Specification for Electrical works – 2009 (in PDF format,Size: 6.4MB)

Specification for Electrical works – 2009 (in PDF format,Size: 6.4MB)

Specification for Electrical works – 2009 (in PDF format,Size: 6.4MB)

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

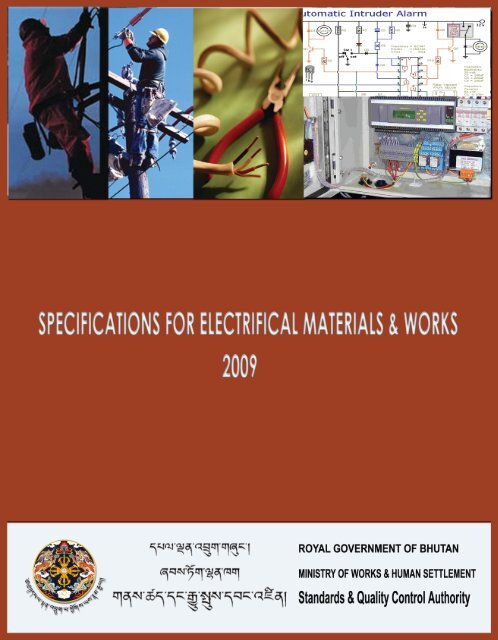

MINISTRY OF WORKS AND HUMAN SETTLEMENTSTANDARDS AND QUALITY CONTROL AUTHORITYSPECIFICATIONS FOR ELECTRICAL MATERIALS AND WORKS<strong>2009</strong>

DisclaimerThe BSR (both Civil and <strong>Electrical</strong>)‐ <strong>2009</strong> is prepared and published primarily as a toolto assist <strong>in</strong> the estimation of project costs. Due to difficulty <strong>in</strong> obta<strong>in</strong><strong>in</strong>gcomprehensive and accurate rates from base towns, and the associated complexity <strong>in</strong>their analysis, the BSR reflects only suggestive averages and not accurate currentmarket rates. Material and labour rates also fluctuate frequently, and by the time ofthe publication of this book, many rates would have already changed. Hence users areadvised to refra<strong>in</strong> from us<strong>in</strong>g the BSR <strong>for</strong> the purposes of fill<strong>in</strong>g tenders, evaluat<strong>in</strong>gtenders, award<strong>in</strong>g <strong>works</strong> and/or mak<strong>in</strong>g contractual payments. The publisher is <strong>in</strong> noway accountable or answerable <strong>for</strong> any issues/disputes aris<strong>in</strong>g as a result of<strong>in</strong>dividuals or agencies us<strong>in</strong>g the rates <strong>in</strong> the BSR‐<strong>2009</strong> as a basis <strong>for</strong> fill<strong>in</strong>g theirtenders, evaluat<strong>in</strong>g tenders, award<strong>in</strong>g <strong>works</strong> and/or mak<strong>in</strong>g contractual payments.©All rights reserved with SQCA, MoWHS. Reproduction <strong>for</strong> sale of this publication, <strong>in</strong> part(s) orwhole, <strong>in</strong> any <strong>for</strong>m or by any means, by any agency or <strong>in</strong>dividual, is a punishable offence and isstrictly prohibited.

[Year]<strong>Specification</strong>s <strong>for</strong> <strong>Electrical</strong> Materials and Works <strong>2009</strong>Table of Contents1‐ ABBREVIATIONS............................................................................................................................ 52‐ DEFINITIONS ................................................................................................................................. 63‐ GENERAL ......................................................................................................................................... 103.1.1 Draw<strong>in</strong>gs .......................................................................................................................... 103.1.2 Materials .......................................................................................................................... 103.1.3 Workmanship ................................................................................................................... 103.1.4 Rat<strong>in</strong>gs of electrical components ..................................................................................... 113.1.5 Structural alteration to build<strong>in</strong>gs ..................................................................................... 113.1.6 Work <strong>in</strong> occupied build<strong>in</strong>gs .............................................................................................. 113.1.7 Test<strong>in</strong>g and commission<strong>in</strong>g on completion ..................................................................... 113.1.8 Additional load to an exist<strong>in</strong>g Installation ....................................................................... 113.1.9 Connection to ancillary build<strong>in</strong>gs ..................................................................................... 124‐ WIRING SYSTEM ............................................................................................................................. 134.1 PVC Cas<strong>in</strong>g and Capp<strong>in</strong>g ...................................................................................................... 134.1.1 Fix<strong>in</strong>g cas<strong>in</strong>g‐capp<strong>in</strong>g ................................................................................................... 134.1.2 Provid<strong>in</strong>g earth cont<strong>in</strong>uity wires .................................................................................. 144.1.3 <strong>Size</strong> and Measurement ................................................................................................. 144.2 Conduit Wir<strong>in</strong>g ..................................................................................................................... 164.2.1 PVC Conduits/HDPE Pipes ................................................................................................ 194.2.1.1 Surface ...................................................................................................................... 194.2.1.2 Concealed .................................................................................................................. 194.2.1.3 Provid<strong>in</strong>g Earth Cont<strong>in</strong>uity Wires .............................................................................. 204.2.1.4 PVC conduit size ........................................................................................................ 204.2.2 MS Conduits ..................................................................................................................... 204.2.2.1 Surface ...................................................................................................................... 204.2.2.2 Concealed .................................................................................................................. 214.2.2.3 Provid<strong>in</strong>g Earth Cont<strong>in</strong>uity Wires .............................................................................. 214.2.2.4 Conduit size and Measurement ................................................................................ 214.2.3 Steel Conduits ................................................................................................................. 224.2.3.1 Surface ...................................................................................................................... 224.2.3.2 Provid<strong>in</strong>g Earth Cont<strong>in</strong>uity Wires .............................................................................. 224.2.3.3 Conduit size and measurement ................................................................................ 225‐ INTERNAL WIRING PRACTICES ....................................................................................................... 235.1 Circuit wir<strong>in</strong>g ........................................................................................................................ 235.2 Sub‐ma<strong>in</strong> wir<strong>in</strong>g ................................................................................................................... 235.3 Power distribution ma<strong>in</strong>s wir<strong>in</strong>g ......................................................................................... 235.4 System of wir<strong>in</strong>g and loads .................................................................................................. 235.5 Jo<strong>in</strong>ts & loop<strong>in</strong>g back ........................................................................................................... 245.6 Pass<strong>in</strong>g through wall ............................................................................................................ 245.7 Pass<strong>in</strong>g through floor ........................................................................................................... 245.8 Bunch<strong>in</strong>g of Cables .............................................................................................................. 246‐ POINT WIRING ................................................................................................................................ 256.1 Measurement of po<strong>in</strong>t wir<strong>in</strong>g .............................................................................................. 25Standards & Quality Control Authority, MoWHS Page 1

[Year]<strong>Specification</strong>s <strong>for</strong> <strong>Electrical</strong> Materials and Works <strong>2009</strong>7‐ BOXES (SURFACE/RECESSED) ......................................................................................................... 267.1 Wooden, PVC and Steel boxes ............................................................................................ 267.2 MS Boxes ............................................................................................................................. 268‐ FITTINGS, ACCESSORIES AND APPLIANCES .................................................................................... 278.1 Fitt<strong>in</strong>gs ................................................................................................................................. 278.2 Lamps ................................................................................................................................... 278.3 Lum<strong>in</strong>aries ........................................................................................................................... 308.3.1 Indoor Lum<strong>in</strong>aries ................................................................................................................. 308.3.1.1 Home light<strong>in</strong>g Lum<strong>in</strong>aries ......................................................................................... 308.3.1.2 Lum<strong>in</strong>aries <strong>for</strong> Commercial areas ............................................................................. 308.3.1.3 Lum<strong>in</strong>aries <strong>for</strong> decorative and accent light<strong>in</strong>g ......................................................... 318.3.1.4 Lum<strong>in</strong>aries <strong>for</strong> Industries uses .................................................................................. 328.3.1.5 Bulkhead lum<strong>in</strong>aries ................................................................................................. 328.3.1.6 Indoor <strong>in</strong>dustrial well glass lum<strong>in</strong>aries ..................................................................... 328.3.1.7 Lum<strong>in</strong>aries <strong>for</strong> hazardous areas ............................................................................... 338.3.2 Outdoor Lum<strong>in</strong>aries ......................................................................................................... 338.3.2.1 Public light<strong>in</strong>g lum<strong>in</strong>aries.......................................................................................... 338.3.2.2 Lum<strong>in</strong>aries <strong>for</strong> Environment light<strong>in</strong>g ........................................................................ 348.3.2.3 Floodlight<strong>in</strong>g Lum<strong>in</strong>aries .......................................................................................... 348.4 Accessories .............................................................................................................................. 348.4.1 Switches ........................................................................................................................... 348.4.2 Lamp Holders ................................................................................................................... 358.4.3 Ceil<strong>in</strong>g Rose ...................................................................................................................... 358.4.4 Socket Outlets .................................................................................................................. 358.4.5 Socket outlet <strong>for</strong> call bell ................................................................................................. 368.4.6 Socket outlet <strong>for</strong> telephone ............................................................................................. 368.4.7 Attachment of fitt<strong>in</strong>gs and accessories ........................................................................... 368.5.1 Ceil<strong>in</strong>g Fans ...................................................................................................................... 378.5.2 Exhaust Fans ..................................................................................................................... 398.5.3 Fan Regulators ................................................................................................................. 398.5.4 Immersion Water Heater and Geyser .............................................................................. 398.5.5 Electric Stove .................................................................................................................... 408.5.6 Room Heater .................................................................................................................... 408.5.7 Air Cooler and Refrigerator .............................................................................................. 408.5.8 Electric iron, rice/curry cooker and water boiler vacuum cleaner, drier, iron, mixture 419‐ CABLES ............................................................................................................................................ 429.1 Cable Types and Classification ............................................................................................. 429.2 Cable <strong>Size</strong> Selection ............................................................................................................. 439.3 Cable Storage and Handl<strong>in</strong>g ................................................................................................ 439.4 Cable Installation ................................................................................................................. 449.5 Cable Lay<strong>in</strong>g ......................................................................................................................... 449.5.1 Directly buried .................................................................................................................. 449.5.2 Lay<strong>in</strong>g <strong>in</strong> pipe ................................................................................................................... 459.5.3 Lay<strong>in</strong>g <strong>in</strong> closed duct or trench ........................................................................................ 459.5.4 Lay<strong>in</strong>g on surface or open duct ........................................................................................ 459.6 Cable Term<strong>in</strong>ation & Jo<strong>in</strong>t<strong>in</strong>g .............................................................................................. 4510‐ CONTROL GEARS .......................................................................................................................... 48Standards & Quality Control Authority, MoWHS Page 2

[Year]<strong>Specification</strong>s <strong>for</strong> <strong>Electrical</strong> Materials and Works <strong>2009</strong>10.1 Ma<strong>in</strong> Switchgears, Switchboard and their Location ........................................................ 4810.2 Types of Switchboards ..................................................................................................... 4910.2.1 H<strong>in</strong>ged Type Metal Boards .............................................................................................. 4910.2.2 Fixed Type Metal Boards ................................................................................................. 4910.3 Mark<strong>in</strong>g of Apparatus ...................................................................................................... 5010.4 Ma<strong>in</strong> and Branch Distribution Boards and their Location ............................................... 5010.5 Control at Po<strong>in</strong>t of Entry of Supply .................................................................................. 5110.6 Bus‐Bars and Bus‐Bar chambers ...................................................................................... 5210.6.1 Bus Bar Chambers ........................................................................................................... 5210.6.2 Bus Bars ........................................................................................................................... 5210.6.3 Bus‐Bar Supports and Attachments ................................................................................ 5210.6.3.1 Supports .................................................................................................................... 5210.6.3.2 Connections to Bus Bars ........................................................................................... 5310.6.3.3 Clearances ................................................................................................................. 5310.6.4 Bus Bar Mark<strong>in</strong>gs............................................................................................................. 5310.6.4.1 The colours and letters (or symbols) <strong>for</strong> bus bars ..................................................... 5310.6.4.2 Phase sequence and polarity .................................................................................... 5410.7 Arrangement of Bus Bars and Ma<strong>in</strong> Connections ............................................................ 5410.7.1 A.C. System .................................................................................................................. 5410.7.2 D.C. System .................................................................................................................. 5511‐ COMPOUND/STREET LIGHTING WORK ........................................................................................ 5611.1 Outdoor Fitt<strong>in</strong>gs ............................................................................................................... 5611.2 Steel Tubular Poles ........................................................................................................... 5612‐ EARTHING ..................................................................................................................................... 5712.1 Types of Earth Electrodes ................................................................................................ 5712.2 Selection of Earth Electrode ............................................................................................ 5712.3 Arrangement <strong>for</strong> Earthed Electrode ................................................................................ 5712.3.1 Pipe Earth Electrode ..................................................................................................... 5712.3.2 Plate Earth Electrode .................................................................................................... 5712.3.3 Strip or Conductor Electrode ........................................................................................ 6012.4 Method of Install<strong>in</strong>g Water<strong>in</strong>g Arrangement .................................................................. 6012.5 Location <strong>for</strong> Earth Electrode ............................................................................................ 6012.6 Artificial Treatment of Soil ............................................................................................... 6012.7 Number of Earth Electrodes <strong>for</strong> Installation .................................................................... 6112.8 Resistance of Earth .......................................................................................................... 6112.9 <strong>Size</strong> of Earth<strong>in</strong>g Lead ........................................................................................................ 6112.9.1 Ma<strong>in</strong> earth<strong>in</strong>g Lead ...................................................................................................... 6112.9.2 <strong>Size</strong> of Earth Lead <strong>for</strong> Substations/Generat<strong>in</strong>g Stations .............................................. 6112.9.3 <strong>Size</strong> of Earth Cont<strong>in</strong>uity Conductor ............................................................................... 6212.10 Method of Connect<strong>in</strong>g Earth Lead to Earth Electrode .................................................... 6212.11 Protection of Earth<strong>in</strong>g Lead ............................................................................................. 6213‐ PAINTING ...................................................................................................................................... 6313.1 Preparation of the surface ............................................................................................... 6313.2 Application ....................................................................................................................... 6313.3 Scope ................................................................................................................................ 6313.4 Pa<strong>in</strong>t<strong>in</strong>g of Conduit and Accessories ................................................................................ 6314‐ TESTING OF INSTALLATION .......................................................................................................... 64Standards & Quality Control Authority, MoWHS Page 3

[Year]<strong>Specification</strong>s <strong>for</strong> <strong>Electrical</strong> Materials and Works <strong>2009</strong>14.1 Insulation Resistance Test ................................................................................................ 6414.2 Polarity Test of Switch ..................................................................................................... 6514.3 Earth Cont<strong>in</strong>uity Test ....................................................................................................... 6514.4 Measurement of Earth Electrode Resistance .................................................................. 6515‐ PROTECTION OF BUILDING AGAINST LIGHTNING ........................................................................ 6715.1 Pr<strong>in</strong>ciple of Protection ..................................................................................................... 6715.2 Zone of Protection ........................................................................................................... 6715.3 Materials and Dimensions ............................................................................................... 6715.4 Design Considerations ..................................................................................................... 6915.5 Down Conductors ............................................................................................................ 6915.6 Jo<strong>in</strong>ts and Bonds .............................................................................................................. 7015.7 Fasteners .......................................................................................................................... 7015.8 Earth Term<strong>in</strong>ations .......................................................................................................... 7015.9 Earth Electrode ................................................................................................................ 7016‐ SAFETY PROCEDURE ..................................................................................................................... 71Standards & Quality Control Authority, MoWHS Page 4

[Year]<strong>Specification</strong>s <strong>for</strong> <strong>Electrical</strong> Materials and Works <strong>2009</strong>1‐ ABBREVIATIONSThe follow<strong>in</strong>g abbreviations wherever they appear <strong>in</strong> the specifications shall have the mean<strong>in</strong>gor implication hereby assigned to them.A : AmpereA.C : Alternat<strong>in</strong>g CurrentC.I : Cast IronCFLs : Compact Fluorescent LampsDB : Distribution BoardD.C : Direct CurrentELCB : Earth Leakage Circuit BreakerG.I : Galvanized IronGLS : General Light<strong>in</strong>g ServiceHF : High FrequencyHID : High Intensity DischargeHRC : High Ruptur<strong>in</strong>g CapacityHT : High TensionI : CurrentICDB : Iron Clad Distribution BoardKV : Kilo VoltKW : Kilo WattLT : Low TensionMCB : M<strong>in</strong>iature Circuit BreakerMS : Mild SteelPVC : Polyv<strong>in</strong>yl ChlorideR : ResistanceRCCB : Residual Current Circuit BreakerSDB : Sub Distribution BoardSPMCB : S<strong>in</strong>gle Pole M<strong>in</strong>iature Circuit BreakerSPN : S<strong>in</strong>gle Pole & NeutralTPN : Triple Pole & NeutralV : VoltW : WattStandards & Quality Control Authority, MoWHS Page 5

[Year]<strong>Specification</strong>s <strong>for</strong> <strong>Electrical</strong> Materials and Works <strong>2009</strong>2‐ DEFINITIONSThe def<strong>in</strong>itions given below shall be applicable to all sections unless otherwise <strong>in</strong>dicated.2.1 Accent light<strong>in</strong>g: Directional light<strong>in</strong>g to emphasize a particular object or draw attention to apart of the field of view.2.2 Alum<strong>in</strong>ium conductor steel re<strong>in</strong><strong>for</strong>ced: In Alum<strong>in</strong>ium conductor steel re<strong>in</strong><strong>for</strong>cedconductor, alum<strong>in</strong>ium wires surround a core consist<strong>in</strong>g of one or more steel wires.2.3 Arrester: A non‐l<strong>in</strong>ear device to limit the amplitude of voltage on a power l<strong>in</strong>e. The termimplies that the device stops over voltage problems (i.e. light<strong>in</strong>g).2.4 Armour<strong>in</strong>g: : It consists of one or two layers of galvanized steel wire or steel tape, toprotect the cable from mechanical <strong>in</strong>jury while lay<strong>in</strong>g it and dur<strong>in</strong>g the course of handl<strong>in</strong>g2.5 Alternat<strong>in</strong>g current: The term alternat<strong>in</strong>g current refers to a current that reverses atregular recurr<strong>in</strong>g <strong>in</strong>tervals of time and that has alternately positive and negative values.2.6 Arc<strong>in</strong>g contacts (arc<strong>in</strong>g horns): Arc<strong>in</strong>g contacts are the contacts on which the arc is drawnafter the ma<strong>in</strong> contacts of a switch have parted.2.7 Bond<strong>in</strong>g jumper: A bare or <strong>in</strong>sulated conductor used to ensure the required electricalconductivity between metal parts required to be electrically connected. Frequently usedfrom a bond<strong>in</strong>g bush<strong>in</strong>g to the service equipment enclosure to provide a path aroundconcentric knockouts <strong>in</strong> an enclosure wall: also used to bond one raceway to another.2.8 Bus‐Bar: A heavy, rigid conductor used <strong>for</strong> high voltage feeders.2.9 B<strong>in</strong>d<strong>in</strong>g wire: Annealed alum<strong>in</strong>ium wire is used <strong>for</strong> fasten<strong>in</strong>g conductor to p<strong>in</strong> and shackle<strong>in</strong>sulator.2.10 Base: A base of a switch is the ma<strong>in</strong> member to which the conduct<strong>in</strong>g parts or <strong>in</strong>sulatorunit are attached. It may also have parts of the operat<strong>in</strong>g or control mechanism attached.2.11 Cables: A length of one or more than one <strong>in</strong>sulated conductors, which are laid up togetherand surrounded by a protect<strong>in</strong>g cover.2.12 Clear lamps: Clear lamps absorb least amount of light but due to high brightness needshield<strong>in</strong>g from direct view.2.13 Conductor: A substance, which offers low resistance to the passage of electric current.2.14 Cross arms: It provides support to the <strong>in</strong>sulators.Standards & Quality Control Authority, MoWHS Page 6

[Year]<strong>Specification</strong>s <strong>for</strong> <strong>Electrical</strong> Materials and Works <strong>2009</strong>2.15 Conduit: A tubular raceway <strong>for</strong> data or power cables. Metallic conduit is common, althoughnon‐metallic <strong>for</strong>ms may also be used.2.16 Conduit jo<strong>in</strong>ts: S<strong>in</strong>ce the conduits are available <strong>in</strong> smaller lengths, so to obta<strong>in</strong> acont<strong>in</strong>uous length of the conduit the two are coupled together by means of coupl<strong>in</strong>g.2.17 Decorative light<strong>in</strong>g: Decorative light<strong>in</strong>g is determ<strong>in</strong>ed by the aesthetic and architecturalconsiderations, utility light<strong>in</strong>g is primarily on economic considerations.2.18 Earthl<strong>in</strong>g: Earthl<strong>in</strong>g or ground<strong>in</strong>g is the term used <strong>for</strong> electrical connection to general massof earth.2.19 Earth Ground: A low impedance path to earth <strong>for</strong> the purposed of discharg<strong>in</strong>g lightn<strong>in</strong>g,static, and radiated energy, and to ma<strong>in</strong>ta<strong>in</strong> the ma<strong>in</strong> service entrance at earth potential.2.20 Earth wire: A conductor connected to earth and usually situated <strong>in</strong> proximity to theassociated live conductors.2.21 Earth electrode: A metal plate or pipe, which is electrically connected to the general massof earth.2.22 Flexible cable: A cable conta<strong>in</strong><strong>in</strong>g one or more cores, each <strong>for</strong>med of a group of wires, thediameter of the wires be<strong>in</strong>g sufficiently small to af<strong>for</strong>d flexibility.2.23 Flood light<strong>in</strong>g: It is the term used <strong>for</strong> light<strong>in</strong>g of construction projects, park<strong>in</strong>g areas,recreation and sports ground, etc.2.24 Fixture: The assembly that houses a lamp or lamps, and which may <strong>in</strong>clude a hous<strong>in</strong>g, amount<strong>in</strong>g brackets or pole socket, a lamp holder, a ballast, a reflector or mirror, and or arefractor, lens, or diffuser lens.2.25 Fuse: A strip or wire or metal <strong>in</strong>serted <strong>in</strong> series with a circuit which, when it carries anexcess of current over its rated capacity, will burn out.2.26 Fluorescent lamp: The lamp is filled with low‐pressure argon gas and a drop of mercury.2.27 Girder clips: It is used to fix the conduit to the wooden plugs <strong>in</strong> the wall.2.28 Guard wires: Wires which are used at all po<strong>in</strong>ts where a l<strong>in</strong>e crosses a street or road andhave to be earthed at all po<strong>in</strong>ts where their cont<strong>in</strong>uity is broken.2.29 Grounded: Conducted to earth or to some conduct<strong>in</strong>g body that serves <strong>in</strong> place of theearth.2.30 Ground: A conduct<strong>in</strong>g connection, whether <strong>in</strong>tentional or accidental, between an electricalcircuit or equipment and the earth, or to some conduct<strong>in</strong>g body that serves <strong>in</strong> place ofearth.Standards & Quality Control Authority, MoWHS Page 7

[Year]<strong>Specification</strong>s <strong>for</strong> <strong>Electrical</strong> Materials and Works <strong>2009</strong>2.31 High Intensity Discharge Lamps (HID): A general group of lamps consist<strong>in</strong>g of mercury,metal halide, high‐pressure sodium, and low pressure sodium lamps.2.32 Incandescent lamp: The light spectrum of an <strong>in</strong>candescent lamp is cont<strong>in</strong>uous, it conta<strong>in</strong>sall the colours, but conta<strong>in</strong>s relatively excess of red and yellow radiations and less of blueand violet radiations.2.33 Insulator: A device <strong>for</strong> fasten<strong>in</strong>g and support<strong>in</strong>g a conductor. Glass and porcela<strong>in</strong> areemployed almost universally <strong>for</strong> support<strong>in</strong>g overhead wires.2.34 Lamp: The component of lum<strong>in</strong>aries that produces the actual light.2.35 Light<strong>in</strong>g arrester or a surge diverter: It is a protective device, which conducts the highvoltage surges on the power system to the ground.2.36 Lum<strong>in</strong>aries/Lum<strong>in</strong>aries: A complete light<strong>in</strong>g system, <strong>in</strong>clud<strong>in</strong>g a lamp or lamps and afixture.2.37 Mercury vapour lamps: In this lamp, the discharge tube is filled <strong>in</strong> a bulb of hard glassprovided with an <strong>in</strong>ternal mirror reflector.2.38 Megger: A test <strong>in</strong>strument <strong>for</strong> measur<strong>in</strong>g the <strong>in</strong>sulation resistance of conductors and otherelectrical equipment; specifically, a mega‐ohm (million ohms) meter.2.39 Mercury lamps: An electric discharge lamp <strong>in</strong> which the major portion of the radiation isproduced by the excitation of mercury atoms.2.40 Metal halide lamps: A discharge lamp <strong>in</strong> which the light is produced by the radiation fromthe mixture of metallic vapour and the products of disassociation.2.41 Pole: A pole of a switch consists of the parts necessary to control one conductor of acircuit. A switch may be s<strong>in</strong>gle pole or multiple, depend<strong>in</strong>g upon the number of s<strong>in</strong>gle polesthat are operated simultaneously.2.42 Reflector lamps: A reflector lamp is provided with high quality <strong>in</strong>ternal mirror, whichfollows exactly the parabolic shape of the lamp.2.43 Stay wires: Stay wires are required to be earthed with an earth wire unless there are<strong>in</strong>sulated by a stra<strong>in</strong> <strong>in</strong>sulator placed at a height not less than 3m from the ground.2.44 Serv<strong>in</strong>g: The protective material over the metal sheath<strong>in</strong>g or the wire armour of a cable isknown as serv<strong>in</strong>g.2.45 Struts: Struts may be used, where it is not possible to use stay wires due to limitation ofspace.Standards & Quality Control Authority, MoWHS Page 8

[Year]<strong>Specification</strong>s <strong>for</strong> <strong>Electrical</strong> Materials and Works <strong>2009</strong>2.46 Socket outlet: A device carry<strong>in</strong>g three metallic contacts designed <strong>for</strong> engagement withcorrespond<strong>in</strong>g plug p<strong>in</strong>s and arranged <strong>for</strong> connections to fixed wir<strong>in</strong>g.2.47 Sodium lamps: It is a low‐pressure gas discharge lamp, consist<strong>in</strong>g of a U‐shaped glass tube,filled with an <strong>in</strong>ert gas and some sodium, which can be seen <strong>in</strong> the <strong>for</strong>m of solidified dropson the <strong>in</strong>ner wall when the lamp is cold.2.48 Switch: A device of mak<strong>in</strong>g, break<strong>in</strong>g, or chang<strong>in</strong>g the connections <strong>in</strong> an electric current.2.49 Surge: A short duration high voltage condition. A surge lasts <strong>for</strong> several cycles where atransient lasts less than one half cycle.2.50 Switchboard: A large s<strong>in</strong>gle panel, frame or assembly of panels hav<strong>in</strong>g switches, overcurrent,and other protective devices, buses, and usually <strong>in</strong>struments mounted on the faceare not <strong>in</strong>tended to be <strong>in</strong>stalled <strong>in</strong> cab<strong>in</strong>ets.2.51 Thyrite type arrester: Thyrite type arresters <strong>in</strong>corporate non‐l<strong>in</strong>ear resistors and areextensively used on systems operat<strong>in</strong>g at high voltages.Standards & Quality Control Authority, MoWHS Page 9

[Year]<strong>Specification</strong>s <strong>for</strong> <strong>Electrical</strong> Materials and Works <strong>2009</strong>3‐ GENERALThese <strong>Specification</strong>s are drawn to <strong>in</strong>dicate the essential requirements and precautions tobe taken regard<strong>in</strong>g electrical <strong>in</strong>stallation <strong>for</strong> ensur<strong>in</strong>g efficient, safe, economical andpractical use of electrical materials and equipments <strong>in</strong>clud<strong>in</strong>g prevention of fire hazards.The electrical <strong>in</strong>stallation and general safety precautions shall be carried out <strong>in</strong> accordancewith the <strong>Specification</strong>s specified hereunder and shall be <strong>in</strong> con<strong>for</strong>mity with:3.1.1 Draw<strong>in</strong>gs• Build<strong>in</strong>g Code of Bhutan‐ 2003 (Part 2: Build<strong>in</strong>g Services);• Any documents related to electrical <strong>in</strong>stallation, test<strong>in</strong>g and commission<strong>in</strong>gpublished by the Bhutan Electricity Authority, Department of Energy and;• Relevant Indian Standards wherever not covered <strong>in</strong> this specification.The <strong>works</strong> shall be carried out <strong>in</strong> accordance with the draw<strong>in</strong>gs enclosed with the tenderdocuments and also with modifications thereto from time to time as approved by theEng<strong>in</strong>eer‐<strong>in</strong>‐charge.All wir<strong>in</strong>g diagrams shall <strong>in</strong>dicate clearly <strong>in</strong> plan, the ma<strong>in</strong> switchboard, the distributionboards, the runs of various ma<strong>in</strong>s and their classification and controls. All circuits shall be<strong>in</strong>dicated and numbered <strong>in</strong> the wir<strong>in</strong>g diagram and all po<strong>in</strong>ts shall be given the samenumber as the circuit to which they are electrically connected. Distribution boards shallalso be marked to <strong>in</strong>dicate the circuit numbers controlled by them.3.1.2 MaterialsAll materials supplied shall be new and con<strong>for</strong>m<strong>in</strong>g to relevant Standard <strong>Specification</strong>swherever they exist. Materials approved/standardized by the Royal Government from timeto time only shall be used <strong>in</strong> any electrical work unless otherwise stated or directed by theEng<strong>in</strong>eer‐<strong>in</strong>‐charge.3.1.3 WorkmanshipGood workmanship is an essential requirement to be complied with. The entire work shallbe carried out under the direct supervision of a licensed electrician and/or qualifiedsupervisor employed by the contractor who shall rectify then and there, the defectspo<strong>in</strong>ted out by the Eng<strong>in</strong>eer‐<strong>in</strong>‐charge and/or senior officials of the Department dur<strong>in</strong>g theprogress of work.Standards & Quality Control Authority, MoWHS Page 10

[Year]<strong>Specification</strong>s <strong>for</strong> <strong>Electrical</strong> Materials and Works <strong>2009</strong>3.1.4 Rat<strong>in</strong>gs of electrical componentsAll components <strong>in</strong> a wir<strong>in</strong>g <strong>in</strong>stallation shall be of appropriate rat<strong>in</strong>gs of voltage, currentand frequency as required at the respective sections of the electrical <strong>in</strong>stallations <strong>in</strong> whichthey are used.All conductors, switches and accessories shall be of such size as to be capable of carry<strong>in</strong>g,without their respective rat<strong>in</strong>gs be<strong>in</strong>g exceeded, the maximum current that will normallyflow through them.3.1.5 Structural alteration to build<strong>in</strong>gsNo alteration that shall affect the structure of build<strong>in</strong>g shall be done unless sanction of theEng<strong>in</strong>eer‐<strong>in</strong>‐charge has first been obta<strong>in</strong>ed. All chases, ducts, holes etc. required <strong>in</strong>connection with the electrical <strong>works</strong> shall be provided and filled by the contractor at hisown cost to the orig<strong>in</strong>al architectural f<strong>in</strong>ish of the build<strong>in</strong>gs. For new build<strong>in</strong>gs, thesechases, ducts, holes etc. shall be provided when the build<strong>in</strong>g is <strong>in</strong> progress.3.1.6 Work <strong>in</strong> occupied build<strong>in</strong>gsWhen the build<strong>in</strong>g is occupied and major portion of the work is required to be done underthat condition the work shall be carried out <strong>in</strong> such a way that there is m<strong>in</strong>imum<strong>in</strong>convenience to the occupants. In such cases, it may be necessary to work be<strong>for</strong>e andafter office hours as required.3.1.7 Test<strong>in</strong>g and commission<strong>in</strong>g on completionAfter completion of the <strong>works</strong>, and be<strong>for</strong>e hand<strong>in</strong>g it over to the client, it shall be ensuredthat the <strong>in</strong>stallation is tested and commissioned.3.1.8 Additional load to an exist<strong>in</strong>g InstallationAn addition, temporary or permanent, shall not be made to the authorized load of anexist<strong>in</strong>g <strong>in</strong>stallation until it has been def<strong>in</strong>itely ascerta<strong>in</strong>ed that the current carry<strong>in</strong>gcapacity and the condition of the exist<strong>in</strong>g accessories, conductors, switches etc. affectedare adequate <strong>for</strong> the <strong>in</strong>creased load.Standards & Quality Control Authority, MoWHS Page 11

[Year]<strong>Specification</strong>s <strong>for</strong> <strong>Electrical</strong> Materials and Works <strong>2009</strong>3.1.9 Connection to ancillary build<strong>in</strong>gsUnless otherwise specified, electrical connections to ancillary build<strong>in</strong>gs such as out‐house,garages etc., adjacent to the ma<strong>in</strong> build<strong>in</strong>g at a distances not greater than 3 m and whereno road <strong>in</strong>tervenes shall be taken <strong>in</strong> an earthed G.I. pipe of suitable size <strong>in</strong> the exposedportion at a height of not less than 2.5 m. This applies to both runs of ma<strong>in</strong>s or sub ma<strong>in</strong>sor circuit wir<strong>in</strong>g between the build<strong>in</strong>gs. When the distance between the build<strong>in</strong>gs exceed 3m or a road way <strong>in</strong>tervenes, separate ma<strong>in</strong>s shall be run from the ma<strong>in</strong> build<strong>in</strong>g to ancillarybuild<strong>in</strong>g and the portion of the same exposed to weather proof cable on G.I. bearer wire ata height not less than 4 m above the ground. Alternatively PVC <strong>in</strong>sulated wire <strong>in</strong> G.I. pipe orunderground cable may be used below ground level.Standards & Quality Control Authority, MoWHS Page 12

[Year]<strong>Specification</strong>s <strong>for</strong> <strong>Electrical</strong> Materials and Works <strong>2009</strong>4‐ WIRING SYSTEMThe wir<strong>in</strong>g shall be carried out on such a system as may be specified <strong>in</strong> the TenderSchedule. Power and Heat<strong>in</strong>g wir<strong>in</strong>g shall be kept separately and dist<strong>in</strong>ct from Light<strong>in</strong>g andFan wir<strong>in</strong>g. Recessed conduit wir<strong>in</strong>g system may generally be adopted <strong>for</strong> this purpose. Thewir<strong>in</strong>g shall be done on distribution system with ma<strong>in</strong> and branch distribution boards atconvenient physical and electrical centres. All conductors shall run, as far as possible, alongthe walls and ceil<strong>in</strong>g so as to be easily accessible and capable of be<strong>in</strong>g thoroughly<strong>in</strong>spected. In no case, the open wir<strong>in</strong>g shall run above the false ceil<strong>in</strong>g without the approvalof Eng<strong>in</strong>eer. In all types of wir<strong>in</strong>g, due consideration shall be given <strong>for</strong> neatness, goodappearance and safety.4.1 PVC Cas<strong>in</strong>g and Capp<strong>in</strong>g4.1.1 Fix<strong>in</strong>g cas<strong>in</strong>g‐capp<strong>in</strong>gPVC cas<strong>in</strong>g and capp<strong>in</strong>g shall be of standard material free from defects of any k<strong>in</strong>d. Itshould be properly f<strong>in</strong>ished and con<strong>for</strong>m to relevant standards. This system of wir<strong>in</strong>g issuitable <strong>for</strong> low voltage <strong>in</strong>stallation where polyv<strong>in</strong>yl chloride (PVC), rubber, plastic or otherapproved <strong>in</strong>sulated cables shall be used <strong>in</strong> the wir<strong>in</strong>g work carried with<strong>in</strong> PVC cas<strong>in</strong>genclosure. PVC cas<strong>in</strong>g and capp<strong>in</strong>g wir<strong>in</strong>g shall not be used <strong>in</strong> damp or poorly ventilatedplaces without tak<strong>in</strong>g suitable precaution.PVC cas<strong>in</strong>g and capp<strong>in</strong>g should be strong and properly fitted so as to hold wires laid <strong>in</strong> it toits full capacity even under the ceil<strong>in</strong>g. For this reason, the thickness of the PVC cas<strong>in</strong>g andcapp<strong>in</strong>g shall be 1.6mm <strong>for</strong> sizes up to 25mm and 1.5mm or more <strong>for</strong> sizes up to 50mm. Itshould be rigidly screwed at 150mm <strong>in</strong>terval crosswise with suitable wood screws of 25mmlength turned <strong>in</strong> PVC sleeve <strong>in</strong>serted <strong>in</strong> neatly drilled holes of proper size and depth withcup washer to give proper grip over more surface area. Provid<strong>in</strong>g and fix<strong>in</strong>g of PVC cas<strong>in</strong>gand capp<strong>in</strong>g <strong>in</strong>clude bends, elbows, tees, <strong>in</strong>side and outside corners, round blocks andpa<strong>in</strong>t<strong>in</strong>g. It can be run whether <strong>in</strong> horizontal or vertical position as required. As much aspossible, the colour of the cas<strong>in</strong>g and capp<strong>in</strong>g shall match the colour of the surface onwhich it is laid.When wir<strong>in</strong>g is to be carried out <strong>in</strong> places where aesthetic views is of great concern and toharmonize the look with the site condition, special cas<strong>in</strong>g capp<strong>in</strong>g shall be submitted to theEng<strong>in</strong>eer <strong>for</strong> approval prior to lay<strong>in</strong>g out <strong>for</strong> the work. The <strong>in</strong>spection shall be done fromtime to time as the work progresses. Capp<strong>in</strong>g shall not be put on until the work has been<strong>in</strong>spected after the wires are laid <strong>in</strong> position and approved by the Eng<strong>in</strong>eer‐<strong>in</strong>‐charge.Standards & Quality Control Authority, MoWHS Page 13

[Year]<strong>Specification</strong>s <strong>for</strong> <strong>Electrical</strong> Materials and Works <strong>2009</strong>4.1.2 Provid<strong>in</strong>g earth cont<strong>in</strong>uity wiresThe earth cont<strong>in</strong>uity wire shall be provided <strong>in</strong> the cas<strong>in</strong>g throughout the length of wir<strong>in</strong>g.The size of earth cont<strong>in</strong>uity wire shall be not less than 1.5 sq.mm (16SWG) and 2.5sq.mm(14SWG) bare copper wire <strong>for</strong> light and power circuit respectively. All metallic parts,switchboards, light fitt<strong>in</strong>gs and power sockets shall be connected to the earth wires andthe connection shall be electrically and mechanically sound4.1.3 <strong>Size</strong> and MeasurementThe length of the PVC cas<strong>in</strong>g capp<strong>in</strong>g is available from 1.8 to 3m.The unit of measurementshall be <strong>in</strong> metres, measured to the nearest cm. The width, depth and thickness of PVCcas<strong>in</strong>g and capp<strong>in</strong>g shall be as given below:a. 12mm x 12mm x 1.2mm thick d. 32mm x 12mm x 1.5mm thickb. 20mm x 12mm x 1.2mm thick e. 40mm x 12mm x 1.5mm thickc. 25mm x 12mm x 1.2mm thick f. 50mm x 12mm x 1.5mm thickTable 1 gives the dimensions of PVC cas<strong>in</strong>g and capp<strong>in</strong>g and Table 2 shows the maximumnumber of PVC <strong>in</strong>sulated 650/1100 V grade copper/alum<strong>in</strong>ium conductors that can bedrawn <strong>in</strong> a given size of cas<strong>in</strong>g.Width ofcas<strong>in</strong>g orcapp<strong>in</strong>gNo. ofgroovesWidth ofgroovesTable 1: Dimension of PVC cas<strong>in</strong>g and capp<strong>in</strong>gWidthofdivid<strong>in</strong>gfilletThicknessof outerwallThicknessof cas<strong>in</strong>gThicknessofcapp<strong>in</strong>gThicknessat backundergrooveLengthmm mm mm mm mm mm mm mm meter44 2 6 12 10 16 6 651 2 9 13 10 19 10 664 2 13 18 10 19 10 10 2.5 to 376 2 16 24 10 25 10 1089 2 16 35 10 32 13 10102 2 19 38 10 32 13 13Standards & Quality Control Authority, MoWHS Page 14

[Year]<strong>Specification</strong>s <strong>for</strong> <strong>Electrical</strong> Materials and Works <strong>2009</strong>Table 2: No. of P.V.C <strong>in</strong>sulated 650/1100 V grade (Copper or Alum<strong>in</strong>ium) conductor cablethat can be drawn <strong>in</strong> one groove of the cas<strong>in</strong>gNom<strong>in</strong>al crosssectionalarea of conductorsq.mm44 mmX16 mm51 mmX19 mm64 mmX19 mm76 mmX25 mm89 mmX32 mm102 mmX32 mm1.5 2 2 2 9 12 122.5 1 2 2 4 8 94 1 2 2 4 6 96 .. 1 1 4 6 610 .. 1 1 4 4 416 .. .. 1 1 2 225 .. .. .. 1 2 235 .. .. .. .. 1 150 .. .. .. .. .. 170 .. .. .. .. .. 1Standards & Quality Control Authority, MoWHS Page 15

[Year]<strong>Specification</strong>s <strong>for</strong> <strong>Electrical</strong> Materials and Works <strong>2009</strong>4.2 Conduit Wir<strong>in</strong>ga) Type and size of conduitAll conduit pipes shall be of approved gauge (Not less than 16 SWG <strong>for</strong> conduits of sizesupto 32 mm diameter and not less than 14 SWG <strong>for</strong> conduits of size above 32 mmdiameter) solid drawn or reamed by weld<strong>in</strong>g f<strong>in</strong>ished with galvanized or stove enameledsurface. All conduit accessories shall be of threaded type. The maximum number of PVC<strong>in</strong>sulated 650/1100 V grade (copper or alum<strong>in</strong>um) conductor cable that can be drawn <strong>in</strong>one conduit of various sizes shall be as given <strong>in</strong> the Table 3 below, and the number ofcables per conduit shall not be exceeded. No steel conduit less than 19 mm <strong>in</strong> diametershall be used.Table 3: Maximum number of PVC Insulated 650/1100 V Grade alum<strong>in</strong>ium/copperconductor cable that can be drawn <strong>in</strong> one conduit.Nom<strong>in</strong>al Cross 20mm 25mm 32mm 38m 51mm 64mmsectional areaof conductor S B S B S B S B S B S B<strong>in</strong> sq.mm1 2 3 4 5 6 7 8 9 10 11 12 131.5 5 4 10 8 18 12 ‐ ‐ ‐ ‐ ‐ ‐2.5 5 3 8 6 12 10 ‐ ‐ ‐ ‐ ‐ ‐4 3 2 6 5 10 8 ‐ ‐ ‐ ‐ ‐ ‐6 2 ‐ 5 4 8 7 ‐ ‐ ‐ ‐ ‐ ‐10 2 ‐ 4 3 6 5 8 6 ‐ ‐ ‐ ‐16 ‐ ‐ 2 2 3 3 6 5 10 7 12 825 ‐ ‐ ‐ ‐ 3 2 5 3 8 6 9 735 ‐ ‐ ‐ ‐ ‐ ‐ 3 2 6 5 8 650 ‐ ‐ ‐ ‐ ‐ ‐ ‐ ‐ 5 3 6 570 ‐ ‐ ‐ ‐ ‐ ‐ ‐ ‐ 4 3 5 4Note:1. The above table shows the maximum capacity of conduits <strong>for</strong> a simultaneousdraw<strong>in</strong>g <strong>in</strong> of cables.2. The columns headed “S” apply to runs of conduit which have distance notexceed<strong>in</strong>g 4.25 m between draw <strong>in</strong> boxes and which do not deflect from thestraight by an angle of more than 15 degrees. The columns headed “B” apply toruns of conduit, which deflect from the straight by an angle of more than 15degree.3. Conduit sizes are nom<strong>in</strong>al external diametersStandards & Quality Control Authority, MoWHS Page 16

[Year]<strong>Specification</strong>s <strong>for</strong> <strong>Electrical</strong> Materials and Works <strong>2009</strong>b) Fix<strong>in</strong>g of conduitConduit pipes shall be fixed by heavy gauge saddles, secured to suitable PVC sleeves orother equivalent type with screws <strong>in</strong> an acceptable manner at an <strong>in</strong>terval of not more thanone meter but on either side of the couplers or bends or similar fitt<strong>in</strong>gs. Saddles shall befixed at a distance of 30 cm from the centre of such fitt<strong>in</strong>gs. The saddle should not be lessthan 24 gauge <strong>for</strong> conduits up to 25 mm dia. and not less than 20 gauge <strong>for</strong> largerdiameter.When conduits pipes are to be laid along the trusses, steel jo<strong>in</strong>ts etc. the same shall besecured by means of ord<strong>in</strong>ary clips or glider clips as required by the Eng<strong>in</strong>eer‐<strong>in</strong>‐charge.Where it is not possible to drill holes <strong>in</strong> the truss members, suitable clamps with bolts andnuts shall be used. The width and the thickness of the ord<strong>in</strong>ary clips or glider clips andclamps shall not be less than as <strong>in</strong>dicated <strong>in</strong> Table 4 below:Table 4: Width and thickness of saddle clipsFor clamps or ord<strong>in</strong>ary clips<strong>Size</strong> of conduit Width of saddle clips Thickness of clip20 mm 20 mm 20 SWG25 mm 20mm 20 SWG32mm & above 25mm 18 SWGc) Conduit jo<strong>in</strong>tsConduit pipes shall be jo<strong>in</strong>ed by means of screwed couples and screwed accessories only.In long distance straight run of conduit, <strong>in</strong>spection type couplers at reasonable <strong>in</strong>tervalsshall be provided or runn<strong>in</strong>g threads with couplers and jam nuts shall be provided. In thelater case the bare threaded portion shall be treated with anticorrosive preservative.Threads on conduit pipes <strong>in</strong> all cases shall be between 13 mm and 19 mm long sufficient toaccommodate pipes full threads portion of couplers or accessories. Cut ends of conduitpipes shall have no sharp edges or any burrs left to avoid damage to the <strong>in</strong>sulation ofconductors while pull<strong>in</strong>g them through such pipes.d) Mak<strong>in</strong>g of chaseThe chase <strong>in</strong> the wall shall be neatly made and ample dimensions to permit the conduit tobe fixed <strong>in</strong> the manner desired. In the case of build<strong>in</strong>gs under construction, conduits shallbe f<strong>in</strong>ished neatly after erection of conduit. In case of exposed brick/rubble masonry work,special care shall be taken to fix the conduit and accessories <strong>in</strong> position along with thebuild<strong>in</strong>g work.Standards & Quality Control Authority, MoWHS Page 17

[Year]<strong>Specification</strong>s <strong>for</strong> <strong>Electrical</strong> Materials and Works <strong>2009</strong>e) Fix<strong>in</strong>g of conduit <strong>in</strong> chaseThe conduit pipe shall be fixed by means of staples or by means of saddles not more than60 cm apart or by any other approved means of fix<strong>in</strong>g. Fix<strong>in</strong>g of standard bends shall beavoided as far as practicable and all curves/bend shall be ma<strong>in</strong>ta<strong>in</strong>ed by bend<strong>in</strong>g theconduit pipe itself with a long radius that will permit easy draw<strong>in</strong>g of conductors. Allthreaded jo<strong>in</strong>ts of conduit pipes shall be treated with preservative compound to preventfrom rust<strong>in</strong>g.f) Erection and earth<strong>in</strong>g of conduitFix<strong>in</strong>g of conduit shall have to be completed <strong>in</strong> all respect be<strong>for</strong>e the wires are drawn. Aftercomplet<strong>in</strong>g the fix<strong>in</strong>g of conduit, it shall be tested <strong>for</strong> mechanical rigid and electricallysound cont<strong>in</strong>uity throughout its runn<strong>in</strong>g length. Gas or water pipe shall not be used asearth<strong>in</strong>g electrode. If conduit pipes are liable to mechanical damage they shall beadequately protected. In a conduit system pipe must be cont<strong>in</strong>uous when pass<strong>in</strong>g throughwalls and floors. Earth<strong>in</strong>g wire shall run throughout its length and properly bonded toconduit pipe where possible to get uni<strong>for</strong>m ground<strong>in</strong>g effect.g) Inspection boxesSuitable size of <strong>in</strong>spection boxes to the m<strong>in</strong>imum requirements shall be provided to permitperiodical <strong>in</strong>spection and to facilitate draw<strong>in</strong>g/replacement of wires conveniently. Theseshall be mounted flushed with the wall. Suitable ventilation holes shall be provided <strong>in</strong> the<strong>in</strong>spection box covers condensation and heat radiation.h) Protection of conduits aga<strong>in</strong>st rustIf the materials are of the GI or Steel, the outer surface of the conduit <strong>in</strong>clud<strong>in</strong>g all bends,unions, tees, junction boxes etc. <strong>for</strong>m<strong>in</strong>g part of the conduit system shall be adequatelyprotected aga<strong>in</strong>st rust when such system is exposed to weather by be<strong>in</strong>g pa<strong>in</strong>ted with twocoats of oxide pa<strong>in</strong>t applied be<strong>for</strong>e they are fixed. In all cases, no bare threaded portion ofconduit pipe shall be allowed unless such bare threaded portion is treated withanticorrosive preservation or covered with approved plastic compound.i) Pa<strong>in</strong>t<strong>in</strong>g of conduits and accessoriesAfter <strong>in</strong>stallation, all accessible surfaces of conduit pipes, fitt<strong>in</strong>gs, switch and regulatorboxes etc. shall be pa<strong>in</strong>ted <strong>in</strong> compliance with clauses under Pa<strong>in</strong>t<strong>in</strong>g. No pa<strong>in</strong>t<strong>in</strong>g isrequired <strong>for</strong> PVC conduit/HDPE pipe and cas<strong>in</strong>g capp<strong>in</strong>g unless otherwise specified.j) Glider ClipsFor all sizes of conduit, the size of clamp<strong>in</strong>g rod shall be 7 SWG diameter.Standards & Quality Control Authority, MoWHS Page 18

[Year]<strong>Specification</strong>s <strong>for</strong> <strong>Electrical</strong> Materials and Works <strong>2009</strong>k) Bends <strong>in</strong> conduitsAll necessary bends <strong>in</strong> the system <strong>in</strong>clud<strong>in</strong>g diversion shall be <strong>for</strong>med either by bend<strong>in</strong>g thepipes by an approved method of heat<strong>in</strong>g, or by <strong>in</strong>sert<strong>in</strong>g suitable accessories such asbends, elbows or similar fitt<strong>in</strong>gs, or by fix<strong>in</strong>g cast iron <strong>in</strong>spection boxes whichever is mostsuitable. Radius of bends <strong>in</strong> conduit pipes shall not be less than 7.5 cm. No length ofconduit shall have more than the equivalent of four quarter bends from outlet to outlet.l) OutletsThe switch box shall be made of either rigid PVC mold<strong>in</strong>g, or mild steel or cast iron on allsides except at the front. In the case of boxes, wall thickness shall be at least 3 mm and <strong>in</strong>case of welded mild steel sheet boxes the wall thickness shall not be less than 18 gauge <strong>for</strong>boxes, upto a size of 20 mm X 30 cm and above this size 16 gauge M.S, boxes shall be used.Except when otherwise stated 3 mm thick phenolic lam<strong>in</strong>ated sheets shall be fixed on thefront with brass screws. Clear depth of the box shall not be less than 60 mm and this shallbe <strong>in</strong>creased suitably to accommodate mount<strong>in</strong>g of fan regulators <strong>in</strong> flush pattern.4.2.1 PVC Conduits/HDPE Pipes4.2.1.1 SurfaceProvid<strong>in</strong>g and fix<strong>in</strong>g of surface PVC conduit pipes <strong>in</strong>clude bends and circular boxes andpa<strong>in</strong>t<strong>in</strong>g if required. PVC conduits shall be of standard material free from defects of anyk<strong>in</strong>d. It should be properly f<strong>in</strong>ished and con<strong>for</strong>m<strong>in</strong>g to relevant standards.Provid<strong>in</strong>g and fix<strong>in</strong>g of PVC conduit 1.8 mm thick <strong>for</strong> sizes up to 25mm and 2mm thick from32mm to 50mm, run whether <strong>in</strong> horizontal or vertical position as required. It should berigidly fixed on the wall surface with conduit saddles of thickness 1.8mm <strong>for</strong> sizes up to25mm and 2mm thick <strong>for</strong> pipe sizes from 32mm to 50mm at the spac<strong>in</strong>g of not more than50cm. However, saddles have to be provided at the ends of the pipes if bend and circularboxes are used. The saddles are to be rigidly fixed on the wall with wooden screws of sizes50mm long <strong>for</strong> stone masonry wall surface and 35mm <strong>for</strong> brick wall surface, screwed <strong>in</strong>PVC sleeves of appropriate size. The holes <strong>for</strong> PVC sleeves have to be drilled by motor drillsus<strong>in</strong>g appropriate size bits to required depth. In case of conduits laid on the woodensurface, the screws of 25mm length shall be directly screwed and no sleeve is required.4.2.1.2 ConcealedPVC conduits shall not be used <strong>for</strong> concealed/recessed wir<strong>in</strong>g. Instead, wherever MSconduits are not feasible, HDPE pipes of appropriate size shall be used. However, PVCaccessories like boxes, sleeves, corners may be used. The HDPE pipes can be run whether<strong>in</strong> horizontal or vertical position as required. It should be embedded <strong>in</strong> the wall up to depthfrom 16mm to 25mm from the f<strong>in</strong>ished plaster level. Where applicable, the pipe has to beStandards & Quality Control Authority, MoWHS Page 19

[Year]<strong>Specification</strong>s <strong>for</strong> <strong>Electrical</strong> Materials and Works <strong>2009</strong>secured by b<strong>in</strong>d<strong>in</strong>g wire tied on the nail to hold it till the plaster<strong>in</strong>g sets to its strength. Incase of the pipes laid <strong>in</strong> RCC <strong>works</strong>, it has to be tied securely by b<strong>in</strong>d<strong>in</strong>g wire to the externalre<strong>in</strong><strong>for</strong>cement bars and should be flushed <strong>in</strong> the ceil<strong>in</strong>g surface. Lay of pipe diagonally canbe permitted <strong>in</strong> the brick/stone masonry wall, provided there is no cross<strong>in</strong>g with otherpipes or change <strong>in</strong> direction.4.2.1.3 Provid<strong>in</strong>g Earth Cont<strong>in</strong>uity WiresThe earth cont<strong>in</strong>uity wire shall be provided throughout the length of wir<strong>in</strong>g. The size ofearth cont<strong>in</strong>uity wire shall be not less than 1.5 sq.mm (16SWG) and 2.5sq.mm (14SWG)bare copper wire <strong>for</strong> light and power circuit respectively. All metallic parts, switchboards,light fitt<strong>in</strong>gs and power sockets shall be connected to the earth wires and the connectionshall be electrically and mechanically sound.4.2.1.4 PVC conduit sizeThe length of PVC conduit shall be available from 2.5 to 3metres. The unit of measurementshall be <strong>in</strong> metres and measured to the nearest cm. The diameters of the PVC conduit shallbe:a. 19mm diameter, d. 40mm diameter,b. 25mm diameter, e. 50mm diameter,c. 32mm diameter,4.2.2 MS Conduits4.2.2.1 SurfaceProvid<strong>in</strong>g and fix<strong>in</strong>g of MS conduit pipes <strong>in</strong>cludes bends and circular boxes <strong>in</strong>clud<strong>in</strong>gpa<strong>in</strong>t<strong>in</strong>g. The MS conduit pipe shall run whether <strong>in</strong> horizontal or vertical position asrequired. It should be rigidly fixed on the wall surface with conduit saddles of thickness 24SWG <strong>for</strong> sizes up to 25mm and 20 SWG <strong>for</strong> pipe sizes from 32mm to 50mm at the spac<strong>in</strong>gof not more than 100cm. However, saddles have to be provided at the end of the pipes ifbends and circular boxes are used. The saddles are to be rigidly fixed on the wall withwooden screws of sizes 50mm long <strong>for</strong> stone masonry wall surface and 35mm <strong>for</strong> brick wallsurface, screwed <strong>in</strong> PVC sleeves of appropriate size. The holes <strong>for</strong> PVC sleeves have to bedrilled by motor drills us<strong>in</strong>g appropriate size bits. In case of conduits laid on the woodensurface, the screws of 25mm length shall be directly screwed and no sleeve is required.All conduit <strong>works</strong> shall be f<strong>in</strong>ished by fil<strong>in</strong>g the sharp edges and provid<strong>in</strong>g bush<strong>in</strong>gs and jamnuts from <strong>in</strong>side and outside the junction boxes, switchboards and DBs/SDBs where thewir<strong>in</strong>g term<strong>in</strong>al ends from the pipe. Thread<strong>in</strong>g has to be provided at the pipe edge up to20mm.Standards & Quality Control Authority, MoWHS Page 20

[Year]<strong>Specification</strong>s <strong>for</strong> <strong>Electrical</strong> Materials and Works <strong>2009</strong>4.2.2.2 ConcealedProvid<strong>in</strong>g and fix<strong>in</strong>g of MS conduit pipe of specified gauge as <strong>in</strong>dicated aga<strong>in</strong>st the sizesmentioned hereunder, run whether <strong>in</strong> horizontal or vertical position as required. It shouldbe embedded <strong>in</strong> the wall up to depth from 16mm to 25mm from the f<strong>in</strong>ished plaster level.Where applicable, the pipe has to be secured by b<strong>in</strong>d<strong>in</strong>g wire tied on the nail to hold it tillthe plaster<strong>in</strong>g sets to its strength. In case of the pipes laid <strong>in</strong> RCC <strong>works</strong>, it has to be tiedsecurely by b<strong>in</strong>d<strong>in</strong>g wire to the external re<strong>in</strong><strong>for</strong>cement bars and should be flushed <strong>in</strong> theceil<strong>in</strong>g surface. Lay<strong>in</strong>g pipe diagonally can be permitted <strong>in</strong> the brick/stone masonry wall,provided there is no cross<strong>in</strong>g with other pipes or change <strong>in</strong> direction.4.2.2.3 Provid<strong>in</strong>g Earth Cont<strong>in</strong>uity WiresThe earth cont<strong>in</strong>uity wire shall be provided throughout the length of wir<strong>in</strong>g. The size ofearth cont<strong>in</strong>uity wire shall be not less than 1.5 sq.mm (16SWG) and 2.5sq.mm (14SWG)bare copper wire <strong>for</strong> light and power circuit respectively. All metallic parts, switchboards,light fitt<strong>in</strong>gs and power sockets shall be connected to the earth wires and the connectionshall be electrically and mechanically sound.4.2.2.4 Conduit size and MeasurementThe length of MS conduit pipe shall be available from 2.5 to 3metres. The unit ofmeasurement shall be <strong>in</strong> metres and measured to the nearest cm. The diameter andthickness <strong>in</strong> SWG of the MS conduit pipe are given here below:a. 20mm diameter x 18SWG thick d. 40mm diameter x 14 SWG thickb. 25mm diameter x 16SWG thick e. 50mm diameter x 14 SWG thickc. 32mm diameter x 14SWG thickProvid<strong>in</strong>g & fix<strong>in</strong>g MS conduit pipes <strong>in</strong>clude bends and circular boxes <strong>in</strong>clud<strong>in</strong>g pa<strong>in</strong>t<strong>in</strong>g.The unit of measurement shall be <strong>in</strong> metres and measured to the nearest cm.Standards & Quality Control Authority, MoWHS Page 21

[Year]<strong>Specification</strong>s <strong>for</strong> <strong>Electrical</strong> Materials and Works <strong>2009</strong>4.2.3 Steel Conduits4.2.3.1 SurfaceProvid<strong>in</strong>g and fix<strong>in</strong>g of surface steel conduit pipes <strong>in</strong>cludes bends and circular boxes. In theareas of aesthetic concern, sta<strong>in</strong>less steel conduit pipe shall be provided. When surfacesteel conduit is provided, steel saddle of thickness 24SWG or base holder with coupler asapplicable shall be used to match the looks. The steel saddles or base holders shall beprovided at the spac<strong>in</strong>g of not more than 30cm. The saddles have to be provided at the endof the bends, circular boxes and tees. The saddles are to be rigidly fixed on the wall withwooden screws of sizes 50mm long <strong>for</strong> stone masonry wall surface and 35mm <strong>for</strong> brick wallsurface, screwed <strong>in</strong> PVC sleeves of appropriate size. The holes <strong>for</strong> PVC sleeves have to bedrilled by motor drills us<strong>in</strong>g appropriate size bits. In case of conduits laid on the woodensurface, the screws of 25mm length shall be directly screwed and no sleeve is required.4.2.3.2 Provid<strong>in</strong>g Earth Cont<strong>in</strong>uity WiresThe earth cont<strong>in</strong>uity wire shall be provided throughout the length of wir<strong>in</strong>g. The size ofearth cont<strong>in</strong>uity wire shall be not less than 1.5 sq.mm (16SWG) and 2.5sq.mm (14SWG)bare copper wire <strong>for</strong> light and power circuit respectively. All metallic parts <strong>in</strong>clud<strong>in</strong>g thepipes, switchboards, light fitt<strong>in</strong>gs and power sockets shall be connected to the earth wiresand the connection shall be electrically and mechanically sound4.2.3.3 Conduit size and measurementThe length of PVC conduit shall be available from 2.5 to 3metres. The unit of measurementshall be <strong>in</strong> metres and measured to the nearest cm. The standard lengths available arefrom 1.8 to 3m. The diameters shall be:a. 20mm diameter, d. 40mm diameter,b. 25mm diameter, e. 50mm diameter,c. 32mm diameter,Provid<strong>in</strong>g & fix<strong>in</strong>g Steel conduit pipes <strong>in</strong>clude bends and boxes, etc. The unit ofmeasurement shall be <strong>in</strong> metres and measured to the nearest cm.Standards & Quality Control Authority, MoWHS Page 22

[Year]<strong>Specification</strong>s <strong>for</strong> <strong>Electrical</strong> Materials and Works <strong>2009</strong>5‐ INTERNAL WIRING PRACTICES5.1 Circuit wir<strong>in</strong>gCircuit wir<strong>in</strong>g shall mean portion of wir<strong>in</strong>g from the distribution board to the switchboard.Where the circuit wir<strong>in</strong>g is looped to more than one switchboard, such wir<strong>in</strong>g shall beconsidered as circuit wir<strong>in</strong>g and the wire size should rema<strong>in</strong> the same. The measurement ofthe circuit wir<strong>in</strong>g shall be on l<strong>in</strong>ear basis and the unit shall be <strong>in</strong> metres.5.2 Sub‐ma<strong>in</strong> wir<strong>in</strong>gSubma<strong>in</strong> wir<strong>in</strong>g is the wir<strong>in</strong>g from outgo<strong>in</strong>g term<strong>in</strong>al of the ma<strong>in</strong>/power distribution ma<strong>in</strong>bus‐bars to the distribution switchgears. The measurement of such circuit wir<strong>in</strong>g shall beon l<strong>in</strong>ear basis and the unit shall be <strong>in</strong> metres.5.3 Power distribution ma<strong>in</strong>s wir<strong>in</strong>gIn the large build<strong>in</strong>g/premises where the provision of ma<strong>in</strong> and subma<strong>in</strong> switchgears aloneis not feasible, the power distribution ma<strong>in</strong> needs to be provided. The wir<strong>in</strong>g of such ma<strong>in</strong>shall be from the out‐go<strong>in</strong>g term<strong>in</strong>al of the ma<strong>in</strong> control panel busbar to the <strong>in</strong>com<strong>in</strong>gterm<strong>in</strong>al of the power distribution ma<strong>in</strong> switch. The measurement of such circuit wir<strong>in</strong>gshall be on l<strong>in</strong>ear basis and the unit shall be <strong>in</strong> metres.5.4 System of wir<strong>in</strong>g and loadsWhen the connected load of the build<strong>in</strong>g or premises exceeds more than 12KW, threephasewir<strong>in</strong>g shall be carried out. Light<strong>in</strong>g circuit (6 ampere) and power circuit (16 ampererat<strong>in</strong>g) shall be separated from the distribution board <strong>in</strong> all types of wir<strong>in</strong>g. Connected loadof the circuit shall be equally distributed. In case of three phase wir<strong>in</strong>g, balanc<strong>in</strong>g of loadamong the phases shall be carried out as equally as possible. Due consideration shall begiven <strong>for</strong> neatness, good appearance, safety and electrically and mechanically soundconnections.There shall not be more than 8 po<strong>in</strong>ts and the load shall not exceed more than 800Wattson one particular light<strong>in</strong>g circuit controlled by a 6A MCB. Individual 16A MCBs shall beprovided <strong>for</strong> every power socket.Standards & Quality Control Authority, MoWHS Page 23

[Year]<strong>Specification</strong>s <strong>for</strong> <strong>Electrical</strong> Materials and Works <strong>2009</strong>5.5 Jo<strong>in</strong>ts & loop<strong>in</strong>g backThe wir<strong>in</strong>g shall be done <strong>in</strong> the “Loop<strong>in</strong>g system”. Phase or live conductors shall be loopedat the switch box and neutral conductor can be looped from the light, fan and socket outletpo<strong>in</strong>ts. Where jo<strong>in</strong>t box is required due to unavoidable situation, mechanically andelectrically sound connector shall make all jo<strong>in</strong>ts <strong>in</strong> suitable and proper junction box. Inboth systems of wir<strong>in</strong>g no bare or twist jo<strong>in</strong>ts shall be made. In through run of cables, if thelength of f<strong>in</strong>al circuit, sub‐ma<strong>in</strong> is more than the length of the standard coil, jo<strong>in</strong>ts shall bemade by means of approved connectors <strong>in</strong> suitable junction boxes. The brass connectorsare suitable <strong>for</strong> the mechanical and electrically connections.5.6 Pass<strong>in</strong>g through wallWhen wir<strong>in</strong>g cables are to pass through walls, care shall be taken to see that the wires passvery freely through protective (PVC/steel) pipe or porcela<strong>in</strong> tube of suitable size, and thatthe wires pass through <strong>in</strong> a straight l<strong>in</strong>e without any twist or cross <strong>in</strong> them on either end ofsuch holes. The ends of metallic pipes shall be neatly bushed with porcela<strong>in</strong>, PVC or otherapproved material.5.7 Pass<strong>in</strong>g through floorWhile pass<strong>in</strong>g through the floor or ceil<strong>in</strong>g, care shall be taken to protect the conductorfrom mechanical damages. In order to protect from such damages, a solid pipe without anyjo<strong>in</strong>t and bend shall be provided with bushes at both ends. Provid<strong>in</strong>g <strong>in</strong>spection box at bothends can enable easy draw<strong>in</strong>g of wire.All floor open<strong>in</strong>gs <strong>for</strong> carry<strong>in</strong>g any wir<strong>in</strong>g must be suitable sealed after <strong>in</strong>stallation.5.8 Bunch<strong>in</strong>g of CablesCables carry<strong>in</strong>g direct current may, if desired be bunched whatever their polarity, butcables carry<strong>in</strong>g alternat<strong>in</strong>g current, if <strong>in</strong>stalled <strong>in</strong> metal conduit shall always be bunched sothat the outgo<strong>in</strong>g and return cables are drawn <strong>in</strong>to same conduit. Should the bunch<strong>in</strong>g ofreturn wire not be possible, the pipe shall be properly bonded with the earth wire.Standards & Quality Control Authority, MoWHS Page 24

[Year]<strong>Specification</strong>s <strong>for</strong> <strong>Electrical</strong> Materials and Works <strong>2009</strong>6‐ POINT WIRINGPo<strong>in</strong>t wir<strong>in</strong>g shall <strong>in</strong>clude all <strong>works</strong> necessary <strong>for</strong> complete wir<strong>in</strong>g of length up to 10m, <strong>in</strong>clud<strong>in</strong>gswitch and circuit up to term<strong>in</strong>ation po<strong>in</strong>t as described below:a) Lamp holder (<strong>in</strong>cludes the holders also <strong>in</strong> case of angle and batten po<strong>in</strong>ts).b) Pendant/fans/call bell po<strong>in</strong>ts (up to and <strong>in</strong>clud<strong>in</strong>g ceil<strong>in</strong>g rose)c) Socket outlet (<strong>in</strong> case of light socket outlet po<strong>in</strong>t and <strong>in</strong>cludes a socket outlet).The above applies to surface or recessed/concealed wir<strong>in</strong>g of all types as required.6.1 Measurement of po<strong>in</strong>t wir<strong>in</strong>gBased on the lengths of wir<strong>in</strong>g, po<strong>in</strong>ts are classified as under:Short po<strong>in</strong>t : Length of po<strong>in</strong>t not exceed<strong>in</strong>g 3m.Medium po<strong>in</strong>t : Length of po<strong>in</strong>t exceed<strong>in</strong>g 3m but not exceed<strong>in</strong>g 6m.Long po<strong>in</strong>t : Length of po<strong>in</strong>t exceed<strong>in</strong>g 6m but not exceed<strong>in</strong>g 10mThe length of po<strong>in</strong>t exceed<strong>in</strong>g 10 shall be measured on l<strong>in</strong>ear basisStandards & Quality Control Authority, MoWHS Page 25