Trelleborg Rubber Wear Panels - Trelleborg.com.au

Trelleborg Rubber Wear Panels - Trelleborg.com.au

Trelleborg Rubber Wear Panels - Trelleborg.com.au

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Trelleborg</strong> <strong>Rubber</strong> <strong>Wear</strong> <strong>Panels</strong>

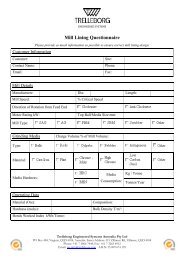

<strong>Trelleborg</strong> <strong>Rubber</strong> <strong>Wear</strong> <strong>Panels</strong><strong>Trelleborg</strong> <strong>Rubber</strong> <strong>Wear</strong> <strong>Panels</strong>are available in various highquality rubber <strong>com</strong>pounds.Thicknesses vary from 25mmto 150mm.<strong>Trelleborg</strong> <strong>Rubber</strong> <strong>Wear</strong> <strong>Panels</strong>are hot vulcanised onto steelbacking plates to ensure there isno delaminating.The liners can be supplied flator curved to suit mill trunnions,trommels, l<strong>au</strong>nders and othercurved surfaces.<strong>Trelleborg</strong> <strong>Rubber</strong> <strong>Wear</strong> <strong>Panels</strong>can be supplied with a profiledworking face. Profile panels aretypically used around the impactpoint in transfer chutes to ensurethe impact angle is 90 degreesfor optimum wear performance.<strong>Trelleborg</strong> <strong>Rubber</strong> <strong>Wear</strong> <strong>Panels</strong>can be shaped and supplied asper customer requirements.<strong>Trelleborg</strong> <strong>Rubber</strong> <strong>Wear</strong> <strong>Panels</strong>can be designed and shaped tosuit chutes, deflectors, screenimpact feed boxes, mill feedcarts and any other high impactabrasive application.Fastening MethodsStudded Counter Bore T Section

When selecting the appropriatewear material for use in chutesor deflectors, there are manyfactors that should be consideredincluding velocity, abrasion indexof the ore, particle shape bulkdensity, angle of impact, etc.As the graph below indicates,rubber is best suited to impactangles between 60 o and 90 o .When the natural angle ofparticle trajectory is less than60 o <strong>Trelleborg</strong> re<strong>com</strong>mends theuse of our profiled rubber linerso that the impact angle will begreater than 60 o .<strong>Wear</strong> index100<strong>Rubber</strong>SteelCeramics50Minerals range0° 30° 60° 90°Angle of impactIn chutes where building upor bogging is not a concern,installation of <strong>Trelleborg</strong> <strong>Wear</strong>Bars to create a series of microledges/rock boxes will deliveradditional life to the chute lineras the ore held up on the wearbars will protect the parent linersfrom impact.

Other <strong>Trelleborg</strong> Products<strong>Trelleborg</strong> Composite Ceramic<strong>Wear</strong> Liners<strong>Trelleborg</strong> Mining Hose<strong>Trelleborg</strong> <strong>Rubber</strong> Mill LinersSheet <strong>Rubber</strong> Productsfor the Mining Industry<strong>Trelleborg</strong> Speciality Mining HosesTrommels and Trommel <strong>Panels</strong><strong>Trelleborg</strong> <strong>Rubber</strong> Lined Products Dragline Fairlead Buffers <strong>Trelleborg</strong> Special <strong>Rubber</strong> ProductsBrisbanePhone +61 (7) 3866 7444Facsimile + 61 (7) 3263 4912Email: tqr.info@trelleborg.<strong>com</strong>www.trelleborg.<strong>com</strong>.<strong>au</strong>MelbournePhone +61 (0) 407 966 291Facsimile + 61 (7) 3263 4912Email: tqr.info@trelleborg.<strong>com</strong>www.trelleborg.<strong>com</strong>.<strong>au</strong>PerthPhone +61 (8) 9256 6000Facsimile + 61 (8) 9353 5990Email: tqr.info@trelleborg.<strong>com</strong>www.trelleborg.<strong>com</strong>.<strong>au</strong>9366 7/09