Download Issue 131 - January/February 2010 - SPE WA

Download Issue 131 - January/February 2010 - SPE WA

Download Issue 131 - January/February 2010 - SPE WA

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

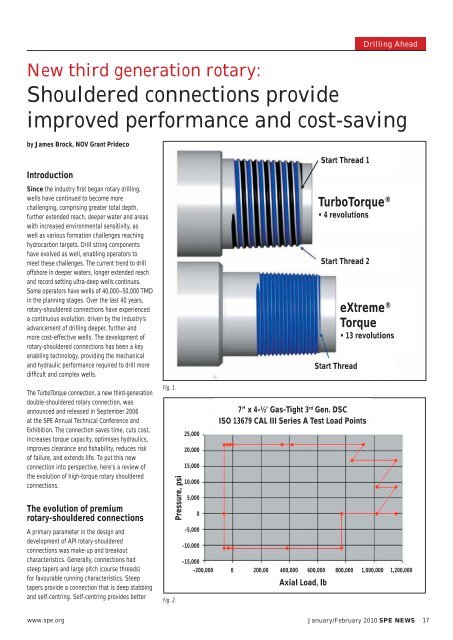

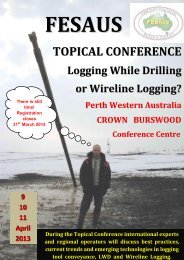

Drilling AheadDrilling AheadNew third generation rotary:Shouldered connections provideimproved performance and cost-savingby James Brock, NOV Grant PridecoIntroductionStart Thread 1Since the industry fi rst began rotary drilling,wells have continued to become morechallenging, comprising greater total depth,further extended reach, deeper water and areaswith increased environmental sensitivity, aswell as various formation challenges reachinghydrocarbon targets. Drill string componentshave evolved as well, enabling operators tomeet these challenges. The current trend to drilloffshore in deeper waters, longer extended reachand record setting ultra-deep wells continues.Some operators have wells of 40,000–50,000 TMDin the planning stages. Over the last 40 years,rotary-shouldered connections have experienceda continuous evolution, driven by the industry’sadvancement of drilling deeper, further andmore cost-effective wells. The development ofrotary-shouldered connections has been a keyenabling technology, providing the mechanicaland hydraulic performance required to drill morediffi cult and complex wells.TurboTorque ®• 4 revolutionsStart Thread 2Start ThreadeXtreme ®Torque• 13 revolutionsThe TurboTorque connection, a new third-generationdouble-shouldered rotary connection, wasannounced and released in September 2006at the <strong>SPE</strong> Annual Technical Conference andExhibition. The connection saves time, cuts cost,increases torque capacity, optimises hydraulics,improves clearance and fi shability, reduces riskof failure, and extends life. To put this newconnection into perspective, here's a review ofthe evolution of high-torque rotary shoulderedconnections.The evolution of premiumrotary-shouldered connectionsFig. 1.Pressure, psi25,00020,00015,00010,0005,00007” x 4-½’ Gas-Tight 3 rd Gen. DSCISO 13679 CAL III Series A Test Load PointsA primary parameter in the design anddevelopment of API rotary-shoulderedconnections was make-up and breakoutcharacteristics. Generally, connections hadsteep tapers and large pitch (course threads)for favourable running characteristics. Steeptapers provide a connection that is deep stabbingand self-centring. Self-centring provides betterFig. 2.-5,000-10,000-15,000-200,000 0 200,00 400,000 600,000 800,000 1,000,000 1,200,000Axial Load, lbwww.spe.org<strong>January</strong>/<strong>February</strong> <strong>2010</strong> <strong>SPE</strong> NEWS 17