INSTALLATION-READY TECHNOLOGY - Victaulic

INSTALLATION-READY TECHNOLOGY - Victaulic

INSTALLATION-READY TECHNOLOGY - Victaulic

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Victaulic</strong>Installation-Ready TM TechnologyIn 1925, <strong>Victaulic</strong> standardgrooved end couplings set thebar for pipe joining efficiency.Today, <strong>Victaulic</strong> installationreadyTM couplings are raisingit to a whole new level.<strong>Victaulic</strong> installation-ready TM couplings are the fastestand safest joining method available because they• install up to 10 times faster than welded joints• install up to 6 times faster than flanged joints• feature no loose parts during installationCOUPLINGS FEATURING PATENTED installation-ready TM technologyStyle 009NStyle 607Style 107Style 177NThe Style 009N FireLock EZ ®rigid coupling for fireprotection systems.The Style 607 QuickVic ®rigid coupling for joiningcopper potable watersystems.The Style 107 QuickVic ®rigid coupling for joiningcarbon steel and stainlesssteel s piping systems.The Style 177N flexibleQuickVic ® coupling for joiningcarbon steel and stainlesssteel s piping systems.sFor pressure and temperature ratings when used with stainless steel, contact <strong>Victaulic</strong>.The Rx roll set is necessary for grooving stainless steel, see 24.01 for more details.

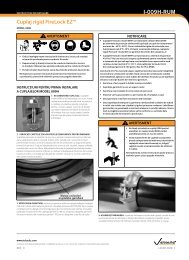

<strong>Victaulic</strong>Installation-Ready TM TechnologyA truly innovative pipe joining solution,no need to disassemble, no loose parts.<strong>Victaulic</strong> patented installation-ready TM couplings provide fast,easy pipe connections. No need to disassemble the coupling.No loose parts to lose or drop. The single unit design allowsan installer to assemble an installation-ready TM coupling bysimply inserting the coupling onto the grooved end of a pipe,fitting, valve or accessory and then tightening the nuts.lube it!Apply a thin coat of <strong>Victaulic</strong> lubricantto the sealing lips of the gasket.stab it!Simply push installation-ready TM coupling ontoa grooved pipe end or component. The gasketcenter lip lets you know when to stop.EHP Delivers Better Performance.Most installation-ready TM couplings featurethe <strong>Victaulic</strong> proprietary Grade “EHP” gasketmaterial for unmatched performance on watersystems from -30°F to 250°F (-34°C to 121°C).EHP is geometrically optimized for unparalleledperformance under pressure, heat, assembly,stress and relaxation.

For Use On Stainless Steel.Style 107 and Style 177N QuickVic couplingscan be used on Schedule 10S (or heavier)stainless steel s applications and are availablehot dipped galvanized upon request.join it!Push the second pipe end or componentup to the center lip of the gasket from theother side of the coupling.tighten it!Using a standard hand tool or an impact wrench*,tighten the two bolts for a secure, reliable joint.Further Enhance Efficiency.Installation-ready TM couplings are installed using standardhand tools; however, to further enhance efficiencyon the job, these couplings can be installed usinga cordless impact wrench.*For illustration purposes only. Refer tothe appropriate Installation Instructions.* Consult <strong>Victaulic</strong> I-100 Field Installation Handbook for proper impact wrench installation usage.sFor pressure and temperature ratings when used with stainless steel, contact <strong>Victaulic</strong>.The Rx roll set is necessary for grooving stainless steel, see 24.01 for more details.

Style 107QuickVic Rigid CouplingStyle 177NQuickVic Flexible CouplingApplicationsHVAC, Utility Piping, Process PipingApplicationsHVAC, Utility Piping, Process Piping, MiningPipe MaterialCarbon Steel, Schedule 10 (or heavier)Stainless Steel s and GalvanizedGasket Grade**“EHP” EPDM and “T” NitrilePipe MaterialCarbon Steel, Schedule 10 (or heavier)Stainless Steel s and GalvanizedGasket Grade**“EHP” EPDM and “T” NitrileMaximum Temperature RatingMaximum Temperature Rating250º F / 121º C 250º F / 121º CMaximum Pressure RatingMaximum Pressure Rating750 psi / 5170 kPa 1000 psi / 6900 kPa

Nothing competes with <strong>Victaulic</strong>installation-ready TM technology.COMPRESS PROJECT SCHEDULES.Standard grooved couplings install up to 5 timesfaster than welded joints and up to 3 times fasterthan flanged.Now, <strong>Victaulic</strong> installation-ready TM couplings install inless than half the time of standard grooved couplings.6.0NUMBER OF MEN ON SITEShift MaximumManpower Line<strong>Victaulic</strong>Peak Man-PowerWeldedPeak Man-PowerMeet or BeatProject Schedule5.0Installation-Ready GroovedWeldMECHANICAL CONSTRUCTION WEEKSMAN HOURS PER JOINT4.03.02.01.00.02 1/2" 3" 4" 5" 6" 8" 10" 12"PIPE SIZEREDUCE MATERIAL HANDLING.Unlike standard couplings, installationreadyTM couplings are installed withoutthe need to disassemble the coupling.No loose bolts and nuts translatesto less material handling on site.BETTER MANAGE LABOR RISK.Because installation-ready TM couplings requirefewer steps to install, the result is consistently fasterpipe joints which allows contractors to optimizecrew size and better manage their labor risk.ENHANCE JOBSITE SAFETY.No flames. No fumes. No loose parts. In additionto being flame-free and devoid of noxious fumesduring installation, installation-ready TM couplingsfeature no loose parts to drop or lose reducingmaterial handling on site and thereby reducing riskof injury.

Piping. Systems. Solutions.Mechanical pipe joining technology originatedin 1925 when <strong>Victaulic</strong> designed the first grooved endpipe joining system for water and air service piping.Recognized for its design capability and speed of assembly,<strong>Victaulic</strong> grooved end pipe joining technology transformedthe piping industry, leading to dramatic gains in productivity.That’s why among specifying engineers, owners and contractorsaround the world, <strong>Victaulic</strong> is the preferred mechanical systemsolution for new construction, retrofit and maintenance.Visit www.victaulic.com/installationready for more information.VICTAULIC GLOBAL CONTACT INFORMATIONUS & WORLD HEADQUARTERSP.O. Box 31Easton, PA 18044-0031 USA4901 Kesslersville RoadEaston, PA 18040 USA1 800 PICK VIC1 800 742 5842(within North America)1 610 559 33001 610 250 8817 (fax)pickvic@victaulic.comCANADA123 Newkirk RoadRichmond Hill, ON L4C 3G5905 884 7444905 884 9774 (fax)viccanada@victaulic.comCENTRAL ANDSOUTH AMERICAP.O. Box 31Easton, PA 18044-0031 USA4901 Kesslersville RoadEaston, PA 18040 USA610 559 3300610 559 3608 (fax)vical@victaulic.comUNITED KINGDOMUnits B1 & B2, SG1 Industrial ParkCockerell CloseGunnels Wood RoadStevenageHertfordshire, SG1 2NB (UK)44 0 1438 310 69044 0 1438 310 699 (fax)viceuro@victaulic.beEUROPEPrijkelstraat 369810 Nazareth, Belgium32 9 381 15 0032 9 380 44 38 (fax)viceuro@victaulic.beMIDDLE EASTP.O. Box 17683Unit XB 8Jebel Ali Free ZoneDubaiUnited Arab Emirates971 4 883 88 70971 4 883 88 60 (fax)INDIA<strong>Victaulic</strong> Piping ProductsIndia Priv. Ltd.Indialand Global Industrial ParkPlot 4, Hinjewadi, Phase I,MulshiPune 411057 (India)91 20 67 919 30091 20 67 919 361 (fax)ASIAUnit 06-10, Floor 3AA Mansion 291 Fumin RoadShanghai, China 20003186 21 6170 122286 21 6170 1221 (fax)vicap@victaulic.comAustralia and New Zealand7 Chambers RoadUnit 1Altona North, VictoriaAustralia 30251 300 PIC VIC1 300 742 842(within Australia)61 3 9392 400061 3 9392 4096 (fax)vicaust@victaulic.comwww.victaulic.comPB-110 5512 REV E Updated 12/2013<strong>Victaulic</strong>, INSTALLTION-<strong>READY</strong>, FIRELOCKEZ AND QUICKVIC ARE REGISTERED TRADEMARKS of <strong>Victaulic</strong> Company.© 2013 <strong>Victaulic</strong> Company. All rights reserved.