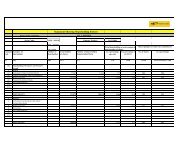

as on July, 2012 - til india

as on July, 2012 - til india

as on July, 2012 - til india

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

14S O S SMsamples should be taken for alll lfluids. When it’s performed regularly,coupled with expert interpretati<strong>on</strong>, itwill help lower maintenance costs.Combined with S O S SM , effectivel lc<strong>on</strong>taminati<strong>on</strong> c<strong>on</strong>trol reduces breakdownsand <str<strong>on</strong>g>as</str<strong>on</strong>g>sociated costs. Keeping machinesystem clean eliminates comp<strong>on</strong>ent wearand improves system efficiency andresp<strong>on</strong>se under varying loads.Because 80% of hydraulic system failurescan be traced to c<strong>on</strong>taminati<strong>on</strong>, here aresome tips that will help you focus <strong>on</strong>cleanliness.Types of C<strong>on</strong>taminantsllllAbr<str<strong>on</strong>g>as</str<strong>on</strong>g>ive particles like aluminium andsilica cause sticky valves and poorpump performance.Water in hydraulic fluid forms bubblesthat pit internal comp<strong>on</strong>ent surfaces.Air in the system causes jerky moti<strong>on</strong>.Heat reduces the lubricity of hydraulicfluid, accelerating comp<strong>on</strong>ent wear.Sources of C<strong>on</strong>taminantsllllExposure to external envir<strong>on</strong>ment viaworn seals, faulty g<str<strong>on</strong>g>as</str<strong>on</strong>g>kets, leakyvalves or defects in cylinder rods.Internal wear due to insufficientlubricati<strong>on</strong> or improper clearances.Installing new comp<strong>on</strong>ents, like dirtyhoses.Adding fluids that were stored in dirtyc<strong>on</strong>tainers.C<strong>on</strong>trolling C<strong>on</strong>taminantsllUse particle counter to <str<strong>on</strong>g>as</str<strong>on</strong>g>sess thecleanliness of the fluid before and afterfiltrati<strong>on</strong>.Flush a dirty system and fill it withnew fluid.Use these simple t<str<strong>on</strong>g>as</str<strong>on</strong>g>ks and derivesignificant impact <strong>on</strong> your hydraulic systemefficiency.C<strong>on</strong>taminati<strong>on</strong> c<strong>on</strong>trol and SlOlS SM analysisare two very effective ways you canc<strong>on</strong>sider to improve your machineavailability and performance. Performedat regular intervals these take minimumtime and cost but have huge returns <strong>on</strong>your investment.lllllCheck the machine for leaksduring daily walkaround inspecti<strong>on</strong>.Use proper filters and change themregularly.Use proper hydraulic fluid, filtering itwhen transferred between storagelocati<strong>on</strong>s.Use desiccant breathers <strong>on</strong> fluidstorage c<strong>on</strong>tainers to prevent waterand c<strong>on</strong>taminant ingressi<strong>on</strong> inside thesystem.Remove c<strong>on</strong>taminants from a dirtysystem with kidney loop mobilefiltrati<strong>on</strong>.C<strong>on</strong>tributed byDr. Deb<str<strong>on</strong>g>as</str<strong>on</strong>g>ish MukherjeeIn-charge-Scheduled Oil Sampling Lab, TIPL