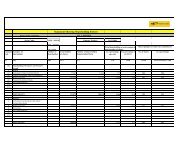

as on July, 2012 - til india

as on July, 2012 - til india

as on July, 2012 - til india

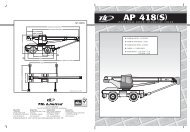

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

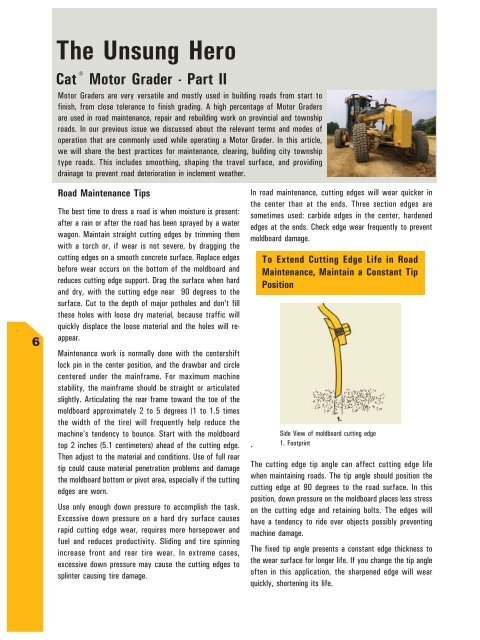

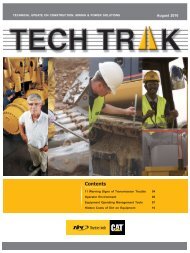

The Unsung HeroCat ® Motor Grader - Part IIMotor Graders are very versa<strong>til</strong>e and mostly used in building roads from start tofinish, from close tolerance to finish grading. A high percentage of Motor Gradersare used in road maintenance, repair and rebuilding work <strong>on</strong> provincial and townshiproads. In our previous issue we discussed about the relevant terms and modes ofoperati<strong>on</strong> that are comm<strong>on</strong>ly used while operating a Motor Grader. In this article,we will share the best practices for maintenance, clearing, building city townshiptype roads. This includes smoothing, shaping the travel surface, and providingdrainage to prevent road deteriorati<strong>on</strong> in inclement weather.6Road Maintenance TipsThe best time to dress a road is when moisture is present:after a rain or after the road h<str<strong>on</strong>g>as</str<strong>on</strong>g> been sprayed by a waterwag<strong>on</strong>. Maintain straight cutting edges by trimming themwith a torch or, if wear is not severe, by dragging thecutting edges <strong>on</strong> a smooth c<strong>on</strong>crete surface. Replace edgesbefore wear occurs <strong>on</strong> the bottom of the moldboard andreduces cutting edge support. Drag the surface when hardand dry, with the cutting edge near 90 degrees to thesurface. Cut to the depth of major potholes and d<strong>on</strong>'t fillthese holes with loose dry material, because traffic willquickly displace the loose material and the holes will reappear.Maintenance work is normally d<strong>on</strong>e with the centershiftlock pin in the center positi<strong>on</strong>, and the drawbar and circlecentered under the mainframe. For maximum machinestability, the mainframe should be straight or articulatedslightly. Articulating the rear frame toward the toe of themoldboard approximately 2 to 5 degrees (1 to 1.5 timesthe width of the tire) will frequently help reduce themachine's tendency to bounce. Start with the moldboardtop 2 inches (5.1 centimeters) ahead of the cutting edge.Then adjust to the material and c<strong>on</strong>diti<strong>on</strong>s. Use of full reartip could cause material penetrati<strong>on</strong> problems and damagethe moldboard bottom or pivot area, especially if the cuttingedges are worn.Use <strong>on</strong>ly enough down pressure to accomplish the t<str<strong>on</strong>g>as</str<strong>on</strong>g>k.Excessive down pressure <strong>on</strong> a hard dry surface causesrapid cutting edge wear, requires more horsepower andfuel and reduces productivity. Sliding and tire spinningincre<str<strong>on</strong>g>as</str<strong>on</strong>g>e fr<strong>on</strong>t and rear tire wear. In extreme c<str<strong>on</strong>g>as</str<strong>on</strong>g>es,excessive down pressure may cause the cutting edges tosplinter causing tire damage.In road maintenance, cutting edges will wear quicker inthe center than at the ends. Three secti<strong>on</strong> edges aresometimes used: carbide edges in the center, hardenededges at the ends. Check edge wear frequently to preventmoldboard damage..To Extend Cutting Edge Life in RoadMaintenance, Maintain a C<strong>on</strong>stant TipPositi<strong>on</strong>Side View of moldboard cutting edge1. FootprintThe cutting edge tip angle can affect cutting edge lifewhen maintaining roads. The tip angle should positi<strong>on</strong> thecutting edge at 90 degrees to the road surface. In thispositi<strong>on</strong>, down pressure <strong>on</strong> the moldboard places less stress<strong>on</strong> the cutting edge and retaining bolts. The edges willhave a tendency to ride over objects possibly preventingmachine damage.The fixed tip angle presents a c<strong>on</strong>stant edge thickness tothe wear surface for l<strong>on</strong>ger life. If you change the tip angleoften in this applicati<strong>on</strong>, the sharpened edge will wearquickly, shortening its life.