e n v i r o n m e n t a l s u s t a i n a b i l i t yPlanning Ahead<strong>MillerCoors</strong> is committed to water stewardship andis focused on better understanding water risks inour communities. We work closely with communitystakeholders, including local governments and nonprofitorganizations, to understand the challenges ofwater scarcity and quality, and the potential impact onour business.According to the World Business Council forSustainable Development, water scarcity refers toan excess of demand for water over available supplyfor agricultural, industrial and domestic needs.<strong>MillerCoors</strong> Texas and California breweries arelocated in water scarce regions, while our Golden,North Carolina and Georgia breweries are locatedin water stressed regions. We are conducting anassessment to strategically evaluate the long-termwater outlook in these regions. <strong>MillerCoors</strong> also plansto complete a water footprint in 2011, evaluating ourwater use throughout the entire supply chain to betterunderstand our overall direct and indirect water usage.Major SavingsWe constantly strive to find innovative and creativeways to manage our water usage.• At our Virginia brewery, water reduction projectssaved nearly 5.3 million gallons of water annually,reducing water usage by nearly 16 percentin 2009.• Leinenkugel’s invested in a new pasteurizer that willreduce water usage by 25 percent, an annual savingsof 15–20 million gallons of water.• Our California brewery partnered with a localuniversity to identify areas of the brewery’s campusbest suited for a desert walking trail that would notrequire any watering.• Our Milwaukee brewery was the first in the<strong>MillerCoors</strong> system to install a green roof to absorbrainwater and help reduce storm water runoff.looking back.We did not meet our goal of reducing our water usage to a 3.96:1.00 waterto-<strong>beer</strong>ratio. In 2009, we shifted 12 percent of production to differentbreweries as a result of the joint venture, and clearly felt the impact onour water usage. We are investing in capital improvements to achieveour 2015 goal, and also aligned our CSR investments in support of watersustainability initiatives in all of our brewery and corporate communities.SABMiller Group Head of Manufacturing Maurice Egan andMilwaukee brewery employees Joan Giuliani and Deon Van Ason the Milwaukee brewery’s green roof.GREAT ENERGY<strong>MillerCoors</strong> is committed to reducing its total energy useacross all operations by:• Reducing its carbon footprint• Focusing on renewable energy• Lessening emissions2015 goalReducetotalenergy useby 15%In 2009, <strong>MillerCoors</strong> reduced its overallenergy consumption by 3.6 percentper barrel of <strong>beer</strong> across its eightmajor breweries. This reduction wasaccomplished as we shifted productionof 12 percent of our <strong>beer</strong> portfolio, theequivalent of eight million barrels, to differentbreweries as a result of the joint venture between Miller and Coors.We are also taking steps to achieve our 2015 energy reduction goal.We are making capital improvements at our breweries, investigating heatrecovery options and implementing utilities equipment replacementprojects to improve efficiency.In 2009, <strong>MillerCoors</strong> reduced its greenhouse gas emissions by 1.2 percentacross all operations and facilities. We renewed our commitment tothe U.S. Environmental Protection Agency’s Climate Leaders program,pledging to reduce corporate-wide greenhouse gas emissions eightpercent by 2015. The company has an accomplished history with theprogram, as Coors Brewing Company was recognized forexceeding its goal early,reducing emissionslooking•ahead.20 percent perproductionindexComplete water supply assessments, including a•10-year forward look at our water scarce regionsConduct capital improvements for waterfrom 2005 to 2008.•reduction projects to achieve 2015 goalExplore packaging water reuse opportunities12

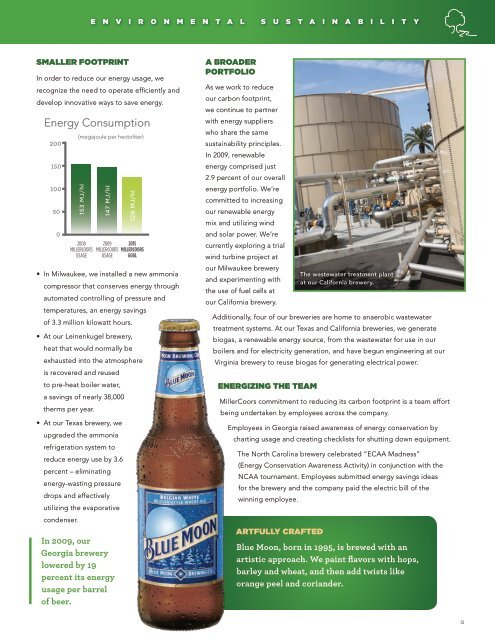

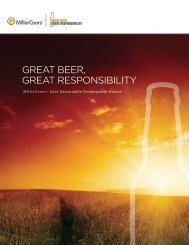

e n v i r o n m e n t a l s u s t a i n a b i l i t ySmaller FootprintIn order to reduce our energy usage, werecognize the need to operate efficiently anddevelop innovative ways to save energy.Energy Consumption200150100500(megajoule per hectoliter)153 MJ/hl2008<strong>MillerCoors</strong>usage147 MJ/hl2009<strong>MillerCoors</strong>usage• In Milwaukee, we installed a new ammoniacompressor that conserves energy throughautomated controlling of pressure andtemperatures, an energy savingsof 3.3 million kilowatt hours.• At our Leinenkugel brewery,heat that would normally beexhausted into the atmosphereis recovered and reusedto pre-heat boiler water,a savings of nearly 38,000therms per year.• At our Texas brewery, weupgraded the ammoniarefrigeration system toreduce energy use by 3.6percent – eliminatingenergy-wasting pressuredrops and effectivelyutilizing the evaporativecondenser.In 2009, ourGeorgia brewerylowered by 19percent its energyusage per barrelof <strong>beer</strong>.128 MJ/hl2015<strong>MillerCoors</strong>GOALA BroaderPortfolioAs we work to reduceour carbon footprint,we continue to partnerwith energy supplierswho share the samesustainability principles.In 2009, renewableenergy comprised just2.9 percent of our overallenergy portfolio. We’recommitted to increasingour renewable energymix and utilizing windand solar power. We’recurrently exploring a trialwind turbine project atour Milwaukee breweryand experimenting withthe use of fuel cells atour California brewery.Additionally, four of our breweries are home to anaerobic wastewatertreatment systems. At our Texas and California breweries, we generatebiogas, a renewable energy source, from the wastewater for use in ourboilers and for electricity generation, and have begun engineering at ourVirginia brewery to reuse biogas for generating electrical power.Energizing the TeamThe wastewater treatment plantat our California brewery.<strong>MillerCoors</strong> commitment to reducing its carbon footprint is a team effortbeing undertaken by employees across the company.Employees in Georgia raised awareness of energy conservation bycharting usage and creating checklists for shutting down equipment.The North Carolina brewery celebrated “ECAA Madness”(Energy Conservation Awareness Activity) in conjunction with theNCAA tournament. Employees submitted energy savings ideasfor the brewery and the company paid the electric bill of thewinning employee.Artfully CraftedBlue Moon, born in 1995, is brewed with anartistic approach. We paint flavors with hops,barley and wheat, and then add twists likeorange peel and coriander.13