IT38G Integrated Toolcarrier - AEHQ5220-03 - Kelly Tractor

IT38G Integrated Toolcarrier - AEHQ5220-03 - Kelly Tractor

IT38G Integrated Toolcarrier - AEHQ5220-03 - Kelly Tractor

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

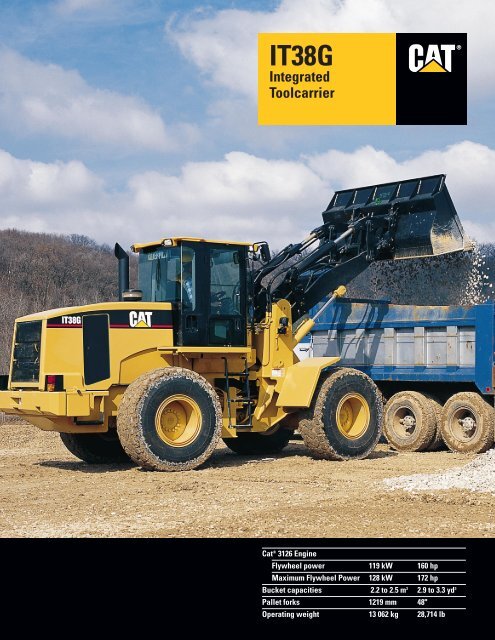

<strong>IT38G</strong><strong>Integrated</strong><strong>Toolcarrier</strong>®Cat ® 3126 EngineFlywheel power 119 kW 160 hpMaximum Flywheel Power 128 kW 172 hpBucket capacities 2.2 to 2.5 m 3 2.9 to 3.3 yd 3Pallet forks 1219 mm 48"Operating weight 13 062 kg 28,714 lb

1241 Jacket water aftercooler2 Air intake heater*5373 Radius cone injector nozzle4 Camshaft roller followers5 Two-piece pistonNew ceramic coated ring package76 Induction hardened forgedcrankshaft87 Series fuel filters withecological drain hoses8 Large spin-on oil filter6* Optional on some configurations.Camshaft roller followers reduce wearand frictional power losses fordurability and fuel economy. Followersand pushrods can be replaced withoutremoving the camshaft.Two-piece, articulated pistons withforged steel crown and forgedaluminum skirt provide durability,lower engine sound levels, enhancedfuel efficiency with improved thermaland structural capability. The newChrome Ceramic Surface (CCS) ringpackage, specifically developed forhigh load/high temperature applications,significantly improves ring and borelife.Crankshaft is forged and inductionhardened for long-term durability. It hasseven main journals, eightcounterweights, and is dynamicallybalanced for smooth operation. Thecrankshaft is completely regrindable.Connecting rods can be removedthrough the tops of the cylinders forease of service.Deep skirt engine block design ensuresrigidity and reduces vibration.Caterpillar engine oil is formulated tooptimize engine life and performanceand is strongly recommended for use inCat diesel engines.Factory remanufactured parts. A largechoice of factory remanufactured partsreduces total repair costs.5

▲Power TrainThe Cat power train makes dependable performance a standard feature.11 Heavy duty axles and brakes aredesigned to last in all kinds ofoperating conditions. Planetary finaldrives use full-floating bronze sleevebearings in the planet gears anddifferential pinion. Oil-disc brakesare adjustment free and fullyenclosed to lock out contaminants.Patented Duo-Cone Seals betweenthe axle shafts and housings keeplubrication in and dirt out. Oscillatingrear axle helps ensure four-wheelground contact for traction andstability, even on rugged terrain.Power shift transmission withautomatic shift capability is designedand built by Caterpillar. Theelectronically controlled power shifttransmission allows full-power speedand directional changes. Fullymodulated shifts increase componentlife and productivity, and help reduceoperator fatigue.Easy maintenance is designed into thetransmission. Built-in pressure taps helpreduce troubleshooting time forincreased machine availability. Oilsampling valves allow quick, cleanaccess to the transmission for S•O•S oilanalysis. The daily oil level check isdone from ground level through a wellprotectedsight gauge.2 Optional Traction Control System is astate-of-the-art Caterpillar electronicsystem. Sensors (A) measure rotationof each axle shaft and vehiclearticulation angle (B). When a tireslips, the system applies the servicebrake for that wheel and torque istransferred through the differential tothe opposite wheel with bettertraction, whether traveling straightahead or turning. An energymanagement system also monitorsbrake energy and protects the brakesby automatically reducing brakepressure as needed. The systemoperates on all four wheelsindependently, providing themaneuverability of an opendifferential and the power of alimited slip.Optional limited-slip differentials andNoSPIN rear differentials are alsoavailable to deliver traction in poorunderfoot conditions.(B)(A)(A)2(A)▲(A)6

Operator's StationComfort and control — top-quality operator's station will help maximize productivity.16712121188114312135102998

The <strong>IT38G</strong> cab is a spacious andcomfortable work environment thatpromotes productive operation. Thenew cab includes larger windows, betterergonomics and generous storage areas.Access/egress is through a new twodoordesign. Both doors open fully andlock flush against the side of the cab.Doors are available with either fixed orsliding glass windows. Steps are wideand angled out for secure footing.1 Larger windows improve theviewing area in all directions.Twelve percent more glass area(compared to the former model)opens the operator’s view forexcellent forward and peripheralviewing. The stylish, sloping hoodallows the operator a better view tothe rear of the machine. View to thebucket corners is better, too.Silicone-bonded windshield andrear window eliminate pillarobstructions and improveserviceability.2 Automatic shift control allows theoperator to concentrate on the work,not gear selection. Preset factoryshift points ensure each shift occursat optimum torque. A switch allowsthe operator to select eitherautomatic or manual shifting. Thelow-effort shift control allows onehandedshifting for speed ordirectional changes.3 Joystick (optional) combines liftand tilt function on one lever. (Notavailable with 4th valve hydraulicarrangement).4 Pilot-assisted hydraulic bucketcontrols make low-effort operationpossible.5 Padded, adjustable wrist rest helpsreduce fatigue.6 Load-sensing, steering system withflow amplification matches steeringresponse to applicationrequirements.7 Steering console and all themachine’s primary gauges can bepositioned infinitely within the tiltrange by the operator. With thestroke of a lever, the entire consolelifts effortlessly out of the way foreasy access or egress.8 Dual suspended brake pedalsserve brake and transmissionneutralizer functions (left pedalonly for neutralizer) so theoperator can maintain high enginerpm for full hydraulic flow.9 Generous storage space includes:■■Lockable compartment forpersonal items.Molded compartments forlunchbox, cooler, thermos, cupor can.10 Parking brake.11 LED warning indicators.12 Improved ventilation for better airflow to the operator and windows.Six repositioned vents throughoutthe cab keep air flowing. A largerecirculation filter ensures betterair quality and contributes tooperator comfort.13 Third valve control for actuating thequick coupler pin to retainattachments, or for controlling thehydraulic flow when usingpowered attachments.Radio-ready cab includes a 12-voltconverter (5-amp), speakers, antenna,all wiring and brackets forentertainment radio installation.Seat options include the standard seatwith adjustable fore/aft position,seatback angle, lumbar support, bottomcushion height, armrest angle andsuspension stiffness. The seat cover isa combination of durable, breathablecloth and vinyl. Also available is theoptional Cat Contour Series Seat, withadded back support extension andelectrically adjustable air suspension.Both seats are equipped with a 76 mm(3 in) wide, retractable seat belt.Other options available for the <strong>IT38G</strong>operator’s station:■■■■■■■Sun visor for the front windshield.Roll-down sun screen for the rearwindow.External mirror package.Auxiliary lighting package.Air conditioning.Ride Control allows the selection ofthree different travel modes:■■■Off: always off service.On: always in service.Auto: system will automaticallybe actuated when machinetravels at a speed greater than6 mph and will be turned offbelow 6 mph.Remote F-N-R Switch9

AttachmentsAdd versatility to your machine with a wide range of buckets and attachmentsdesigned for the <strong>IT38G</strong> to optimize your operation.High Dump Side Dump Log and Lumber MillyardCore Forks Rakes Tire Loader BroomsBuckets.■ High Dump — ideal for loadingstockpiled, light material into highsided trucks or hoppers.■ Side Dump — permits loaders tooperate in congested worksites. Alsodumps forward like a conventionalbucket.■ Other available buckets:-Woodchip.-Coal.-Fertilizer.-Light material.-Rock.-Sand and gravel.-Landfill/refuse.-Multi-purpose.Forks.■ Log and Lumber — ideal for a widerange of jobs — loading, decking andsorting lumber, logs, or palletizedmaterial. (Various tine lengths andclamps available.)■ Millyard — maximize loaderefficiency in millyard applications.■ Other available forks:-Pallet forks (various clamp options).-Core forks.Other Attachments.■ Rakes — For fast, economicalremoval of brush, trees, stumps androcks. (Top clamp option available.)■ Tire loader — specially designed tofeed tires to shredder or load trucks.■ Brooms — are ideal for clearingparking lots, industrial plants,millyards, airport runways andstreets.■ Also available:-Material handling arms.-Snow plows.-V-plow.-Reversible plows.See your Caterpillar dealer for these,as well as a number of other specialtyattachments available from CaterpillarWork Tools and Services.10

Factory Installed AttachmentsA wide variety of factory attachment combinations optimize performance and versatility.Material Handling BucketsDesigned for excellent performance instockpile applications. Flat floordesign. Bolt-on cutting edges arestandard.Material Handling ArmThe material handling arm provides aboom for placing material fromoverhead — great for lowering pipes orbeams into position on constructionprojects. Adjustable extension length;hook and shackle included.Pallet ForksFork configurations are as varied as theapplications they serve. Available in awide range of lengths. Log forks (withor without top clamp) and millyardforks are available from CaterpillarWork Tools and Services.11

Quick CouplerChange attachments quickly from the cab.As an integral part of the <strong>IT38G</strong>, the quick coupler allowsmost attachments to be changed in under 30 seconds. Astandard third valve actuates attachment retaining pins withoutthe operator leaving the cab, or the manual diverter valve canbe used to route hydraulic flow to a powered attachment. Anoptional fourth valve provides additional hydraulic flow forpowered attachments.LinkageAdvanced linkage design provides maximum control.The 8-bar linkage provides parallel lift, keeping the load levelthroughout the entire lifting range, especially important whenusing forks. This lets the operator concentrate on placing theload instead of continually adjusting the forks to retain theload. It's simply faster and more efficient.12

ServiceabilityKeep your machine up and running with easy-to-perform daily maintenance.Maintenance has never been moreaccessible than on G-Series machines.Fast, easy maintenance at extendedintervals means improved uptime andgreater value.■ Lockable, ground level service doorsgive quick access to engine oil filland dipstick, coolant sight gauge, airfilter indicator, fuel tank fill andbattery disconnect switch. Sightgauges for hydraulic and transmissionoil levels are also easily viewablefrom the ground.■ 254 liter (67 gallon) fuel tankprovides extra capacity for long workdays.■ Grouped remote grease fittings allowground level access for lubricating tiltand steering cylinder pins and rearaxle oscillation bearings.■ Caterpillar fluid filters are especiallydesigned to assure maximumcomponent life. The unique designuses non-metallic centertube andmolded end-caps, which fully blendwith media ensuring no internalleakage.■ Cat high efficiency fuel filters featurecellulose/synthetic blend media thatremove more than 98 percent ofparticles that are two microns orlarger, maximizing fuel injector life.Caterpillar Radial Seal air filters donot require tools to service, reducingmaintenance time. The ultra-highefficiency primary air filter elementis coated with a fine layer of fibersthat prevent dust particles fromentering the filter media. This resultsin more efficient filtration, extendedservice intervals, and extended filterlife – all contributing to reducedoperating costs.Caterpillar Extended Life Coolantallows extended change intervals upto 6,000 hours.Maintenance-free batteries areprotected by a built-in battery box inthe left rear frame. These premiumhigh output Caterpillar batteries aredesigned for high cranking power andmaximum protection againstvibration, offering extended servicelife in severe earthmovingapplications.Individual Multi-Row Modular corereduces time to repair or replace theradiator.Electronic Technician provides selfdiagnostics of the Traction ControlSystem, transmission and PayloadControl System to allow effective andefficient troubleshooting by servicepersonnel.■■■■■Sloped hood, electrically activated, tiltsup for complete access to the engine,cooling system and other majorcomponents. If needed, the hood can beremoved quickly and easily byremoving three pins and disconnectinga single harness connector. A built-inlifting point facilitates easy lift off.Sampling valves allow quick, cleanaccess to engine, transmission andhydraulic oils, and provide the mostrepresentative oil samples for analysis.S•O•S oil analysis enables schedulingof downtime for component repair orreplacement before major problemsoccur.Caterpillar engine, transmission andhydraulic oils deliver maximumperformance and service life.Factory remanufactured parts. A largechoice of factory remanufactured partsand dealer proposed repair optionsincreases machine availability andreduces repair cost.13

Total Customer SupportUnmatched in the industry.Customer support agreements. CatDealers offer a wide variety of productsupport agreements. Dealers will workwith customers to develop a plan thatbest meets specific needs. To protect aninvestment, these plans can cover theentire machine, including attachments.Selection. Make detailed comparisonsof the machines being consideredbefore a purchase. How long docomponents last? What is the cost ofpreventive maintenance? What is thetrue cost of lost production? CatDealers can give precise answers tothese questions.Purchase. Look past initial price.Consider the financing options availableas well as day-to-day operating costs.This is also the time to look at dealerservices that can be included in the costof the machine to yield lowerequipment owning and operating costsover the long run.Operation. Improving operatingtechniques can boost profits. CatDealers have training videotapes,literature and other ideas to helpincrease productivity.Maintenance. More and moreequipment buyers are planning foreffective maintenance before buyingequipment. Choose from a wide rangeof maintenance services at the time youpurchase a machine. Repair optionprograms guarantee the cost of repairsup front. Diagnostic programs such asS•O•S Oil Analysis and TechnicalAnalysis help avoid unscheduledrepairs.Replacement. Repair, rebuild orreplace? Cat Dealers can help evaluatethe cost involved so customers canmake the right choice.Product support. Cat Dealers utilize aworldwide computer network to find instockparts to minimize downtime. Savemoney with Cat Remanufactured parts.Receive the same warranty andreliability as new products at costsavings of 40 to 70 percent.14 <strong>IT38G</strong> <strong>Integrated</strong> <strong>Toolcarrier</strong> specifications

EngineFour-stroke cycle, six-cylinder 3126 turbocharged and aftercooled diesel engine.*Power rating conditionsRatings* kW hp■ Japan MOC■ direct-electric 24-volt starting andFlywheel■ based on standard air conditions of@ 2,200 rpm 119 160 25° C (77° F) and 99 kPa (29.32 inMaximum flywheelHg) dry barometer■@ 1,700 rpm 128 172 used 35° API gravity fuel havingan LHV of 42 780 kJ/kgThe following ratings apply at 2,200rpm when tested under the specifiedstandard conditions for the specified(18,390 Btu/lb) when used at 30° C(86° F) [ref. a fuel density of838.9 g/L (7.001 lb/U.S. gal)]standard:■ flywheel power advertised is theFlywheel power kW hp PS power available when the engine isCaterpillar 119 160 — equipped with fan, alternator, airISO 9249 119 160 — cleaner, and muffler■ no derating required up to 2300 mSAE J1349 119 160 —(7,500 ft) altitudeEEC 80/1269 119 160 —FeaturesDIN 70020 — — 166■ direct-injection fuel system withindividual adjustment-free unitMaximum torque (net) @ 1,200 rpminjectors for cylinders874 Nm 645 lb-ft■ water jacket aftercooledTotal torque rise 69%■ 3-ring aluminum-alloy/forged steel2-piece articulated pistons, camground,tapered and cooled by oilDimensionsBore 110 mm 4.3 in sprayStroke 127 mm 5.0 in ■ Chrome Ceramic Surface (CSS) ringDisplacement 7.2 liters 439 in 3 package, designed for high load/hightemperature applicationsExhaust emissions■ induction-hardened, forged crankshaft■The 3126 meets the following emissions uniflow cylinder head design withrequirements:two alloy-steel valves per cylinder■■deep-skirted cast cylinder blockEU■■tapered connecting rodsUS EPA Tier 1■ oscillating roller-followerscharging system with two 12-volt,950 CCA Caterpillar maintenancefreebatteries, heavy-duty starter anda 50-amp alternatorTransmissionCountershaft power shift transmissionwith four speeds forward and threereverse.Maximum travel speeds(standard 20.5-R25 XTLA 1 ★ L2 tires)km/h mphForward 1 7.4 4.62 13.4 8.33 23.4 14.54 39.4 24.5Reverse 1 7.4 4.62 13.4 8.33 23.4 14.5Features■ single lever to control both speed anddirection■ separate control to lock in neutral■ single-stage, single-phase torqueconverter■ automatic shift capability■ quick gear kickdown button■ F-37 high energy friction materialprovides extended clutch life■ externally mounted controls withquick disconnects for easy diagnosticchecks■ high contact ratio gears are precisionground for quiet operation■ transmission cooler bypass valve700 946645 lb-ft 874 N•m500676Torque(lb-ft)400541Torque(N•m)300405200100172 hp 128 kWPower(hp)140120Working{ Range }160 hp 119 kW1001000 1200 1400 1600 1800 2000 2200Engine rpm2701351048975Power(kW)High Torque RiseThe unit-injected fuel system delivers a controlled increase of fuel as the enginelugs back from rated speed. This results in horsepower greater than ratedpower. The combination of increased torque rise and maximum horsepowerimproves response, provides greater rimpull, more lift force and faster cycletimes. Maximum flywheel power of 128 kW (172 hp) occurs at 1,700 rpm whenpower is needed during the working cycle.<strong>IT38G</strong> <strong>Integrated</strong> <strong>Toolcarrier</strong> specifications15

Final DrivesAxles■ Traction Control System availableFixed front, oscillating rear (±13°).Features■ maximum single-wheel rise and fall:420 mm (16.5")Features■■ conventional differentials, enclosedbrakes and final drivesto axle housings■■ threaded nuts to set bearing pre-load■ Patented Duo-Cone Seals betweenaxle shaft and housing■ uses SAE 30W (oil change interval:2,000 hours or one year)■ limited slip and NoSPIN differentialsavailablePlanetary final drives consist of ringgears and planetary carrier assemblies.ring gears are pressed in and doweledcarrier assemblies include:— planet gears with full-floatingbronze sleeve bearings— planet shafts— retaining pins— bearings— sun gear shafts— planetary carriersSteeringFull hydraulic power steering. Meets SAE J1511 FEB94 and ISO 5010:1992BrakesMeet the following standards: OSHA,SAE J1473 OCT90, ISO 3450-1996.Service brake features■ full-hydraulic actuated, oil-discbrakes■ completely enclosed and sealed■ adjustment-free■ separate circuits for front and rearaxles■ dual pedal braking system■ left pedal functions as brake orbrake/neutralizerParking brake features■ mechanical, shoe-type brake■ mounted on transmission output■ pull-cable operatedRatingsMinimum turning radius(over tire)5480 mm (18')Steering angle, each direction 40°Hydraulic output at 2597 rpm and 6900kPa (1,000 psi)102 liters/min (27 gpm)Relief valvesetting 22 800 kPa (3,306 psi)Features■ center-point frame articulation■ load sensing hydraulic steering pump■ front and rear wheels track■ flow-amplified, closed-center,pressure-compensated system■ steering-wheel operated meteringpump controls flow to steeringcylinders■ full-flow filtering■ adjustable steering columnLoader Hydraulic SystemOpen-centered, interrupted series system with full-flow filtering. System is completely sealed. Pilot-operated controls.Work tools system, vane-type pumpOutput at 2597 rpm and6900 kPa (1,000 psi)with SAE 10W oil at 66° C (150° F) 163 liters/min 43 gpmRelief valve setting 24 800 kPa 3600 psiCylinders, double acting:lift, bore and stroke 120.7 x 715 mm 4.75 x 28.15"Cylinder, double acting:tilt, bore and stroke 114.3 x 732 mm 4.5 x 28.8"Pilot system, variable displacement piston-type pump*Output at 2,597 rpm and6900 kPa (1,000 psi)with SAE 10W oil at 66° C (150° F) 102 liters/min 27 gpmWorking pressure 3000 kPa 435 psi*Common with steering pump.Hydraulic cycle timesecondsRaise 5.8Dump 2.0Lower, empty, float down 2.9Total 10.7Features■ completely enclosed system■ low effort, pilot-operated controls■ full-flow filtering■ reusable couplings with O-ring faceseals■ pilot shutoff valve disables bucketfunctions■ tilt-out hydraulic oil cooler is standard■ Caterpillar XT hoses■ pressure taps■ Automatic Ride Control systemavailable16 <strong>IT38G</strong> <strong>Integrated</strong> <strong>Toolcarrier</strong> specifications

TiresTubeless, nylon, loader-design tires.Choice of■ 20.5-25, 12 PR (L-2)■ 20.5-25, 12 PR (L-3)■ 20.5-R25 GP-2B 1★ (L-3) steel radial■ 20.5-R25 XTLA 1★ (L-2) standard■ 20.5-R25 XHA 1★ (L-3) steel radial■ 555/70-R25 XLD70 1★ (L-3)low profileLow profile tires will have the following affect on specs:Width over tires +17 mm +0.7 "Ground clearance -44 mm -1.7 "Vertical bucket dimension -44 mm -1.7 "Dig depth +44 mm +1.7 "Reach +80 mm +3.1 "Operating weight +20 kg +44 lbStraight tip load +15 kg +33 lbFull turn static tip load +13 kg +29 lbRun out speeds -7 %Rimpull +9 %Departure angle -3 %Service Refill CapacitiesNote:In certain applications (such as load-andcarrywork) the loader‘s productivecapabilities might exceed the tires‘ tonneskm/h(ton-mph) capabilities. Caterpillarrecommends that you consult a tiresupplier to evaluate all conditions beforeselecting a tire model.Bucket ControlsPilot-operated lift and tilt circuits.CabCaterpillar cab and Rollover ProtectiveStructure (ROPS) are standard in NorthAmerica, Europe and Japan.Features■ meets OSHA and MSHA limits foroperator and sound exposure withdoors and windows closed (accordingto ANSI/SAE J1166 MAY90)■ ROPS meets the following criteria:— SAE J394— SAE 1040 APR88—ISO 3471-1:1986—ISO 3471:1994■ also meets the following criteria forFalling Objects Protective Structure:—SAE J231 JAN81—3449:1992 LEVEL IINoteWhen properly installed and maintained,the cab offered by Caterpillar whentested with doors and windows closedaccording to ANSI/SAE J1166 MAY90,meets OSHA and MSHA requirementsfor operator sound exposure limits ineffect at time of manufacture. Theoperator sound pressure level is75 dB(A) when measured per ISO 6394or 86/662/EEC.Liters GallonsFuel tank (dry fill) 254 67Cooling system 48 12.7Crankcase 20 5.3Transmission 30 7.9Differentials and final drivesfront 24 6.3rear 27 7.1Hydraulic system(including tank) 90 23.8Hydraulic tank 76 20.1Lift circuit features■ four positions: raise, hold, lower andfloat■ adjustable automatic kickout fromhorizontal to full liftTilt circuit features■ three positions: tilt back, hold anddump■ adjustable automatic tool positionerfor desired loading angle■ doesn't require visual spottingControls■ three lever control (standard)■ fourth valve selector switch (optional)■ joystick (optional) combines lift andtilt controls (not available with 4thvalve)■ lever lockout■ remote F-N-R switch (optional)<strong>IT38G</strong> <strong>Integrated</strong> <strong>Toolcarrier</strong> specifications17

DimensionsAll dimensions are approximateED<strong>IT38G</strong>GBFCAA varies with fork lengthB 955 mm 3' 2"C 25 mm 1"D 1670 mm 5' 6"E 945 mm 3' 1"F 1865 mm 6' 1"G 3715 mm 12' 2"Fork tine length 1220 mm 4'Reach with arms horizontal and forks level 2890 mm 9'6"Overall length 7825 mm 25'8"Static tipping load with level arms and forks,600 mm (23.6") load center, straight 7196 kg 15,860 lbStatic tipping load with level arms and forks,600 mm (23.6") load center, full 40° turn 6218 kg 13,710 lbOperating weight 12 469 kg 27,490 lbDimensions, static tipping load and operating weight are based on standard machineconfiguration with 20.5 R25 XTLA (L-2)) tires, full fuel tank, coolant, lubricants and operator.Machine stability and operating weight are affected by tire size and other attachments.18 <strong>IT38G</strong> <strong>Integrated</strong> <strong>Toolcarrier</strong> specifications

DimensionsAll dimensions are approximate.ACBDEF<strong>IT38G</strong>GHJKA 3645 mm 11' 11"B 3075 mm 10' 1"C 2505 mm 8' 3"D 6420 mm 21' 1"E 5855 mm 19' 3"F 5295 mm 17' 5"G 3815 mm 12' 6"H 4615 mm 15' 2"J 5415 mm 17' 9"K 1560 mm 5' 1"L 1840 mm 6' 0"M 2310 mm 7' 7"N 2775 mm 9' 1"P 2280 mm 7' 6"Q 2930 mm 9' 7"R 3580 mm 11' 9"LMNPQRHandling arm position Retracted Mid-position ExtendedOperating load 40° articulation 2049 kg 4510 lb 1729 kg 3810 lb 1492 kg 3290 lbStatic tipping loadStraight 4746 kg 10,460 lb 4009 kg 8840 lb 3463 kg 7630 lbFull 40° turn 4098 kg 9<strong>03</strong>0 lb 3457 kg 7620 lb 2983 kg 6570 lbOperating weight 12 380 kg 27,290 lb 12 380 kg 27,290 lb 12 380 kg 27,290 lbDimensions, static tipping load and operating weight are based on standard machine configuration with 20.5 R25, XTLA (L-2) tires, full fueltank, coolant, lubricants, and operator.NOTE: Machine stability and operating weight are affected by tire size, tire ballast and other attachments.<strong>IT38G</strong> <strong>Integrated</strong> <strong>Toolcarrier</strong> specifications19

DimensionsAll dimensions are approximate.VULT<strong>IT38G</strong>RSHGFO P QJDEBCKMANA see overall length*B 3020 mm 9' 11"C 1510 mm 4' 11"D 1905 mm 6' 3"E 400 mm 1' 4"F 2215 mm 7' 3"G 3210 mm 10' 6"H 3300 mm 10' 10"J 690 mm 2' 3"K 235 mm 9.3"L see reach @ 45° discharge angle*M see digging depth*N 54°O 48.8°P 46.6° @ carry (SAE)Q see dump clearance*R 3625 mm 11' 11"S 3930 mm 12' 11"T see overall height*U 45°V 44.6°Note: Dimensions listed are for machines equipped with 20.5 R25 XTLA (L-2) tires.*See operating specifications on page 21Supplemental SpecificationsGroundWidth over tiresclearancedimensionsweighttipping loadmm inches mm inches mm inches kg lb kg lbRemove cab only, ROPS — — — — — — -198 -430 -191 -42020.5-25 12 PR (L-2) 2605 102.6 400 15.8 1 0.04 -60 -130 -39 -8020.5-25 12 PR (L-3) 2600 102.4 425 16.7 25 .98 85 180 56 12020.5 R25 XTLA (L-2) 2600 102.4 400 15.7 — — — — — —20.5 R25 GP-2B (L-2/3) 2595 102.2 410 16.1 10 0.39 130 280 86 19020.5 R25 XHA (L-3) 2595 102.2 405 15.9 5 0.20 172 380 114 250Note: Tire options include tires and rims.20 <strong>IT38G</strong> <strong>Integrated</strong> <strong>Toolcarrier</strong> specificationsChange inverticalChange inoperatingChange inarticulated static

Operating SpecificationsGeneral purposebucketRated bucket capacity (§) m 3yd 32.5 2.4 2.23.3 3.1 2.9Bolt-onBolt-on Bolt-onBolt-onedgesedgesteethteethStruck capacity (§) m 3yd 3Width (§)mmft/inDump clearance at fullmmlift and 45° discharge** ft/inReach at full liftmmand 45° discharge**ft/inReach at 45° discharge and mm2130 mm (7 ft 0 in) clearance ft/inReach with lift armsmmhorizontal and bucket level ft/inDigging depth (§)mminOverall length**mmft/inOverall height with bucket mmat full raise (§)ft/inLoader clearance circle with mmbucket in carry position (§) ft/inStatic tipping load straight* (§) kglbStatic tipping loadkgfull 40° turn* (§)lbBreakout force*** (§)kglbOperating weight* (§)kglb2.1 1.9 2.0 1.82.7 2.5 2.6 2.42710 2710 2735 27358' 11" 8' 11" 9' 0" 9' 0"2800 2800 2720 27209' 2" 9' 2" 8' 11" 8' 11"1200 1200 1290 129<strong>03</strong>' 11" 3' 11" 4' 3" 4' 3"1655 1655 1705 17055' 5" 5' 5" 5' 7" 5' 7"2520 2520 2640 26408' 3" 8' 3" 8' 8" 8' 8"70 70 45 452.8 2.8 1.8 1.87485 7485 7600 760024' 7" 24' 7" 24' 11" 24' 11"5235 5120 5235 512017' 2" 16' 10" 17' 2" 16' 10"12 135 12 135 12 225 12 22539' 10" 39' 10" 40' 1" 40' 1"8861 8859 9059 911019,535 19,530 19,970 20,0807621 7630 7806 786016,800 16,820 17,210 17,33012 650 12 692 12 738 12 78227,890 27,980 28,080 28,18013 062 12 984 12 967 12 89928,800 28,630 28,590 28,440BucketSizeyd 3 m 32.75 2.13.00 2.33.25 2.5kg/m 3lb /yd 3Bucket Selection Guide1400 1600 1800 20002400 2600 2800 3000 3200Material DensityUnder utilizedOptimumMaximum loadSpecifications and ratings conform to all applicable standardsrecommended by the Society of Automotive Engineers. SAEStandards J732c govern loader ratings and are denoted in the textby (§).* Static tipping load and operating weight shown are based onstandard machine configuration with sound-suppression cab andROPS, 20.5 R25 XTLA (L-2) tires, full fuel tank, coolant, lubricantsand operator.** Dump clearance, reach and overall length dimensions for bucketequipped with teeth reflect actual dimensions. SAE J732C allowsdimensions for bucket with teeth to reflect the dimension using thecutting edge. Caterpillar Inc. uses actual equipped bucketdimensions.*** Measured 102 mm (4.0"): behind tip of cutting edge with buckethinge pin as pivot point in accordance with SAE J732C.**** All buckets shown can be used on the high lift arrangement. Highlift column shows changes in specifications from standard lift tohigh lift. Add or subtract as indicated to or from specifications givenfor appropriate bucket to calculate high lift specifications.<strong>IT38G</strong> <strong>Integrated</strong> <strong>Toolcarrier</strong> specifications21

Standard EquipmentStandard equipment may vary. Consult a Caterpillar dealer for specifics.ElectricalAlarm, back-upAlternator (50-amp)Batteries (heavy duty, maintenancefree, 950 CCA)Converter, 12-voltIgnition key start/stop switchLighting system, Halogen (six total)Main disconnect switchStarter, electric, (heavy duty)Starting, and charging system (24-volt)Operator EnvironmentCab, pressurized and soundsuppressed, rollover protectivestructure (ROPS)Cigar lighter and ashtrayCoat hookControl, work tool lever lockoutCup and thermos holdersHeater and defrosterHorn, electric (steering wheelmounted)Implement lever lockoutInstrumentation, GaugesEngine coolant temperatureFuel levelHydraulic oil temperatureTransmission oil temperatureLight, dome (cab)Mirrors, rearview (inside mounted)Radio ready cab, includes antenna,speakers and converter (12-volt, 5-amp)Seat, cloth, KAB (adjustable backrest,armrest, lumbar support)Seat belt, retractable, 76 mm (3”)wideSocket (12-volt)Steering column, adjustable angleStorage box, lockableWarning indicatorsBattery chargeElectrical systemEngine coolant temperatureEngine oil pressureHydraulic oil temperatureParking brakePrimary steering oil pressureSecondary steering oil pressureService brake oil pressureTransmission oil temperatureWindshield washers/wipers, wet-arm(front and rear), intermittent frontwiperPower TrainBrakes, full hydraulic, enclosed wetdiscEngine, Cat 3126 turbochargedaftercooled dieselFan, radiator cooling, hydraulicdrivenFilters, fuel, primary and secondary(in series)Fuel priming aidFuel/water separatorMufflerPrecleaner, engine air intakeRadiator, multi-row (six) modular(IMRM)Switch, transmission neutralizeron/offTorque converterTransmission, countershaft,automatic power shift (4F/3R),with fully automatic speed rangecontrol and quick gear kickdownbuttonHydraulicsControls, pilot hydraulicDiagnostic connectors, hydraulicSteering, load-sensing hydraulicValve, diverter, hydraulic control ofthird valve flow between quickcoupler and attachmentsValve, thirdOther Standard EquipmentAntifreeze, extended life, protectionto -34C (-29F)CounterweightFenders, front and rearGuard, bottom (crankcase, fuel tank,oil pan)Hitch, drawbar with pinHood, non-metallic one pieceIndicatorsAir cleaner serviceCoolant level sight gaugeHydraulic oil level sight gaugeTransmission oil level sight gaugeKickout, lift, automaticKickouts (2), return to work,adjustableLinkage, sealed 8-bar parallel liftQuick coupler, hydraulic actuatedValves, oil samplingVandalism protection caplocksTires, Rims, and WheelsAn allowance for tires is included in thebase machine price.22 <strong>IT38G</strong> <strong>Integrated</strong> <strong>Toolcarrier</strong> specifications

<strong>IT38G</strong> <strong>Integrated</strong> <strong>Toolcarrier</strong><strong>AEHQ5220</strong>-<strong>03</strong> (06-01)(Replaces <strong>AEHQ5220</strong>-02)© 1999, 2001 CaterpillarPrinted in U.S.A.Materials and specifications are subject to change without notice.