AIR CONDITIONER - Heronhill Air Conditioning Ltd

AIR CONDITIONER - Heronhill Air Conditioning Ltd

AIR CONDITIONER - Heronhill Air Conditioning Ltd

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

FILE NO. SVM-05020SERVICE MANUAL<strong>AIR</strong> <strong>CONDITIONER</strong>SPLIT WALL TYPERAS-13UKHP-ES4 / RAS-13UAH-ES4RAS-10UKHP-ES4 / RAS-10UAH-ES4RAS-13UKP-ES4 / RAS-13UA-ES4RAS-10UKP-ES4 / RAS-10UA-ES4RAS-07UKP-ES4 / RAS-07UA-ES4May 2005

1. SPECIFICATIONSCONTENTS2. CONSTRUCTION VIEWS2-1 Indoor Unit2-2 Outdoor Unit (RAS-13UAH-ES4, RAS-10UAH-ES4,RAS-13UA-ES4, RAS-10UA-ES4)2-3 Outdoor Unit (RAS-07UA-ES4)3. WIRING DIAGRAM3-1 RAS-13UKHP-ES4 / RAS-13UAH-ES43-2 RAS-10UKHP-ES4 / RAS-10UAH-ES43-3 RAS-13UKP-ES4 / RAS-13UA-ES43-4 RAS-10UKP-ES4 / RAS-10UA-ES43-5 RAS-07UKP-ES4 / RAS-07UA-ES44. SPECIFICATION OF ELECTRICAL PARTS4-1 Indoor Unit (RAS-13UKHP-ES4 RAS-10UKHP-ES4)4-2 Outdoor Unit (RAS-13UAH-ES4)4-3 Outdoor Unit (RAS-13UA-ES4)4-4 Outdoor Unit (RAS-10UAH-ES4)4-5 Indoor Unit (RAS-13UKP-ES4, RAS-10UKP-ES4,RAS-07UKP-ES4)4-6 Outdoor Unit (RAS-10UA-ES4)4-7 Outdoor Unit (RAS-07UA-ES4)5. REFRIGERATION CYCLE DIAGRAM5-1 RAS-13UKHP-ES4 / RAS-13UAH-ES45-2 RAS-10UKHP-ES4 / RAS-10UAH-ES45-3 RAS-13UKP-ES4 / RAS-13UA-ES45-4 RAS-10UKP-ES4 / RAS-10UA-ES45-5 RAS-07UKP-ES4 / RAS-07UA-ES46. CONTROL BLOCK DIAGRAM6-1 RAS-13UKHP-ES4 / RAS-13UAH-ES4RAS-10UKHP-ES4 / RAS-10UAH-ES46-2 RAS-13UKP-ES4 / RAS-13UA-ES4RAS-10UKP-ES4 / RAS-10UA-ES4RAS-07UKP-ES4 / RAS-07UA-ES47.OPERATION DESCRIPTION7-1 Outline of <strong>Air</strong> Conditioner Control7-2 Description of Operation Circuit7-3 Hi POWER Mode7-4 High-Temperature Limit Control7-5 Low-Temperature Limit Control7-6 Defrost Operation7-7 Current Limit Control7-8 Auto Restart Function7-9 Filter Check Lamp7-10 Self-Cleaning function7-11 QUIET Mode7-12 COMFORT SLEEP mode− 1 −FILE NO. SVM-05020

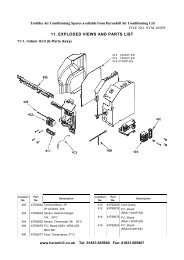

8. INSTALLATION PROCEDURE8-1 Safety Cautions8-2 Installation Diagram of Indoor and Outdoor Units8-3 Installation8-4 Indoor Unit8-5 Outdoor Unit8-6 How to Set Remote Control Selector Switch8-7 Others9. TROUBLESHOOTING CHART9-1 Troubleshooting Procedure9-2 Basic Check Items9-3 Primary Judgement9-4 Self-Diagnosis by Remote Control (Check Code)9-5 Troubleshooting Flowcharts9-6 Troubleshooting for Remote Control (Including The Indoor P.C. Board)10. PARTS REPLACEMENT10-1 Indoor Unit10-2 Outdoor Unit11. EXPLODED VIEWS AND PARTS LIST11-1 Indoor Unit (E-Parts Assy) (For Heat pump model)11-2 Indoor Unit (E-Parts Assy) (For Cooling model)11-3 Indoor Unit11-4 Outdoor Unit (RAS-13UAH-ES4)11-5 Outdoor Unit (RAS-10UAH-ES4)11-6 Outdoor Unit (RAS-13UA-ES4)11-7 Outdoor Unit (RAS-10UA-ES4)11-8 Outdoor Unit (RAS-07UA-ES4)FILE NO. SVM-05020• This air conditioner is charged withHFC (R410A) that doesn't deplete theOzone layer.• This air conditioner requires specialinstallation for the refrigerant R410A.− 2 −

1. SPECIFICATIONSFILE NO. SVM-05020MODEL RAS-13UKHP-ES4 RAS-13UKP-ES4RAS-13UAH-ES4RAS-13UA-ES4ITEM Cooling Heating CoolingCapacity220V 240V 220V 240V 220V 240VkW 3.74 3.82 4.32 4.40 3.90 3.95Phase1∅ Power source V 220 − 240Hz 50Power consumption kW 1.15 1.19 1.18 1.22 1.19 1.23Power factor % 98 96 98 96 98 97Running Indoor A 0.15current Outdoor A 5.20 5.00 5.35 5.15 5.35 5.15Starting current A 30 29Moisture removal lit/h 2.0NoiseRefrigerantRefrigerant controlIndoor (H/M/L) dB 41/35/31Outdoor (220-240V) dB 49 51 49 51 49 50Name of refrigerantRated amountGas side sizeConnection typeFlare connectionLiquid side size mm ∅6.35Interconnection Connection typepipeMaximum length(One way)Maximum heightdifferenceFlare connectionINDOOR UNIT RAS-13UKHP-ES4 RAS-13UKP-ES415* 1Height mm 275Dimensions Width mm 790Depth mm 208Net weight kg 10Evaporator typeIndoor fan typeFinned tubeCross flow fanHigh fan m 3 /h 630 650 630<strong>Air</strong> volume Medium fan m 3 /h 520 550 520Low fan m 3 /h 430 490 430Fan motor output W 20<strong>Air</strong> filterHoneycomb woven filter with PP frameOUTDOOR UNIT RAS-13UAH-ES4 RAS-13UA-ES4Height mm 550Dimensions Width mm 780Depth mm 270Net weight kg 4038Condenser typeOutdoor fan typeFinned tubePropeller fan<strong>Air</strong>flow volume m 3 /h 2120 2200 2120 2200 2030 2150Fan motor output W 42CompressorSafety deviceLouver typeModelR410Akg 0.95mmmCapillary tube∅ 12.7m 6PA150X2C-4FTOutput W 1100Fuse, Overload relayAutomatic louverUsable outdoor temperature range °C 15 ~ 43 −10 ~ 24 15 ~ 4330− 3 −

FILE NO. SVM-05020MODEL RAS-10UKHP-ES4 RAS-10UKP-ES4RAS-10UAH-ES4RAS-10UA-ES4ITEM Cooling Heating CoolingCapacity220V 240V 220V 240V 220V 240VkW 2.73 2.73 2.92 2.96 2.73 2.73Phase1∅ Power source V 220 − 240Hz 50Power consumption kW 0.83 0.85 0.79 0.82 0.83 0.85Power factor % 98 97 97 96 98 97Running Indoor A 0.15current Outdoor A 3.71 3.50 3.55 3.40 3.71 3.50Starting current A 18Moisture removal lit/h 1.2NoiseRefrigerantRefrigerant controlIndoor (H/M/L) dB 39/33/26Outdoor (220-240V) dB 47 49 47 49 46 47Name of refrigerantR410ARated amount kg 0.79 0.70Capillary tubeGas side size mm ∅ 9.52Connection typeFlare connectionLiquid side size mm ∅ 6.35Interconnection Connection typepipeMaximum length(One way)Maximum heightdifferenceFlare connectionm 10* 1INDOOR UNIT RAS-10UKHP-ES4 RAS-10UKP-ES4Height mm 275Dimensions Width mm 790Depth mm 208Net weight kg 10Evaporator typeIndoor fan typeFinned tubeCross flow fanHigh fan m 3 /h 570 610 610<strong>Air</strong> volume Medium fan m 3 /h 460 520 460Low fan m 3 /h 340 400 340Fan motor output W 20<strong>Air</strong> filterHoneycomb woven filter with PP frameOUTDOOR UNIT RAS-10UAH-ES4 RAS-10UA-ES4Height mm 550Dimensions Width mm 780Depth mm 270Net weight kg 32 30Condenser typeOutdoor fan typeFinned tubePropeller fan<strong>Air</strong>flow volume m 3 /h 2030 2150 2030 2150 1740 1850Fan motor output W 30 20CompressorSafety deviceLouver typeModelm 5Output W 750PA108X1C-4FZDNFuse, Overload relayAutomatic louverUsable outdoor temperature range °C 15 ~ 43 −10 ~ 24 15 ~ 43− 4 −

FILE NO. SVM-05020ITEMCapacityMODEL220VRAS-07UKP-ES4RAS-07UA-ES4Cooling240VkW 2.23 2.27PhasePower source V 220 − 2401∅Hz 50Power consumption kW 0.68 0.70Power factor % 98 96Running Indoor A 0.15current Outdoor A 3.00 2.90Starting current A 13Moisture removal lit/h 0.8NoiseRefrigerantRefrigerant controlIndoor (H/M/L) dB 38/32/26Outdoor (220-240V) dB 44 45Name of refrigerantR410ARated amount kg 0.63Capillary tubeGas side size mm ∅9.52Connection typeFlare connectionLiquid side size mm ∅6.35Interconnection Connection typepipeINDOOR UNITMaximum length(One way)Maximum heightdifferenceFlare connectionm10* 1RAS-07UKP-ES4Height mm 275Dimensions Width mm 790Depth mm 208Net weight kg 10Evaporator typeIndoor fan typeFinned tubeCross flow fanHigh fan m 3 /h 570<strong>Air</strong> volume Medium fan m 3 /h 460Low fan m 3 /h 340Fan motor output W 20<strong>Air</strong> filterOUTDOOR UNITHoneycomb woven filter with PP frameRAS-07UA-ES4Height mm 530Dimensions Width mm 660Depth mm 240Net weight kg 27Condenser typeOutdoor fan typeFinned tubePropeller fan<strong>Air</strong>flow volume m 3 /h 1420 1520Fan motor output W 30CompressorSafety deviceLouver typeModelmPA82X1C-4DZDNOutput W 605Fuse, Overload relayAutomatic louverUsable outdoor temperature range °C 15 ~ 435− 5 −

FILE NO. SVM-05020Note : 1• Capacity is based on the following temperature conditions.TemperatureConditionCoolingJIS B8615-1HeatingIndoor unit inlet air temperatureOutdoor unit inlet air temperature(DB) 27°C 20°C(WB) 19°C 15°C(DB) 35°C 7°C(WB) 24°C 6°CNote : 2*1 No need to charge extra refrigerant.− 6 −

FILE NO. SVM-050202-2. Outdoor Unit (RAS-13UAH-ES4, RAS-10UAH-ES4,RAS-13UA-ES4, RAS-10UA-ES4)A∅ 6 HoleA Detail Drawing (Back Leg)3103025236600R15R5.531030232.5115 125102B Detail Drawing (Front Leg)310302∅ 6 Hole∅ 11x14 Hole3652R15∅ 30 Drain outlet∅ 436FAN GUARD2-∅ 11x14 Hole(For ∅ 8-∅ 10 anchor bolt)BCOVER PV530Z265270600 90780 62310330Electricalpart cover1207554Liquid side(Flare ∅ 6.35)Gas side(Flare ∅ 9.52)10 SeriesGas side(Flare ∅ 12.7)13 SeriesB or more325Z ViewInstallation dimension600<strong>Air</strong> inletService port600 or more 13 Series 10 SeriesA 600 mm 400 mm100 or more<strong>Air</strong> outletA or moreB 100 mm 45 mm4x∅ 11 Long holes (For∅ 8-∅ 10 anchor bolt)− 8 −

2. CONSTRUCTION VIEWSFILE NO. SVM-050202-1. Indoor UnitFront panelBack body<strong>Air</strong> inlet <strong>Air</strong> filter Heat exchanger790 2086 60275Knock out system<strong>Air</strong> outlet486 60Knock out system40486453120 59080HangerDrain hose (0.54m)45Hanger320620235 235215 215Minimumdistanceto ceiling65 or moreHangerConnecting pipe (0.43m)(Flare ∅6.35)Connecting pipe (0.33m)(For 13 series ; Flare ∅12.7For 07, 10 series ; Flare ∅ 9.52)For stud bolt(∅ 8~∅10)For stud bolt (∅6)2645275Minimumdistanceto ceiling170 or moreMinimumdistanceto ceiling170 or more190160HangerHanger3257 1890150 160 160150 90Installation plate outlineCenter lineWireless remote control− 7 −

FILE NO. SVM-050202-3. Outdoor Unit (RAS-07UA-ES4)A97A Detail Drawing (Back Leg)∅6 Hole273.52656605036 R 15R 5.5273.559.5∅25Drain outletBB Detail Drawing (Front Leg)273.5265∅6 Hole∅11x14 Hole3650660R 15Fan guard2-∅11x14 hole(for ∅8-∅10 anchor bolt)Cover PV∅420Z530242500 97.5 (11)66056273.5 (pitch)297(12.5)1264854Liquid side(Flare ∅6.35)Gas side(Flare ∅9.52)Z ViewService portInstallation dimension600100 or more<strong>Air</strong> inlet600 or more325100 or more 600 or more<strong>Air</strong> outlet4x∅11x14 Long holes (for ∅8-∅10 anchor bolt)− 9 −

FILE NO. SVM-050203-2. RAS-10UKHP-ES4 / RAS-10UAH-ES4LNBRWBLUGRN & YELSINGLE PHASE220-240V 50HzBLKP0413T02C.T.13CN27CN0311BLKSG01DSA22BLKR22VARISTOR3BLK 4THERMOPNKRY03SENSOR (TA)11PNK22RY0173°CTHERMAL FUSECN04T6.3A 250VACFUSE F01RY04CR01CN01 CR021 21 2HEAT EXCHANGERSENSOR (TC)BLKBLKLouverMotorR21VARISTORYELC01YELYELCN07YEL5 4 3 2 15 4 3 2 1MAIN P.C. BOARDWP-003150°CWHIL01CN25DC5VBLU1 12 23 34 45 56 6INFRARED RAYS RECEIVEAND INDICATION PARTS1 2 3 4 5 6 7 8 9 10 111 2 3 4 5 6 7 8 9 10 11C02CR03BLUCN10BLKBLUGRYYELBRWREDWHIIC03C15BLU55BLUR26BLUR319BLUR25R27BLU3 13 1BLUDB01BLUWHI1 2 3 4 5 6 7 8 9 10 111 2 3 4 5 6 7 8 9 10 11VoltageRegulatorMicroPowerModuleDC12VCN14+C63CN111 2 31 2 3AC FAN MOTORINDOORTERMINALBLOCKBLKWHIREDBLU1 2 3 4GRN&YELINDOOROUTDOORTERMINALBLOCK 3BLK1(L)2(N)4BLK BLKCHASSISOUTDOORSOLENOID COILOVERLOAD RELAYREDCAPACITORBLKREDREDWHI BLKCOMPRESSORFANMOTORPNKWHICAPACITORAWLF-240-30AHF-240-30BDetails A− 11 −

3-3. RAS-13UKP-ES4 / RAS-13UA-ES4FILE NO. SVM-05020CN25Infrared rays receiverand indication parts.1 2 3 4 5 6 7 8 9 10 111 2 3 4 5 6 7 8 9 10 11TRANS (TT-10)Heat ExchangerSensor (TC)Thermo Sensor (TA)LNSingle Phase220V~, 50HzGRN&YELBRW (L)BLU (N)CN14CN011 12 2CN031 12 2BLUBLUBLUBLUBLUBLUBLUBLUBLUBLUWHI1 2 3 4 5 6 7 8 9 10 111 2 3 4 5 6 7 8 9 10 11F01T6.3 A250 VACR213C15RY01R22L0142 13SG01DSA4C01BLKP04RED11DB50IC03WHI33 CN05C50+R46BLURegulatorcircuitR4711R4833GRYCN06D38MCC-920DC 12 VDC 5 VCR03C58CN071 1WHI2 2YEL3 3YEL4 4YEL5 5YELCN11YEL1 12 2GRYBRW3 3CN105 53 31 1WHIBLKRED1 12 23 34 45 5Louver motor150 C1 12 23 34 45 56 6Indoor FAN motorCN31CN041 21 2TEMP FUSEINDOORTERMINALBLOCKBLKWHI1 2GRN&YELPNKINDOORPNK73 COUTDOORTERMINALBLOCKOUTDOOR1(L)2(N)CHASSISBLK BLK REDREDCAPACITORCAPACITORFAN MOTORREDWHIACOMPRESSORPNKWHIHF-240-30BDetails AWLF-240-30A− 12 −

3-4. RAS-10UKP-ES4 / RAS-10UA-ES4FILE NO. SVM-05020CN25Infrared rays receiverand indication parts.1 2 3 4 5 6 7 8 9 10 111 2 3 4 5 6 7 8 9 10 11TRANS (TT-10)Heat ExchangerSensor (TC)Thermo Sensor (TA)LNSingle Phase220V~, 50HzGRN&YELBRW (L)BLU (N)CN14CN011 12 2CN031 12 2BLUBLUBLUBLUBLUBLUBLUBLUBLUBLUWHI1 2 3 4 5 6 7 8 9 10 111 2 3 4 5 6 7 8 9 10 11F01T6.3 A250 VACR213C15RY01R22L0142 13SG01DSA4C01BLKP04RED11DB50IC03WHI33 CN05C50+R46BLURegulatorcircuitR4711R4833GRYCN06D38MCC-920DC 12 VDC 5 VCR03C58CN071 1WHI2 2YEL3 3YEL4 4YEL5 5YELCN11YEL1 12 2GRYBRW3 3CN105 53 31 1WHIBLKRED1 12 23 34 45 5Louver motor150 C1 12 23 34 45 56 6Indoor FAN motorCN31CN041 21 2TEMP FUSEINDOORTERMINALBLOCKBLKWHI1 2GRN&YELPNKINDOORPNK73 COUTDOORTERMINALBLOCKOUTDOOR1(L) 2(N) CHASSISBLKBLKREDREDCAPACITORCAPACITORFAN MOTORREDWHIOVERLOAD RELAYCOMPRESSORREDWHI− 13 −

3-5. RAS-07UKP-ES4 / RAS-07UA-ES4FILE NO. SVM-05020CN25Infrared rays receiverand indication parts.1 2 3 4 5 6 7 8 9 10 111 2 3 4 5 6 7 8 9 10 11TRANS (TT-10)Heat ExchangerSensor (TC)Thermo Sensor (TA)LNSingle Phase220V~, 50HzGRN&YELBRW (L)BLU (N)CN14CN011 12 2CN031 12 2BLUBLUBLUBLUBLUBLUBLUBLUBLUBLUWHI1 2 3 4 5 6 7 8 9 10 111 2 3 4 5 6 7 8 9 10 11F01T6.3 A250 VACR213C15RY01R22L0142 13SG01DSA4C01BLKP04RED11DB50IC03WHI33 CN05C50+R46BLURegulatorcircuitR4711R4833GRYCN06D38MCC-920DC 12 VDC 5 VCR03C58CN071 1WHI2 2YEL3 3YEL4 4YEL5 5YELCN11YEL1 12 2GRYBRW3 3CN105 53 31 1WHIBLKRED1 12 23 34 45 5Louver motor150 C1 12 23 34 45 56 6Indoor FAN motorCN31CN041 21 2TEMP FUSEINDOORTERMINALBLOCKBLKWHI1 2GRN&YELPNKINDOORPNK73 COUTDOORTERMINALBLOCKOUTDOOR1(L)2(N)CHASSISBLK BLK REDREDCAPACITORCAPACITORFAN MOTORREDWHIAOVERLOAD RELAYCOMPRESSORPNKWHIHF-240-30BWLF-240-30ADetails A− 14 −

3. WIRING DIAGRAMFILE NO. SVM-050203-1. RAS-13UKHP-ES4 / RAS-13UAH-ES4LNBRWBLUGRN & YELSINGLE PHASE220-240V 50HzBLKP0413T02C.T.13CN27CN0311BLKSG01DSA22BLKR22VARISTOR3BLK 4THERMOPNKRY03SENSOR (TA)11PNK22RY0173°CTHERMAL FUSECN04T6.3A 250VACFUSE F01RY04CR01CN01 CR021 21 2HEAT EXCHANGERSENSOR (TC)BLKBLKLouverMotorR21VARISTORYELC01YELYELCN07YEL5 4 3 2 15 4 3 2 1MAIN P.C. BOARDWP-003150°CWHIL01CN25DC5VBLU1 12 23 34 45 56 6INFRARED RAYS RECEIVEAND INDICATION PARTS1 2 3 4 5 6 7 8 9 10 111 2 3 4 5 6 7 8 9 10 11C02CR03BLUCN10BLKBLUGRYYELBRWREDWHIIC03C15BLU55BLUBLUR319BLUBLU3 13 1BLUDB01BLUWHI1 2 3 4 5 6 7 8 9 10 111 2 3 4 5 6 7 8 9 10 11VoltageRegulatorR26R27MicroPowerModuleR25DC12VCN14+C63CN111 2 31 2 3AC FAN MOTORINDOORTERMINALBLOCKBLK1WHI2RED3BLU4GRN&YELINDOOROUTDOORTERMINALBLOCKBLK1(L)2(N)BLU3BLU4CHASSISOUTDOORSOLENOID COILREDCAPACITORREDREDWHIBLKCOMPRESSORFANMOTORPNKCAPACITORWHI− 10 −

4. SPECIFICATION OF ELECTRICAL PARTS4-1. Indoor Unit (RAS-13UKHP-ES4, RAS-10UKHP-ES4)FILE NO. SVM-05020No. Parts name Type Specifications1 Fan motor (for indoor) SKF-220-20-4A-1 AC Motor with 150°C thermo fuse2 Thermo sensor (TA-sensor) 10kΩ at 25°C3 Switching transformer (T01) SWT-474 Microcontroller unit (IC30) TMP87CM40AN5 Heat exchanger sensor(TC-sensor)6 Line filter (L01) LC*SS11V-062707 Bridge rectifier (DB01) D3SBA60 4A, 600V8 Capacitor (C02) KMH400VSSN47M22S 47µF, 400V9 Fuse (F01) TSCR6.3A T6.3A, 250VAC10 Varistor (R21, R22) 15G561K 560V11 Resistor (R01) RF-2TK5R6 5.6Ω, Ω 2W12 Louver motor MP24Z 12VDC10kΩ at 25°C27mH, 600mA13 Relay (Comp., RY01) DI12D1 Rating 20A/AC250V, 12VDC14 Relay (Fan, RY03) G5N-1A Rating 3A/AC250V, 12VDC15 Relay (Solenoide, RY04) G5N-1A Rating 3A/AC250V, 12VDC4-2. Outdoor Unit (RAS-13UAH-ES4)No. Parts name Type SpecificationsOutput (Rated) 1100W, 2poles, 1 phase, 220 − 240V, 50Hz1 Compressor PA150X2C-4FT Winding resistance (Ω) C-R C-S(at 20°C) 2.35 3.22Output (Rated) 42W, 6poles, 1 phase, 220 − 240V, 50Hz2 Fan motor (for outdoor) HF-240-42A or Winding resistance (Ω) Red-Black White-BlackWLF-240-42A(at 20°C) 176.2 or 188 290.5 or 28934Running capacitor(for fan motor)Running capacitor(for compressor)DS451155NPQBDS441306CPNKAC 450V, 1.5µFAC 440V, 30µFSolenoid coil5 (for 4-way valve) VHV-01AJ503C1 AC 220 − 240V, 50Hz(for Heat pump model)− 15 −

FILE NO. SVM-050204-3. Outdoor Unit (RAS-13UA-ES4)No. Parts name Type SpecificationsOutput (Rated) 1100W, 2poles, 1 phase, 220 − 240V, 50Hz1 Compressor PA150X2C-4FT Winding resistance (Ω) C-R C-S(at 20°C) 2.35 3.22Output (Rated) 30W, 6poles, 1 phase, 220 − 240V, 50Hz2 Fan motor (for outdoor)HF-240-30B orWinding resistance (Ω) Red-Black White-BlackWLF-240-30A(at 20°C) 245 or 237 388.3 or 3803Running capacitor(for fan motor)DS451155NPQB AC 450V, 1.5µF4Running capacitor(for compressor)DS441306CPNK AC 440V, 30µF4-4. Outdoor Unit (RAS-10UAH-ES4)No. Parts name Type SpecificationsOutput (Rated) 750W , 2poles, 1 phase, 220 − 240V, 50Hz1 Compressor PA108X1C-4FZDN Winding resistance (Ω) C-R C-S(at 20°C) 3.75 4.75Output (Rated) 30W, 6poles, 1 phase, 220 − 240V, 50Hz2 Fan motor (for outdoor) HF-240-30B or Winding resistance (Ω) Red-Black White-BlackWLF-240-30A(at 20°C) 245 or 237 388.3 or 380345Running capacitor(for fan motor)Running capacitor(for compressor)Solenoid coil(for 4-way valve)DS451155NPQBDS441256CPNLSQ-373AC 450V, 1.5µFAC 440V, 25µFAC 220 − 240V− 16 −

4-5. Indoor Unit (RAS-13UKP-ES4, RAS-10UKP-ES4, RAS-07UKP-ES4)FILE NO. SVM-05020No. Parts name Type Specifications1 Fan motor (for indoor) SKF-220-20-4A-1 AC Motor with 150°C thermo fuse2 Thermo sensor (TA-sensor) 10kΩat 25°C3 Transformer TT-104 Microcontroller unit (IC30) TMP87CM40AN5 Heat exchanger sensor(TC-sensor)10kΩat 25°C6 Line filter (L01) *SS11V-06270 27mH, 600mA7 Bridge rectifier (DB50) KBP06M/51 1.5A, 600V8 Capacitor (C50) PF1E222MNN1625 2200µF, 25V9 Fuse (F01) BET6.3A T6.3A, 250VAC10 Varistor (R21, R22) 15G561K320 560V11 L ouver motor MP24Z 12VDC12 Relay (Comp., RY01) DI1U Rating 25A/AC250V, 3~48VDC4-6. Outdoor Unit (RAS-10UA-ES4)No. Parts name Type SpecificationsOutput (Rated) 750W, 2poles, 1 phase, 220 − 240V, 50Hz1 Compressor PA108X1C-4FZDN Winding resistance (Ω) C-R C-S(at 20°C) 3.75 4.75Output (Rated) 20W, 6poles, 1 phase, 220 − 240V, 50HzHF-240-20B or2 Fan motor (for outdoor)Winding resistance (Ω) Red-Black White-BlackSKF-240-20B(at 20°C) 387.3 or 235.2 466.2 or 260.13Running capacitor(for fan motor)DS451155NPQB AC 450V, 1.5µF4Running capacitor(for compressor)DS441256CPNAL AC 440V, 25µF− 17 −

FILE NO. SVM-050204-7. Outdoor Unit (RAS-07UA-ES4)No. Parts name Type1Output (Rated) 605W, 2poles, 1 phase, 220 − 240V, 50HzC-RC-S4.84 4.40Output (Rated) 30W, 6poles, 1 phase, 220 − 240V, 50Hz2 Fan motor (for outdoor)HF-240-30B orWinding resistance (Ω) Red-Blac k White-BlackWLF-240-30A(at 20°C)245 or 237 388 or 38034CompressorRunning capacitor(for fan motor)Running capacitor(for compressor)PA82X1C-4DZDNDS451155NPQBWinding resistance (Ω)(at 20°C)AC 450V, 1.5µFDS441256CPNAL AC 440V, 25µFSpecifications– 18 –

5-1. RAS-13UKHP-ES4/ RAS-13UAH-ES45. REFRIGERATION CYCLE DIAGRAMFILE NO. SVM-05020CoolingIndoor unitHeat exchangerT10.39mHeating0.49m(Connecting pipe)(Connecting pipe)∅12.7 ∅6.35Cross flow fanO.D.:12.7mmPO.D.:6.35mmPacked valve(∅12.7)Packed valve(∅6.35)CoolingHeating4-way valveHeating Cooling CompressorPA150X2C-4FTAccumulatorCapillary tube∅1.5x1200lCapillary tube∅1.0x400lHeat exchangerCoolingHeatingPropeller fanOutdoor unitMark(RefrigerantR410A : 0.95 kg.)means check points of Gas Leak.50HzStandar dpressure P(MPaG)Surface temp. of heatexchang er inter changingpipe T1 (°C)Note :• Measure the heat exchanger temperature at the center of U-bend. (By means of TC sensor)*1 • During heating overload operation, a value for the high temperature limit control operation is included.− 19 −Fan speed(indoor)Ambient temp.conditions DB/WB(°C)IndoorOutdoorStandard 2.73 43.5 High 20/15 7/6Heating Overload*1 3.20 ~ 3.60 52.0 ~ 58.5 Low 27/− 24/18Low temperature 2.20 35.0 High 20/− −10/−10Standard 0.85 10.0 High 27/19 35/24Cooling Overload 0.99 14.0 High 32/23 43/26Low temperature 0.65 2.0 Low 21/15 21/15

5-2. RAS-10UKHP-ES4 / RAS-10UAH-ES4FILE NO. SVM-05020CoolingIndoor unitHeat exchangerT10.39m(Connecting pipe)∅9.52HeatingCross flow fan0.49m(Connecting pipe)∅6.35O.D.:9.52mmPO.D.:6.35mmPacked valve(∅9.52)Packed valve(∅6.35)CoolingHeating4-way valveCapillary tube∅1.5x1300lHeating Cooling CompressorPA108X1C-4FZDNAccumulatorCapillary tube∅1.5x1000lHeat exchangerCoolingHeatingPropeller fanOutdoor unitMark(RefrigerantR410A : 0.79 kg.)means check points of Gas Leak.50HzStandar dpressure P(MPaG)Surface temp. of heatexchanger inter changingpipe T1 (°C)Fan speed(indoor)Note :• Measure the heat exchanger temperature at the center of U-bend. (By means of TC sensor)Ambient temp.conditions DB/WB(°C)IndoorOutdoorStandard 2.22 37.0 High 20/15 7/6Heating Overload 3.43 54.0 Low 27/− 24/18Low temperature 2.10 35.0 High 20/− −10/−10Standard 0.95 11.0 High 27/19 35/24Cooling Overload 1.14 15.0 High 32/23 43/26Low temperature 0.85 5.0 Low 21/15 21/15− 20 −

5-3. RAS-13UKP-ES4 / RAS-13UA-ES4FILE NO. SVM-05020CoolingIndoor unitHeat exchangerT10.39m(Connecting pipe)∅12.7Cross flow fan0.49m(Connecting pipe)∅6.35O.D.:12.7mmPO.D.:6.35mmPacked valve(∅12.7)Packed valve(∅6.35)CoolingCooling CompressorPA150X2C-4FTAccumulatorCapillary tube∅1.7x600lHeat exchangerRefrigerantCoolingPropeller fanOutdoor unitMark(R410A : 0.95 kg.)means check points of Gas Leak.50HzStandar dpressure P(MPaG)Surface temp. of heatexchang er inter changingpipe T1 (°C)Fan speed(indoor)Note :•Measure the heat exchanger temperature at the center of U-bend. (By means of TC sensor)Ambient temp.conditions DB/WB(°C)IndoorOutdoorStandard 0.90 9.0 High 27/19 35/24Cooling Overload 1.12 13.0 High 32/23 43/26Low temperature 0.72 2.0 Low 21/15 21/15− 21 −

FILE NO. SVM-050205-4. RAS-10UKP-ES4 / RAS-10UA-ES4CoolingIndoor unitHeat exchangerT10.39m(Connecting pipe)∅9.52Cross flow fan0.49m(Connecting pipe)∅6.35O.D.:9.52mmPO.D.:6.35mmPacked valve(∅9.52)Packed valve(∅6.35)CoolingCooling CompressorPA108X1C-4FZDNCapillary tube∅1.5x1100lHeat exchangerRefrigerantCoolingPropeller fanOutdoor unitMark(R410A : 0.70 kg.)means check points of Gas Leak.50HzStandardpressure P(MPaG)Surface temp. of heatexchanger interchangingpipe T1 (°C)Fan speed(indoor)Ambient temp.conditions DB/WB(°C)IndoorOutdoorStandard 0.98 11.0 High 27/19 35/24Cooling Overload 1.10 15.0 High 32/23 43/26Low temperature 0.85 5.0 Low 21/15 21/15Note :•Measure the heat exchanger temperature at the center of U-bend. (By means of TC sensor)−22−

FILE NO. SVM-050205-5. RAS-07UKP-ES4 / RAS-07UA-ES4CoolingIndoor unitHeat exchangerT10.39m(Connecting pipe)∅9.52Cross flow fan0.49m(Connecting pipe)∅6.35O.D.:9.52mmPO.D.:6.35mmPacked valve(∅9.52)Packed valve(∅6.35)CoolingCooling CompressorPA82X1C-4DZDNCapillary tube∅1.2x550lHeat exchangerRefrigerantCoolingPropeller fanOutdoor unitMark(R-410A : 0.63 kg.)means check points of Gas Leak.50HzStandardpressure P(MPaG)Surface temp. of heatexchanger interchangingpipe T1 (°C)Fan speed(indoor)Ambient temp.conditions DB/WB(°C)IndoorOutdoorStandard 1.00 13.0 High 27/19 35/24Cooling Overload 1.14 18.0 High 32/23 43/26Low temperature 0.75 2.0 Low 21/15 21/15Note :• Measure the heat exchanger temperature at the center of U-bend. (By means of TC sensor)− 23 −

6. CONTROL BLOCK DIAGRAMFILE NO. SVM-050206-1. RAS-13UKHP-ES4 / RAS-13UAH-ES4, RAS-10UKHP-ES4 / RAS-10UAH-ES4Main Unit Control PanelM.C.U.Heat Exchange sensorFunctionsOperationDisplayThermo. Sensor•Louver ControlTimerDisplayCurrent Sensor(Compressor Current)Infrared Rays Signal ReciverInitiallizing CircuitClock FrequencyOscillator Circuit•3-minutes Delay at Restartfor Compressor•Motor Revolution Control•Processing(Temperature Processing)•TimerFilter SignDisplayHi PowerSign DisplayPRE DEF.Sign DisplayIndoor FanMotorPower SupplyCircuitCompressorON/OFFSignalOutdoor FanON/OFFSignal4-Way ValveON/OFFSignalLouverON/OFFSignalNoise FilterRelay Driver, Louver DriverLouverMotorRelayRY01RelayRY03RelayRY04220-240 V~, 50Hz Compressor Outdoor Fan Motor 4-Way ValveREMOTE CONTROLRemote ControlOperation ( )Infrared RaysOperation Mode SelectionAUTO, COOL, DRY, HEAT, FAN ONLYTemperature SettingFan Speed SelectionON TIMER SettingOFF TIMER SettingLouver Auto SwingLouver Direction SettingECOHi powerTIMER 1.3.5.9HCOMFORT SLEEPQUIET− 24 −

6-2. RAS-13UKP-ES4 / RAS-13UA-ES4,RAS-10UKP-ES4 / RAS-10UA-ES4,RAS-07UKP-ES4 / RAS-07UA-ES4FILE NO. SVM-05020Main Unit Control PanelM.C.U.Heat Exchange sensorFunctionsOperationDisplayThermo. Sensor•Louver ControlTimerDisplayInfrared Rays Signal ReciverInitiallizing CircuitClock FrequencyOscillator Circuit•3-minutes Delay at Restartfor Compressor•Motor Revolution Control•Processing(Temperature Processing)•TimerFilter SignDisplayHi PowerSign DisplayFan OnlySign DisplayIndoor FanMotorPower SupplyCircuitCompressorON/OFFSignalLouverON/OFFSignalNoise FilterRelay Driver, Louver DriverLouverMotorRelayRY01220-240 V~, 50Hz Compressor, Outdoor Fan MotorREMOTE CONTROLRemote ControlOperation ( )Operation Mode SelectionAUTO, COOL, DRY, FAN ONLYTemperature SettingFan Speed SelectionON TIMER SettingOFF TIMER SettingLouver Auto SwingLouver Direction SettingECOHi powerTIMER 1.3.5.9HCOMFORT SLEEPQUIETInfrared Rays− 25 −

7. OPERATION DESCRIPTIONFILE NO. SVM-050207-1. Outline of <strong>Air</strong> Conditioner ControlThis is a fixed capacity type air conditioner, which usesAC motor for an indoor fan. The AC motor drivecircuit is mounted in the indoor unit. And electricalparts which driving the compressor and the outdoorfan motor, are mounted in the outdoor unit.The air conditioner is controlled by the controllermounted in the indoor unit. The controller operates allcomponents based on the commands transmitted fromthe remote control and the feedback data of the sensoris as follow:• The temperature measurement at the air inlet ofthe indoor heat exchanger by the indoortemperature sensor•The temperature measurement at the indoorheat exchanger by the indoor heat exchangertemperature sensor• Indoor fan motor operation control• Louver motor control• LED display control• Outdoor fan motor operation control• 4-WAYS-VALVE operation control(Heat pump model only)• Compressor operation control• Receiving the information of the operationstatus and judging the information or theindication of errors7-1-1. Louver control(1) Vertical air flow louverPosition of veritcal air flow louver is automaticallycontrolled according to the operation mode.Besides, position of vertical air flow louver can bearbitrarily set by pressing [FIX] button.The louver position which is set by [FIX] button isstored in the microcontroller, and the louver isautomatically set at the stored position for the nextoperation.(2) SwingIf [SWING] button is pressed when the indoor unitis in operation, the vertical air flow louver startsswinging. When [SWING] button is pressed again,it stops swinging.7-1-2. Indoor fan control (AC Fan motor)(1) The indoor fan is operated by the stepless speedchange AC motor.(2) For air flow level, speed of the indoor fan motor iscontrolled in five steps (LOW, LOW + , MED, MED +and HIGH). If AUTO mode is selected, the fanmotor speed is automatically controlled by thedifference between the preset temperature andthe room temperature.Table 7-1-1LOW + =MED + =FAN TAPLOW+MED2MED+HIGH2Cooling UH H M L L- UL SLOPERATION Fan only H M L L-MODEDry M L L- UL SLHeat UH H M L L- UL SLRAS-07UK Seriesrpm 1350 1300 1200 1050 1000 950 900 800 750 700 650<strong>Air</strong> flow volume (m 3 /h) 650 630 570 490 460 430 400 340 310 280 250RAS-10UK Seriesrpm1350 1300 1250 1050 1000 950 900 800 750 700 650<strong>Air</strong> flow volume (m 3 /h) 650 630 610 490 460 430 400 340 310 280 250ModelRAS-10UKH SeriesRAS-13UK Seriesrpm<strong>Air</strong> flow volume (m 3 /h)rpm<strong>Air</strong> flow volume (m 3 /h)1300 1250 1200 1100 1000 900 800 750 700 650630 610 570 520 460 400 340 310 280 2501350 1300 1150 1100 1050 1000 950 900 850 800 750650 630 550 520 490 460 430 400 370 340 310700280RAS-13UKH Seriesrpm<strong>Air</strong> flow volume (m 3 /h)1350 1300 1150 1100 1050 1020 950 900 850 800 750650 630 550 520 490 470 430 400 370 340 310700280− 26 −

7-2. Description of Operation Circuit(1) When turning on the breaker, the operation lampblinks. This means that the power supply is on.(2) When pressing [ ] button on the remote control,receiving beep sounds from the indoor unit, andthe next operation is performed together withopening the vertical air flow louver.(3) Once the operation mode is set, it is memorized inthe microcontroller so that the previous operationcan be effected thereafter simply by pressing[ ] button.7-2-1. Fan only operation([MODE] button on the remote control is setto the fan only operation.)(1) When [FAN] button is set to AUTO, the indoor fanmotor operates as shown in Fig. 7-2-1. When[FAN] button is set to LOW, LOW + , MED, MED + orHIGH, the motor operates with a constant air flow.7-2-2. Cooling operation([MODE] button on the remote control is setto the cooling operation.)(1) The compressor, 4-way valve, outdoor fan andoperation display on the remote control arecontrolled as shown in Fig. 7-2-2.(Room temp.) - (Preset temp.)Presettemp.°C0.50FILE NO. SVM-05020ONONOFF OFF OFF ONCompressor4-way valveOutdoor fanOPERATIONdisplay(Room temp.) (Preset temp.)-Presettemp.°C+3+2.5+2+1.5+1+0.50(Preset temp.: 22 °C)NOTE :*1: The values marked with *1 are calculated andcontrolled by the difference in motor speedbetween M+ and L-.(2) The Hi POWER, ECO and COMFORT SLEEPoperation cannot be set.Fig. 7-2-1 Setting of air flow [FAN:AUTO]M+*1*1*1L-Fig. 7-2-2(2) When [FAN] button is set to AUTO, the indoor fanmotor operates as shown in Fig. 7-2-3. When[FAN] button is set to LOW, LOW + , MED, MED + orHIGH, the motor operates with a constant air flow.(Room temp.) − (Preset temp.)Presettemp.°C+3+2.5+2+1.5+1+0.50-0.5M+NOTE :*1: The values marked with *1 are calculated andcontrolled by the difference in motor speedbetween M+ and L-.*1*1*1L-Fig. 7-2-3 Setting of air flow [FAN:AUTO]- 27-

7-2-3. Dry operation([MODE] button on the remote control is setto the dry operation.)(1) The compressor, 4-way valve, outdoor fan andoperation display on the remote control arecontrolled as shown in Fig. 7-2-4.FILE NO. SVM-050207-2-4. Heating operation *Heat pump model only([MODE] button on the remote control is setto the heating operation.)(1) The compressor, 4-way valve, outdoor fan andoperation display on the remote control arecontrolled as shown in Fig. 7-2-6.(Room temp.) (Preset temp.)-Presettemp.°C+3+2+10ON:6min.OFF:4min.ON:5min.OFF:5min.OFFCompressorOFF4-way valveON:6min.OFF:4min.ON:5min.OFF:5min.OFFOutdoor fanONOPERATIONdisplayPresettemp.(Room temp.) (Preset temp.)-°C0-0.5OFF ON OFF ONONCompressor4-way valveONOutdoor fanOPERATIONdisplayFig. 7-2-4(2) The microcontroller turns the compressor on andoff at the regular intervals (4 to 6 minutes). Whilethe compressor is turning off, the indoor fan motoroperates in the SUPER LOW position.The pattern of operation depending on the relationbetween room temperature and presettemperatures is shown in Fig. 7-2-5.Room temp.Preset temp.+1Preset temp.CompressorOutdoor fanON ON ON ONOFF OFF OFFIndoor fan L *SL L SL L SL L*Super LowFig. 7-2-5Fig. 7-2-6(2) When [FAN] button is set to AUTO, the indoor fanmotor operates as shown in Fig. 7-2-7. When[FAN] button is set to LOW, LOW + , MED, MED + orHIGH, the motor operates with a constant air flow.Presettemp.(Room temp.) (Preset temp.)-°C0-0.5-1-1.5-2-5.0-5.5[FAN AUTO]*1, *2 : The values marked with *1 and *2 arecalculated and controlled by the difference inmotor speed between M+ and L.M +Fig. 7-2-7 Setting of air flow [FAN:AUTO]L*1*2H(3) [FAN] button on the remote control is set to AUTOonly.(4) The Hi POWER, ECO, COMFORT SLEEP andQUIET operations cannot be set.- 28 -

(3) The indoor heat exchanger restricts revolvingspeed of the fan motor to prevent a cold draft. Theupper limit of the revolving speed is shown inFig. 7-2-8 and Table 7-2-1.Indoor heat exchanger temperatureIndoor heat exchanger temperature*2*213UKH Series4241292834332120A+4A− 8 A+4A− 8*6 *510UKH Series46453231A+4A− 8°C34332120A+4A− 8*6 *5°CNOTES :*1: The fan stops for 2 minutes after thermostat-OFF.*2: A is 24°C when the preset temperature is 24°C ormore and A is the preset temperature when it isunder 24 °C.*3: SL means Super Low.AUTO*4: Calculated from difference in motor speedbetween SL and H.Fig. 7-2-8 Cold draft preventing control*4SL*3SL*1StopAUTO*4SL*3SL*1StopManual(One of 5 steps)L-H (Up toseting speed)Manual(One of 5 steps)L- H (Up toseting speed)*5 and *6:Table 7-2-1Fan *5 *6speed Starting period Stabilized periodAUTO ·· From 12 to 25 minutesUp until 12 minutespassed after startingthe unit· From 12 to 25 minutespassed after startingthe unit and roomtemperature is 3 °Clower than preset· temperature ·passed after startingthe unit and roomtemperature isbetween presettemperature and 3 °Clower than presettemperature 25 minutes or morepassed after startingthe unitManual · Room temperature · Room temperature(L - H) < Preset temperature- 4 °CPreset temperature-3.5 °C7-2-5. Automatic operation([MODE] button on the remote control is setto the automatic operation.)(1) One of 3 operations (Cooling, Fan only or Heating)is selected according to difference between thepreset temperature and the room temperature atwhich the automatic operation has started, asshown in Fig. 7-2-9. The Fan only operationcontinues until the room temperature reaches alevel at which another mode is selected.(2) Temporary AutoWhen the [TEMPORARY] button on the indoor unitis pushed, the preset temperature is fixed at 24 °Cand the indoor unit is controlled as shown inFig. 7-2-9.(Room temp.) - (Preset temp.)°C+40-1Cooling operationThe louver moves to the position sameas Hi POWER operation.Heating operationUKH SeriesFILE NO. SVM-05020Cooling operationFan only operationUK SeriesFig. 7-2-9- 29 -

7-3. Hi POWER Mode([Hi POWER] button on the remotecontrol is pressed.)When [Hi POWER] button is pressed while the indoorunit is in Auto, Cooling or Heating operation, HiPOWER mark is indicated on the display of the remotecontrol and the unit operates as follows.(1) Automatic operation· The indoor unit operates in according to thecurrent operation.(2) Cooling operation• The setting temperature drops 3°C.(The value of the setting temperature on theremote control does not change.)• If the room temperature is higher than thesetting temperature by 3.5°C or more, thehorizontal louver moves to the Hi POWERposition automatically. Then when the roomtemperature is 1°C less than the settingtemperature the horizontal louver returnsautomatically.• FAN speed : [AUTO]If the room temperature is higher than thesetting temperature by 3.5°C or more, the airconditioner operates at maximum airflow level.If the room temperature is higher than thesetting temperature by less than 3.5°C, the airconditioner operates at normal airflow level.• FAN speed : One of 5 levelsIf the room temperature is higher than thesetting temperature by 3.5°C or more, the airconditioner operates at higher consecutiveairflow level. If the room temperature is higherthan the setting temperature by less than 3.5°C,the air conditioner operates at normal airflowlevel.(3) Heating operation (UKH Series only)· The preset temperature increases 2°C,(The value of the preset temperature on theremote control does not change.)· The indoor unit operates in normal heatingmode except the preset temperature is higher(+2°C).(4) The Hi POWER mode can not be set in Dry or Fanonly operation.7-4. High-Temperature Limit Control*Heat pump model onlyThe microcontroller detects the indoor heat exchangertemperature to prevent pressure of a refrigerating cyclefrom increasing excessively.The compressor and outdoor fan motor are controlledas shown in Fig. 7-4-1.Compressor Outdoor fanOFFONONFig. 7-4-17-5. Low-Temperature Limit ControlThe microcontroller detects the indoor heat exchangertemperature to prevent the indoor heat exchanger fromfreezing.The compressor and outdoor fan motor are controlledas shown in Fig. 7-5-1 and 7-5-2.13UKH Series13UK Series(°C)6210UKH Series10UK Series07UK SeriesHeat exchangertemperature(°C)75OFFOFFONHeat exchangertemperatureFILE NO. SVM-05020Fig. 7-5-1Compressor Outdoor fanONHeat exchangertemp.(°C)605352Compressor Outdoor fanONLess than 2°C continuesfor 5 minutesOFFLess than 5 °C continuesfor 5 minutesOFFFig. 7-5-2- 30 -

7-6. Defrost Operation *Heat pump model onlyDuring the heating operation, the outdoor heatexchanger temperature goes down and sometimes it isfrozen.In this case, the air conditioner stops the heatingoperation and starts the defrost operation to melt ice.7-6-1. Condition to start the defrost operationThe defrost operation starts whichever belowconditions are satisfied.(1) When the cumulative compressor operating time islonger than 40 or 90 minutes and differencebetween the indoor heat exchanger temperatureand the room temperature is less than thespecified value. (This value is decided by themicroprocessor.) (Control example is shown inFig. 7-6-1. In case of B or C, the defrost operationstarts.)(2) When the current limit control or the hightemperature limit control is performed for total of90 minutes.Indoor heat exchanger temp- Room tempADBCCumulativecompressoroperating timeDEFROST LAMP :FILE NO. SVM-05020(1) The heating operation is performed for at least 90minutes.(2) The defrost operating time is 10 minutes.7-6-3. Ending condition at defrost operation(1) When the compressor current becomes 7.5A ormore during defrost operation, the defrostoperation stops and the heating operation restarts.(The current sensor detects the compressorcurrent.)(2) The defrost operation continues for at most6 minutes or 10 minutes.· During defrost operation, the PRE-DEF. lamp ison and the indoor and outdoor fans are off.· The compressor start protection timer is interlookedwith the PRE-DEF. lamp. So the PRE-DEF.Lamp is off (the fans stop) for about 3 minutesafter the [ ] button is turned on. Whenthe compressor is turned on, the PRE-DEF. lampcomes on. After the heat ex-changer is preheatedto about 24 °C or higher, the PRE-DEF. Lampgoes off, and the indoor fan starts.Fig. 7-6-1 (Indoor fan speed : M)7-6-2. Defrost operation time control(1) The heating operation is performed for at least40 minutes.(2) The maximum defrost operating time is 6 minutes.The defrost operating time for the 4th cycle is10 minutes. (When the outdoor temperature isvery low, however, the defrost operating time is10 minutes.)minutes40minutes40minutes40minutes40HeatingDefrostHeatingDefrostHeatingDefrostHeatingDefrostMax 6 minutes10 minutes1 cycleFig. 7-6-2- 31 -

7-7. Current Limit Control *Heat pump modelonlyThe microcontroller detects the input current so as toprevent it exceeds a specified value by means ofcontrolling the outdoor fan control as described in (1)and (2).FILE NO. SVM-05020(1) Current limit control (Cooling operation)Control is performed as shown below by detectingthe compressor operating current with a currentsensor (C.T).Input current13UKH Series / 10UKH Series13.5A / 19.2A I412.5A / 17.8A I3CompressorOutdoor fanMore than I4 continues for 3 secondsOFFMore than I3 continues for 5 secondsOFFONFig. 7-7-1(2) Current limit control (Heating operation)Control is performed as shown in Fig. 7-7-2Input current13UKH Series / 10UKH Series13.5A / 19.2A I412.5A / 17.8A I3CompressorOutdoor fanMore than I4 continues for 3 secondsOFFMore than I3 continues for 5 secondsOFF10A / 15.6AI2ONOFF9A / 15.0AI1ONFig. 7-7-2Remark :1. This function is available only for heat pump model (Cooling models have no a current sensor (C.T.)).2. For 10UKH Series, the value of currents shown on the diagram above are two times the actualoperating value. This is because the lead wire operated two times through the C.T.- 32 -

7-8. Auto Restart FunctionThe indoor unit is equipped with an automaticrestarting function which allows the unit to restartoperating with the set operating conditions in the eventof power supply being accidentally shut down. Theoperation will resume without warning three minutesafter power is restored.This function is not set to work when shipped from thefactory. Therefore it is necessary to set it to work.7-8-1. How to set auto restart functionFILE NO. SVM-05020To set the auto restart function, proceed as follows:The power supply to the unit must be on; the functionwill not set if the power is off.Push the [TEMPORARY] button located in the centerof the front panel continuously for three seconds.The unit receives the signal and beeps three times.The unit then restarts operating automatically in theevent of power supply being accidentally shut down.When the unit is on standby (Not operating)OperationMotionsPush [TEMPORARY] button for more The unit is on standby.than three seconds.¯The unit starts to operate.The green lamp is on.¯ After approx. three seconds,03SThe unit beeps three times The lamp changes fromand continues to operate.green to orange.[TEMPORARY] buttonIf the unit is not required to operate at this time, push [TEMPORARY]button once more or use the remote control to turn it off.When the unit is in operationOperationMotionsPush [TEMPORARY] button for more The unit is in operation. The green lamp is on.than three seconds.¯[TEMPORARY] button03SThe unit stops operating.¯The unit beeps three timesAfter approx. three seconds,The green lamp is turned off.If the unit is required to operate at this time, push [TEMPORARY]button once more or use the remote control to turn it on.···While this function is being set, if the unit is inoperation, the orange lamp is on.This function can not be set if the timer operationhas been selected.When the unit is turned on by this function, thelouver will not swing even though it was swingingautomatically before shutting down.·While the filter check lamp is on, the[TEMPORARY] button has the function of filterreset button.- 33 -

7-8-2. How to cancel auto restart functionTo cancel auto restart function, proceed as follows:Repeat the setting prodedure: the unit receives thesignal and beeps three times.The unit will be required to be turned on with theremote control after the main power supply is turnedoff.FILE NO. SVM-05020When the unit is on standby (Not operating)OperationMotionsPush [TEMPORARY] button for more The unit is on standby.than three seconds.¯The unit starts to operate.The orange lamp is on.¯ After approx. three seconds,03SThe unit beeps three times The lamp changes fromand continues ¯ to operate.orange to green.[TEMPORARY] buttonIf the unit is not required to operate at this time, push [TEMPORARY]button once more or use the remote control to turn it off.When the unit is in operationOperationMotionsPush [TEMPORARY] button for more The unit is in operation. The orange lamp is on.than three seconds.¯[TEMPORARY] button03SThe unit stops operating.¯The unit beeps three timesAfter approx. three seconds,The orange lamp is turned off.If the unit is required to operate at this time, push [TEMPORARY]button once more or use the remote control to turn it on.·While this function is being set, if the unit is inoperation, the orange lamp is on.7-8-3. Power failure during timer operationWhen the unit is in Timer operation, if it is turned offbecause of power failure, the timer operation iscancelled. Therefore, set the timer operation again.7-9. Filter Check LampWhen the elapsed time reaches 1000 hours, the filtercheck lamp indicates. After cleaning the filters, turn offthe filter check lamp.7-9-1. How to turn off filter check lampPush [TEMPORARY] button on the indoor unit.Note:If [TEMPORARY] button is pushed while the filtercheck lamp is not indicating, the indoor unit will startthe Automatic Operation.- 34-

7-10. Self-Cleaning functionFILE NO. SVM-05020Self-Cleaning function is designed to reduce humidity that causes mold to form inside the air conditioning unit.This advanced, efficient system reduces moisture in the coil. When air conditioner is turned off, the internal fanactivates and dries the moisture in the coil for 20 minutes, then it turns off automatically.Operation display ON OFF OFFFCU fanONrpm is depend on presetting.ONrpm is SL speed.OFFFCU louver OPEN CLOSE CLOSETimer displayON or OFFdepend on presetting of timer function.ONON or OFFdepend on presetting of timer function.CompressorON or OFFdepend on presetting per room temperature.OFFOFFCDU fanON or OFFdepend on presetting per room temperature.Cool mode or dry modeoperation more than 10 mins.OFFOFF8 8-Self-Cleaning modeOperation timeoperate 20 mins.Turn off by remote controller ortimer-off function.Automatically turn-off.• The Self-Cleaning function is set as default at ex-factory.• Self-Cleaning operation can stop manually by press [ ] button of the remote control two more time.7-10-1. How to cancel Self-Cleaning functionTo cancel the Self-Cleaning function, proceed asfollows:• Press [TEMPORARY] button one time or use remotecontrol to turn on air conditioner. The OPERATIONdisplay will show in orange color (When AUTO-RESTART is ON) or green color (When AUTO-RESTART is OFF).• Hold down the [TEMPORARY] button for more than20 seconds. (The air conditioner will stop suddenlywhen the [TEMPORARY] button is pressed but keepholding it continue. Then will beep 3 times in the first3 seconds but it is not related to Self-Cleaningfunction)• After holding about 20 seconds, the air conditionerwill beep 5 times without any blinking of display.• The Self-Cleaning Operation had been cancelled.Remarks• Per setting of Self-Cleaning function above, AUTO-RESTART function had been cancelled. To setAUTO-RESTART again, please follow item 7-8-1.7-10-2. How to set Self-Cleaning function.To set the Self-Cleaning function, proceed as follows.• Press [TEMPORARY] button one time or use remotecontrol to turn on air conditioner. The OPERATIONdisplay will show in orange color (When AUTO-RESET is ON) or green color (When AUTO-RESTART is OFF).• Hold down the [TEMPORARY] button for more than20 seconds. (The air conditioner will stop suddenlywhen the [TEMPORARY] button is pressed but keepholding it continue. Then will beep 3 times is the first3 seconds but it is not related to Self-Cleaningfunction)• After holding about 20 seconds, the air conditionerwill beep 5 times and OPERATION display blinks5 times.• The Self-Cleaning function had been set.Remarks• Per setting of Self-Cleaning function above, AUTO-RESTART function had been cancelled. To setAUTO-RESTART again, please follow item 7-8-1.– 35 –

FILE NO. SVM-050207-11. QUIET ModeQuiet mode is the system which, control therevolving speed of indoor fan to work constantlyat lower than speed L. In addition, noise level ofindoor unit is less than usual.When the [QUIET] button is pressed, the fan of theindoor unit will be restricted the revolving speed atspeed L - until the [QUIET] button is pressed onceagain (cancel Quiet mode).Remarks :1. Quiet mode is unable to work in dry mode.2. Quiet mode is appropriate to work with lesscooling load and less heating load condition.Because of the fan speed L- may cause notenough the cooling capacity or heating capacity.7-12. COMFORT SLEEP modeThe principles of comfort sleep mode are:• Quietness for more comfortable.• Save energy by changing room temperatureautomatically.• The air condition can shut down by itselfautomatically.Remarks:1. Comfort sleep mode will not operate in dry modeand fan only mode.2. Comfort sleep mode is appropriate to work with lesscooling load and less heating load condition.Because of the fan speed L- may cause not enoughthe cooling capacity or heating capacity.7-12-1. Cooling mode• The fan speed of indoor unit operates automatically,it relates with the compressor's operation.Compressor’s Operation Fan SpeedON L-OFFSL• The preset temperature will increase 1°C after theComfort sleep mode has operated for 1 hour andthe temperature will increase another 1°C after thecomfort sleep mode has operated for 2 hour. (Thevalue of the preset temperature on the remote controldoes not change.)• Press the [COMFORT SLEEP] button to choose theoperating hours. Repeat pressing to select the hours.(1hr, 3hr, 5hr or 9hr)• If the [COMFORT SLEEP] button is pressed againmeans cancel comfort sleep mode.7-12-2. Heating mode• The fan speed of indoor unit operates automatically,it relates with the compressor's operation.Compressor’s Operation Fan SpeedON L-OFFSL• The preset temperature will drop down 1°C after thecomfort sleep mode has operated for 1 hour and thetemperature will decrease another 1°C after thecomfort sleep mode has operated for 2 hour. (Thevalue of the preset temperature on the remote control.dose not change.)• Press the [COMFORT SLEEP] button to choose theoperating hours. Repeat pressing to select the hours.(1hr, 3hr, 5hr or 9 hr)• If the [COMFORT SLEEP] button is pressed againmeans cancel comfort sleep mode.- 36 -

8. INSTALLATION PROCEDUREFILE NO. SVM-050208-1. Safety CautionsFor general public usePower supply cord of parts of appliance for Outdoor use shall be at least polychloroprene sheathed flexiblecord (design H07 RN-F), or cord designation 245 IEC66.CAUTIONNew Refrigerant <strong>Air</strong> conditioner Installation• THIS <strong>AIR</strong> <strong>CONDITIONER</strong> USES THE NEW HFC REFRGERANT (R410A), WHICH DOES NOT DESTROYTHE OZONE LAYER.R410A refrigerant is apt to be affected by impurity such as water, oxidizing membranes, and oils because thepressure of R410A refrigerant is approx. 1.6 times of refrigerant R22. As well as the adoption of this newrefrigerant, refrigerating machine oil has also been changed. Therefore, during installation work, be sure thatwater, dust, former refrigerant, or refrigerating machine oil does not enter into the refrigerating cycle of anew-refrigerant air conditioner.To avoid mixing refrigerant and refrigerating machine oil, the sizes of charging port connecting sections onthe main unit are different from those for the conventional refrigerant, and different size tools are alsorequired. Accordingly, special tools are required for the new refrigerant (R410A) as shown below. Forconnecting pipes, use new and clean piping materials with high-pressure withstand capabilities, designed forR410A only, and ensure that water or dust does not enter. Moreover, do not use any existing piping as itspressure withstand may be insufficient, and may contain impurities.CAUTIONTo Disconnect the Appliance from the Main Power SupplyThis appliance must be connected to the main power supply by means of a circuit breaker or a switch with acontact separation of at least 3 mm.If this is not possible, a power supply plug with earth must be used. This plug must be easily accessible afterinstallation. The plug must be disconnected from the power supply socket in order to disconnect theappliance completely from the mains.− 37 −

DANGER− 38 −FILE NO. SVM-05020• FOR USE BY QUALIFIED PERSONS ONLY.• TURN OFF MAIN POWER SUPPLY BEFORE ATTEMPTING ANY ELECTRICAL WORK. MAKE SUREALL POWER SWITCHES ARE OFF. FAILURE TO DO SO MAY CAUSE ELECTRIC SHOCK.• CONNECT THE CONNECTING CABLE CORRECTLY. IF THE CONNECTING CABLE IS CONNECTEDWRONGLY, ELECTRIC PARTS MAY BE DAMAGED.• CHECK THE EARTH WIRE THAT IT IS NOT BROKEN OR DISCONNECTED BEFORE INSTALLATION.• DO NOT INSTALL NEAR CONCENTRATIONS OF COMBUSTIBLE GAS OR GAS VAPORS.FAILURE TO FOLLOW THIS INSTRUCTION CAN RESULT IN FIRE OR EXPLOSION.• TO PREVENT OVERHEATING THE INDOOR UNIT AND CAUSING A FIRE HAZARD, PLACE THE UNITWELL AWAY (MORE THAN 2 M) FROM HEAT SOURCES SUCH AS RADIATORS, HEATORS,FURNACE, STOVES, ETC.• WHEN MOVING THE <strong>AIR</strong>-<strong>CONDITIONER</strong> FOR INSTALLING IT IN ANOTHER PLACE AGAIN, BE VERYCAREFUL NOT TO GET THE SPECIFIED REFRIGERANT (R410A) WITH ANY OTHER GASEOUSBODY INTO THE REFRIGERATION CYCLE. IF <strong>AIR</strong> OR ANY OTHER GAS IS MIXED IN THEREFRIGERANT, THE GAS PRESSURE IN THE REFRIGERATION CYCLE BECOMES ABNORMALLYHIGH AND IT RESULTINGLY CAUSES BURST OF THE PIPE AND INJURIES ON PERSONS.• IN THE EVENT THAT THE REFRIGERANT GAS LEAKS OUT OF THE PIPE DURING THEINSTALLATION WORK, IMMEDIATELY LET FRESH <strong>AIR</strong> INTO THE ROOM. IF THE REFRIGERANT GASIS HEATED BY FIRE OR SOMETHING ELSE, IT CAUSES GENERATION OF POISONOUS GAS.WARNING• Never modify this unit by removing any of the safety guards or bypassing any of the safety interlockswitches.• Do not install in a place which cannot bear the weight of the unit.Personal injury and property damage can result if the unit falls.• Before doing the electrical work, attach an approved plug to the power supply cord.Also, make sure the equipment is properly earthed.• Appliance shall be installed in accordance with national wiring regulations.If you detect any damage, do not install the unit. Contact your TOSHIBA dealer immediately.CAUTION• Exposure of unit to water or other moisture before installation could result in electric shock.Do not store it in a wet basement or expose to rain or water.• After unpacking the unit, examine it carefully for possible damage.• Do not install in a place that can increase the vibration of the unit. Do not install in a place that can amplifythe noise level of the unit or where noise and discharged air might disturb neighbors.• To avoid personal injury, be careful when handling parts with sharp edges.• Please read this installation manual carefully before installing the unit. It contains further important instructionsfor proper installation.REQUIREMENT OF REPORT TO THE LOCAL POWER SUPPLIERPlease make absolutely sure that the installation of this appliance is reported to the local power supplierbefore installation. If you experience any problems, or if the installation is not accepted by the supplier, theservice agency will take adequate countermeasures.Remark per EMC Directive 89/336/EECTo prevent flicker impressions during the start of the compressor (technical process) following installationconditions do apply.1. The power connection for the air conditioner has to be done at the main power distribution. This distributionhas to be of an impedance.Normally the required impedance is reached at a 32A fusing point. <strong>Air</strong> conditioner fuse has to be 16A max.!2. No other equipment should be connected to this power line.3. For detailed installation acceptance, please contact your power supplier whether its restriction does applyfor products like washing machines, air conditioners or electrical ovens.4. For power details of the air conditioner, refer to the rating plate of the product.

8-2. Installation Diagram of Indoor and Outdoor UnitsFILE NO. SVM-05020Before installing thewireless remote control• With the remote control coveropen, load the batteries suppliedcorrectly, observing theirpolarity.170 mmor more65 mm or moreHook1 InstallationplateFor the rear left and leftpipingWall2 Wireless remote controlCover3 Batteries<strong>Air</strong> filterHook170 mmor moreInsert the cushion betweenthe indoor unit and wall,and tilt the indoor unit forbetter operation.(Attach to the front panel)ShieldpipeDo not allow the drain hoseto get slack.5Sasa Zeolite Plus filter6 Bio-enzyme & Gingko filter8 Pan head wood screwCut the piping holesloped slightly2 Wireless remotecontrolMake sure to run the drainhose sloped downward.13 series 07,10 seriesA 600 mm 400 mmB 100 mm 45 mm4 Remote control holderThe auxiliary piping can beconnected the left, rear left,rear right, right, bottom rightor bottom left.Right600 mm or moreB mm or moreVinyl tapeApply aftercarrying out adrainage test.SaddleRear rightRear leftBottom rightLeftBottom left100 mm or moreA mm or more600 mm or moreExtensiondrain hose(Not available,provided byinstallerInsulate the refrigerantpipes separately withinsulation, not together.6 mm thick heat resistingpolyethylene foam− 39 −

8-3. Installation8-3-1. Optional installation partsFILE NO. SVM-05020PartCodeABCParts nameRefrigerant pipingLiquid side : ∅6.35 mmGas side : ∅9.52 mm (07, 10 series)Gas side : ∅12.70 mm (13 series)Pipe insulating material(polyethylene foam, 6 mm thick)Putty, PVC tapesQ'tyOneeach1OneeachRAS-10, 13 SeriesRAS-07 Series115 mm32.5 mm30125 mm<strong>Air</strong> inlet500 mm<strong>Air</strong> inlet97 mm310 mm7 mm73 mm102 mm275 mm60 mm<strong>Air</strong> outlet600 mm90 mmDrain outlet<strong>Air</strong> outletDrain outletFig. 8-3-1• Secure the outdoor unit with fixing bolts and nuts if the unit is likely to be exposed to a strong wind.• Use ∅8 mm or ∅10 mm anchor bolts and nuts.• If it is necessary to drain the defrost water, attach 9 drain nipple and 10 cap water proof to thebottom plate of the outdoor unit before installing it.− 40−

FILE NO. SVM-050208-3-2. Accessory and installation partsPartNo.Part name (Q'ty)PartNo.Part name (Q'ty)PartNo.Part name (Q'ty)147Installation plate x 1Remote control holder x 1Mounting screw ∅4 x 25 s x 62Wireless remote control x 15Sasa Zeolite Plus filter x 18Pan head wood screw∅3.1 x 16 s x 2369Battery x 2Bio-enzyme & Gingko filter x 1Drain nipple* x 1 (For Heat pump model only)OthersNameOwner’s manualInstallation manual!Cap water proof* x 2(For Heat pump model only)The part marked with asterisk (*) is packaged with theoutdoor unit.− 41 −

8-3-3. Installation/Servicing toolsFILE NO. SVM-05020In the case of an air conditioner using R410A, in order to prevent any other refrigerant from being chargedaccidentally, the service port diameter of the outdoor unit control valve (3 way valve) has been changed. (1/2UNF 20 threads per inch)• In order to increase the pressure withstand strength of the refrigerant piping, flare processing diameter andsize of opposite side of flare nuts have been changed. (for copper pipes with nominal dimensions 1/2 and 5/8)New tools for R410A Applicable to R22 model ChangesGauge manifoldCharge hoseElectronic balancefor refrigerant chargingTorque wrench(nominal dia. 1/2, 5/8)Flare tool(clutch type)Gauge for projectionadjustmentVacuum pump adapterGas leakage detectorAs pressure is high, it is impossible to measure bymeans of conventional gauge. In order to preventany other refrigerant from being charged, eachport diameter has been changed.In order to increase pressure withstand strength,hose materials and port size have been changed(to 1/2 UNF 20 threads per inch).When purchasing a charge hose, be sure toconfirm the port size.As pressure is high and gasification speed is fast,it is difficult to read the indicated value by meansof a charging cylinder, as air bubbles occur.The size of opposing flare nuts has been increased.Incidentally, a common wrench is used for nominaldiameters 1/4 and 3/8.By increasing the clamp bar's receiving hole,strength of spring in the tool has been improved.Used when flare is made with a conventional flaretool.Connected to conventional vacuum pump. It isnecessary to use an adapter to prevent vacuumpump oil from flowing back to the charge hose.The charge hose connecting part has two ports:one for conventional refrigerant (7/16 UNF 20threads per inch) and one for R410A. If thevacuum pump mineral oil mixes with R410A,a sludge may occur and damage the equipment.Exclusive for HFC refrigerant.• Incidentally, the "refrigerant cylinder" comes with the refrigerant designation (R410A) and protector coating inthe U. S ARI specified rose color (ARI color code: PMS 507).• Also, the "charge port and packing for refrigerant cylinder" require 1/2 UNF 20 threads per inchcorresponding to the port size of the charge hose.– 42 –

FILE NO. SVM-050208-4. Indoor Unit8-4-1. Installation place• A place which provides the spaces around theindoor unit as shown in the above diagram.• A place where there is no obstacle near the air inletand outlet.• A place that allows easy installation of the piping tothe outdoor unit.• A place which allows the front panel to be opened.8-4-2. Cutting a hole and mounting installationplateWhen installing the refrigerant pipes from the rear.CAUTION• Direct sunlight to the indoor unit's wirelessreceiver should be avoided.• The microprocessor in the indoor unit should notbe too close to RF noise sources.(For details, see the owner's manual.)The center of the pipehole is above the arrow.Fig. 8-4-2100 mmPipehole∅65 mm• A place where there are no obstacles such as acurtain that may block the signal from the indoorunit.• Do not install the remote control in a place exposedto direct sunlight or close to a heating source, suchas a stove.• Keep the remote control at least 1 m apart from thenearest TV set or stereo equipment. (This isnecessary to prevent image disturbances or noiseinterference.)• The location of the remote control should bedetermined as shown below.1. After determining the pipe hole position on themounting plate (A), drill the pipe hole (∅65 mm) ata slight downward slant to the outdoor side.NOTE• When drilling a wall that contains a metal lath, wirelath or metal plate, be sure to use a pipe hole brimring sold separately.For installation of the indoor unit, use the paper patternon the back.Indoor unit75°(Side view)7 m(Top view)Indoor unit5 m45°45°5 m* 7 m17085Hook6282.5ReceptionrangeRemotecontrolReceptionrange* : Axial distanceRemote controlPipe holeHookThreadHookPipe hole1InstallationplateFig. 8-4-1Indoor unitWeight7 Mounting screwFig. 8-4-3− 43 −

FILE NO. SVM-050201. Securely fit the installation plate onto the wall byscrewing it in the upper and lower parts to hook upthe indoor unit.2. To mount the installation plate on a concrete wallwith anchor bolts, utilize the anchor bolt holes asillustrated in the above figure.3. Install the installation plate horizontally in the wall.CAUTIONWhen installing the installation plate with amounting screw, do not use the anchor bolt hole.Otherwise the unit may fall down and result inpersonal injury and property damage.Installation plate5 mm dia. holeClip anchor(local parts)CAUTIONFig. 8-4-4AnchorboltProjection15 mm or less7 Mountingscrew∅4 x 25sFailure to firmly install the unit may result inpersonal injury and property damage if the unit falls.8-4-3. Electrical work1. The supply voltage must be the same as the ratedvoltage of the air conditioner.2. Prepare the power source for exclusive use with theair conditioner.CAUTION• This appliance can be connected to the mains ineither of the following two ways.(1) Connection to fixed wiring:A switch or circuit breaker which disconnectsall poles and has a contact separation of atleast 3 mm must be incorporate in the fixedwiring. An approved circuit breaker orswitches must used.(2) Connection with power supply plug:Attach power supply plug with power cordand plug it into wall outlet. An approvedpower supply cord and plug must be used.NOTE• Ensure all wiring is used within its electrical rating.RAS-13UKHP-ES4 RAS-10UKHP-ES4Model RAS-13UKP-ES4 RAS-10UKP-ES4RAS-07UKP-ES4Power sourceMaximumrunning currentPlug socket &fuse rating50 Hz, 220 − 240 V Single phase12A 7.5A16APower cord 1.3 mm 2 or more 1 mm 2 or more• In case of block, brick, concrete or similar typewalls, make 5 mm dia. holes in the wall.• Insert clip anchors for appropriate 7 mountingscrews.NOTE• Secure four corners and lower parts of theinstallation plate with 4 to 6 mounting screws toinstall it.− 44 −

FILE NO. SVM-05020Wiring of the connecting cable can be carried outwithout removing the front panel.1. Remove the air inlet grille.Open the air inlet grille upward and pull it towardyou.2. Remove the terminal cover and cord clamp.3. Insert the connecting cable (according to the localcords) into the pipe hole on the wall.4. Take out the connecting cable through the cableslot on the rear panel so that it protrudes about15 cm from the front.5. Insert the connecting cable fully into the terminalblock and secure it tightly with screws.6. Tightening torque : 1.2 N·m (0.12 kgf·m)7. Secure the connecting cable with the cord clamp.8. Fix the terminal cover, rear plate bushing and airinlet grille on the indoor unit.For RAS-13/10/07UKConnectingcableabout 15 cmScrewTerminalcoverScrewFig. 8-4-760 mm10 mmCord clampScrew1 2Earth lineTerminal block1 2Earth lineConnecting cableCAUTION• Be sure to refer to the wiring system diagramlabeled inside the front panel.• Check local electrical cords and also any specificwiring instructions or limitations.For RAS-13/10UKHConnectingcableabout 15 cmTerminalcoverScrewCord clamp1 2 34 1 2 3Terminal block4Earth line10 mm50 mmStripping length of the connecting cableFig. 8-4-8NOTE• Use stranded wire only.• Wire type : H07 RN-F or more• When attaching the air inlet grille, the contrary ofthe removed operation is performed.ScrewScrewFig. 8-4-5Connecting cable10 mm80 mm70 mmEarth lineFig. 8-4-910 mm10 mm50 mmStripping length of the connecting cableFig. 8-4-6− 45−

FILE NO. SVM-050208-4-4. Piping and drain hose installation* Since dewing results in a machine trouble, makesure to insulate both the connecting pipes. (Usepolyethylene foam as insulating material.)Rear rightRear leftBottom leftLeftBottom rightRightDie-cuttingFront panel slitChangingdrain hose1. Die-cutting Front panel slitFor leftward connection, cut out slit on the left side ofthe front panel. (A knife will produce splinters, so usenippers.)2. Changing drain hoseFor leftward connection, bottom leftward connectionand rear leftward connection’s piping, it is necessary tochange the drain hose and drain cap.How to remove the drains capClip drain cap by needle-nose plier, and pull out.Piping preparationHow to fix the drains cap1) Insert hexagonal wrench (4 mm) in a centerhead.4 mmFig. 8-4-122) Firmly insert drains cap.No gapCAUTIONInsert a hexagonwrench (4 mm)Fig. 8-4-13Firmly insert the drain hose and drain cap; otherwise,water may leak.Do not apply lubricating oil(refrigerant machine oil) wheninserting the drain cap.Application causes deteriorationand drain leakage of the plug.• After scribing slits of the front panel with a knife or amaking-off pin, cut them with a pair of nippers or anequivalent tool.Fig. 8-4-10How to install the drain hoseFirmly insert drain hose connecting part until hitting ona heat insulator.SlitFig. 8-4-14Heat insulatorDrain hose• After scribing slits of the front panel with a knife or amaking-off pin, cut them with a pair of nippers or anequivalent tool.Fig. 8-4-11SlitFig. 8-4-15− 46 −

FILE NO. SVM-05020Bend the connecting pipe so that it is laid within 43 mmabove the wall surface. If the connecting pipe is laidexceeding 43 mm above the wall surface, the indoorunit may unstably be set on the wall. When bending theconnecting pipe, make sure to use a spring bender soas not to crush the pipe.Bend the connection pipe within a radius of 30 mm.To connect the pipe after installation of the unit (figure)8-4-5. Indoor unit fixing1. Pass the pipe through the hole in the wall, and hookthe indoor unit on the installation plate at the upperhooks.2. Swing the indoor unit to right and left to confirm thatit is firmly hooked up on the installation plate.3. While pressing the indoor unit onto the wall, hook itat the lower part on the installation plate. Pull theindoor unit toward you to confirm that it is firmlyhooked up on the installation plate.270 mm170 mmGas side(To the forefront of flare)Liquid side1Hook here1 Installationplate43 mmOutward form of indoor unitR 30 mm (Use polisin (polyethylene)core or the like for bending pipe.)2HookFig. 8-4-17Press(unhook)80Use the handle of screwdriver, etc.Fig. 8-4-16• For detaching the indoor unit from the installationplate, pull the indoor unit toward you while pushingits bottom up at the specified parts.NOTEIf the pipe is bent incorrectly, the indoor unit mayunstably be set on the wall.After passing the connecting pipe through the pipehole, connect the connecting pipe to the auxiliary pipesand wrap the facing tape around them.PushPushCAUTION• Bind the auxiliary pipes (two) and connectingcable with facing tape tightly. In case of leftwardpiping and rear-leftward piping, bind the auxiliarypipes (two) only with facing tape.Fig. 8-4-18Indoor unitAuxiliary pipesConnecting cableInstallation plate• Carefully arrange pipes so that any pipe does notstick out of the rear plate of the indoor unit.• Carefully connect the auxiliary pipes andconnecting pipes to each other and cut off theinsulating tape wound on the connecting pipe toavoid double-taping at the joint, moreover, sealthe joint with the vinyl tape, etc.• Since dewing results in a machine trouble, makesure to insulate both the connecting pipes. (Usepolyethylene foam as insulating material.)• When bending a pipe, carefully do it, not to crush it.− 47 −

FILE NO. SVM-050208-4-6. Drainage1. Run the drain hose sloped downwards.NOTE• Hole should be made at a slight downward slant onthe outdoor side.50 mmor moreDo not rise thedrain hose.Fig. 8-4-192. Put water in the drain pan and make sure that thewater is drained out of doors.3. When connecting extension drain hose, insulate theconnecting part of extension drain hose with shieldpipe.Drain hoseCAUTIONDo not putthe drainhose endinto water.Shield pipeInside the roomFig. 8-4-20Do not form thedrain hose intoa wavy shape.Do not putthe drainhose end inthe drainageditch.Extension drain hoseArrange the drain pipe for proper drainage from theunit.Improper drainage can result in dew-dropping.This air conditioner has the structure designed to drainwater collected from dew, which forms on the back ofthe indoor unit, to the drain pan.Therefore, do not store the power cord and other partsat a height above the drain guide.8-5. Outdoor Unit8-5-1. Installation place• A place which provides the spaces around theoutdoor unit as shown in the left diagram.• A place which can bear the weight of the outdoorunit and does not allow an increase in noise leveland vibration.• A place where the operation noise and dischargedair do not disturb your neighbors.• A place which is not exposed to a strong wind.• A place free of a leakage of combustible gases.• A place which does not block a passage.• When the outdoor unit is to be installed in anelevated position, be sure to secure its feet.• An allowable length of the connecting pipe is up to10 m (RAS-10UA) or 15 m (RAS-13UA).• An allowable height level is up to 5 m (RAS-10,07UA)or 6 m (RAS-13UA).• A place where the drain water does not raise anyproblem.CAUTION1. Install the outdoor unit without anything blockingthe air discharging.2. When the outdoor unit is installed in a placeexposed always exposed to strong wind like acoast or on a high storey of a building, securethe normal fan operation using a duct or a windshield.3. In particularly windy areas, install the unit suchas to avoid admission of wind.4. Installation in the following places may result introuble.Do not install the unit in such places.• A place full of machine oil.• A saline-place such as the coast.• A place full of sulfide gas.• A place where high-frequency waves are likelyto be generated as from audio equipment,welders, and medical equipment.WallDrain guideStrongwindSpace for pipesFig. 8-5-1Fig. 8-4-21− 48 −

FILE NO. SVM-050208-5-2. Refrigerant piping connection1. Cut the pipe with a pipe cutter.90°DieObliquityFig. 8-5-2PipeARoughness2. Insert a flare nut into the pipe, and flare the pipe.• Projection margin in flaring : A (Unit : mm)WarpOuter dia.of copper pipe(Unit : N·m)Tightening torque∅6.35 16 to 18 (1.6 to 1.8 kgf·m)∅9.52 30 to 42 (3.0 to 4.2 kgf·m)∅12.70 50 to 62 (5.0 to 6.2 kgf·m)• Tightening torque of flare pipe connectionsThe operating pressure of R410A is higher than that ofR22. (Approx. 1.6 times). It is therefore necessary tofirmly tighten the flare pipe connecting sections (whichconnect the indoor and outdoor units) up to thespecified tightening torque. Incorrect connections maycause not only a gas leakage, but also damage to therefrigerant cycle.Flare at indoor unit sideFig. 8-5-3Rigid (Clutch type)Outer dia. R410A Conventionalof copper pipe tool used tool used6.35 0 to 0.5 1.0 to 1.59.52 0 to 0.5 1.0 to 1.512.70 0 to 0.5 1.0 to 1.5Fig. 8-5-4Flare at outdoor unit sideImperial (wing nut type, conventional tool)Outer dia.of copper pipeR410A6.35 1.5 to 2.09.52 1.5 to 2.012.70 2.0 to 2.5Fig. 8-5-5Mark lineAlign the centers of the connecting pipes and tightenthe flare nut as far as possible with your fingers. Thentighten the nut with a spanner and torque wrench asshown in the figure.Externallythreaded sideHalf unionFlare nutInternallythreaded sideCAUTION• Do not apply excess torque.• Otherwise, the nut may crack depending on theconditions.Use a wrench to secure.CAUTIONUse a torque wrench to tighten.Fig. 8-5-6• KEEP IMPORTANT 4 POINTS FOR PIPING WORK(1) Take away dust and moisture (Inside of theconnecting pipes.)(2) Tight connection (between pipes and unit)(3) Evacuate the air in the connecting pipes usingVACUUM PUMP.(4) Check gas leak (connected points)− 49 −

8-5-3. EvacuatingAfter the piping has been connected to the indoor unit,you can perform the air purge together at once.<strong>AIR</strong> PURGEEvacuate the air in the connecting pipes and in theindoor unit usinga vacuum pump. Do not use the refrigerant in theoutdoor unit.For details, see the manual of the vacuum pump.Be sure to use a vacuum pump with counter-flowprevention function so that inside oil of the pump doesnot flow backward into pipes of the air conditionerwhen the pump stops. (If oil inside of the vacuum pumpenters into the air conditioner, which use R410A,refrigeration cycle trouble may result.)1. Connect the charge hose from the manifold valve tothe service port of the gas side packed valve.2. Connect the charge hose to the port of the vacuumpump.3. Open fully the low pressure side handle of thegauge manifold valve.4. Operate the vacuum pump to start evacuating.Perform evacuating for about 15 minutes if the pipinglength is 20 meters. (15 minutes for 20 meters)(assuming a pump capacity of 27 liters per minute.)Then confirm that the compound pressure gaugereading is −101 kPa (−76 cmHg).5. Close the low pressure side valve handle of gaugemanifold.6. Open fully the valve stem of the packed valves(both sides of Gas and Liquid).7. Remove the charging hose from the service port.8. Securely tighten the caps on the packed valves.• Open the valve stem all the way out; but do not tryto open it beyond the stopper.• Securely tighten the valve stem cap with torque inthe following table:Gas side(∅12.70 mm)Gas side(∅9.52 mm)Liquid side(∅6.35 mm)Service portFILE NO. SVM-05020Fig. 8-5-850 to 62 N·m(5.0 to 6.2 kgf·m)30 to 42 N·m(3.0 to 4.2 kgf·m)16 to 18 N·m(1.6 to 1.8 kgf·m)9 to 10 N·m(0.9 to 1.0 kgf·m)Hexagonal wrenchis required.4 mmCompound pressure gaugePressure gauge-101kPa (-76cmHg)Handle LoCharge hose(For R410A only)Connecting pipeManifold valveHandle Hi(Keep full closed)Charge hose(For R410A only)Vacuum pumpadapter forcounter-flowprevention(For R410A only)VacuumpumpPacked valve at gas sideService port(Valve core (Setting pin))Packed valve at liquid sideFig. 8-5-7− 50 −

FILE NO. SVM-050208-5-4. Wiring connection1. Remove the valve cover from the outdoor unit.2. Connect the connecting cable to the terminal asidentified with their respective matched numbers onthe terminal block of indoor and outdoor unit.3. When connecting the connecting cable to theoutdoor unit terminal, make a loop as shown in theinstallation diagram of indoor and outdoor unit, toprevent water coming in the outdoor unit.4. Insulate the unused cords (conductors) from anywater coming in the outdoor unit. Proceed them sothat they do not touch any electrical or metal parts.For RAS-13/10UAH10 mm10 mm70 mmEarth line60 mmTerminal blockTerminalscrewConnectingcableFig. 8-5-9ScrewEarthlineCord clamp8-6. How to Set Remote Control SelectorSwitchWhen two indoor units ae installed in seperated rooms,there is no need to change the selector switch.• When two indoor units are installed in the sameroom or the adjacent two rooms, they may becontrolled simultaneously with a single remotecontrol. To prevent this, set either unit and itsremote control to B setting. (Both units are set to Asetting before shipment.)• The remote control signal is not recived when theindoor unit setting is different from the remotecontrol one.1. Set the remote control selector switch with theindoor unit.1) Turn the circuit breaker of the main power switch offbefore setting the selector switch.2) Remove the <strong>Air</strong> inlet grille and Front panel. (Refer topage 63, 10-1)3) Select the terminal of selector switch from[A position] to [B position].For RAS-13/10/07UATerminal block10 mm60 mmEarth lineTerminalscrewScrewEarthline10 mm50 mmConnectingcableCord clampSelector SwitchFig. 8-5-10CAUTION• Wrong wiring connection may cause someelectrical parts burn out.• Be sure to comply with local codes on runningthe wire from indoor unit to outdoor unit (size ofwire and wiring method etc.)• Every wire must be connected firmly.LED AssemblyFig. 8-6-1NOTE• Wire type: H07 RN-F or 245 IEC66 (2.0 mm 2 ormore)− 51 −

FILE NO. SVM-050202. Set the remote control selector switch with theremote control8-7. Others8-7-1. Gas leak test[B] is indicated on the liquid crystal display whensetting remote control selector switch to B. [A] isnot indicated on the display even if the selectorswitch is set to A.Valve cover1) Load the remote control with the batteries.2) Press the [CHECK] button using something withsharp point. (The preset temperature on the remotecontrol changes to [00].)3) Press the [MODE] button while pressing the[CHECK] button, [B] is indicted at the right of thepresent temperature display.• To reset the switch to the [A] setting, press the[MODE] button again while pressing the [CHECK]button.Service capconnectionValve stem capconnectionFig. 8-7-1• Check the flare nut connections, valve stem capconnections and service port cap connections forgas leak with a leak detector or soap water.8-7-2. Test operationTo switch the TEST RUN (COOL) mode, pressTEMPORARY button for 10 sec.(The beeper will make a short beep.)[MODE] buttonTEMPORARY buttonFig. 8-7-2[CHK] buttonFig. 8-6-23. Confirm that the indoor unit can operate withthe new setting.8-7-3. Auto restart settingThis product is designed so that, after a power failure,it can restart automatically in the same operating modeas before the power failure.InformationThe product was shipped with Auto Restart functionin the off position. Turn it on as required.• Press and hold the TEMPORARY button for about3 seconds. After 3 seconds, the electronic beepermakes three short beeps to tell you the AutoRestart has been selected.• To cancel the Auto Restart, follow the stepsdescribed in the section Auto Restart Function ofthe Owner’s Manual.− 52 −