Download Issue 131 - January/February 2010 - SPE WA

Download Issue 131 - January/February 2010 - SPE WA

Download Issue 131 - January/February 2010 - SPE WA

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

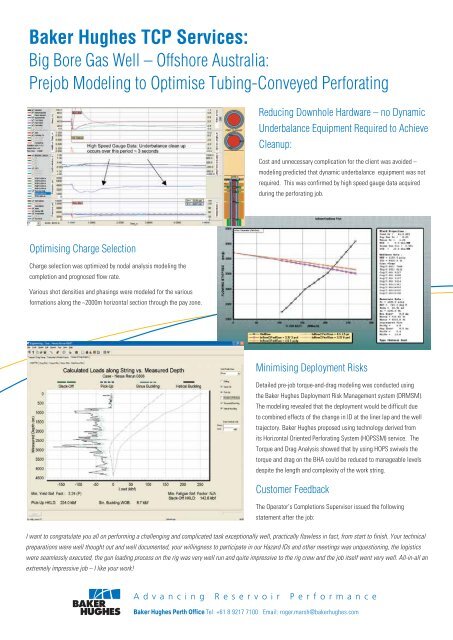

Baker Hughes TCP Services:Big Bore Gas Well – Offshore Australia:Prejob Modeling to Optimise Tubing-Conveyed PerforatingReducing Downhole Hardware – no DynamicUnderbalance Equipment Required to AchieveCleanup:Cost and unnecessary complication for the client was avoided –modeling predicted that dynamic underbalance equipment was notrequired. This was confirmed by high speed gauge data acquiredduring the perforating job.Optimising Charge SelectionCharge selection was optimized by nodal analysis modeling thecompletion and prognosed flow rate.Various shot densities and phasings were modeled for the variousformations along the ~2000m horizontal section through the pay zone.Minimising Deployment RisksDetailed pre-job torque-and-drag modeling was conducted usingthe Baker Hughes Deployment Risk Management system (DRMSM).The modeling revealed that the deployment would be difficult dueto combined effects of the change in ID at the liner lap and the welltrajectory. Baker Hughes proposed using technology derived fromits Horizontal Oriented Perforating System (HOPSSM) service. TheTorque and Drag Analysis showed that by using HOPS swivels thetorque and drag on the BHA could be reduced to manageable levelsdespite the length and complexity of the work string.Customer FeedbackThe Operator’s Completions Supervisor issued the followingstatement after the job:I want to congratulate you all on performing a challenging and complicated task exceptionally well, practically flawless in fact, from start to finish. Your technicalpreparations were well thought out and well documented, your willingness to participate in our Hazard IDs and other meetings was unquestioning, the logisticswere seamlessly executed, the gun loading process on the rig was very well run and quite impressive to the rig crew and the job itself went very well. All-in-all anextremely impressive job – I like your work!Advancing Reservoir PerformanceBaker Hughes Perth Office Tel: +61 8 9217 7100 Email: roger.marsh@bakerhughes.com