Spiral Bevel Gearboxes - Diequa Corporation

Spiral Bevel Gearboxes - Diequa Corporation

Spiral Bevel Gearboxes - Diequa Corporation

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

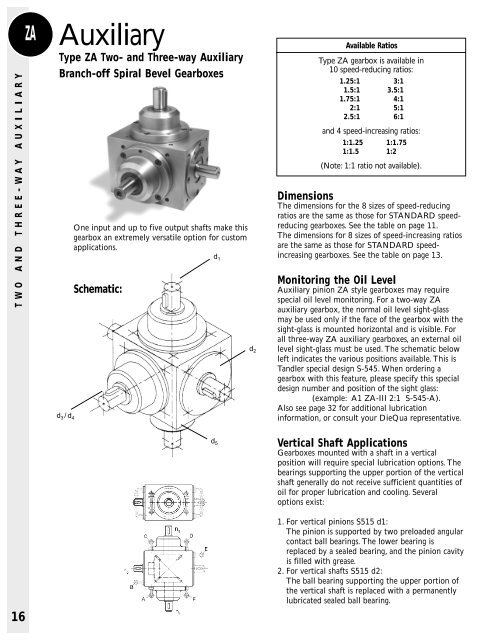

TWO AND THREE-WAY AUXILIARY16ZAAuxiliaryType ZA Two- and Three-way AuxiliaryBranch-off <strong>Spiral</strong> <strong>Bevel</strong> <strong>Gearboxes</strong>d 3 / d 4One input and up to five output shafts make thisgearbox an extremely versatile option for customapplications.d 1Schematic:d 2d 5Available RatiosType ZA gearbox is available in10 speed-reducing ratios:1.25:1 3:11.5:1 3.5:11.75:1 4:12:1 5:12.5:1 6:1and 4 speed-increasing ratios:1:1.25 1:1.751:1.5 1:2(Note: 1:1 ratio not available).DimensionsThe dimensions for the 8 sizes of speed-reducingratios are the same as those for STANDARD speedreducinggearboxes. See the table on page 11.The dimensions for 8 sizes of speed-increasing ratiosare the same as those for STANDARD speedincreasinggearboxes. See the table on page 13.Monitoring the Oil LevelAuxiliary pinion ZA style gearboxes may requirespecial oil level monitoring. For a two-way ZAauxiliary gearbox, the normal oil level sight-glassmay be used only if the face of the gearbox with thesight-glass is mounted horizontal and is visible. Forall three-way ZA auxiliary gearboxes, an external oillevel sight-glass must be used. The schematic belowleft indicates the various positions available. This isTandler special design S-545. When ordering agearbox with this feature, please specify this specialdesign number and position of the sight glass:(example: A1 ZA-III 2:1 S-545-A).Also see page 32 for additional lubricationinformation, or consult your DieQua representative.Vertical Shaft Applications<strong>Gearboxes</strong> mounted with a shaft in a verticalposition will require special lubrication options. Thebearings supporting the upper portion of the verticalshaft generally do not receive sufficient quantities ofoil for proper lubrication and cooling. Severaloptions exist:1. For vertical pinions S515 d1:The pinion is supported by two preloaded angularcontact ball bearings. The lower bearing isreplaced by a sealed bearing, and the pinion cavityis filled with grease.2. For vertical shafts S515 d2:The ball bearing supporting the upper portion ofthe vertical shaft is replaced with a permanentlylubricated sealed ball bearing.