Shell Tellus S2 M

Shell Tellus S2 M

Shell Tellus S2 M

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

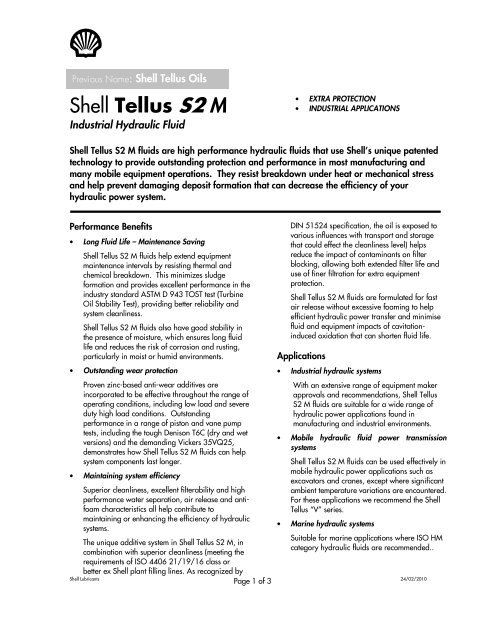

Previous Name: <strong>Shell</strong> <strong>Tellus</strong> Oils<strong>Shell</strong> <strong>Tellus</strong> <strong>S2</strong> MIndustrial Hydraulic Fluid• EXTRA PROTECTION• INDUSTRIAL APPLICATIONS<strong>Shell</strong> <strong>Tellus</strong> <strong>S2</strong> M fluids are high performance hydraulic fluids that use <strong>Shell</strong>’s unique patentedtechnology to provide outstanding protection and performance in most manufacturing andmany mobile equipment operations. They resist breakdown under heat or mechanical stressand help prevent damaging deposit formation that can decrease the efficiency of yourhydraulic power system.Performance Benefits• Long Fluid Life – Maintenance Saving<strong>Shell</strong> <strong>Tellus</strong> <strong>S2</strong> M fluids help extend equipmentmaintenance intervals by resisting thermal andchemical breakdown. This minimizes sludgeformation and provides excellent performance in theindustry standard ASTM D 943 TOST test (TurbineOil Stability Test), providing better reliability andsystem cleanliness.<strong>Shell</strong> <strong>Tellus</strong> <strong>S2</strong> M fluids also have good stability inthe presence of moisture, which ensures long fluidlife and reduces the risk of corrosion and rusting,particularly in moist or humid environments.• Outstanding wear protectionProven zinc-based anti-wear additives areincorporated to be effective throughout the range ofoperating conditions, including low load and severeduty high load conditions. Outstandingperformance in a range of piston and vane pumptests, including the tough Denison T6C (dry and wetversions) and the demanding Vickers 35VQ25,demonstrates how <strong>Shell</strong> <strong>Tellus</strong> <strong>S2</strong> M fluids can helpsystem components last longer.• Maintaining system efficiencySuperior cleanliness, excellent filterability and highperformance water separation, air release and antifoamcharacteristics all help contribute tomaintaining or enhancing the efficiency of hydraulicsystems.The unique additive system in <strong>Shell</strong> <strong>Tellus</strong> <strong>S2</strong> M, incombination with superior cleanliness (meeting therequirements of ISO 4406 21/19/16 class orbetter ex <strong>Shell</strong> plant filling lines. As recognized byPage 1 of 3<strong>Shell</strong> LubricantsDIN 51524 specification, the oil is exposed tovarious influences with transport and storagethat could effect the cleanliness level) helpsreduce the impact of contaminants on filterblocking, allowing both extended filter life anduse of finer filtration for extra equipmentprotection.<strong>Shell</strong> <strong>Tellus</strong> <strong>S2</strong> M fluids are formulated for fastair release without excessive foaming to helpefficient hydraulic power transfer and minimisefluid and equipment impacts of cavitationinducedoxidation that can shorten fluid life.Applications• Industrial hydraulic systemsWith an extensive range of equipment makerapprovals and recommendations, <strong>Shell</strong> <strong>Tellus</strong><strong>S2</strong> M fluids are suitable for a wide range ofhydraulic power applications found inmanufacturing and industrial environments.• Mobile hydraulic fluid power transmissionsystems<strong>Shell</strong> <strong>Tellus</strong> <strong>S2</strong> M fluids can be used effectively inmobile hydraulic power applications such asexcavators and cranes, except where significantambient temperature variations are encountered.For these applications we recommend the <strong>Shell</strong><strong>Tellus</strong> “V” series.• Marine hydraulic systemsSuitable for marine applications where ISO HMcategory hydraulic fluids are recommended..24/02/2010

Specifications and Approvals<strong>Tellus</strong> <strong>S2</strong> M fluids have the following approvals:Denison Hydraulics (HF-0, HF-1, HF-2)Cincinnati Machine P-68 (ISO 32), P-70 (ISO 46), P-69(ISO 68)Eaton Vickers M-2950 SEaton Vickers I-286 S<strong>Tellus</strong> <strong>S2</strong> M fluids are listed by:Bosch Rexroth Ref 17421-001 and RD 220-1/04.03<strong>Tellus</strong> <strong>S2</strong> M fluids meet or exceed the requirements ofthe following standards:ISO 11158 (HM fluids)AFNOR NF-E 48-603ASTM 6158-05 (HM fluids)DIN 51524 Part 2 HLP typeSwedish Standard SS 15 54 34 AMGB 111181-1-94 (HM fluids)For a full listing of equipment approvals andrecommendations please consult your local <strong>Shell</strong>technical help desk.Health and SafetyGuidance on Health and Safety is available on theappropriate Material Safety Data Sheet, which can beobtained from your <strong>Shell</strong> representative.Typical Physical CharacteristicsCompatibility<strong>Shell</strong> <strong>Tellus</strong> <strong>S2</strong> M fluids are suitable for use with mosthydraulic pumps. However, please consult your <strong>Shell</strong>Representative before using in pumps containingsilver plated componentsFluid Compatibility<strong>Shell</strong> <strong>Tellus</strong> <strong>S2</strong> M fluids are compatible with mostother mineral oil based hydraulic fluids. However,mineral oil hydraulic fluids should not be mixed withother fluid types (e.g. environmentally acceptable orfire resistant fluids).Seal & Paint Compatibility<strong>Shell</strong> <strong>Tellus</strong> <strong>S2</strong> M fluids are compatible with sealmaterials and paints normally specified for use withmineral oils.Protect the EnvironmentTake used hydraulic fluid to an authorized collectionpoint. Do not discharge into drains, soil or water.AdviceAdvice on applications not covered in this leafletmay be obtained from your <strong>Shell</strong> representative.<strong>Shell</strong> <strong>Tellus</strong> <strong>S2</strong> M 22 32 46 68 100ISO Fluid Type HM HM HM HM HMKinematic Viscosity (ASTM D 445)@ 0°C, cSt@ 40°C, cSt@ 100°C, cSt180224.3338325.4580466.71040688.6179010011.1Viscosity Index (ISO 2909) 100 99 98 97 96Density @ 15°C (ISO 12185), kg/l 0.866 0.875 0.879 0.886 0.891Flash Point (ISO 2592)(Cleveland Open Cup), °C210 218 230 235 250Pour Point (ISO 3016), °C -30 -30 -30 -24 -24These characteristics are typical of current production. Whilst future production will conform to <strong>Shell</strong>'s specification,variations in these characteristics may occur.<strong>Shell</strong> LubricantsPage 2 of 324/02/2010

Viscosity - Temperature Diagram for <strong>Shell</strong> <strong>Tellus</strong> <strong>S2</strong> M100001000Kinematic viscosity, cSt10010100684632221-20 0 20 40 60 80 100 120Temperature, °C<strong>Shell</strong> LubricantsPage 3 of 324/02/2010