Spiral Bevel Gearboxes - Diequa Corporation

Spiral Bevel Gearboxes - Diequa Corporation

Spiral Bevel Gearboxes - Diequa Corporation

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

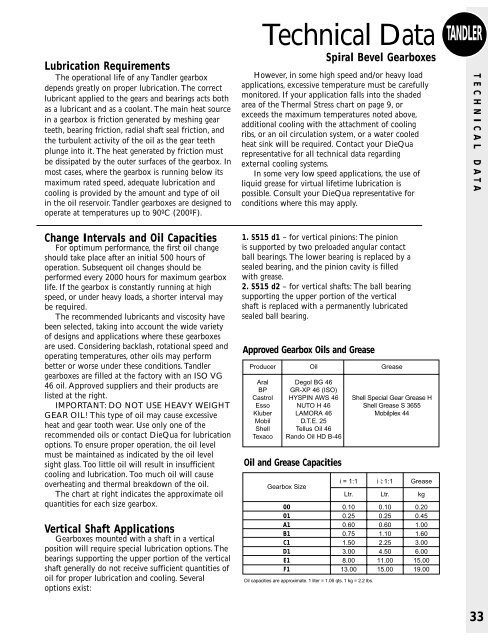

Lubrication RequirementsThe operational life of any Tandler gearboxdepends greatly on proper lubrication. The correctlubricant applied to the gears and bearings acts bothas a lubricant and as a coolant. The main heat sourcein a gearbox is friction generated by meshing gearteeth, bearing friction, radial shaft seal friction, andthe turbulent activity of the oil as the gear teethplunge into it. The heat generated by friction mustbe dissipated by the outer surfaces of the gearbox. Inmost cases, where the gearbox is running below itsmaximum rated speed, adequate lubrication andcooling is provided by the amount and type of oilin the oil reservoir. Tandler gearboxes are designed tooperate at temperatures up to 90ºC (200ºF).Technical Data<strong>Spiral</strong> <strong>Bevel</strong> <strong>Gearboxes</strong>However, in some high speed and/or heavy loadapplications, excessive temperature must be carefullymonitored. If your application falls into the shadedarea of the Thermal Stress chart on page 9, orexceeds the maximum temperatures noted above,additional cooling with the attachment of coolingribs, or an oil circulation system, or a water cooledheat sink will be required. Contact your DieQuarepresentative for all technical data regardingexternal cooling systems.In some very low speed applications, the use ofliquid grease for virtual lifetime lubrication ispossible. Consult your DieQua representative forconditions where this may apply.TANDLERTECHNICAL DATAChange Intervals and Oil CapacitiesFor optimum performance, the first oil changeshould take place after an initial 500 hours ofoperation. Subsequent oil changes should beperformed every 2000 hours for maximum gearboxlife. If the gearbox is constantly running at highspeed, or under heavy loads, a shorter interval maybe required.The recommended lubricants and viscosity havebeen selected, taking into account the wide varietyof designs and applications where these gearboxesare used. Considering backlash, rotational speed andoperating temperatures, other oils may performbetter or worse under these conditions. Tandlergearboxes are filled at the factory with an ISO VG46 oil. Approved suppliers and their products arelisted at the right.IMPORTANT: DO NOT USE HEAVY WEIGHTGEAR OIL! This type of oil may cause excessiveheat and gear tooth wear. Use only one of therecommended oils or contact DieQua for lubricationoptions. To ensure proper operation, the oil levelmust be maintained as indicated by the oil levelsight glass. Too little oil will result in insufficientcooling and lubrication. Too much oil will causeoverheating and thermal breakdown of the oil.The chart at right indicates the approximate oilquantities for each size gearbox.Vertical Shaft Applications<strong>Gearboxes</strong> mounted with a shaft in a verticalposition will require special lubrication options. Thebearings supporting the upper portion of the verticalshaft generally do not receive sufficient quantities ofoil for proper lubrication and cooling. Severaloptions exist:1. S515 d1 – for vertical pinions: The pinionis supported by two preloaded angular contactball bearings. The lower bearing is replaced by asealed bearing, and the pinion cavity is filledwith grease.2. S515 d2 – for vertical shafts: The ball bearingsupporting the upper portion of the verticalshaft is replaced with a permanently lubricatedsealed ball bearing.Approved Gearbox Oils and GreaseProducerAralBPCastrolEssoKluberMobilShellTexacoOilDegol BG 46GR-XP 46 (ISO)HYSPIN AWS 46NUTO H 46LAMORA 46D.T.E. 25Tellus Oil 46Rando Oil HD B-46Oil and Grease CapacitiesGearbox Size0001A1B1C1D1E1F1i = 1:1Ltr.0.100.250.600.751.503.008.0013.00Oil capacities are approximate. 1 liter = 1.06 qts. 1 kg = 2.2 lbs.GreaseShell Special Gear Grease HShell Grease S 3655Mobilplex 44i > < 1:1Ltr.0.100.250.601.102.254.5011.0015.00Greasekg0.200.451.001.603.006.0015.0019.0033