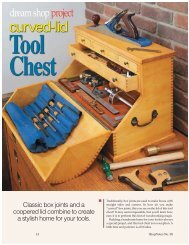

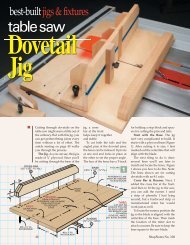

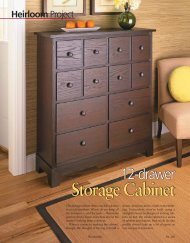

2-page article - Woodsmith Woodworking Seminars

2-page article - Woodsmith Woodworking Seminars

2-page article - Woodsmith Woodworking Seminars

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

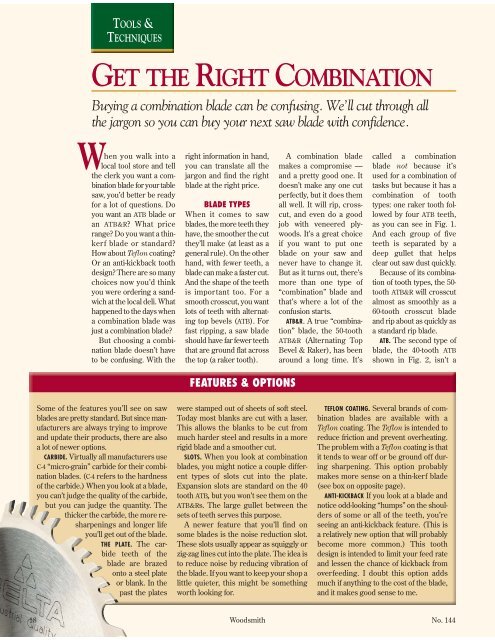

TOOLS &TECHNIQUESGET THE RIGHT COMBINATIONBuying a combination blade can be confusing. We’ll cut through allthe jargon so you can buy your next saw blade with confidence.When you walk into alocal tool store and tellthe clerk you want a combinationblade for your tablesaw, you’d better be readyfor a lot of questions. Doyou want an ATB blade oran ATB&R? What pricerange? Do you want a thinkerfblade or standard?How about Teflon coating?Or an anti-kickback toothdesign? There are so manychoices now you’d thinkyou were ordering a sandwichat the local deli. Whathappened to the days whena combination blade wasjust a combination blade?But choosing a combinationblade doesn’t haveto be confusing. With theright information in hand,you can translate all thejargon and find the rightblade at the right price.BLADE TYPESWhen it comes to sawblades, the more teeth theyhave, the smoother the cutthey’ll make (at least as ageneral rule). On the otherhand, with fewer teeth, ablade can make a faster cut.And the shape of the teethis important too. For asmooth crosscut, you wantlots of teeth with alternatingtop bevels (ATB). Forfast ripping, a saw bladeshould have far fewer teeththat are ground flat acrossthe top (a raker tooth).A combination blademakes a compromise —and a pretty good one. Itdoesn’t make any one cutperfectly, but it does themall well. It will rip, crosscut,and even do a goodjob with veneered plywoods.It’s a great choiceif you want to put oneblade on your saw andnever have to change it.But as it turns out, there’smore than one type of“combination” blade andthat’s where a lot of theconfusion starts.ATB&R. A true “combination”blade, the 50-toothATB&R (Alternating TopBevel & Raker), has beenaround a long time. It’scalled a combinationblade not because it’sused for a combination oftasks but because it has acombination of toothtypes: one raker tooth followedby four ATB teeth,as you can see in Fig. 1.And each group of fiveteeth is separated by adeep gullet that helpsclear out saw dust quickly.Because of its combinationof tooth types, the 50-tooth ATB&R will crosscutalmost as smoothly as a60-tooth crosscut bladeand rip about as quickly asa standard rip blade.ATB. The second type ofblade, the 40-tooth ATBshown in Fig. 2, isn’t aFEATURES & OPTIONSSome of the features you’ll see on sawblades are pretty standard. But since manufacturersare always trying to improveand update their products, there are alsoa lot of newer options.CARBIDE. Virtually all manufacturers useC-4 “micro-grain” carbide for their combinationblades. (C-4 refers to the hardnessof the carbide.) When you look at a blade,you can’t judge the quality of the carbide,but you can judge the quantity. Thethicker the carbide, the more resharpeningsand longer lifeyou’ll get out of the blade.THE PLATE. The carbideteeth of theblade are brazedonto a steel plateor blank. In thepast the plateswere stamped out of sheets of soft steel.Today most blanks are cut with a laser.This allows the blanks to be cut frommuch harder steel and results in a morerigid blade and a smoother cut.SLOTS. When you look at combinationblades, you might notice a couple differenttypes of slots cut into the plate.Expansion slots are standard on the 40tooth ATB, but you won’t see them on theATB&Rs. The large gullet between thesets of teeth serves this purpose.A newer feature that you’ll find onsome blades is the noise reduction slot.These slots usually appear as squiggly orzig-zag lines cut into the plate. The idea isto reduce noise by reducing vibration ofthe blade. If you want to keep your shop alittle quieter, this might be somethingworth looking for.TEFLON COATING. Several brands of combinationblades are available with aTeflon coating. The Teflon is intended toreduce friction and prevent overheating.The problem with a Teflon coating is thatit tends to wear off or be ground off duringsharpening. This option probablymakes more sense on a thin-kerf blade(see box on opposite <strong>page</strong>).ANTI-KICKBACK If you look at a blade andnotice odd-looking “humps” on the shouldersof some or all of the teeth, you’reseeing an anti-kickback feature. (This isa relatively new option that will probablybecome more common.) This toothdesign is intended to limit your feed rateand lessen the chance of kickback fromoverfeeding. I doubt this option addsmuch if anything to the cost of the blade,and it makes good sense to me.18 <strong>Woodsmith</strong> No. 144

1Flat-toppedraker toothfor rip cutsFlatbottomkerf2Top edgesof teeth havealternate bevelsV- shapedkerfATBteethAnti-kickback"hump" slowsrate of feedGulletclears chipsShoulder ofplate holds andbacks up toothNoisereductionslot quietsblade bylimitingvibrationDeep gulletsclear chipsand act asexpansionslotsATB-R BLADETeeth arebrazed ontocut steel plateATB BLADEExpansion slotkeeps bladefrom distortingas it heats uptrue “combination” blade— there’s only one type oftooth. So it’s sometimescalled a “general-purpose”blade. It does the samething with a slightly differentstrategy. The low numberof teeth allow it to ripquickly, and the ATBshape of the teeth allowfor a smooth crosscut.Honestly, it’s hard tofind much of a differencein the performance of 40-tooth ATB and 50-toothATB&R blades. Both typeswill do a good job of ripping,crosscutting, andcutting plywood.So how do you choosethe right blade? I’d suggestyou take a look atsome of the specific featureson each blade (asdescribed in the box atleft) and pick the bladewith the extras that areimportant to you. But first,there’s one other “type” ofblade you might want totake a look at.“SUPER PREMIUM” ATB. Theother “type” of combinationblade is what I thinkof as a “super premium”blade. It also has a 40-tooth ATB design, and itmight feature a “planerstyle”tooth, as describedin the margin. But whatreally sets this type ofblade apart is its quality(and its price). It’s manufacturedto much higherstandards than other combinationblades.For instance, the plateof the blade is flattened towithin .001" of runout(side-to-side movement).And the teeth are alsoground with more precisionthan on an ordinaryblade. In fact, sometimesthe teeth are even doubleground.So what you endup with is a combinationblade that’s not much of acompromise — it’ll makeall types of cuts verysmoothly and easily.So how do you find a“super premium” blade?About the only way to distinguishit is by its price.You can pick up a standardATB or ATB&R bladefor about $40 to $70. A“super premium” bladecan run from $90 to $120.And that’s the big drawbackto this type of blade.It isn’t cheap.Also, the “super premium”blade, like any othersaw blade, will only cutwell if it stays sharp.When it gets dull, it mightnot cut much better than aless expensive blade. Plus,to get it resharpened tothe same precision, youmay have to send it backto the factory.It might sound like Idon’t think this type ofblade is worth the cost,but that’s not the case. Weuse one of these bladeshere in the <strong>Woodsmith</strong>shop. Right out of the box,it’ll cut smoother than anycombination blade you’veever used, and if you’rewilling to spend themoney, I’m sure you won’tbe disappointed.But before deciding onthe type of combinationblade to buy, you mightwant to think about thekind of work you’re goingto do with your saw.If you plan to use yoursaw blade “hard” (to cutas much dimensional lumberas you do fine hardwoods),one of the lessexpensive ATB or ATB&Rcombination blades mightbe the best way to go. Butif you plan to build mostlyfurniture-quality projectsand want glass-smoothcuts, a “super premium”blade is hard to beat. WWHAT ABOUT THIN-KERF?Both the ATB and the ATB&R blades areavailable in thin-kerf models. Thistype of blade cuts a 3 / 32" kerf insteadof the 1 / 8" kerf of a standard blade.Since the blade is cutting a thinnerkerf, it needs less power fromthe saw. If your saw is a littleunderpowered or you just wantto give your saw a little morecapacity, a thin-kerf blademight be a good idea. Butthin-kerf blades are morelikely to overheat, so aTeflon coating might beworth the extra cost.PlanertoothSidestaperStandardATB tooth{ A planer-style toothhas less radial clearancethan a standardATB tooth. (Its sidesaren’t as tapered.)So the tooth hasmore contact withthe wood and makesa very smooth cut.No. 144 <strong>Woodsmith</strong> 19