You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

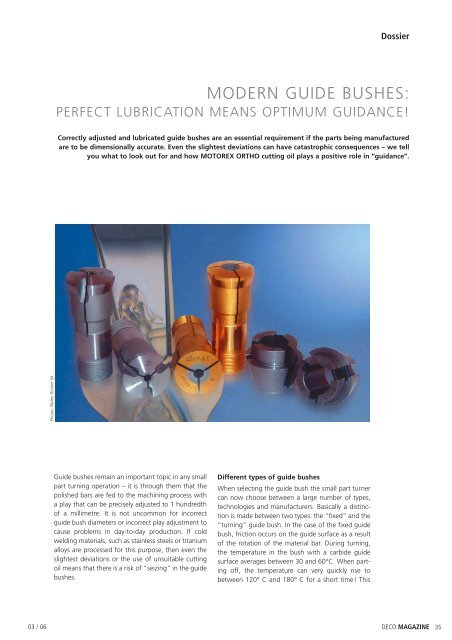

DossierMODERN GUIDE BUSHES:PERFECT LUBRICATION MEANS OPTIMUM GUIDANCE!Correctly adjusted and lubricated guide bushes are an essential requirement if the parts being manufacturedare to be dimensionally accurate. Even the slightest deviations can have catastrophic consequences – we tellyou what to look out for and how MOTOREX ORTHO cutting oil plays a positive role in “guidance”.Photos: Walter Dünner SAGuide bushes remain an important topic in any smallpart turning operation – it is through them that thepolished bars are fed to the machining process witha play that can be precisely adjusted to 1 hundredthof a millimetre. It is not uncommon for incorrectguide bush diameters or incorrect play adjustment tocause problems in day-to-day production. If coldwelding materials, such as stainless steels or titaniumalloys are processed for this purpose, then even theslightest deviations or the use of unsuitable cuttingoil means that there is a risk of “seizing” in the guidebushes.Different types of guide bushesWhen selecting the guide bush the small part turnercan now choose between a large number of types,technologies and manufacturers. Basically a distinctionis made between two types: the “fixed” and the“turning” guide bush. In the case of the fixed guidebush, friction occurs on the guide surface as a resultof the rotation of the material bar. During turning,the temperature in the bush with a carbide guidesurface averages between 30 and 60°C. When partingoff, the temperature can very quickly rise tobetween 120° C and 180° C for a short time! This03 / 06DECO MAGAZINE 35