Download Issue 131 - January/February 2010 - SPE WA

Download Issue 131 - January/February 2010 - SPE WA

Download Issue 131 - January/February 2010 - SPE WA

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

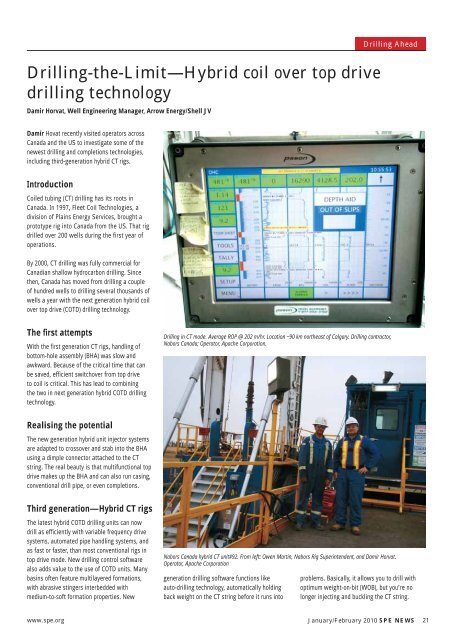

Drilling-the-Limit—Hybrid coil over top drivedrilling technologyDamir Horvat, Well Engineering Manager, Arrow Energy/Shell JVDrilling AheadDamir Hovat recently visited operators acrossCanada and the US to investigate some of thenewest drilling and completions technologies,including third-generation hybrid CT rigs.IntroductionCoiled tubing (CT) drilling has its roots inCanada. In 1997, Fleet Coil Technologies, adivision of Plains Energy Services, brought aprototype rig into Canada from the US. That rigdrilled over 200 wells during the first year ofoperations.By 2000, CT drilling was fully commercial forCanadian shallow hydrocarbon drilling. Sincethen, Canada has moved from drilling a coupleof hundred wells to drilling several thousands ofwells a year with the next generation hybrid coilover top drive (COTD) drilling technology.The first attemptsWith the fi rst generation CT rigs, handling ofbottom-hole assembly (BHA) was slow andawkward. Because of the critical time that canbe saved, effi cient switchover from top driveto coil is critical. This has lead to combiningthe two in next generation hybrid COTD drillingtechnology.Drilling in CT mode. Average ROP @ 202 m/hr. Location ~90 km northeast of Calgary. Drilling contractor,Nabors Canada; Operator, Apache Corporation.Realising the potentialThe new generation hybrid unit injector systemsare adapted to crossover and stab into the BHAusing a dimple connector attached to the CTstring. The real beauty is that multifunctional topdrive makes up the BHA and can also run casing,conventional drill pipe, or even completions.Third generation—Hybrid CT rigsThe latest hybrid COTD drilling units can nowdrill as effi ciently with variable frequency drivesystems, automated pipe handling systems, andas fast or faster, than most conventional rigs intop drive mode. New drilling control softwarealso adds value to the use of COTD units. Manybasins often feature multilayered formations,with abrasive stingers interbedded withmedium-to-soft formation properties. NewNabors Canada hybrid CT unit#92. From left: Owen Martin, Nabors Rig Superintendent, and Damir Horvat.Operator, Apache Corporationgeneration drilling software functions likeauto-drilling technology, automatically holdingback weight on the CT string before it runs intoproblems. Basically, it allows you to drill withoptimum weight-on-bit (WOB), but you’re nolonger injecting and buckling the CT string.www.spe.org<strong>January</strong>/<strong>February</strong> <strong>2010</strong> <strong>SPE</strong> NEWS 21