour Nationwide Emergency Service• Underwater Work ... Our Specialty!• Complete Environmental ServicesCheck out our Web Page @ www.lagoonpros.comD & K ENVIRONMENTAL, Inc.(800) 555-6380Fax: (620) 275-1156Office: (620) 275-8032Home: (620) 276-7898Circle No. 102 on ReplyCircle No. 103 on Reply4 FEED•LOT <strong>February</strong> 2007

Circle No. 104 on Reply

Retail Beef Prices To Hold Steady in 2007Consumers can look forward tosteady retail beef prices in 2007 asbeef demand levels out and cattlemencontinue to produce adequatesupplies of beef.“Retail beef prices averaged$3.98 per pound in 2006, down 10¢from the $4.08 we saw in 2005,”said Jim Gill, market director forthe Texas Cattle Feeders Association(TCFA) in Amarillo. Speakingat the annual TCFA Year-End NewsConference, Gill said strong beefdemand has supported higher beefprices for several years. “Butpresently, beef demand seems tobe leveling out and it is likely that2007’s retail beef price will showvery little change from this year.”For cattle feeders, the predictionis much the same—2007 fedcattle prices should trade in arange similar to the price rangeseen in 2006. Gill’s outlook for fedcattle prices: $78 to $86 in the firstquarter; $82 to $88 in the secondquarter; $84 to $90 in the thirdquarter; and $86 to $94 in thefourth quarter.“Fed cattle prices during 2006averaged near $86 per cwt. with arange from $78 to $98 during theyear,” he said. Fed cattle priceswere pressured by record-settingslaughter weights combined withhigher-than-expected cow slaughterdue to the extended drought.Slaughter weights in 2007 will likelytrend lower in response to higherfeed costs, he said.Those higher feed costs will bedriven by high corn costs asethanol demand continues to fuelthe grain complex. “Since mid-September, corn prices have increasedmore than $1.10 per bushelon the futures market,” Gill said.The increase is driving cost of gainhigher in feedyards, Gill said, andif any winter weather develops inthe next several months, cost ofgain could go higher yet.Looking down the road, Gill saysfeeder cattle supplies will continueto tighten over the next severalyears as ranchers retain heifers.“The cow herd expansion thatstarted several years ago hasslowed or even stopped this yeardue to the drought,” Gill said.While that will put a bullishfoundation under feeder cattleprices, pressure will continue tocome from higher corn prices. Infact, cow-calf and stocker operatorshave seen feeder cattle pricescome under pressure the past fewmonths due to escalating corncosts, Gill said. In the last threemonths, feeder steers at the AmarilloLivestock Auction have tradedin a range from $124 in Septemberto $100 in December, losing nearly20 percent of their value. ♦Circle No. 107 on Reply8 FEED•LOT <strong>February</strong> 2007

Circle No. 108 on Reply

Determining “Fair Pay”Sometimes employees have ahard time understanding the challengeof setting a competitive andfair wage. I once had an employeetell me that he could make a lotmore money working as a welderat the local semi-trailer manufacturer.I suggested that he go andtake that job, since he would bebetter off. His response? “Are youkidding, I don’t want to work in allthat smoke, and I don’t even knowhow to weld!” We talked. He continuedworking at his current pay.Setting competitive, appropriateand fair compensation levels foremployees is becoming more difficult.Existing businesses knowwhich employees are the best ones,and tend to pay higher wages tokeep them. The pool of potentialnew employees is limited in mostareas of the country, so employersmay be reluctant to pay high startingwages for people with unknownpotential. Added to theserealities is the need to keep ourcurrent employees satisfied withfair pay, even though they mayhave a wide variety of reliability,skills, efficiency and potential.For introductory employees, weneed to be certain that our pay iscompetitive with the local busi-by Don Tylernesses that hire out of the samepool of candidates. If the peoplewe want to hire would also beworking in retail, light manufacturingor food service, then we haveto know their starting pay and benefitpackage. If we only hire peoplewith some experience, then our focusshould be on the compensationlevels of other agricultural employersin the area.When we are determining compensationlevels for Foremen, Supervisorsor Managers, we need tolook at similar positions throughouta wider region. These positionshave higher pay and candidates aremore willing to move to take a betterposition.Existing employees need toknow that their pay is fair with otherpositions in the area and betweenthem and their coworkers.There are many factors that go intosetting pay levels. Experience,local pay scale for similar jobs,profitability of the company, responsibilitylevel of the job, howmany people are available locallyto do that type of work, educationlevel, years of service, loyalty tothe company, reliability, attitude,etc. are all important criteria forsetting a person’s compensation.Circle No. 109 on Reply10 FEED•LOT <strong>February</strong> 2007

“Equal pay” is not practical.“Fair pay” is what we should try toachieve. Communicating these factorsto our employees can helpthem understand our difficulty insetting compensation levels. Someemployees want “equal pay,” so wemay have to remind them thatequal pay is not fair if some workedhard and others only did the minimum.Pay rarely seems “fair” to theperson who gets less than someoneelse.Employees need to be warnedabout sharing their level of paywith any other employee. In somecompanies this is a matter of policy.Pay is a private matter betweenthe employer and the employee,and discussing it almost alwayscauses frustration, resentment,jealousy and bitterness. I have seengood employees actually go to lowerpaying jobs because they believedunfounded rumors aboutwhat their coworkers were beingpaid. Employees rarely have all thefacts concerning what theircoworkers get paid, and tend to“cherry pick” the information thatis to their benefit.Some operations have benefitssuch as a Company vehicle todrive, housing, meat, etc. In thesesituations, employees may not appreciatethe tax savings to themsince these benefits are not fullyreflected as income. To help themunderstand their real value, I encourageemployers to print out acomparison of their net pay withthese benefits against their net paywithout them, and include it withtheir paycheck either once a monthor at least every quarter. This remindsthe employee of their truecompensation and gives themmore accurate information whenthey try to compare their pay tothat of their friends.♦Don Tyler is a managementcoach and advisor from ClarksHill, IN. His book, The CompleteGuide to Managing AgriculturalEmployees can be reviewed atdontyler.com, and Don can bereached at 765-523-3259.Circle No. 111 on ReplyCircle No. 112 on ReplyFEED•LOT <strong>February</strong> 2007 11

Getting a Handle on GradeFeeding sector discusses how to hit quality targetsFeeding Quality Forums inNorth Platte, Neb., and Amarillo,Texas, last November shed lighton many of the factors that play arole in delivering higher qualitybeef to consumers. Opening remarksby cosponsoring Feed•Lotmagazine editor Robert Strong setthe stage by noting how far technologyhas advanced.“Fifty-eight years after the transistorwas invented, digital technologyis still in its infancy,” hesaid. “But it looks like it is startingto help us in the beef industry andgood things are yet to come. We’llbe able to track the complete historyon each animal as well as themass of data to separate any variableyou can imagine. They all deservemore study, especially whenreducing variability could make lifemore predictable and, hopefully,more profitable.”Pfizer Animal Health, Inc., andCertified Angus Beef LLC (CAB)joined in sponsoring the forums.Larry Corah, CAB vice president,laid out the challenges ofmeeting consumer demand. Citingthe most recent National BeefQuality Audit (NBQA), he said themain problem is a declining trendin quality grade. That is followed bythe 21-year increase in yield gradeand even longer-term increase incarcass weight variability.While genetics are a critical factor,Corah said many existing cattleare on the quality-grade line.That means minor management adjustmentscould change their carcassvalues in the near term. Helisted six factors contributing tolower marbling: health, feedlotstructure, gender, understanding ofFeeders must askwhether efficiencyand quality areopposing traits, andif quality hasreceived enoughpriority.marbling as a lifetime event, implantstrategy and, probably,ethanol byproduct feeding.Glen Dolezal, Cargill Meat Solutions’director of technical applications,provided details on why thepacker views the transition to instrumentgrading as one of the most positivedevelopments in the industry.Randy Blach, executive vicepresident of Cattle-Fax, said increasedconsumer demand added$215 per head to live cattle pricessince 1998. He showed the familiarbar graphs of increasing cattle andcarcass weights, with inventoriespoised to put still more beef on themarket. However, Blach warnedthat continued demand is questionableunless quality grades improve.The boxed beef cutout valuespreads from April 2003 to October2006 were $24.39 for Prime-Choice and $22.91 for CAB-Select,he noted. This is part of a fiveyearuptrend.The NBQA called for an idealharvest mix of seven percentPrime, 62 percent Choice and 31percent Select, compared to 2.8percent Prime and 52.9 percentChoice in 2005. Although Blachsaid the market could not absorbthe ideal overnight, a return to increasingquality grade could stimulatethe demand needed.Moreover, he said the reopeningexport markets will demand moreChoice and Prime product.“Price spreads need to stay wideto create incentive for producers,”Blach said. “That will lead to morecattle sold on grids as feeding profitmargins will narrow on commoditycattle.”Circle No. 113 on Reply12 FEED•LOT <strong>February</strong> 2007

Daryl Tatum, Colorado StateUniversity animal science professor,reviewed the components ofconsumer demand and how producerscan best deliver the “pleasurableeating experience” forwhich they will pay more. Genotypedetermines the upper limit forintramuscular fat (IMF, or marbling)deposition, Tatum said, butmanagement either preserves orharms marbling potential.Most producers know thatonce cattle have more thanenough energy to meet growth demand,they begin to store the extraenergy as fat. But Tatum saidproducers may not be as familiarwith Kelly Bruns’ South DakotaState University research thatshows marbling is deposited mostrapidly when given the opportunityearly in the feeding period.In fact, a growing body of researchshows a window from two toeight months of age that is criticalfor marbling development. That’swhy it takes coordination throughthe supply chain to realize the qualitypotential in cattle, Tatum said.Otherwise, calves with stunted marblingend up piling on backfat anddeveloping yield grade (YG) problems.One solution is to increase thediscount for YG4s, he added.Fred Owens, Oklahoma StateUniversity emeritus professor andParticipants in the Feeding Quality Forums discussed many of the factors that play arole in delivering higher quality beef to consumers.Pioneer consultant, talked aboutnutrition and a coordinated approachto quality. Cow-calf producersmust start with sire selectionand using feedlot and carcass datato cull cows and manage calveswith preconditioning vaccinationsand weaning so they are ready forthe stocker phase, Owens said.Stockers and feedlot operatorsshould buy or feed only tame cattlewith known and appropriatehealth and nutritional background,use no implants, sort finished cattleto outcome and return all datato the ranch of origin, he added.Pfizer veterinarians Lonty Bryantand John Pollreisz, along with nutritionistGary Sides, provided specificsolutions to many of the qualitychallenges. “Feeders sometimeswant all products, such as de-wormers,to be the same so they can leastcosteverything,” Pollreisz said.“That can lead to disaster.”As the industry moves toyounger cattle and strives for evergreaterefficiency, Pollreisz andBryant said feeders must askwhether efficiency and quality areopposing traits, and if quality hasreceived enough priority.Sides advocated a holistic approachthroughout the productionsystem and reviewed the “energeticsof growth and marbling.” Using emptybody fat as a fixed percentage,Sides showed that growth implantsmay be useful in helping some cattlereach heavier carcass weights. Healso noted Iowa State University researchthat suggests implants shouldbe matched with protein source tooptimize quality grades. ♦Specializing In:Turn-Key Feedyard Construction• Hog Site Construction • CompleteDairy Construction • Sprinkler SystemCAD Engineered Design • GPS Survey• Slipform Concrete Feedbunks • Dirtworkof All Types • Laser-Equipped Machinery• All types of FencingCircle No. 114 on ReplyFEED•LOT <strong>February</strong> 2007 13

Searching For Yield Signs — Online Yield Calculator Can HelpBeef producers now have an onlinecalculator to help estimate subprimalyields and their approximatevalues, based on current marketprices, before their cattle go to market,according to NCBA. The newresource, called the Beef CutoutCalculator (a featured link atwww.beefresearch.org), is fundedby the beef checkoff and designedby faculty and graduate students atColorado State University (CSU).By plugging a few numbers intothis interactive tool, users can generatea report that estimates cutoutweights for individual animals, differentiatedby USDA yield grade,cutting style, external fat trim leveland initial live animal or carcassweight. Additionally, the report reflectscurrent market values sincethe software uses the prior week’sUSDA-AMS National Weekly BeefPrices for Boxed Beef Cutouts &Cuts in its calculations. NewUSDA-AMS information is uploadedto the system every Friday.“I think this calculator could behelpful to producers who feed theirown cattle – or those who don’t,but have a relationship with a feeder,said Myron Williams, a SouthDakota producer and chairman ofthe Industry and Producer ServicesGroup. “It could help producersconsider more market options, liketrying for a grid or a specialty market,and help them build herd history,if that’s a practice in theirparticular operation. It could alsogive the producer and the feeder abetter idea of the animal’s value.”While the calculations arestrong value indicators, Belk said,it’s important to keep in mind thatthey are based on averages of typicalbeef cattle harvested in theUnited States, and individual valuesmay vary.The calculated reports accommodateall users by providingIMPS/NAMP numbers for productidentification, as well as illustratedcarcass diagrams and digital photosof most of the common subprimalbeef cuts. It was designed withuser friendliness in mind, and evendisplays on-screen video examplesto walk users through the steps togenerate a report.Users select from several commoncutout strategies, althoughnot all cutout options are represented.Strategies depend on thefat trim level selected. For example,the bone-in rib is an option ifthe user selects commodity trimbut not an option if the user selects1/8th- inch trim. A possible site upgradewould include values forcuts targeting export markets.The calculator could also helpidentify the value of various managementdecisions on the ranch orin the feedlot, Belk said.“For example, a feeder is tryingto decide on how much longerhe/she might feed a group of cattleto try and ‘hit the marketpeaks.’ Then, by accounting forpossible changes in carcassweight and grade as a result ofsuch a decision, the feeder canproject the net gain/loss given thecurrent market conditions.”Belk added that the calculatoris expected to help all levels of theproduction chain, including nichemarketprocessors – such as verysmall or medium sized companies– or even consumers who buy asteer and have it processed fortheir own use.The beef cutout calculator isavailable on the newly designedWeb site for the checkoff-fundedCenter for Research and KnowledgeManagement (www.beefresearch.org).Here, visitors can findcheckoff-funded materials on currentand past research in the areasof product enhancement, beef safety,human nutrition and market research.The site may also beaccessed through CSU at www.ansci.colostate.edu/content.♦Circle No. 115 on Reply14 FEED•LOT <strong>February</strong> 2007

Circle No. 116 on Reply

Understanding Vaccines — Vaccination ConsiderationsSecond in a Two Part Series. By Lee Bob Harper, DVM, Pfizer Animal HealthAre you following protocols tomaximize your calf vaccination results?Here’s a checklist of strategiesto consider.Getting calves on feed and acclimatedat the feedlot is everyone’sgoal to increase performanceand decrease morbidity. Vaccinationplays an important role in thatprocess. Here are some strategiesthat can help aid in vaccinationprogram effectiveness.• Pay Attention to BoosterRequirementsMost feedyards recognize theneed to vaccinate calves with unknownhealth histories shortly afterarrival, but the booster doseoften gets overlooked. A boostershot typically follows the initial vaccinationand helps push or “boost”the level of immune protection inthat animal to a higher level.Not all vaccines require a booster,so it is best to read and followthe label, which varies from productto product. For instance, mostmodified-live virus (MLV) vaccineshave a one-dose claim for IBR andBVD. But there are products suchas Bovi-Shield GOLD® and othersthat have a one-dose claim, exceptfor the BRSV portion which requiresa booster. In general, mostof the killed vaccines require abooster dose 2 to 4 weeks after theinitial dose.If a booster is recommended,the timing of administration per thelabel-recommended schedule iscritical in order for the vaccine towork properly and to achieve peaklevels of immunity. If the boosterdose is given too soon after the firstdose, the immune response is notproperly amplified by the boosterand will be short lived.A common practice I see is thatfeedyards will vaccinate calves atarrival and then revaccinate 5 to 10days later when stress subsidesand calves have become more acclimatedto the feedyard setting.This practice of revaccination isappropriate in many cases, but it isoften mistaken as a booster. Instead,a true booster dose is administered14 to 28 days after the initialvaccination.If a booster shot isn’t given whenrecommended, recognize that youare taking a risk, especially withkilled vaccines. Some years you maynot experience increased sicknessand death loss among the cattle, butthen a year may come with a higherdisease challenge and you may seean increase in pulls (morbidity) oreven deads (mortality). This can occuras a result of failure to give abooster dose that was required orrecommended on the label.• Understand DifferencesBetween MLV and KilledVaccinesNever assume all vaccines arethe same. The product label claims,usage and manufacturing processesall vary. In comparing MLVs andkilled vaccines, the primary differenceis in how the vaccines aremanufactured.As its name implies, a MLV is alive-virus vaccine, but its ability tocause disease has been destroyedwhile preserving the ability to generatea robust immune response.Meanwhile, a killed vaccine is consideredsafer and more stable becauseit isn’t alive.While MLV and killed vaccinescan both be effective against viralrespiratory pathogens, most researchindicates the MLV producesa more rapid, longer-lasting immuneresponse. For IBR and BVDprotection, a MLV is well-suited tofeedyard settings.Meanwhile, the safety and stabilityof killed vaccines tend towork well for cow-calf operationsCircle No. 117 on Reply16 FEED•LOT <strong>February</strong> 2007

vaccinating pregnant cows. Onlycertain MLVs can be administeredto pregnant cows or nursing calvesif label directions are followed.When using these approved vaccines,a rancher must administer apre-breeding shot to his or hercows or heifers prior to breeding.Then those animals could receivea booster dose of the vaccine duringpregnancy. However, manyranches don’t vaccinate pre-breeding,so they opt for using a killedvaccine after breeding.Killed vaccines are also sometimesrecommended for highlystressed calves in feedlot settingsbecause they are thought to beeasier on the calf’s immune system.But there are differing opinions,and your veterinarian is theone best positioned to give youTaking cattle for a booster shothelps push or “boost” the levelof immune protection in thatanimal to a higher level.sound advice.Another considerationin comparing the two:MLV vaccines require mixinga lyophilized powderand liquid together to activatethe vaccine and theproduct must then beused within 1.5 hours. Sosome individuals mayconsider a killed vaccineeasier to work with.Either way the choice betweenMLV and killed vaccines comesdown to the particular needs of thecattle being vaccinated. It’s alwaysbest to visit with your veterinarianto select the product and strategythat fits your situation.• Select Proven Products Backedby ResearchRecently there have been someconversations in the industry aboutthe need for vaccine rotation. However,there is no data to supportthis claim.Considering that the IBR virushas minimal genetic variability anda vaccine that stimulates immunityto Type 1 and Type 2 BVD will givebroad spectrum protection, there isno need for vaccine rotation.Instead, the most important decisionis to select and stay with aproven product that has the researchdata supporting its efficacy.Bottomline: Do your homeworkon the vaccine products you administer,read and follow the labelinstructions, and work closely withyour veterinarian to maximize yourvaccination results.♦Lee Bob Harper is a technical servicesveterinarian with Pfizer AnimalHealth based in Gruver, Texas, andworks with feedlots in that region.Blow-Hard Bunk CleanerEnd End Your Your Bunk Cleaning Problems••NeverNevermissmissa feedingfeeding• Works in any shape bunks••FlyWorkssprayingin anyattachmentshape bunksavailable•• Replaces Fly spraying men attachment and shovels available•• Over Replaces 22 years men of and proven shovels performance• Over 15 years of proven performanceS & W WELDING, INC.S 1-800-881-5510& W WELDING, INC.402-372-55101-800-881-5510West West Point, Point, NE 68788VHS video & references availableVHS video & references availableVisit our web site, www.swwelding.comCircle No. 118 on ReplyCircle No. 119 on ReplyFEED•LOT <strong>February</strong> 2007 17

Feeding Efficiency - Change in the Beef Industryby Bob Strong“If we take new information andadjust our methods of operation, wehave changed.” This is not a directquote from Henry Gardiner but it isexactly what Gardiner AngusRanch, Ashland, Kansas has done.In a 17 year period prior to 1977,Gardiner Angus bulls on feed for140 – 150 days on a feedyard #4 rationwere gaining 2.7lb/day and consuming7.48lb of feed per pound ofgain. Since 1977 their bulls on testfor 85 days have been gaining 5.5-5.8pounds on 40 percent less feed on afeedyard #3 ration.According to Henry Gardiner,the improvement in genetic toolssince 1977 in selecting sires and femaleshas led to this change. Out oftheir 1,000 registered cow herdGardiner Angus Ranch (GAR) selectsthe top four to five percent oftheir heifers for replacements toend up with 50 females who produce70 – 75 percent of their registeredcalves by embryo transfer. Inthis manner they bring 50 newheifers, after their first calf, intothe embryo transfer program eachyear to amplify genetic improvements.All of the GAR registeredcow herd is sold within five yearsbecause of their rapid change in genetics.They also have 1,000 commercialAngus females, includingyearling heifers. Around 60 percentof those females will produce registeredcalves from the donor herdusing embryo transfer.By selecting sires and femalessince 1977 using EPD’s, ultrasound,ribeye area, back fat and marbling,GAR has made tremendousprogress. A GAR bull calf can beexpected to have an average gainper day of 5.65 pounds on an 85 dayfeed test, usinga ration3 of a 4 stepration. It willtake about4.4 poundsof feed ona dry matterbasisto producea poundof gain.SelectingHenry Gardinerfor efficiency is not unique to GardinerAngus Ranch. However, theconsistency of investing in testingand the use of technology is. For instance,their 30 acre breeding centerwhere they transfer over 2,000embryos a year is very unusual.The 30 acre breeding centerhas 4,800 feet of feed bunks. Allanimals are within 600 feet ofCircle No. 120 on Reply18 FEED•LOT <strong>February</strong> 2007

the artificial insemination barn.Perimeter bunk lines provide allweather access.Gardiner has many cooperatorswho have used GAR bulls for morethan a decade.Jim Lee of Maxwell, New Mexico,said, “Customers buy GAR geneticsfor many of their differentqualities, including low birthweight, outstanding growth, supercarcass values for end productprofitability, and a very long listgoes on from there. Regardless ofthe original reasons, the other valuesare there to be discoveredwhen needed.“I recently read an article aboutthe long-term reality of high cornprices. Suddenly, I realized that thecalf that can get to market thefastest, with the least amount ofcorn and the highest carcass valuewill be absolutely essential in thefuture,” he said. “So, no matterwhat originally led a producer toGAR genetics, the hidden value ofThe 30 acre breeding center has over 1900 feet of all weather alleys. All animals arewithin 600 feet of Artificial insemination barn.survival in a high priced corn marketcame built in.”Henry Gardiner is consideredone of the most progressive cattleproducers in the nation. He and GardinerAngus Ranch in Ashland,Kansas, have received many awardsfor their pioneering work in the beefindustry. Henry, his wife Nan, theirthree sons and families are thefourth generation on the ranch. ♦Circle No. 121 on ReplyFEED•LOT <strong>February</strong> 2007 19

The Time Has ComeDNA technology — practical for all segments of the industryThe beef industry has known foryears that marketing fed cattle ona live basis leaves much efficiencyto be gained. Now it is possible togain inside information throughFeeding mixed groups of cattle leads toinefficiencies, but with IGENITY and markerassistedmanagement, cattle can be sorted anddirected to a more economical endpointDNA technology for a growing listof traits of economic importance.A new era of beef production hasindeed arrived.The process of applying this informationto managementsituations is called markerassistedmanagement.John Pollak, the executivedirector of the NBCEC, anorganization committed toresearch related to the geneticevaluation of beef cattle,says this is a tool thatcan have immediate implicationsfor the feeding segmentof the industry.“Using DNA technology,through marker-assistedmanagement, is an opportunityfor feedlots and operationswhere producersare retaining ownership tosort cattle toward specificendpoints based on their potentialto hit certain grids,” Pollak says.A powerful toolOne feedyard that understandsthe importance of this advancedtechnology is Decatur County FeedYard, Inc., in Oberlin, Kan. This38,000-head operation has alwaysbeen ahead of the game when itcomes to marketing cattle andmaximizing performance. The yardhas specialized in retained ownershipsince 1981, and has been sortingcattle based on ultrasound datafor nearly 20 years.Dan Dorn is involved in supplydevelopment for Decatur CountyFeed Yard and he says DNAtechnology is a tool to use to complementtraditional managementpractices. (see article Feedstuffsdated 1/8/2007 ‘Test MarketDesirable Genes or go to feedstuffsfoodlink.com)“We already manage cattle to aneconomic or genetic endpoint,”Dorn says. “Having the ability toknow more information about anindividual animal through DNAtechnology allows us to better marketthat animal to a specific target.”One study showed how the valueof a pen of cattle would increaseby $5,381, or $28.81 per head, ifheavy carcasses, yield grade 4and 5 carcasses, and standardcarcasses were eliminated andthe percentage of select carcasseswas reduced from 21 percent to10 percent.These benchmarks are all withinreach with the comprehensiveIGENITY ® profile, which includesanalysis for carcass traits such astenderness potential, fat thickness,ribeye area, yield grade and hotcarcass weight along with parentagein multiple-sire settings.Management and selection gohand in handWorking with producers is somethingDecatur County Feed Yardsees as contributing greatly to thesuccess of this technology. Dornsays the process of getting producersinvolved has become easier asthe technology is now more cost-effectiveand user-friendly. ♦Circle No. 122 on Reply20 FEED•LOT <strong>February</strong> 2007

Treason, Heresy and Seditionby Ann BarnhardtWell, if that title doesn’t piqueyour interest, nothing will!Here goes:We are in the CATTLE business.We are NOT in the beefbusiness.Allow me to explain myself beforeyou gather the wood to burnme at the stake. The beef market isa totally separate market that haslittle-to-nothing to do with the profitabilityof cattle PRODUCERS. Iknow this is contrary to everythingyou are being told. I know this iscompletely counter-cultural. Staywith me. We sell CATTLE. We buyCATTLE. That is the market thatwe should be preoccupied with.We do not need to know what theSelect chuck market is doing. Wehave no need to research the 90-10ground beef market. What the hideand offal markets are doing haveno bearing on us or our ability tobe profitable.None. Let the packers and retailersworry about those things.Those are THEIR markets, notours. We are the lucky ones. We getto worry about the glorious, profit-ladenCATTLE markets. Do notrebuff this blessing!This concept meshes with theneed to carefully and objectivelysort our daily tasks into true, productiveWORK, and non-productivebusywork. Eliminate the latter.What good is it to sit in front of acomputer screen in the evenings,desperately engaged in the daily intrigueof the beef market . . . a marketin which we have essentially noparticipation? When was the lasttime you sold a brisket? When wasthe last time you sold a flank or sirloin?What purpose does it serve toruminate over the Choice rib market. . . and have no idea how to calculatethe return on the gain? Howcan it be “wise” to endlessly wringone’s hands over the cutout . . . andhave no clue what our cost of gainis? I see these conditions almostHOURLY. We are barking up thewrong tree.Aggregate demand for beef dictatesONLY how BIG the cattle industrycan be. As demandincreases, more cattle can exist,We sell CATTLE.We buy CATTLE.That is the marketthat we should bepreoccupied with.and therefore more cattle producerscan exist. As demand shrinks,marginal producers will find themselvesbeing squeezed out. The trulyskilled marketers already exist inthe upper-echelons of this industry(you may be surprised who I considerthe “upper-echelon” - it maybe your neighbor who hauls cattlearound in a bumper trailer!), andneed not be overly concerned withdemand contraction, and the resultingattrition. Marketing skillmakes your place in this industrysecure. Lack of marketing skillleaves you vulnerable, whether youare a 100,000 head feedlot or aweekend warrior with 20 head inthe back pasture.♦There are no guarantees. Nothing iscertain. You are solely responsible foryour decisions. Information containedherein is believed to be reliable, but noindependent verification has been madeand there are no guarantees as to its accuracyor completeness. The risk of lossin trading futures and options can besubstantial, and investors should verycarefully consider the inherent risks.Visit Ann at www.Barnhardt.biz.Circle No. 123 on ReplyFEED•LOT <strong>February</strong> 2007 21

Circle No. 124 on Reply

Plains Nutrition Council MeetingScheduled, New Location for 2007The spring conference of thePlains Nutrition Council will beMarch 29-30, 2007. There is achange in the location from previousyears. This year it will beheld at the Marriott Plaza in SanAntonio, Texas.The conference will begin at1:00pm on March 29th and adjournat 12:00 p.m. on the 30th.Elanco will be sponsoring apre-conference symposium from8:30am until 11:30am on March29th. The pre-conference symposiumis open to all attending thePlains Nutrition Council springconference.Complete information on theconference, lodging, registrationand speakers is available by visitinghttp://amarillo.tamu.edu/ programs/beeftce/or calling TedMcCollum at 806-677-5600.Some attendees from last year:Left to Right, Bill Dickie, Ne., SteveArmbruster, Ok., Tim Murphy, Co. JimSimpson Tx, Caroline Eng, KennethEng,Tx, Tom Peters, Ill, DavidMcClellan Ne.Registration for members is $50and $80 for nonmembers beforeMarch 2, 2007.The conference is a good placeto see your peers and gain newinformation.♦Circle No. 125 on Reply24 FEED•LOT <strong>February</strong> 2007Circle No. 126 on Reply

Where Are Corn Prices Headed?by Dr. James Mintert, Professor, Department of Ag Economics, Kansas State UniversityHow high will corn prices go thisspring and summer and will theyplummet when the 2007 harvestgets underway, as they did in 1996?Comparing the two years for similaritiesand differences might shedsome light on what’s likely to happenthis year.The increase in corn prices in late1995 and 1996 was primarily drivenby a supply shortfall. Corn productionduring 1995 totaled just 7.4 billionbushels, 27 percent below theprior year’s record level. Prices roseto ration the markedly smaller supplyamong competing uses. Laterthat year, when it was apparent thatcorn supplies would be ample, fueledby a sharp rebound in U.S. cornproduction to 9.2 billion bushels (25percent higher than in 2005); pricesplummeted because the supplyshortfall was effectively over.The increase in corn prices in thecurrent corn marketing year is notsupply driven. The 2006 corn crop,which was the third largest corncrop on record, totaled 10.7 billionbushels, just three percent smallerthan the prior year. The boost incorn prices instead has been drivenby strong demand. In fact, USDAprojects that corn usage during the2006-2007 marketing year will total11.8 billion bushels, or about 1.2 billionbushels more than last fall’s harvest.What does this mean for 2007and 2008? Even with a substantial2007 corn acreage increase andhigher yields, ending stocks are expectedto remain very tight.The reason is demand for cornused to produce ethanol is increasingby leaps and bounds.According to USDA, 1.6 billionbushels of corn were used to produceethanol in 2005-2006. Cornused to produce ethanol during thecurrent marketing year is expectedto climb to 2.15 billion bushels andpreliminary estimates indicate 3.2to 3.3 billion bushels of corn couldbe used to produce ethanol duringKansas Monthly Average Corn Prices2007-2008, a 51 percent increasecompared to this year. If that turnsout to be the case, corn endingstocks at the end of the 2007/2008marketing year could equal aboutfive percent of total usage, nearUSDA’s projection of six percent forthe 2006-2007 marketing year.What does all this mean for cattlefeeders? Although ethanol demandis heavily dependent ongovernment policy decisionsregarding subsidies, tariffs, andmandated usage levels, it looks likedemand for corn used to produceethanol will remain strong in theforeseeable future. As a result, U.S.cattle feeders can expect to seetwo things; 1) corn prices that averagefar above historical normsand 2) greater corn price variabilitythan in the past. And that meansit will pay to more aggressivelymanage feed price risk. ♦Circle No. 127 on ReplyFEED•LOT <strong>February</strong> 2007 25

The “Risks” in High Risk CattleThe term high risk cattle is nearly as old as the feedingindustry itself and yet its definition or componentsare vague to many. While we could probably get agreementin the general definition that high risk denotesan expectation of an increased animal health challenge,we would find divergence if asking questionssuch as “Which cattle are high risk?” or “What are thecosts associated with high risk cattle?”If we are in the feeding business, then we are alsoin the business of deciding what animals to put onfeed. We look at the relationships between weight, sex,price, futures markets, season, and expected productioncosts. We likely have a mental adjustment for salebarn vs country origin and perhaps others; but do wehave the true value difference? What are our criteria?Is it maximizing profit potential or do certain biasescome into the equation – heifers, horns, Holsteins, etc?Everyone’s first answer to the question “What costsare associated with high risk cattle?” is more deathloss; then comes more medicine costs, more labor, etc.There are other equally important costs which are seldomidentified. Among these are the number of railers,the difference in cost of gain and total weightThe All-Natural Pelleted CottonseedFeed for Beef CattleA flowable, high bulk density source of fat, fiber,and protein in an easy to handle form. No needto stock separate fat (yellow grease/tallow),protein (meals), and fiber when you can get it allin an easy to mix form! Successful feedlot studiesat Texas Tech and Oklahoma State availableon request – Excellent feed-to-gain and meatquality results and many other benefits! Wholecottonseed in a pellet – what a great idea!FUZ Z TMPELLETS(ALL IN ONE PACKAGE)For Information call: Bob Lundy 901-320-8633For ordering call:North Carolina Plant 252-536-0829Georgia Plant 229-388-8008www.cottonfloz.comby Marc Roth, M.S. P.A.S.gained and differences in market value.The premise of this article is that we have too manyhigh risk cattle in the system and that the reason is thatwe don’t send the correct pricing incentive back to theproducers of these cattle.There’s an old adage which goes, “You won’t improvewhat you don’t measure,” and I believe that summarizesthe situation surrounding high risk cattle. Mostoperators have not actually measured to knowwhether or not their front end price discount actuallyresulted in equalizing the profitability potential on theback end. In order to begin to accumulate this information,it is necessary to have a consistent method ofclassifying the risk status of the cattle. This is the onlyway in which your information will be meaningful. Visualobservation as cattle arrive at the feedyard hasbeen the most common method and is probably theleast useful. While visual observation will tell us if wealready have a “wreck” in progress, it offers little orno assurance as to what will happen in the next fewweeks. Additionally, the buying (i.e., pricing) decisionhas already occurred. We need to know how to classifythe cattle before we bid on them.Table 1 offers an example of how this can be done.These are parameters that you know at purchase. Youcan modify the parameters to better fit your operationor your experience. The point is to cover the bases andhave a template for consistency. Don’t worry a lotabout the intermediate risk cattle. Begin by learningthe differences between the value of those cattle thatare solidly in your high risk and low risk groups. I suggestthat you group your data into close-outs in calendarquarters. This will take out some seasonal variationwhile still leaving large enough numbers to be meaningful.Refer to Table 2 for a typical data set.There are now adjustments to be made. The cattlecome in at different weights, so that must be standardized.Let’s agree to adjust both groups to 600 pounds usinga 5¢ per pound slide. This will have the high riskgroup costing $105.12 per cwt ($107.67 – (51 pounds x5¢)) and the low risk group costing $107.34 per cwt($106.34 + (20 pounds x 5¢)). This tells us that basis 600#the high risk cattle were delivered $2.22 per cwt or$13.32 per head cheaper than the low risk cattle.We next need to look at the sales price. Markets canmove significantly during a quarter and as the distributionof sales, over the quarter, will likely be different,selling price should be standardized. One note ofcaution here – if you know the sales price effect of railers,don’t standardize that away. The number of railer(realizer) cattle will be between 50 percent to 100 percentof the number of dead cattle. Since these railersCircle No. 128 on Reply26 FEED•LOT <strong>February</strong> 2007

Table 1SALE BARN CALVESDISTANCE HAULED750 H H MH H MHCOUNTRY CALVESDISTANCE HAULED750 H M LM H LML = LOW RISK M = MODERATE RISK H = HIGH RISKbring roughly 35 cents per pound,they may affect the total averageselling price of the pen by nearly $1per cwt. That, then, is a true part ofthe cost of high risk cattle andshould not be removed. In thisdata, we know that railer proceedsare part of the sales price; but haveno detail so we will give the highrisk group the benefit of the doubtto the tune of 92¢ per cwt x 1,110pounds = $10.21 per head, keepingin mind that this may well havebeen a railer effect rather than amarket timing effect.We are now ready to look at theprofitability and we see a differenceof $26.78 per head advantage to thelow risk group. Now, let’s total startingwith our 600 pound adjusted differenceof $13.32 per head with thehigh risk group being the lowestpriced; but the low risk group wasstill $26.78 per head more profitableYearling Steer / HeiferCutting BullPre-Conditioned CalfWeaned CalfUnweaned Calfwhich means that in order to equalizethe profitability potential, thehigh risk group would need to havebeen discounted by $40.10 per heador by $29.89 per head depending onwhether or not the sales price differencewas due to railers. In otherwords, for these heifers, bought at600 pounds, the appropriate discountas compared to low riskheifers would have been between$4.91 per cwt - $6.85 per cwt ($5-7per cwt).From the data I’ve seen over theyears, this example tends to be towardthe narrow end of the rangewhereas the wide end is closer to$75 per head. There is a tendencytoward a pattern of seasonalitywith wider price spreads neededwhen placing cattle in the third andfourth quarters (closing out in thefirst and second quarters).When subjected to this type ofanalysis, steers usually show thatthey require wider discounts thanheifers. I am convinced that is theeffect of cutting bulls in the steerdata, although I do not have thedata to prove that belief.In summary, the risks in highrisk cattle when compared to lowrisk cattle going on feed at equalweight are as follows:1. more death loss2. more medicine costs3. more railer (realizer) cattle,50 percent -100 percent of thedeath loss4. less weight gain, weight gainx (selling price – cost of grain) =gain value5. higher cost of gain, generally$7-$8 per cwt on a deads in basis6. more “out” cattle if selling oncarcass meritWith large numbers, you also encounterissues with labor requirements,crowded hospital andrecovery pens, over-taxed facilities,and low employee morale.The appropriate discount forhigh risk cattle probably rangesfrom $40-$75 per head with thewider spreads required whenplacing during the third and fourthquarter. These discounts are withoutcutting bulls. Producersshould devise a simple system toobtain uniformity of classifyingthese cattle. The objective shouldbe to maximize profit and thatshould be used to determinewhether or not purchase pricespreads were adequate. ♦Table 2No. In In Out SaleHead Weight Cost Weight PriceCostGain(Deads In)Med.Cost/HeadDeathLossProfitHeadHigh Risk 2410 549 $107.67 1110 $87.83 $65.78 $33.76 6.48% -$1.44Low Risk 2511 520 $106.34 1096 $88.75 $59.53 $10.98 1.49% $25.34FEED•LOT <strong>February</strong> 2007 27

BVD: Why Biotype MattersWhen veterinarians discussbovine viral diarrhea (BVD) viruswith producers, they often talkabout the two different genotypes– BVD Type 1 and BVD Type 2. Thetwo BVD biotypes – noncytopathic(NCP) and cytopathic (CP) – areseldom mentioned. Yet, the NCPbiotype causes greater than 90 percentof BVD outbreaks.“According to research, NCPBVD is always the cause of persistentlyinfected (PI) animals,” saysGary Bosch, DVM, director of researchand development at NovartisAnimal Health US, Inc. “NCP isnot something that we can ignore.”If there is a PI animal in the herd,it is constantly shedding the BVDvirus and exposing the herd to diseaseevery day. The animals’ immunesystems are constantly beingprimed to fight off disease, resultingin reduced performance. Theremay not be clinical signs of infection,but economic loss is likely inthe form of a variety of illnesses.BVD viruses fall into two differentgenotypes known as BVD Type1 and BVD Type 2. Viral strains arealso classified by biotype accordingto behavior in cell culture. Astrain is cytopathic (CP) if it killscells in tissue culture or NCP if itdoes not kill cells.“The main difference betweenthe two biotypes is that CP infectscells in the gut lymphoid tissues,”explains Bosch, “while NCP infectsa wider range of cells, including therespiratory tract, blood cells andlymphoid tissue. NCP also persistslonger in the animal.”Producers can eliminate PIcalves, the main source of BVD infection,by:• Screening to detect PIs• Culling positive animals• Quarantining new animals untilthey are determined PI-negativeAffordable <strong>Feedlot</strong>SoftwarePrograms Include:Pro Feeder VIICattle On FeedPro Mini VIIPro Med IIPro Private VRisk ManagerPro Pasture VAge Verification ProgramOption to interface with Quick Books ProOption to interface with other drug and bunk programsAffordable technical support and maintenancePROGRAMS CAN BE INSTALLED ON NETWORKS orMULTIPLE COMPUTERS AT NO ADDITIONAL COST!HI-PLAINS SYSTEMS, INC.www.hiplainsystems.comhiredhand5@cs.com800-327-8295• Incorporating biosecuritymeasures• Vaccinating with a broad-spectrumvaccine that provides protectionagainst BVD Types 1 and 2Because NCP and CP biotypesdistribute through the body differently,research shows that the immunesystem responds differentlyto them, as well. In a research paperpublished in the Journal ofGeneral Virology, Lambot et al. investigatedimmune response differencesof calves infected with a pairof CP and NCP BVD. Results foundthat the NCP biotype produced ahigher and more rapid antibody responsethan the CP virus.In a different research trial, Arsenal®4.1, a modified-live vaccinecontaining NCP and manufacturedby Novartis Animal Health US, Inc.,found that it had a larger, faster antibodyresponse than a vaccinecontaining only CP Type 1.Bosch recommends consultingwith your veterinarian to determinethe best way to control BVD. ♦Five Nations Beef AllianceAgrees on Trade ReformThe national beef associationsof Australia, Canada, Mexico, NewZealand and the U.S. met in Australiarecently and reached a consensuson several items, accordingto NCBA.Among the agreements was aconsensus on trade reform. TheFive Nations Beef Alliance willcontinue to push for further tradeliberalization in the Doha Round ofWTO negotiations. The group supportsexpanded market access viathe removal of tariff and non-tariffbarriers, elimination of export subsidiesand substantial reductionsin domestic support.To achieve fair trade, the allianceurges all beef importing countries toensure that sound science based onOIE guidelines remains the basis forresolving sanitary and photosanitaryissues.♦Circle No. 129 on Reply28 FEED•LOT <strong>February</strong> 2007

Circle No. 130 on Reply

WE ARESPECIALISTS IN:• DUST CONTROL• CATTLE COOLING• DE-WATERINGLet us show you how to turn yourrun-off water into a valuable resource.806-292-6900www.feedlotenvironmental.com“The farm bill may allocate up to50% cost sharing on our systems.2007 may be the last year to sign upfor your local eqip program. Call ustoday for more information.”Winter Herd Health ProblemsMay Be Curbed With GoodNutritionby Paul A. Davis, Ph. D.The cold, muddy, rainy conditions brought on by “OldMan Winter” often exacerbate the potential for healthproblems in cattle. Winter weather presents a two-foldproblem in regard to nutrition and animal health.Colder temperatures and concurring stage of productiondictate a higher plain of nutrition, while grassesand native forages are often dormant and of lownutritional value. While fall-calving cows are nursingolder, larger calves, spring-calving cows are either inheavy gestation or nursing newborn calves. In eithercase, nutritional demands are high and often the foragesand pastures offered cannot provide adequateamounts of protein and energy.To make matters worse, many of the bacteria, viruses,and parasites that plague cattle are inherent to theareas in which cattle are kept and most are opportunistic.Cattle that lose body condition due to malnourishmentand the stresses of calving, rebreeding,and/or weaning become more prone to contracting adisease or parasite infestation. Therefore, the first lineof defense in cattle health may well be nutrition. However,providing adequate nutrition during the wintermonths is not without its challenges.Cold temperatures in and of themselves are a stressorto livestock. During cold weather when it is neededmost, feed intake may be suppressed. Additionally,muddy conditions may cause a depression in intake offive to 25 percent and rain can cause temporary intakereductions of similar magnitude. To overcome the obstaclesof less nutrient density in forages and keep cattlein proper body condition and ward off disease,supplying additional nutrition is essential. Whenstressed cattle are presented with a disease challenge,the subsequent immune response is a protein and energyexpense. In other words, a protein and energy deficiencycan increase the chances of an animalsuccumbing to disease or infection! Furthermore, vaccinesare more efficacious when administered to an animalthat is adequate in status of protein, energy,vitamins, and minerals.Additional health problems may arise during timesof limited forage availability. As cattle are forced tosearch for alternate food sources, weeds, acorns, andmoldy or rotting hay may be utilized. Acorn poisoningis often observed when forage is short and cattle arehoused in pastures with abundant Oak trees. Cattle aredrawn to acorns by taste and tend to overeat greenacorns and become ill due to gallotannin. While providingplenty of hay so that cattle are not hungry or notallowing access to acorns at all are the best preventions,there is no specific antidote for the toxin.Circle No. 131 on Reply30 FEED•LOT <strong>February</strong> 2007

However, cows grazing in pastureswith abundant acorns may be partiallyprotected by feeding themfour pounds of the following mixtureeach day:•44 percent Cottonseed hulls orcorn•40 percent Cottonseed or soybeanmeal•10 percent Hydrated lime• six percent Liquid molasses orvegetable oilToxic weeds that are not normallyconsumed can also becomeproblematic when forage is inshort supply. Consumption of certaintypes of estrogenic molds maybe detrimental to reproduction.Likewise, the unsanitary conditionsassociated with wet, rottinghay may contribute to conditionssuch as foot rot, navel ill, mastitis,and bacterial scours. Supplying nutritionto the herd that is adequatein both quality and quantity can alleviatemuch of this potential.Another health problem oftenassociated with the winter seasonis grass tetany or hypomagnesemia.This disease, brought on byhigh potassium concentrations inlush, growing native or small grainpastures, can be controlled to agreat degree through nutrition.Provide the cow herd with a vitamin-mineralmixture containing 12to 14 percent magnesium and feedas directed, usually four to sevenounces per head per day.Don’t overlook water. If waterbecomes unavailable due to freezingor other problems, cattle willsuffer. Supplements that use salt asan intake limiter and salt-containingvitamin/mineral mixtures canbe dangerous, even deadly, withouta free choice water supply. Onthe same note, make efforts tokeep water clean. Muddy pondsand dirty stock tanks can be breedinggrounds for harmful bacteria.Risk management has longbeen a cornerstone of profitableagriculture. However, not all riskSpring-calving cows are nursingnewborn calves so supplying additionalnutrition is essential.management involves forwardcontracts or hedging. Effectiverisk management for cattlemencan begin on the farm by providingadequate nutrition to wardingoff profit-robbing health problemsduring the winter.♦Circle No. 132 on Reply

FEED•LOT’S COW CALFFEED•LOT’S COW CALFCows May Need High Concentrate Diets this WinterAfter this summer’s drought and hard winter, manycattle producers may have trouble finding enough hayto last all winter.Producers can, however, successfully winter theircows in drylots on high concentrate diets and maintaindesired body condition scores, said Twig Marston,Kansas State University Research and Extension cowcalfspecialist.Feeding a limited, but high concentrate diet will requiregreater monitoring to help avoid problems suchas rumen acidosis, a decrease in rumen pH causing diarrheaand decreased feed intake; bloat, a swelling ofthe rumen that occurs when feed fermentation createsa foamy layer at the top of the rumen, which trapsgasses; and founder, an increase in rumen acid productionand a decrease in pH, he said.The amount of forage a cow should consume dailyranges from .5 to .75 percent of her body weight. Thiswill equal about 5.0 to 7.5 pounds of dry hay, or 30 to45 pounds of silage daily.Producers should provide 2.5 to 3.0 feet of bunkspace per animal and make sure the diet is properlymixed and delivered evenly in the bunk, Marston said.This allows all cows to have access to the feed theyneed to meet their nutritional requirements.Cows also can make eating a habit so they need tobe fed at the same time daily. If they’re hungry, theywill tend to seek weak spots and holes in fences insearch of food.Cows can founder on shelled corn-based diets whenstarch digesters dominate in rumen fermentation, hesaid. To help avoid founder, producers should take aweek to 10 days to slowly adapt cows and their rumenmicroflora to the high concentrate diets. Another solutionis to feed whole corn, which will shift more of thestarch digestion from the rumen to the small intestine.“Normally, cows will need about 12 pounds of corndaily to meet their energy needs,” Marston said. “Wholecorn will actually help with rumen health as it addssome ‘scratch factor’ to the diet — acting in a small waylike forage.”High concentrate diets are non-traditional and usuallyfed for economic reasons, he said. Therefore, producerswill need to balance these diets for cow nutrientrequirements (protein, energy, vitamins, minerals androughage levels) and for least cost value.Nutrient ratios also need to be analyzed. Examples ofnutrient ratios are: calcium to phosphorus, rumen digestibleprotein to rumen “by pass” protein, acid load toenergy density, and roughage type to roughage levels.Producers feeding high concentrate diets will needto increase management and monitor cows moreclosely for cold stress, pen conditions and herd health,and changes in nutrient requirements from mid to lategestationto lactation. Cold stress increases energy demandsand an increase in mud affects bothmaintenance energy requirements and feed intake.Producers should clean pens as needed so cows willhave comfortable and sanitary living conditions, Marstonsaid. As cows make the transition from mid-gestation tolate-gestation to lactation, the feed nutrient density andamount of feed fed will need to be increased.Remember to add trace minerals and vitamin A tothe feed ration also, he said. These nutrients should notbe expensive and can have long-term benefits.To improve feed efficiency, one option producershave is to feed an ionophore. They generally decreasefeed intake, improve feed conversion, maintainor increase daily gain and do not affect carcasscharacteristics.“Some producers are reluctant to feed cowsionophores, but research has repeatedly shown thattheir addition will be economically beneficial,”Marston said. “An ionophore should improve feedefficiency by eight to 10 percent, so it will be quitecost effective.”Getting cattle to grade must start at the beginning,if not sooner. Planning comes before conception. ♦Circle No. 133 on Reply32 FEED•LOT <strong>February</strong> 2007

Top Quality Beef Starts With PotentialIn a Certified Angus Beef LLC(CAB) research review, vice presidentLarry Corah and supply developmentdirector Mark McCullynote the effect of genetic selectionon carcass quality.Cattle can only be managed up totheir genetic potential, they explain.“Both breed and selection withinthat breed affect marbling ability,”Corah says. That puts a premium onplanning. “You must focus on yourend goal from day one—beginningwith genetics,” he says.Breed may provide a simplestarting point.Starting in 2003, the AmericanAngus Association developed dollar-value($Value) indices and, ofcourse, there is a range of values.“We show measurable differencesin beef value between the top andthe bottom sires,” says Sally Northcutt,genetic research director withthe Association.The Beef Value ($B) selection indextakes into account post-weaningperformance and carcass traits,such as marbling and red meatyield. Using it as a selection tool,Northcutt says, “you can make directionalchange in genetics.”These traits are easily passed onfrom one generation to the next.“That’s the nice part about workingwith carcass traits,” Northcuttsays. “They’re moderately to highlyheritable and that indicates thatselection for those economicallyimportant traits can be effective.”Aiming for carcass quality doesn’thave to leave you shortchangedon performance.CAB feedlot data on 12,000 headshows that the highest CAB acceptancecattle had the lowest cost ofgain. Northcutt says producersneed to know what they have, beforethey can know what directionto go with genetic selection.“A lot of producers are trying tomake end-product changes,” shesays. “If they have fed their cattle,they have an idea of their herd’s geneticbase for quality grade and redmeat yield. Then they can use the Association’stools to make changes.”Balanced selection is still amust, Corah and Northcutt say, becauseemphasis on marbling alonecan set back progress in ribeyearea, growth or other traits.“A lot if it is just developing atrack record with the genetic toolsthat work in your program,” North-by Miranda Reimancutt says. “Start out conservatively,not just chasing one trait.”Getting information back ontheir cattle will help producersfine-tune genetics, she adds.“There are more opportunitiesthan ever to learn what your cattlewill do.”♦Circle No. 134 on ReplyFEED•LOT <strong>February</strong> 2007 33FEED•LOT’S COW CALF

Cattlemen Submit Petition to Challenge EPA Air StandardsAfter reviewing hundreds of pages outlining theEPA’s final rule on fugitive dust, the NCBA has challengedthe rule in court. NCBA filed a petition in theU.S. Court of Appeals seeking review of EPA’s air qualitystandards that regulate agricultural dust.The EPA released the rule revising the Clean Air ActNational Ambient Air Quality Standards (NAAQS) forParticulate Matter (PM) on October 17. NCBA hasmaintained that there is no scientific evidence warrantingthe regulation of dust on farms and ranches.“On livestock operations, dust is produced by tillingsoil, planting and harvesting crops, driving on dirtroads, spreading nutrients on fields, mixing feed, andby cattle simply moving around in feedlots. These areexamples of the dust that would be regulated under acoarse PM NAAQS,” says Tamara Thies, NCBA’s directorof environmental issues. “Many farms and ranchesare simply unable to control dust to the level EPArequires, even when using best management practices.The EPA has put agriculture in an impossible situation,with no scientific justification.”NCBA submitted extensive comments on the issue,including technical evidence demonstrating that dustfrom agriculture operations presents no public healthconcerns. “Ranchers are experienced in managing airquality and utilizing dust control practices on theirranches,” says Thies. “Dust is – at most – a nuisanceissue and should be regulated accordingly. It is not ahealth issue that warrants regulation at the level thatEPA’s rule requires.”♦Initial Ethanol PushChallenges Beef Marketby Kay Ledbetter, Texas Ag Extension ServiceLike it or not, ethanol is coming, and beef producersmust be prepared to weather the transitional phase andcapitalize on the potentials in the future, said two speakersat the Southwest Beef Symposium in Amarillo.“The short run is going to be tough, but in the longrun, things will work out,” said Dr. Steve Amosson,Texas Cooperative Extension economist.Feed prices are being driven up by predictions of 3billion gallons of ethanol production capacity comingonline in the next year. Ethanol would require almostan 8-million acre increase in corn acreage, whichequates to an additional 1.1 billion bushels of corn,Amosson said.“I feel the corn prices will range from $3 to $4.25 perbushel on the board for the next couple of years, andthe differential between corn and sorghum will narrow,”he said.Competition for acreage will increase, forcing otherfeed sources and crop prices higher.In the short run, fed cattle prices will remain relativelyunchanged, and feeder cattle and calf prices maycontinue to soften, Amosson said. A rule of thumb, hesaid, is calf prices will drop $1.50 per hundredweightfor every 10 cent rise in corn prices.This is going to reduce the predicted expansionphase of the cattle cycle, he said. But in three to fouryears that reduction will have cattle producers seeingrecord prices.“Cattlemen also have a potential to gain marketshare relative to the swine and poultry industries becausecattle can be fed the distiller’s grain by-products,where the other industries can’t,” Amosson said.“We just have to learn to feed those DDG’s (drieddistiller’s grain),” he said.Dr. Jim MacDonald, Texas Agricultural ExperimentStation beef cattle nutritionist, agreed, saying “You don’thave to like it, but you had better learn how to feed it.”And that, MacDonald said, is his job – helping thecattle producers learn how to feed the byproduct.While ethanol had its share of unfriendly commentsduring the two-day symposium, MacDonald said, “We’regoing to get there, we just have to manage the transition.“A lot of concern has come with ethanol in this area,”he said. “But we are better off with the plants here thannot because we’re not the only game in town.”Dried distiller’s grains from the Midwest are beingshipped into the export market, he said. So the fact thatCircle No. 135 on Reply34 FEED•LOT <strong>February</strong> 2007

®the Panhandle will produce 600 million gallons ofethanol per year soon, resulting in 1.5 million tons ofdistiller’s grains, will help keep prices reasonable.When corn is processed for ethanol, it breaks downto one-third ethanol, one-third carbon dioxide and onethirdbyproduct or distiller’s grain, MacDonald said.These distiller’s grains still have all the nutrientprofile of corn,only the starchhas beenremoved, hesaid. It has 40to 45 percentfiber and 25to 30 percentcrude protein.“It’s going tobe a cheaperprotein sourcein the futureand if used as aforage supplement,it can beused for bothprotein andenergy supplementation,”MacDonaldsaid. ♦Circle No. 136 on ReplyCircle No. 137 on ReplyToll Free: 800-832-1113Phone: 830-757-1181Fax: 830-757-1468Circle No. 138 on ReplyLift, Load, Transfer andFeed Big RoundBales with Ease.The hydraulically (or optional PTO) powered sickle, slices through wet,frozen, or tight bales with minimum waste and full bale feeding control.The perfect tool to efficiently feed long stem hay. Windrows high moisture silagebales and tough hay into bunks or on the ground without damaging leaves. Sideloading fork makes it easy to handle two bales at a time.Get the most out of your hay with a DewEze processor.Call for Free Color Literature!MANUFACTURING, INC.151 E. Hwy 160 • Harper, Kansas 670581-800-835-1042www.deweze.com®ADVANTAGE ADVERTISINGCircle No. 139 on ReplyFEED•LOT <strong>February</strong> 2007 35

ADVANTAGE ADVERTISINGLivestock WaterersSUPERIOR FEATURES:• Electric heat or constant flow models (available in all sizeswith custom designing available)• Newfrost preventer available• Unique, easy-clean brass drain• Stainless steel trough• Thick-walled, insulated and reinforced steam curedconcrete frame• Brass water inlet to high volume, trouble-free valve systemFREEInformation AboutThe Efficiency AndAdvantages Of FeedingHigh Moister Corn.The grinders with the incredible life.We invented the Tub Grinder in1946 and the original grinder isstill in use today. We have a modelto fit your need.Circle No. 140 on ReplyHereford, Texas800-299-8265www.superiortanks.comCircle No. 141 on ReplyWe will be pleased to mail or e-mail you freeinformation on the efficiency and advantages offeeding high moisture corn. Call or e-mailPh: 719-336-7433e-mail: whomfgco@bresnan.netBox 1153, Lamar, Colorado 81052Circle No. 142 on ReplyCircle No. 143 on Reply36 FEED•LOT <strong>February</strong> 2007

Ferrell-RossFlaking Mills24 x 56 Dual-DriveFlakeMasterFlakeMaster Mills are available in a sizeto fit your capacity needs from 18 x 36, 20 x 36,20 x 42, 24 x 48, 24 x 56, 28 x 56 to 32 x 68High Capacity, Energy Efficient, UnmatchedDependability, Low Maintenance, Lower Cost/TonADVANTAGE ADVERTISINGCircle No. 144 on ReplyCircle No. 145 on ReplyFerrell-Ross is the original, a pioneer in Steam Flakingwith designs often imitated, but never duplicated.Ferrell-RossRoll Manufacturing Inc.Hereford, Texas 800-299-9051www.ferrellross.com sales@ferrellross.comSAVES YOUMONEY.Now you canbuy the C&SCommercialProcessorChute andattach any ofour headgates.ScissorsHead GatesRotaryHead GatesUltra-SlideHead GatesCircle No. 146 on Reply877-370-4948FAX #: (402) 371-9117MANUFACTURING, INC.WEBSITES:www.gentleroll.comwww.ebmmanufacturing.comCircle No. 147 on ReplySince 1975C&S CATTLE EQUIPMENTSales 800-257-0097Cummings Sales, Inc. / Garden City, KSemail: cscattle@pld.comwww.cattleequipment.comFEED•LOT <strong>February</strong> 2007 37

ADVANTAGE ADVERTISINGCompleteWorkingFacilities forCattle and BisonSee our new innovative hydraulic chute.National Distributor for Tru-Test ScalesA1 in Name – A1 in Quality, Performance andDependability THAT’S THE BIG DIFFERENCE!A1 Mist Sprayers Resources is the most trusted name in Mist Sprayers!Spray up to 140’ without Booms!High Performance PTO or EngineDriven Mist Blowers★ Insect Control — Mosquito (West Nile),grasshopper, flies, army worms,stinkbugs, bean leaf beetle, and aphids★ Pasture & Range — Fence rows, roadditches, brush, and thistle★ Livestock Fly Control — Cow/calf, dairy,feedlots, swine, and poultry confinementsDirks EarthmovingPrecision Land Forming• Livestock Pen Shaping• Lagoon Construction• Conservation Practices• Site Preparation • Laser EquippedCall Toll Free1-877-872-3057cell # - 620-872-1793Richard Dirks - Scott City, KSCircle No. 149 on ReplyCircle No. 150 on Reply★ Specialized Uses — *NEW* bunk blowerattachment available, cities, parks campgrounds,fly, mosquitoes, and tick controlSport Utility Ranger877-924-2474 orSuper DutyAsk about our new CANNON VOLUTE!877-524-2479www.mistsprayers.com sales@mistsprayers.comINFORMATION OR BROCHURES:PEARSON’S INC.90 COURT ST.THEDFORD, NE 69166308/645-2231Circle No. 151 on ReplyCircle No. 152 on Reply38 FEED•LOT <strong>February</strong> 2007Circle No. 153 on Reply Circle No. 149 on Reply

PROCESSING, SORTING and SHIPPING LAYOUTSBy World Famous Dr. Grandin — Originator of Curved Ranch CorralsGRANDINLIVESTOCK SYSTEMS3504 North Shields / Fort Collins, CO 80524970-229-0703www.grandin.comCircle No. 154 on ReplyCUSTOM DESIGNSERVICE AVAILABLEProven designs used by the largest cattlecompanies. Drawings for gates,hinges, latches, V-chute, crowd tub,sorting pens and loading ramp plus cattlebehavior information.BOOK OF LAYOUTS $55 Check/MOFor Large & Small OperationsINSTRUCTIONAL VIDEO on lowstress cattle handling.VHS $59 – DVD $68DVD set includes additionalSpanish video and picture CDCircle No. 155 on ReplyAgriculturalEngineeringAssociatesPhone: 1-800-499-5893www.agengineering.comThree Decades of Technical LeadershipEQIP Technical Service Provider• <strong>Feedlot</strong> Design• Shipping / Receiving Facilities• Processing / Sorting Facilities• Environmental Permitting and Compliance• Natural SystemGrass Filters, Buffer StripsConstructed WetlandsInfiltration Areas• Water Supply and Distribution• Ethanol ProductionADVANTAGE ADVERTISINGCircle No. 156 on ReplyCOUNTRY WELDING BOX SCRAPERWEST POINT IMPLEMENTis the distributor forthe CountryWelding BoxScraperPhoto is shown with optional scarifer attachmentBenefits of this attachment is that it loosens hardened soil so blade can cut andremove excess soil and by products. This reduces cut and fill time by at least a third.WEST POINT DESIGN SPREADALLFEATURES THAT COUNT:New and Improved Distributor24 teeth per bar for an improved, finerdistribution of material. This benefitsthe no till and minimum tillage farmer.Introducing the optional Spread-AllSpinner attachmentFeatured Benefits Wider pattern ofdistribution and the capabilities of alower tonnage spread per acre dependingon consistency of the material.• 16 or 20 Ton Capacity• Excellent for Leveling Feed Yards THE QUALITY • 6’ x 20’ or 7’ x 20’ Box(especially in winter months for SPEAKS FOR • 20 or 22 Ton Truck Mounted Spreadercleaning off frozen manure)w/7’ x 20’ or 7’ x 22’ Box Available• Constructed from 1/2” Thick Steel and ITSELF!• Variable Speed Apron with6”x6” Box Beams (weight is built-in, no need to add any)Heavy-Duty Double Apron Chain• Complete with Dual Hydraulic Cylinders, Hoses and Tips• Tandem Oscillating Running Gear• Four 235/16 10-ply Recap Tires with 6 Bolt Hubs• High Floatation Tires• Standard with See Through Extension (allows for Easy• Heavy-Duty Frame & ComponentsSee-Through Visibility • Swivel Clevis Hitch• Aggressive Distributor with Curved• Available in 10’, 12’ & 14’ WidthsTeeth for Even Spread of Material• Lift Height at Blade Edge - 23”• Box Made from No Rust Composite MaterialWEST POINT IMPLEMENT, INC.WEST POINT DESIGN, INC.2074 So. Hwy. 275 / West Point, NE 68788 (402) 372-2408 2074 So. Hwy. 275 / West Point, NE 68788 (402) 372-2408Circle No. 157 on ReplyFEED•LOT <strong>February</strong> 2007 39

ADVANTAGE ADVERTISINGWe offer afull line ofKuhn Knight and Harsh Mixers.Midwest Mixer of Dodge City1501 South SecondDodge City, KS 678011-800-280-7150www.midwestmixer.comMidwest Mixer of Scott City1523 South MainScott City, KS 678711-800-280-7251NO SLIP FLOOR MATSHEAVY DUTY CENTER TREAD 5POUNDS PER SQUARE FOOTFOR ANYWHEREANIMALS MAY SLIP• Processing Areas • Livestock Trailers• Alley and Walk Ways • Horse TrailersDouble D Family Mat Shop, Inc.CALL 1-785-673-4326RT 1 Box 18, Park, KS 67751www.ddfamilymats.netHEIFERSPAYINGSERVICES450-550 Head Spayed/Day• Better Grazing & <strong>Feedlot</strong> Gains• No Pregnancies & Riding• Eliminate Estrous Suppression Drugs• Eliminate Preg Checking Costs• Co-mingle Steers & Heifers• Fewer Prolapses• Happier Neighbors and Customers• Vaginal Spaying Eliminates IncisionScarring & Flank DamageDaryl Meyer, DVM1-800-494-1045Circle No. 158 on ReplyCircle No. 160 on ReplyTHE “ORIGINAL”TROJAN LIVESTOCKEQUIPMENT CO., INC.• Hydraulic • Hydraulic Chutes Chutes • Panels• Tubs • Portable & Alleys Tubs (Fixed & Alleys Hydraulics)•• Reconditioned Chutes• Truck • Other & Stock Cattle Trailer Equipment Loadouts1-800-687-1543Weatherford, OKBowmanLivestock EquipmentCompany118 N. Broadway – Herington, KS – 67449785-258-3991Feed lotmodelchuteBOWMAN is theHeaviest Built Livestock Equipmentin the World.Many Have Tried to Copy UsBut None Have Succeeded!It May Look Like a Bowman. WhyDoesn’t it Perform like a Bowman?of Herington, KansasAmerica’s PremierCattle HandlingEquipmentwww.bowmanlivestockequipment.comCircle No. 161 on ReplyCircle No. 162 on Reply40 FEED•LOT <strong>February</strong> 2007Circle No. 163 on Reply Circle No. 159 on ReplyBOWMANTHE BATCH BOXGIVES YOU 1/3 MORE USEOF FEED TRUCKS WITH1/3 LESS MAN HOURSWhile the truckis unloading theloader is refillingthe BatchBox.STREAMLINE YOURFEEDING WITH ABATCH BOX402-843-5671feedingsystems.bizFeeding Systems, LLC309 Plantation St. • Elgin, NE 68636

CONCRETE INDUSTRIES“The bunks are easier for ourbunk cleaners to clean, andmuch stronger. If you hit onewith a truck, you hurt thetruck, not the bunk. We’vealso solved our rust problems,the Concrete IndustriesBunk’s neck rail support doesnot rust out.”Bill PadillaGray Country FeedersCimarron, KSADVANTAGE ADVERTISINGCircle No. 164 on ReplyCircle No. 166 on ReplyHUNTER AGRI.CONSTRUCTIONJerry Hunter, OwnerSLIP FORM CONCRETE BUNKSDirt Work — Laser ControlFencing — Ditching — Portable Concrete PlantButler Metal Buildings and Grain BinsPour-in-Place Bunk For Small JobsTurnkey <strong>Feedlot</strong> Construction806-244-5330 — 800-644-5330PLAN &DESIGNHIWAY 54 WEST • P.O. BOX 464 • DALHART, TX 79022Circle No. 168 on ReplyFEED•LOT <strong>February</strong> 2007 41Circle No. 169 on Reply Circle No. 167 on ReplyCircle No. 165 on Replydivisionof U.B.C.CALL TODAY...1-800-545-7411316-275-7591111 J.C. Street Box 599Garden City, KS 67846ANIMALBREEDING• Pregnancy Testing• AI • Herd Health• Calf Delivery & Calf CareAnd Many Other Services You andYour Help Will Be Able To DoSAVE TIME, MONEYAND CATTLE CALL1-800-552-3538 or Write forFree Catalog / Class ScheduleGraham School, Inc.641 W. Hwy 31 - Dept. FL • Garnett, KS 66032www.grahamschool.com90 Years of ContinuousService/Over 30,000 Graduates