Orkot Marine Bearings: Engineering Manual - Trelleborg.com.au

Orkot Marine Bearings: Engineering Manual - Trelleborg.com.au

Orkot Marine Bearings: Engineering Manual - Trelleborg.com.au

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Engineering</strong> <strong>Manual</strong>Version 4.0

<strong>Orkot</strong> ® <strong>Marine</strong> <strong>Bearings</strong><strong>Engineering</strong> <strong>Manual</strong> for Rudder and Water Lubricated Propeller Shaft <strong>Bearings</strong>ContentsAbout this <strong>Manual</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2A Global Approach . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2<strong>Orkot</strong> ® <strong>Marine</strong> <strong>Bearings</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2Management Systems and Classification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2Material Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3Service and Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5Web Site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5World Wide Availability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5<strong>Marine</strong> Stock Tube Sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5Standard Production Capacity Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6Contact Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6Rudder <strong>Bearings</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7Bearing Design Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7Material Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7Housing and Shaft Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7Shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8Wall Thickness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8Bearing Interference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8Bearing Clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9Machining Tolerance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9Water Lubricated Stern Tube <strong>Bearings</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10Bearing Design Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10Material Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10Shaft Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10Multi Groove Bearing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10Twin Groove Bearing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10Special Designs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10Staves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11Water Flow Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11Bearing Interference and Clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12Machining Tolerance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13Fitting Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14Bonding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16Machining Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17Health and Safety Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19Calculation Sheets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .231

<strong>Orkot</strong> ® <strong>Marine</strong> <strong>Bearings</strong><strong>Engineering</strong> <strong>Manual</strong> for Rudder and Water Lubricated Propeller Shaft <strong>Bearings</strong>About this <strong>Manual</strong>The information in this manual allows the user tocorrectly design <strong>Orkot</strong> ® <strong>Marine</strong> <strong>Bearings</strong> and givesguidance on machining and fitting. It is intended foruse by persons with technical training at their owndiscretion. The design of <strong>Orkot</strong> ® <strong>Marine</strong> <strong>Bearings</strong>should take into account the current rules andregulations of the relevant classification society.A Global Approach<strong>Orkot</strong> ® <strong>Marine</strong> <strong>Bearings</strong> is a world leadingmanufacturer and supplier of bearings to the shippingand marine industries.Supported by an extensive global network ofmanufacturing plants, agents and distributors, <strong>Orkot</strong> ®<strong>Marine</strong> <strong>Bearings</strong> are able to offer the highest levels ofquality of service associated with a leading <strong>com</strong>panywithin the marine industry.Part of the Smiths group of <strong>com</strong>panies, <strong>Orkot</strong> ® <strong>Marine</strong><strong>Bearings</strong> have been active within the <strong>Marine</strong> andshipping industries for over 25 years.Extensive experience has been gained within theshipbuilding and offshore industries with a widerange of applications on board both merchant andmilitary vessels.<strong>Orkot</strong> ® <strong>Marine</strong> <strong>Bearings</strong><strong>Orkot</strong> ® <strong>Marine</strong> <strong>Bearings</strong> are manufactured from <strong>au</strong>nique synthetic <strong>com</strong>position incorporating solidlubricants for dry running to ensure outstanding wearlife. Virtually no swelling in sea water and very lowthermal coefficient of expansion provide dimensionalstability in arctic and tropical seas. It does not corrodeor promote corrosion of the housing and toleratesboth edge loading and misalignment.Management Systems andClassification<strong>Orkot</strong> ® Composites operate a fully integratedmanagement system which incorporates, ISO9000:2000 Quality Management System, ISO14001:1996 Environmental Management Systemand OHSAS 18001:1999 Health and SafetyManagement SystemStrict quality control and testing ensure materialconformance and batch traceability. Routine testing isperformed to simulate the extreme operationalenvironments where the materials are used.<strong>Orkot</strong> ® Composites hold type approval certification forTLM <strong>Marine</strong> and TXM <strong>Marine</strong> grades from the worldsleading classification societies. We can supply fulllisting of the certificates we hold upon request.This listing can also be found on our website:www.orkotmarine.<strong>com</strong>2

<strong>Orkot</strong> ® <strong>Marine</strong> <strong>Bearings</strong><strong>Engineering</strong> <strong>Manual</strong> for Rudder and Water Lubricated Propeller Shaft <strong>Bearings</strong>Material PropertiesTable 1: MetricProperties Unit TLM <strong>Marine</strong> TXM <strong>Marine</strong>Compressive StrengthNormal to Laminate N/mm 2 >300 >280Parallel to Laminate N/mm 2 >90 >90Tensile Strength N/mm 2 >60 >55Flexural Strength N/mm 2 >65 >65Elastic ModulusBending N/mm 2 x 10 4 0.19 0.18Tensile N/mm 2 x 10 4 0.32 0.32Shear Strength N/mm 2 80 80Impact Strength (ISO179/1987 Charpy Impact Unnotched)Normal to Laminate KJ/m 2 122 122Hardness - Rockwell M 100 100Density g/cm 3 1.3 1.3Swell in Water, % of wall thickness %

<strong>Orkot</strong> ® <strong>Marine</strong> <strong>Bearings</strong><strong>Engineering</strong> <strong>Manual</strong> for Rudder and Water Lubricated Propeller Shaft <strong>Bearings</strong>Material PropertiesTable 2: ImperialProperties Unit TLM <strong>Marine</strong> TXM <strong>Marine</strong>Compressive StrengthNormal to Laminate lbs/in 2 >43511 >40611Parallel to Laminate lbs/in 2 >13053 >13053Tensile Strength lbs/in 2 >8702 >7977Flexural Strength lbs/in 2 >9427 >9427Elastic ModulusBending lbs/in 2 x 10 4 27.557125 26.10675Tensile lbs/in 2 x 10 4 46.412 46.412Shear Strength lbs/in 2 11603 11603Impact Strength (ISO179/1987 Charpy Impact Unnotched)Normal to Laminate KJ/in 2 0.079 0.079Hardness - Rockwell M 100 100Density lbs/in 3 0.047 0.047Swell in Water, % of wall thickness %

<strong>Orkot</strong> ® <strong>Marine</strong> <strong>Bearings</strong><strong>Engineering</strong> <strong>Manual</strong> for Rudder and Water Lubricated Propeller Shaft <strong>Bearings</strong>Service and Support<strong>Orkot</strong> ® <strong>Marine</strong> <strong>Bearings</strong> have a team of experiencedand highly skilled engineers who offer a full and<strong>com</strong>plete service tailored to your specificrequirements. Some aspects of this service are:● Re<strong>com</strong>mendations on adapting our bearings tospecific environmental and operational conditions.● Calculation of bearing dimensions for pre-despatchor on site machining● Technical assistance with bearing installations● Full technical backup and support throughout theservice life of the bearing● 24 hour emergency supportThis extensive support service is <strong>com</strong>plimented by a<strong>com</strong>prehensive range of technical documentation andthe <strong>Orkot</strong> ® <strong>Marine</strong> <strong>Bearings</strong> calculation program.Web SiteVisit our website on: www.orkotmarine.us forgeneral and technical information on <strong>Orkot</strong> ® <strong>Marine</strong><strong>Bearings</strong> products and applications. You will be ableto view and download certificates, literature andother documents.World Wide Availability<strong>Orkot</strong> ® <strong>Marine</strong> <strong>Bearings</strong> distribution network is set upto meet the urgent demands of modern ship repairing.Standard <strong>Orkot</strong> ® TLM <strong>Marine</strong> tubes, which can beshipped the same day, are stocked world wide by localdistributors in the major ship repairing centres. Theseare backed up by additional large stocks in ourmanufacturing plants.Our modern, well equipped facilities can manufacturespecific sizes of raw material in both tube and sheetform for despatch within 24 hours. They can alsosupply a full range of finished-machined productsquickly and economically, including:● Plain bearings● Flanged bearings● Grooved bearings● Staves● Thrust bearings● Spherical bearings● Wear rings● Pads● Strips● Washers<strong>Marine</strong> Stock Tube Sizes TableTable 3Reference od id Length Weight od id Length Weight(mm) (mm) (mm) (Kg) (inch) (inch) (inch) (lbs)TLM 13 95 47.6 500 3.5 3.7 1.9 19.7 7.7TLM 21 118 66.7 500 4.9 4.6 2.6 19.7 10.8TLM 22 150 88.9 500 7.5 5.9 3.5 19.7 16.5TLM 23A 170 108 500 8.8 6.7 4.3 19.7 19.4TLM 23 190 120.7 600 12.5 7.5 4.8 23.6 27.6TLM 24 230 146.1 700 21.9 9.1 5.8 27.6 48.3TLM 26 305 177.8 780 49.1 12.0 7.0 30.7 108.2TLM 29 370 235 650 53.3 14.6 9.3 25.6 117.5TLM 29A 400 270 650 57.8 15.7 10.6 25.6 127.4TLM 31 445 295 570 64.6 17.5 11.6 22.4 142.4TLM 32 480 381 590 51.4 18.9 15.0 23.2 113.3TLM 34 520 403 700 77.2 20.5 15.9 27.6 170.2TLM 36 595 450 710 110.0 23.4 17.7 28.0 242.5TLM 39 650 500 800 134.0 25.6 19.7 31.5 295.4TLM 42 735 600 840 154.0 28.9 23.6 33.1 339.55

<strong>Orkot</strong> ® <strong>Marine</strong> <strong>Bearings</strong><strong>Engineering</strong> <strong>Manual</strong> for Rudder and Water Lubricated Propeller Shaft <strong>Bearings</strong>Standard Production CapacityGuidelinesWith our current standard equipment and productionprocesses we are able to manufacture parts withinthe following guidelines. However we specialise inengineering solutions so please do not hesitate tocontact us if your requirements fall outside ofthese limits.● Tube products up to 2500mm (98”) outside diameterand 1250mm (49”) long● Sheets products up to 860mm (33”) wide and3000mm (118”) long● Rod products up to 200mm (8”) outside diameterand 500mm (19”) longContact DetailsPlease refer to our web site for the contact detailsof your local agent or distributor. Alternatively youcan contact one of our manufacturing plants onthe following:<strong>Orkot</strong> ® <strong>Marine</strong> <strong>Bearings</strong>,Rotherham, South Yorkshire, UK:Phone: +44 1709 789828Fax: +44 1709 789802E-mail: enquiries@orkotmarine.<strong>com</strong>24 hour emergency mobile phone: +44 1709 789840<strong>Orkot</strong> ® <strong>Marine</strong> <strong>Bearings</strong>,Eugene, Oregon, USA:Phone: +1 541 688 5529Fax: +1 541 688 2079E-mail: inquiries.americas@orkotmarine.<strong>com</strong>24 hour emergency mobile phone +1 800 546 75686

<strong>Orkot</strong> ® <strong>Marine</strong> <strong>Bearings</strong><strong>Engineering</strong> <strong>Manual</strong> for Rudder and Water Lubricated Propeller Shaft <strong>Bearings</strong>Rudder <strong>Bearings</strong>This section provides general advice on rudder bearingdesign. It also provides the information required toallow the user to calculate the machining sizes of arudder bearing before and after fitting.Page 24 shows a <strong>com</strong>pleted example of the <strong>Orkot</strong> ®<strong>Marine</strong> <strong>Bearings</strong> calculation for you to examine.Page 23 contains a blank for you to <strong>com</strong>plete yourown calculation. Alternatively please feel free tocontact your local agent, distributor or manufacturingplant and we will be happy to advise you of themachining sizes.A spreadsheet based calculation program is availableupon request.Prior to carrying out any calculation, the followinginformation must be available:● Minimum bearing operating temperature● Approximate ambient temperature duringmachining● Housing and shaft sizes with tolerancesBearing Design Pressure<strong>Orkot</strong> ® TLM <strong>Marine</strong> has classification approval for up to15N/mm 2 (2,176 lb/in 2 ) in rudder bearing applications,while TXM <strong>Marine</strong> has approval for up to 10N/mm 2(1,450 lbs/in 2 ). Clearly, this is linked to the applicationand the other <strong>com</strong>ponents involved. When lookingonly at the properties of <strong>Orkot</strong> ® <strong>Marine</strong> bearings muchhigher loads can be sustained. <strong>Orkot</strong> ® <strong>Marine</strong> bearingsare in use in many other applications such as deckcranes, hatch cover slide pads, mooring systems andships stabilisers operating at bearing pressures rangingfrom 25 up to 100 N/mm 2 (3,626 - 14,504 lb/in 2 ).LubricationWater, grease or oil can provide bearing lubricationdepending on the application. No axial grooves arerequired with lubricated rudder bearings. <strong>Orkot</strong> ® TLM<strong>Marine</strong> rudder bearings are capable of intermittentdry running against K-Monel ® , Inconel ® 625, Stellite ® ,duplex stainless and suitable corrosion resistantstainless steels.Housing and Shaft RequirementsHousingThe bearing housings internal diameter, particularly onrefits, should be measured in at least three positionsalong its length. At least two measurements shouldthen be taken at 90 degrees to each other in the radialplane and the resultant figures used to obtain theaverage diameters of each position. If the housing isoval or tapered <strong>Orkot</strong> ® can still be used if the problem isnot excessive (0.1mm per 100 mm or 0.004” per 4”), thematerial has some elasticity, but it will not <strong>com</strong>pensatefor severe wear. It should be noted that the bearingwill take the shape of the housing when fitted with aninterference.The housing should be provided with an adequatechamfer to prevent shaving the bearing whenpress fitting.After fitting the bearing should be retained at oneend by a shoulder and for additional axial security akeeper ring may be used at the other. The followingdiagram illustrates this method.Material Selection<strong>Orkot</strong> ® TLM <strong>Marine</strong> is the preferred material grade forrudder stock, pintle, neck and carrier bearings. Itincorporates solid lubricants which enable dry runningto ensure outstanding wear life for all rudder bushesoperating above or below the draft line. The materialwill operate without lubrication at pressures of 30N/mm 2 (4,351 lb/in 2 ) for short periods and has beentested at pressures of 14.5 N/mm 2 (2,103 lb/in 2 ) with avelocity of 1.3 m/min (4.3 ft/min) for 1.5 million cycleswith minimum lubrication.<strong>Orkot</strong> ® TXM <strong>Marine</strong> is a high performance materialwhich exhibits lower friction and wear properties thanour TLM <strong>Marine</strong> grade. It is approved to operatewithout lubrication in rudder bearing applications andhas been tested, with lubrication against stainless steelfor submarine steering gear at 57 N/mm 2 (8,267 lb/in 2 )at 1 m/min (3.3 ft/min).Figure 1: Fitted bearingShaftThe shaft or liner surface in contact with an <strong>Orkot</strong> ®<strong>Marine</strong> bearing when lubricated by water must be ofcorrosion resistant material to ensure low wear.Suitable materials are seawater corrosion resistantstainless steel, phosphor bronze, gunmetal, Inconel ®625 and Stellite ® .The shaft should be smooth, without cutting edges.The ideal shaft surface finish is between 0.1 and 0.8 Ramicrometers or 4 and 32 Ra micro inches.7

<strong>Orkot</strong> ® <strong>Marine</strong> <strong>Bearings</strong><strong>Engineering</strong> <strong>Manual</strong> for Rudder and Water Lubricated Propeller Shaft <strong>Bearings</strong>DesignWall ThicknessNormally in refits, the wall thickness of the bearing isfixed by the shaft and housing dimensions.For new bearing designs the optimum wall thicknessshould be calculated as:0.04 x shaft diameter plus 2 mm (0.08”).Any bearing design with a wall thickness below thisvalue should always be checked by our engineeringdepartment to ensure it meets our minimumrequirements.It should be noted that when an <strong>Orkot</strong> ® <strong>Marine</strong>bearing of the optimum thickness is fitted into ahousing the interference is reflected as a reduction ofthe bearings internal diameter after fitting, i.e. thewall thickness before and after fitting will normallyremain constant. <strong>Bearings</strong> with thicker than optimumwalls may give less ”bore closure“.Bearing InterferenceAs with all polymer bearings, the interference requiredto hold the bearing in place during operation is higherthan that required by metal bearings bec<strong>au</strong>se themodulus of polymer materials is lower.Tables 4, 5, 6 and 7 show the various values for“m” and “c” that are required to calculate there<strong>com</strong>mended interference for <strong>Orkot</strong> ® <strong>Marine</strong> rudderbearings. These values are dependent upon theminimum operating temperature of the bearing andthe temperature of the machine shop at the time ofmachining. These temperature figures should be usedin relation with these tables when selecting the valuesof “m” and “c”.Once these values have been obtained from the tablesthey should be entered into the following equation inorder to calculate the required interference.Interference = (m x Housing ID) + cOnce an interference value has been calculated it canbe entered into the <strong>Marine</strong> Bearing Calculation.Table 4 Table 5OperatingValue of "m"TempMachining Temperature (°C)(°C) 0 5 10 15 20 25 300 0.00131 0.00155 0.00178 0.00202 0.00225 0.00249 0.00273-10 0.00178 0.00202 0.00225 0.00249 0.00273 0.00296 0.00320-20 0.00229 0.00253 0.00277 0.00300 0.00324 0.00347 0.00371-30 0.00291 0.00311 0.00331 0.00351 0.00371 0.00391 0.00411OperatingTemp Value(°C) of "c"0 -0.125-10 -0.125-20 -0.143-30 -0.158Table 6 Table 7OperatingValue of "m"TempMachining Temperature (°F)(°F) 32 41 50 59 68 77 860 0.00131 0.00155 0.00178 0.00202 0.00225 0.00249 0.00273-10 0.00178 0.00202 0.00225 0.00249 0.00273 0.00296 0.00320-20 0.00229 0.00253 0.00277 0.00300 0.00324 0.00347 0.00371-30 0.00291 0.00311 0.00331 0.00351 0.00371 0.00391 0.00411OperatingTemp Value(°F) of "c"32 -0.0049214 -0.00492-4 -0.00563-22 -0.006228

<strong>Orkot</strong> ® <strong>Marine</strong> <strong>Bearings</strong><strong>Engineering</strong> <strong>Manual</strong> for Rudder and Water Lubricated Propeller Shaft <strong>Bearings</strong>Bearing ClearanceThe minimum re<strong>com</strong>mended bearing clearance for an<strong>Orkot</strong> ® <strong>Marine</strong> rudder bearing can be established usingthe graphs, Figures 2 and 3. The lower line indicatesthe minimum clearances which we re<strong>com</strong>mend wherethe alignment is good and housing distortion low. Theupper line is based on typical classification minimumclearances, for example, Lloyds Register specify 0.002d+ 1.0mm (0.04") but not less than 1.5 (0.06") mm forsynthetic bearings. Where the Classification Societyrules are not applied it is suggested that a clearance isselected from between these two lines.Diametral clearnace (mm)4.003.503.002.502.001.501.000.5000100200300400500600700800900 10001100 1200Shaft diameter (mm)Re<strong>com</strong>mended by some classification societiesMinimum clearance re<strong>com</strong>mended for <strong>Orkot</strong>® <strong>Marine</strong>Figure 2: Bearing starting clearance in mmDiametral clearnace (inches)0.160.140.120.100.080.060.040.02004812162024283236Shaft diameter (inches)404448Re<strong>com</strong>mended by some classification societiesMinimum clearance re<strong>com</strong>mended for <strong>Orkot</strong>® <strong>Marine</strong>Figure 3: Bearing starting clearance in inches.The equations for the slopes on this graph are asfollows. These equations will allow you to calculate amore accurate clearance figure.ImperialUpper slope (Typical classification minimum):Clearance = (0.002 x Shaft Diameter) + 0.04Lower slope (<strong>Orkot</strong> ® re<strong>com</strong>mended minimum):Clearance = (0.002 x Shaft Diameter) + 0.004Mean between the two slopes (Typically used in <strong>Orkot</strong> ®<strong>Marine</strong> <strong>Bearings</strong> calculations):Clearance = (0.002 x Shaft Diameter) + 0.022Once a clearance value has been calculated it can beentered into the <strong>Marine</strong> Bearing Calculation.Machining ToleranceThe following tables show the machining tolerances<strong>Orkot</strong> ® <strong>Marine</strong> <strong>Bearings</strong> machine shop can achievewhen machining rudder bearings. These can besubstituted into the calculation with your ownmachining tolerance should they differ fromthose stated.Once machining tolerance values have been selectedthey can be entered into the <strong>Marine</strong> BearingCalculation. All of the required elements of thecalculation should now be in place and the finalfigures can now be calculated.Re<strong>com</strong>mended MachiningTolerance OD and ID for <strong>Orkot</strong> ®<strong>Marine</strong> Rudder <strong>Bearings</strong>Table 8Diameter OD and IDmm1 - 100101 - 300301 - 500501 - 900above 900Table 9Tolerance Bandmm0.100.150.200.250.40MetricUpper slope (Typical classification minimum):Clearance = (0.002 x Shaft Diameter) + 1.0Lower slope (<strong>Orkot</strong> ® re<strong>com</strong>mended minimum):Clearance = (0.002 x Shaft Diameter) + 0.1Mean between the two slopes (Typically used in <strong>Orkot</strong> ®<strong>Marine</strong> <strong>Bearings</strong> calculations):Clearance = (0.002 x Shaft Diameter) + 0.55Diameter OD and IDinch0 - 44 - 1212 - 2020 - 36above 36Tolerance Bandinch0.0040.0060.0080.0100.0169

<strong>Orkot</strong> ® <strong>Marine</strong> <strong>Bearings</strong><strong>Engineering</strong> <strong>Manual</strong> for Rudder and Water Lubricated Propeller Shaft <strong>Bearings</strong>Water Lubricated SternTube <strong>Bearings</strong>This section provides general advice on stern tubebearing design. It will also provide the informationrequired to allow the user to calculate a stern tubebearings dimensions before and after fitting.Page 25 shows a <strong>com</strong>pleted example of the <strong>Orkot</strong> ®<strong>Marine</strong> calculation for you to examine. Page 23contains a blank for you to <strong>com</strong>plete your owncalculation. Alternatively please feel free to contactyour local agent, distributor or manufacturingplant and we will be happy to advise you of themachining sizes.Prior to carrying out any calculation, the followinginformation must be available:● Housing and shaft sizes with tolerancesBearing Design PressureWater lubricated propeller shaft bearings need tooperate hydro-dynamically, i.e the shaft speed shouldbe sufficient to generate a water film to separate theshaft from the bearing. The design of these bearings isgoverned by the length to shaft diameter ratio whichcan vary from 4:1 to 2:1 depending on the bearingposition and upon approval from the classificationsocieties. Most classification societies apply a ratio of2:1 for <strong>Orkot</strong> ® <strong>Marine</strong> grades. Full copies of thecertificates are available upon request or from ourweb site: www.orkotmarine.<strong>com</strong>Material SelectionIt should be noted that <strong>Orkot</strong> ® materials are notsuitable for use in high speed grease or oil lubricatedstern shaft systems.<strong>Orkot</strong> ® TLM <strong>Marine</strong> is suitable for the majority ofwater lubricated stern tube systems.<strong>Orkot</strong> ® TXM <strong>Marine</strong> is especially suitable for lowshaft velocities i.e. naval surface ship and submarinestern shafts.Shaft Requirements<strong>Orkot</strong> ® <strong>Marine</strong> bearings can be used with mostrecognised shaft materials and is found to be<strong>com</strong>patible with gunmetal, phosphor bronze, Monel,Inconel ® 625, 18/8 stainless steel.If the bearing is subject to abrasive ingress,consideration should be given to the use of hardershaft liners or carbide coatings. <strong>Orkot</strong> ® <strong>Marine</strong> tends toimprove the surface finish during running. As with allbearings subject to the ingress of abrasive particles,life can be reduced. For the stern tube bearings of avessel operating under such conditions a filtered watersupply is re<strong>com</strong>mended.A shaft surface finish of 0.8 micrometers or 32microinches Ra is required to reduce bedding in wear.DesignA number of bearing designs can be manufacturedfrom <strong>Orkot</strong> ® <strong>Marine</strong> grades for stern tube bearingapplications. The types in order of popularity areas follows:Multi Groove BearingThis conventional bearing design has equi-spacedaxial grooves to allow water to circulate and cool thebearing and to enable debris to pass through withoutc<strong>au</strong>sing damage to the shaft or bearing. This designis suitable for most vessels where shaft velocities arenot high.Twin Groove BearingThis bearing has two large axial grooves at 90 degreesto the static shaft loading position and allows superiorhydrodynamic performance over a wide range of shaftvelocities. It was developed from testing <strong>Orkot</strong> ® TLM<strong>Marine</strong> bearings on a purpose designed shaft testingrig. The design allows for a hydrodynamic film todevelop at low shaft velocities reducing friction andwear. Good hydrodynamic performance is obtainedwith shaft velocities as low as 25 m/min. (82 ft/min).This design should be limited to a maximum 300 mm(11.8") diameter and may also be used for verticalshaft water pumps for marine use.Figure 4: Twin Groove BearingSpecial Designs0.4W W = 0.055d + 6 (.24")[d = shaft dia.]R=0.3dSpecial designs for naval applications that incorporatepartial arc segmental bearings mounted in split bronzehousings are also available.10

<strong>Orkot</strong> ® <strong>Marine</strong> <strong>Bearings</strong><strong>Engineering</strong> <strong>Manual</strong> for Rudder and Water Lubricated Propeller Shaft <strong>Bearings</strong>StavesAn alternative bearing design uses staves machinedfrom <strong>Orkot</strong> ® TLM <strong>Marine</strong> sheet. It should be notedthat in refits the lignum vitae staves used in somevessels can be easily and more economically replacedwith <strong>Orkot</strong> ® TLM <strong>Marine</strong> multi-groove bearings. Afterremoving the worn staves and keeper strips <strong>Orkot</strong> ®bushes can be machined to suit the bronze carrier inthe work shop or alternatively bored insitu.0.14The length to a diameter ratio of an <strong>Orkot</strong> ® <strong>Marine</strong>grade stern tube bearing should be held to 2:1 ifpossible. Today the majority of classification societiesallow this as longer bearings increase the problem ofalignment. If classification rules require a longerbearings to be used it is suggested that the bearingclearance at the forward end for the additional length,above the 2:1 shaft to diameter ratio, should beincreased to provide a safety bearing. This can reducethe risk of misalignment and is illustrated in figure 6.Corfficient of friction0.120.100.080.060.04Shaft diameter=200mm (8")DL=2DIncreased bearing diameter0.0200 20 40 60 80 100 120Shaft Speed (Rpm)The actual bearing should be positionedwhere the load is, hence at the propeller sideFigure 5: Coefficient of friction as a function ofshaft speed.Multi and twin groove designs can be manufactured asfull or split bearings. Full bearings are normally fittedwith an interference fit. This can be achieved by pressfitting or freeze fitting. If more than one bearing isrequired to be fitted into a stern tube, care must betaken to ensure water grooves are in line.Where multi piece bearings abut, a radial groove,similar in size to the bearings longitudinal grooves,should be machined in both bores at the abutment.These grooves ensure that an adequate water flowoccurs even if the water grooves in the abuttedbearings are not aligned correctly.Split bearings should be assembled with aninterference fit, if necessary this can be introducedusing tapered keys.<strong>Orkot</strong> ® have developed various special split bearingdesigns for Naval applications.Figure 6: Long bearing with increased clearance“safety bearing”Water Flow RateA water flow rate of 0.18 litres per minute per mm ofshaft diameter is required or 1.21 US gallons per minper inch of shaft diameter.11

<strong>Orkot</strong> ® <strong>Marine</strong> <strong>Bearings</strong><strong>Engineering</strong> <strong>Manual</strong> for Rudder and Water Lubricated Propeller Shaft <strong>Bearings</strong>Bearing Interference and ClearanceTo simplify the bearing design sizes are tabulated.AWD*To improve shaft running the bottom (6 o'clock)groove should be omitted.The wall thicknesses "A" indicated are the minimumre<strong>com</strong>mended.Bearing to have 3mm x 30° (1/8" x 30°) chamfer onO/D and I/D.The <strong>Orkot</strong> ® <strong>Marine</strong> <strong>Bearings</strong> calculation sheet can beused for stern tube calculations.Rad minFigure 7: Multi groove bearing for 50 mm (2" Dia.)shaft with bottom groove omitted.Warning: Please note that the <strong>Orkot</strong> ® <strong>Marine</strong>Bearing calculation is set up as standard to calculaterudder bearing dimensions. As such the standardinterference and clearance figures given must bechanged to those stated in this section.Table 10: Multi Groove Bearing in mmShaft Size Min Wall Min Min Shaft Number Groove Groove GrooveThickness Interference Clearance of Angle Width DepthA B B Grooves W Dmm mm mm Degrees mm mm30 - 60 8 0.15 0.30 4 72.0 8 460 - 100 9 0.22 0.41 5 60.0 8 4100 - 150 10 0.34 0.52 6 51.4 10 6150 - 200 12 0.43 0.63 7 45.0 10 6200 - 250 14 0.56 0.74 8 40.0 12 7250 - 300 14 0.70 0.85 9 36.0 12 7300 - 350 16 0.84 0.96 10 32.7 14 8350 - 400 16 0.97 1.07 11 30.0 14 8400 - 450 20 1.11 1.18 12 27.7 16 10450 - 500 20 1.25 1.29 13 25.7 16 10500 - 550 22 1.40 1.40 14 24.0 18 11550 - 600 22 1.50 1.51 15 22.5 18 11Table 11: Multi Groove Bearing in inchesShaft Size Min Wall Min Min Shaft Number Groove Groove GrooveThickness Interference Clearance of Angle Width DepthA B B Grooves W Dinch inch inch inch Degrees inch inch1.18 - 2.36 0.315 0.006 0.012 4 72 0.315 0.1572.36 - 3.94 0.354 0.009 0.016 5 60 0.315 0.1573.94 - 5.91 0.394 0.013 0.020 6 51.4 0.394 0.2365.91 - 7.87 0.472 0.017 0.025 7 45 0.394 0.2367.87 - 9.84 0.551 0.022 0.029 8 40 0.472 0.2769.84 - 11.8 0.551 0.028 0.033 9 36 0.472 0.27611.8 - 13.8 0.630 0.033 0.038 10 32.7 0.551 0.31513.8 - 15.7 0.630 0.038 0.042 11 30 0.551 0.31515.7 - 17.7 0.787 0.044 0.046 12 27.7 0.630 0.39417.7 - 19.7 0.787 0.049 0.051 13 25.7 0.630 0.39419.7 - 21.7 0.866 0.055 0.055 14 24 0.709 0.43321.7 - 23.6 0.866 0.059 0.059 15 22.5 0.709 0.43312

<strong>Orkot</strong> ® <strong>Marine</strong> <strong>Bearings</strong><strong>Engineering</strong> <strong>Manual</strong> for Rudder and Water Lubricated Propeller Shaft <strong>Bearings</strong>Machining ToleranceThe following tables show the machining tolerances<strong>Orkot</strong> ® Composites machine shop can achieve whenmachining stern tube bearings. These can besubstituted in the calculation with your own machiningtolerance should they differ from those stated.Warning: Please note that the <strong>Orkot</strong> ® <strong>Marine</strong>Bearing calculation is set up as standard to calculaterudder bearing dimensions. As such the standardmachining tolerance figures given must be changedto those stated in this section.Once machining tolerance values have been selectedthey can be entered into the <strong>Marine</strong> BearingCalculation. All of the required element of thecalculation should now be in place and the finalfigures can now be calculated.Table 12: Re<strong>com</strong>mended MachiningTolerance OD and ID for <strong>Orkot</strong> ®Propeller Shaft <strong>Bearings</strong>Diameter OD and ID Tolerance Bandmmmm1 - 100 0.10101 - 300 0.20301 - 500 0.30501 - 900 0.40Table 13Diameter OD and ID Tolerance Bandinchesinches0 - 4 0.0044 - 12 0.00812 - 20 0.01220 - 36 0.016Note:1. These tolerances are for guidance only, reducingthem will reduce the maximum clearance afterfitting. It is important that out of roundnesstolerance is maintained when chocking<strong>com</strong>pounds are used.2. Propeller shaft bearings are longer than rudderbearings; longer lengths require larger tolerances.13

<strong>Orkot</strong> ® <strong>Marine</strong> <strong>Bearings</strong><strong>Engineering</strong> <strong>Manual</strong> for Rudder and Water Lubricated Propeller Shaft <strong>Bearings</strong>Fitting Methods<strong>Orkot</strong> ® <strong>Marine</strong> <strong>Bearings</strong> can be fitted using any one ofthe following methods:● Freeze fittingMethod 1:Method 2:Method 3:● Press fittingUsing liquid nitrogen(immersion method)Using liquid nitrogen(vapour method)Using dry ice and alcohol● BondingOur preferred method is to freeze fit using liquidnitrogen. However descriptions of all methods can befound in this section.Freeze FittingThis is a fast and efficient assembly method for an<strong>Orkot</strong> ® <strong>Marine</strong> bearing. The thermal properties of thematerial allow a good clearance between the bearingand housing when frozen and the material does notbe<strong>com</strong>e brittle at cryogenic temperatures.Note:Extreme care should be taken when using liquidnitrogen to avoid severe burns. Adequate ventilationshould be provided bec<strong>au</strong>se oxygen is depleted whengassing occurs in confined spaces, suppliers of theproducts will provide a data sheet advising on its use.Method 1:Using liquid nitrogen (immersion method)A suggested procedure for method 1 is as follows:1. Check the od of the bearing in at least 3 positionsaround the top, middle and bottom (a total of 9measurements) making a note of the largestfigure recorded.2. Check the id of the housing in at least 3 positionsaround the top, middle and bottom (a total of 9measurements) making a note of the smallestfigure recorded.3. Provide an insulated container capable ofwithstanding a temperature of -197°C (-320°F) andlarge enough to ac<strong>com</strong>modate the bearing beingfitted with enough clearance on the od tofacilitate the insertion and removal of the bearing.4. Place the bearing inside the container and makeefforts to reduce its internal volume. This can bedone by sealing off un-used areas of the containeror filling any voids with rough cut timbers. Thiswill reduce the amount of liquid nitrogen that willbe required.5. Cover the bearing with the liquid nitrogen andmaintain this level for the duration of theprocedure. The nitrogen level will constantly dropas the liquid boils, turns to gas and escapes to theatmosphere. Use an insulated lid to cover thecontainer when possible. Once the liquid stopsboiling and settles down to a simmer then thebearing can be lifted slightly from the liquid andthe upper od measured to check for sufficient sizereduction. If this has not been achieved then thebearing can be returned to the liquid for 10 to 20minutes and then checked again6. Once sufficient clearance between the bearing andthe housing has been achieved then the bearingcan be removed from the nitrogen andtransported to the housing for fitting.7. The apparatus used to transport the bearing afterfreezing will need to be resistant to the cryogenictemperatures they will encounter (e.g. polyesterslings) and suitable to support the weightsinvolved.8. Ensure that the reduced bearing can be locatedquickly and easily. Once it <strong>com</strong>es into contact withany conductive surfaces the rate with which it willreturn to its original dimensions increases greatly.9. Slide the bearing into position, ensuring that it isheld there while its temperature normalises. Oncethe bearings surfaces have cleared of the ice thatforms on them during normalisation then anysupports can be removed.Method 2:Using liquid nitrogen (vapour method)<strong>Orkot</strong> ® bearings can be fitted without a metalcontainer by vaporising the liquid nitrogen within thebearing. This uses less liquid nitrogen and is thereforesafer and less expensive than the immersion method.Please note however that the rate of bearingcontraction is a lot lower using this method when<strong>com</strong>pared to the immersion method. As such thefreezing procedure will take a lot longerA suggested procedure for method 2 is as follows:1. Check the od of the bearing in at least 3 positionsaround the top, middle and bottom (a total of 9measurements) making a note of the largestfigure recorded.2. Check the id of the housing in at least 3 positionsaround the top, middle and bottom (a total of 9measurements) making a note of the smallestfigure recorded.3. Prepare a plywood disk with an od half waybetween that of the od and the id of the bearing.Drill a 15 / 20mm diameter hole in the middle ofthis disk.4. Place the bearing on a smooth, flat, none poroussurface. Seal the joint between this and the id ofthe bearing with silicone sealant.14

<strong>Orkot</strong> ® <strong>Marine</strong> <strong>Bearings</strong><strong>Engineering</strong> <strong>Manual</strong> for Rudder and Water Lubricated Propeller Shaft <strong>Bearings</strong>5. Manufacture a simple lance from 10 mm (.40") orsimilar copper tube, drill approximately twenty 1mm (.40") diameter holes through both walls ofthe pipe and fit a bleed valve to the pipe to controlthe flow of liquid nitrogen. Ensure that you sealthe open end of the lancee.The diagram (Figure 8) illustrates a method ofensuring the bush is square before the fitting starts.6. Place the plywood disk on top of the bearing,and connect the lance to a pressurised liquidnitrogen tank.7. Turn the valves to control the flow on nitrogenuntil vapour can be seen escaping, under pressurefrom the lance. If liquid starts to exit the lance thenthe flow should be reduced until it stops.8. Place the lance though the hole in the centre ofthe disk and into the bearing. Wrap the bearing inan insulating blanket to reduce energy loss from itssurface.9. During the procedure the nitrogen flow will need tobe monitored and adjusted from time to time.Measure the od at the top of the bearing periodically.Housing-1mmFigure 8: Method of ensuring the bush is squarebefore the fitting starts.Bearing operating temperature:-30°C-10°C-20°C 0°C6020mmstep10. Once sufficient clearance between the bearing andthe housing has been achieved then the bearingcan be transported to the housing for fitting.11. The apparatus used to transport the bearing afterfreezing will need to be resistant to the cryogenictemperatures they will encounter (e.g. polyesterslings) and suitable to support the weights involved.Tonnes504030201012. Ensure that the reduced bearing can be locatedquickly and easily. Once it <strong>com</strong>es into contact withany conductive surfaces the rate with which it willreturn to its original dimensions increases greatly.13. Slide the bearing into position, ensuring that it isheld there while its temperature normalises. Oncethe bearings surfaces have cleared of the ice thatforms on them during normalisation then anysupports can be removed.Method 3:Using dry ice and alcoholFreeze fitting using dry ice and alcohol will onlyprovide the required clearance when using very lightinterferences. As such it is rarely a viable method in itsown right and will often also require press fittingFitting with Hydr<strong>au</strong>lic Press orCentre Pull JacksIf a bearing is to be press fitted, installers should ensurethat they have equipment available to deliver adequateforce to press the bearing fully into the housing. Theease of fitting will vary dependent on the finish of thehousing and this should be considered when calculatingthe force required. When press fitting a bearing it isimportant that it is in line and square with the borebefore the operation beings, an adequate chamfer onthe housing will prevent shaving of the bush.0150 250 350 450 550 650 750 850100 200 300 400 500 600 700 800Diameter (mm)Figure 9: Fitting force (Tonnes)Tons6655443322110Bearing operating temperature:-22°F-14°F-4°F 32°F6 10 14 18 22 26 3 344 8 12 16 20 24 28 32Diameter (inches)Figure 10: Fitting force (Tons)Figures 9 and 10 show the typical fitting force of abearing, length/diameter ratio 1:1An initial force to move the bearing may be higherthan given in the graphThe actual force will vary dependent on the conditionof the housing, leading chamfers and the length/diameter ratio.15

<strong>Orkot</strong> ® <strong>Marine</strong> <strong>Bearings</strong><strong>Engineering</strong> <strong>Manual</strong> for Rudder and Water Lubricated Propeller Shaft <strong>Bearings</strong>BondingThe method of fixture will depend upon the designemployed, however the key point to be emphasisedhere is that in addition to traditional mechanicalfixing, <strong>Orkot</strong> ® materials can be bonded to both itselfand metallic substrates. Please note that if theassembly is to experience in excess of 60-70°C theninterference fitting should be replaced withadhesive bonding.Numerous adhesives are <strong>com</strong>patible with <strong>Orkot</strong> ® andhave been tested within our laboratory facilities.Generally the most suitable adhesives are:● Epoxies.● Acrylics .● Cyanoacrylates.● Polyurethanes.The following is a list of adhesive suppliers whoseproducts have been tested and are approved for usewith <strong>Orkot</strong> ® materials:● Araldite● Belzona● Bisonite● Chockfast● Loctite● PermabondFor specific details of bonding agents and conditionsplease contact our Technical department.General terms and preparations are requiredirrespective of the adhesive to be used.Terms:● The bonding agent is referred to as the adhesive.● The material/surface to which the <strong>Orkot</strong> ® is to bebonded is the substrate.● The distance between the <strong>Orkot</strong> ® and the substrateis the gap.● The ability of the adhesive to bridge and fill the gapis the gap fill.Preparations:● Suitable substrates are <strong>Orkot</strong> ® materials themselvesand various metals (including stainless steel).● Plastics such as polyethylene, polypropylene,polycarbonate, PVC, PTFE are unsuitable substratesfor bonding to <strong>Orkot</strong> ® materials.● The key to effective adhesion is in the preparationof the substrate and the material to be bonded.● Ensure no boundary layers such as oxides or greaseare present. Degrease with a suitable solventensuring local health and safety guidelines arefollowed. <strong>Orkot</strong> ® can be degreased by using a quickwipe with a solvent such as acetone, but exposure tothe solvent must be kept brief so as not to attackthe <strong>Orkot</strong> ® material. Oxides can be removed by useof fine abrasive paper or wire wool.● Roughen the surface. Ideally where metals areinvolved use shot blasting. Ensure any remainingparticulates are removed from the surface. Generallythe slightly fibrous surface of <strong>Orkot</strong> ® does notrequire roughening, though the use of abrasivepaper is acceptable so long as any dust is removed.● The assembled <strong>com</strong>ponents may need support whilethe adhesive sets. This cure time will vary with theconditions under which the adhesive is used.Typically a rule of thumb is that the cure time willhalf for every 10°C increase in temperature.● In terms of assembly, avoid butt joints in favour oflap, so that loads applied to the adhesive joint willact across the assembly in shear.16

<strong>Orkot</strong> ® <strong>Marine</strong> <strong>Bearings</strong><strong>Engineering</strong> <strong>Manual</strong> for Rudder and Water Lubricated Propeller Shaft <strong>Bearings</strong>Machining InstructionsGeneral<strong>Orkot</strong> ® materials are readily machinable byconventional machine shop techniques. As a generalguide, methods used for brass, aluminium or lignumvitae will apply for <strong>Orkot</strong> ® materials. It is preferable touse tungsten carbide turning tools with cutting speedsof 5.5 metres (19 feet) per second. <strong>Orkot</strong> ® materialsmust be machined dry without the use of coolant.TurningTungsten carbide tooling of the butt welded typeusing K20 grade carbide is suitable for mostapplications. If carbide inserts are used, thenaluminium grades with high positive rates give bestresults e.g. Plansee grade H10T, Sandvik H10A orH13A, Mitsubishi HTI10.For heavy wall thickness, the internal and externaldiameters should be machined together to reducevibration.No asbestos is used in the manufacturing of <strong>Orkot</strong> ®<strong>Marine</strong> and the material is <strong>com</strong>pletely non toxic. It ishowever advisable to use adequate dust extractionwhen machining. If unavailable, operators should weardust particle masks.For small volume work and machining of chamfers,radii and other forms, then high speed steel givesgood results, but tool life is shorter than withtungsten carbide.Cutting Angle for ToolsTURNINGPARTING OFFR 1-2mm (0.04 - 0.08 inch)3° - 5°5°5°5° - 20°5°BORING5°3°10°3°15°3°3°Figure 11: Turning and boringFigure 12: Parting offTable 14: Speeds in mmDiameter (mm)Rpm0 - 50 210050 - 100 1000100 - 150 700150 - 200 550200 - 300 350300 - 400 250400 - 500 200500 - 600 175600 - 700 150700 - 800 130800 - 900 120900 - 1000 100Table 15: Speeds in inchesDiameter (inch)Rpm0 - 2 21002 - 4 10004 - 6 7006 - 8 5508 - 12 35012 - 16 25016 - 20 20020 - 24 17524 - 28 15028 - 32 13032 - 36 12036 - 40 10017

<strong>Orkot</strong> ® <strong>Marine</strong> <strong>Bearings</strong><strong>Engineering</strong> <strong>Manual</strong> for Rudder and Water Lubricated Propeller Shaft <strong>Bearings</strong>Table 16: Feed Rates in mmType of Roughing Finishing UnitmachiningTurning 0.7 0.25 mm/revBoring 0.5 0.20 mm/revParting 0.4 0.20 mm/revTable 17: Feed Rates in inchesType of Roughing Finishing UnitmachiningTurning 0.028 0.010 inch/revBoring 0.020 0.008 inch/revParting 0.016 0.008 inch/revGrooving<strong>Orkot</strong> ® materials can be readily grooved on a lathe,shaping, milling or boring machine with a 90 degreemachining head. For most one off applications a latheis adequate. A sharp high speed steel tool ground tothe correct form should be clamped in a long boringbar with a three degree clearance ground on the sideof the tool. No top clearance is required.The chuck may be marked for the correctly spacednumber of grooves and each groove shaped in turn.A 0.2 mm (0.008") depth of cut should be used, forlong bearings a steady may be required. The machinefast traverse, (with the spindle locked) can often beused. Linear speeds up to 10 m/min or 30 feet/mincan be achieved.275025002250275025002250Revolutions per minute (Rpm)20001750150012501000750500250Revolutions per minute (Rpm)20001750150012501000750500250050 200 400 600 800 1000 12000 100 300 500 700 900 110002 8 16 24 32 40 480 4 12 20 28 36 44Diameter (mm)Diameter (inches)Figure 13: Machining Speeds as a function of Rpmand diameter (mm)Figure 14: Machining Speeds as a function of Rpmand diameter (inches)Drilling<strong>Orkot</strong> ® materials are easily drilled using eitherconventional high speed steel or carbide tipped drills.The following speed and feeds are suggested:Table 18: Speeds and Feeds by DrillingDrill Diameter Speed Feedmm Rpm mm/min5 1600 30010 800 40015 600 40020 400 40025 350 40030 300 400Table 19: Speeds and Feeds by DrillingDrill Diameter Speed Feedinch Rpm inch/min0.2 1600 120.4 800 160.6 600 160.8 400 161.0 350 161.2 300 16Depth of CutRoughing 10mm or 0.4inchFinishing 3mm or 0.12inchSmaller cuts may lead to tools rubbing, c<strong>au</strong>sing wearwhich produces excessive heat build up in thefinished part.18

<strong>Orkot</strong> ® <strong>Marine</strong> <strong>Bearings</strong><strong>Engineering</strong> <strong>Manual</strong> for Rudder and Water Lubricated Propeller Shaft <strong>Bearings</strong>Health and Safety Data1. PRODUCT AND COMPANY IDENTIFICATIONProduct name : ‘<strong>Orkot</strong>’ and/or ‘Luytex’Suppliers : <strong>Orkot</strong> Composites <strong>Orkot</strong> CompositesBradmarsh Business Park2535 Prairie RoadRotherhamEugeneS60 1BX Oregon, 97402United KingdomUSAEmergency telephone number : +44 1709 789800 +1 541 688 55292. COMPOSITION / INFORMATION ON INGREDIENTSGeneral Description : Fibre reinforced plastic materialInformation on ingredients : May contain – Polyester/aramid fibres,polyester/epoxy resin, ptfe, molybdenumdisulphide, graphite, calcium carbonate3. HAZARDS IDENTIFICATIONPhysical/chemical hazards : None knownHuman health hazards : None known, avoid breathing machining dust4. FIRST-AID MEASURESInhalation : Fresh air, seek medical advice if irritation developsIngestion : Wash out mouth with water, seek medical adviceSkin contact : Not applicableEye contact : Irrigate with appropriate eye wash5. FIRE-FIGHTING MEASURESSuitable extinguishing media : Water, foam, carbon dioxide, dry powderNot Suitable extinguishing media : Not applicableHazardous de<strong>com</strong>position products : Carbon, carbon oxidesProtection of fire fighters : Use breathing apparatus19

<strong>Orkot</strong> ® <strong>Marine</strong> <strong>Bearings</strong><strong>Engineering</strong> <strong>Manual</strong> for Rudder and Water Lubricated Propeller Shaft <strong>Bearings</strong>6. ACCIDENTAL RELEASE MEASURESPersonal prec<strong>au</strong>tions : Filter mask for dust (machining)Environmental prec<strong>au</strong>tions : Avoid dispersion of dust (machining)Methods for cleaning up : Transfer into suitable containers for disposal7. HANDLING AND STORAGEHandling : Observe good industrial safety and hygiene practice.Storage : Store in a cool, dry place out of direct sunlightRe<strong>com</strong>mended packaging : Paper, card, plastics, wood8. EXPOSURE CONTROLS / PERSONAL PROTECTION<strong>Engineering</strong> measures : When machining use local exh<strong>au</strong>stventilation. Collect dust for disposalMachined swarf is flammableHygiene measures : Avoid breathing machined dust.Occupational exposure limitsChemical name : DustOEL (UK) : < 10 mg/m 3 8 hour TWA tot. inhalable dust< 5 mg/m 3 8 hour respirable dustPersonal protective equipmentRespiratory system : Dust mask, type FFP1 minimumSkin and body : Work clothingHands : Not applicableEyes : Safety goggles when machiningOther protective equipment : Not applicable9. PHYSICAL AND CHEMICAL PROPERTIESPhysical state : SolidColour : Variable – white, black, grey, blue,turquoise, green (<strong>com</strong>pound dependent)Odour : Weak, characteristicMelting point : Does not meltBulk density : 1200 – 1450 kg/m 3Solubility in water : InsolublepH : Not applicableFlash point : Not applicableExplosion properties : As with all dusts a risk of explosion exists inRestricted environments20

<strong>Orkot</strong> ® <strong>Marine</strong> <strong>Bearings</strong><strong>Engineering</strong> <strong>Manual</strong> for Rudder and Water Lubricated Propeller Shaft <strong>Bearings</strong>10. STABILITY AND REACTIVITYStability : StableConditions to avoid : None knownMaterials to avoid : None knownHazardous reactions : None knownHazardous de<strong>com</strong>position products : De<strong>com</strong>position does not occur underre<strong>com</strong>mended storage and handling11. TOXICOLOGICAL INFORMATIONInhalation : Inhalation of dust may c<strong>au</strong>se irritation to respiratory tractAcute toxicity – Oral : None knownSkin irritation : None knownEye irritation : Dust may c<strong>au</strong>se irritationOther information : No know toxicological effects areassociated with this material12. ECOLOGICAL INFORMATIONPersistence/degradability : This material is not readily biodegradableEcotoxicity : No known ecotoxicity existsOther information : Not applicable13. DISPOSAL CONSIDERATIONSWaste of residues : Disposal in accordance with national and local regulationsContaminated packaging : Packaging can be recycled Cleaning agent - water14. TRANSPORT INFORMATIONNational transport regulations (UK) : Not applicable15. REGULATORY INFORMATIONClassification according to EU : This product does not have to be classifiedRegulations 67/548/EEC-88/379/EECSafety phrases : Avoid breathing machining dustContains : Not applicableNational regulationsUnited Kingdom : No additional national regulations are knownto the supplier21

<strong>Orkot</strong> ® <strong>Marine</strong> <strong>Bearings</strong><strong>Engineering</strong> <strong>Manual</strong> for Rudder and Water Lubricated Propeller Shaft <strong>Bearings</strong>16. OTHER INFORMATIONThis safety data sheet is based on <strong>Orkot</strong> ® Composites present knowledge and experience, and is intended to serveas a guide for safe handling of the product regarding to health and environmental aspects.The information given in this data sheet was obtained from sources we believe are reliable. The information is,however, provided without any representation or warranty, expressed or implied, regarding its accuracy orcorrectness.The conditions or methods of handling, storage, use and disposal of the product are beyond our control and maybe beyond our knowledge. For this, and other reasons, we do not assume responsibility and expressly disclaimliability for loss, damage or expense arising out of or in any way connected with the handling, storage, use ordisposal of the product.22

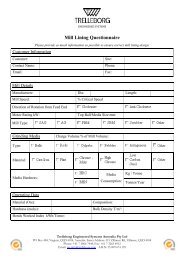

<strong>Orkot</strong> ® <strong>Marine</strong> <strong>Bearings</strong><strong>Engineering</strong> <strong>Manual</strong> for Rudder and Water Lubricated Propeller Shaft <strong>Bearings</strong>Rudder / Stern Shaft Bearing Calculation<strong>Orkot</strong> <strong>Marine</strong> <strong>Bearings</strong>, Bradmarsh Business Park, Rotherham, S60 1BXPhone: +44 1709 789800 Fax: +44 1709 789802. E-mail: enquiries@orkotmarine.<strong>com</strong>Company : Date :Contact : Phone :Vessel Name : Fax :Reference Number :All measurments are in mm unless otherwise stated.Housing I/D Max (mm)Housing I/D Min (mm)Application:Shaft O/D Max (mm)Shaft O/D Min (mm)Operating Temp (Degrees C) Machining Temp (Degrees C)Calculation ChecksOKOKMin Interference (mm) *<strong>Manual</strong> OverideClearance Re<strong>com</strong>mended by SomeClassification SocietiesMin Clearance Re<strong>com</strong>mended by <strong>Orkot</strong>LtdMin Clearance (mm) * (Mean of Above)<strong>Manual</strong> OverideM/C Tolerance (O/D) (mm) ** M/C Tolerance (I/D) (mm) **<strong>Manual</strong> Overide<strong>Manual</strong> Overide(A) Housing I/D Max + Interference Min = Bearing O/D Min (A)+ =(B) Bearing O/D Min (A) + M/C Tolerance (O/D) = Bearing O/D Max (B)+ =(C) Shaft O/D Max + [Bearing O/D Max (B) - Housing I/D Min] + Min Clearance = Bearing I/D Min (C)+ [ - ] + =(D) Bearing I/D Min (C) + M/C Tolerance (I/D) = Bearing I/D Max (D)+ =(E) Bearing I/D Min (C) - [Bearing O/D Max (B) - Housing I/D Min] = Bearing I/D Fitted Min (E)- [ - ] =(F) Bearing I/D Max (D) -[Bearing O/D Min (A) - Housing I/D Max] = Bearing I/D Fitted Max (F)- [ - ] =(G) Fitted Bush I/D Min (E) - Shaft O/D Max = Fitted Clearance Min (G)- =(H) Fitted Bush Max (F) - Shaft O/D Min = Fitted Clearance Max (H)- =* These <strong>au</strong>tomatic figures are the standard clearances and interference's for <strong>Orkot</strong> rudder bearings and can be overriden in the boxes provided if requiredFor Stern tube bearings override these with the figures shown on page 16 of <strong>Orkot</strong>'s <strong>Engineering</strong> <strong>Manual</strong> (v 3.2)** These figures apply to <strong>Orkot</strong>'s machining processes. If your process tolerances are different then override them in the box provided.Copyright Polymer Sealing Solutions 2002This information is confidential and is supplied on the express condition that it shall not be lent or copied or reproduced or disclosed to any other person in whole or inpart without the written permission of <strong>Orkot</strong> Composites, Bradmarsh Business Park, Rotherham, U.K.<strong>Orkot</strong> Composites, Bradmarsh Business Park, Rotherham, S601BX, England.Phone: ++44 (0)1709 789828. Fax: ++44 (0)1709 789802. 24hr Emergency Line: ++44 (0)1709 78984023

<strong>Orkot</strong> ® <strong>Marine</strong> <strong>Bearings</strong><strong>Engineering</strong> <strong>Manual</strong> for Rudder and Water Lubricated Propeller Shaft <strong>Bearings</strong>Rudder / Stern Shaft Bearing Calculation<strong>Orkot</strong> <strong>Marine</strong> <strong>Bearings</strong>, Bradmarsh Business Park, Rotherham, S60 1BXPhone: +44 1709 789800 Fax: +44 1709 789802. E-mail: enquiries@orkotmarine.<strong>com</strong>Company : <strong>Orkot</strong> <strong>Marine</strong> <strong>Bearings</strong> Date : 10-Mar-03Contact : Phil Ryde Phone :Vessel Name : Fax :Reference Number : Application: Rudder Bearing ExampleAll measurments are in mm unless otherwise stated.Housing I/D Max (mm) 550.120 Shaft O/D Max (mm) 500.030Housing I/D Min (mm) 550.050 Shaft O/D Min (mm) 499.980Operating Temp (Degrees C) -10 Machining Temp (Degrees C) 20Calculation ChecksClearance Re<strong>com</strong>mended by SomeOK Classification Societies 2.00OKMin Clearance Re<strong>com</strong>mended by <strong>Orkot</strong>Ltd 1.10Min Interference (mm) * 1.38 Min Clearance (mm) * (Mean of Above) 1.55<strong>Manual</strong> Overide 1.38 <strong>Manual</strong> Overide 1.55M/C Tolerance (O/D) (mm) ** 0.25 M/C Tolerance (I/D) (mm) ** 0.25<strong>Manual</strong> Overide 0.25 <strong>Manual</strong> Overide 0.25(A) Housing I/D Max + Interference Min = Bearing O/D Min (A)550.12 + 1.38 = 551.50(B) Bearing O/D Min (A) + M/C Tolerance (O/D) = Bearing O/D Max (B)551.50 + 0.25 = 551.75(C) Shaft O/D Max + [Bearing O/D Max (B) - Housing I/D Min] + Min Clearance = Bearing I/D Min (C)500.03 + [ 551.75 - 550.05 ] + 1.55 = 503.28(D) Bearing I/D Min (C) + M/C Tolerance (I/D) = Bearing I/D Max (D)503.28 + 0.25 = 503.53(E) Bearing I/D Min (C) - [Bearing O/D Max (B) - Housing I/D Min] = Bearing I/D Fitted Min (E)503.28 - [ 551.75 - 550.05 ] = 501.58(F) Bearing I/D Max (D) -[Bearing O/D Min (A) - Housing I/D Max] = Bearing I/D Fitted Max (F)503.53 - [ 551.50 - 550.12 ] = 502.15(G) Fitted Bush I/D Min (E) - Shaft O/D Max = Fitted Clearance Min (G)501.58 - 500.03 = 1.55(H) Fitted Bush Max (F) - Shaft O/D Min = Fitted Clearance Max (H)502.15 - 499.98 = 2.17* These <strong>au</strong>tomatic figures are the standard clearances and interference's for <strong>Orkot</strong> rudder bearings and can be overriden in the boxes provided if requiredFor Stern tube bearings override these with the figures shown on page 16 of <strong>Orkot</strong>'s <strong>Engineering</strong> <strong>Manual</strong> (v 3.2)** These figures apply to <strong>Orkot</strong>'s machining processes. If your process tolerances are different then override them in the box provided.Copyright Polymer Sealing Solutions 2002This information is confidential and is supplied on the express condition that it shall not be lent or copied or reproduced or disclosed to any other person in whole or inpart without the written permission of <strong>Orkot</strong> Composites, Bradmarsh Business Park, Rotherham, U.K.<strong>Orkot</strong> Composites, Bradmarsh Business Park, Rotherham, S601BX, England.Phone: ++44 (0)1709 789828. Fax: ++44 (0)1709 789802. 24hr Emergency Line: ++44 (0)1709 78984024

<strong>Orkot</strong> ® <strong>Marine</strong> <strong>Bearings</strong><strong>Engineering</strong> <strong>Manual</strong> for Rudder and Water Lubricated Propeller Shaft <strong>Bearings</strong>Rudder / Stern Shaft Bearing Calculation<strong>Orkot</strong> <strong>Marine</strong> <strong>Bearings</strong>, Bradmarsh Business Park, Rotherham, S60 1BXPhone: +44 1709 789800 Fax: +44 1709 789802. E-mail: enquiries@orkotmarine.<strong>com</strong>Company : <strong>Orkot</strong> <strong>Marine</strong> <strong>Bearings</strong> Date : 10-Mar-03Contact : Phil Ryde Phone :Vessel Name : Fax :Reference Number : Application: Stern Tube Bearing ExampleAll measurments are in mm unless otherwise stated.Housing I/D Max (mm) 252.450 Shaft O/D Max (mm) 198.940Housing I/D Min (mm) 252.320 Shaft O/D Min (mm) 198.850Operating Temp (Degrees C) -10 Machining Temp (Degrees C) 20Calculation ChecksClearance Re<strong>com</strong>mended by SomeOK Classification Societies 1.40OKMin Clearance Re<strong>com</strong>mended by <strong>Orkot</strong>Ltd 0.50Min Interference (mm) * 0.56 Min Clearance (mm) * (Mean of Above) 0.95<strong>Manual</strong> Overide 0.43 <strong>Manual</strong> Overide 0.63M/C Tolerance (O/D) (mm) ** 0.15 M/C Tolerance (I/D) (mm) ** 0.15<strong>Manual</strong> Overide 0.20 <strong>Manual</strong> Overide 0.20(A) Housing I/D Max + Interference Min = Bearing O/D Min (A)252.45 + 0.43 = 252.88(B) Bearing O/D Min (A) + M/C Tolerance (O/D) = Bearing O/D Max (B)252.88 + 0.20 = 253.08(C) Shaft O/D Max + [Bearing O/D Max (B) - Housing I/D Min] + Min Clearance = Bearing I/D Min (C)198.94 + [ 253.08 - 252.32 ] + 0.63 = 200.33(D) Bearing I/D Min (C) + M/C Tolerance (I/D) = Bearing I/D Max (D)200.33 + 0.20 = 200.53(E) Bearing I/D Min (C) - [Bearing O/D Max (B) - Housing I/D Min] = Bearing I/D Fitted Min (E)200.33 - [ 253.08 - 252.32 ] = 199.57(F) Bearing I/D Max (D) -[Bearing O/D Min (A) - Housing I/D Max] = Bearing I/D Fitted Max (F)200.53 - [ 252.88 - 252.45 ] = 200.10(G) Fitted Bush I/D Min (E) - Shaft O/D Max = Fitted Clearance Min (G)199.57 - 198.94 = 0.63(H) Fitted Bush Max (F) - Shaft O/D Min = Fitted Clearance Max (H)200.10 - 198.85 = 1.25* These <strong>au</strong>tomatic figures are the standard clearances and interference's for <strong>Orkot</strong> rudder bearings and can be overriden in the boxes provided if requiredFor Stern tube bearings override these with the figures shown on page 16 of <strong>Orkot</strong>'s <strong>Engineering</strong> <strong>Manual</strong> (v 3.2)** These figures apply to <strong>Orkot</strong>'s machining processes. If your process tolerances are different then override them in the box provided.Copyright Polymer Sealing Solutions 2002This information is confidential and is supplied on the express condition that it shall not be lent or copied or reproduced or disclosed to any other person in whole or inpart without the written permission of <strong>Orkot</strong> Composites, Bradmarsh Business Park, Rotherham, U.K.<strong>Orkot</strong> Composites, Bradmarsh Business Park, Rotherham, S601BX, England.Phone: ++44 (0)1709 789828. Fax: ++44 (0)1709 789802. 24hr Emergency Line: ++44 (0)1709 78984025

<strong>Orkot</strong> ® <strong>Marine</strong> <strong>Bearings</strong><strong>Engineering</strong> <strong>Manual</strong> for Rudder and Water Lubricated Propeller Shaft <strong>Bearings</strong>This information in this manual is based on many years of experience in the manufacture and application of <strong>Orkot</strong> ® Composites products.However, unknown parameters and conditions may restrict general statements during usage. It is vital that customers satisfy themselves as tothe suitability of individual products through adequate testing. For this reason, and due to the wide range of applications of our products,Smiths Group plc and <strong>Orkot</strong> ® Composites can accept no liability as to the suitability or correctness of our general re<strong>com</strong>mendations inindividual cases. For specific operating conditions please consult your <strong>Orkot</strong> ® Composites Technical representative.The application limits for pressure, temperature and speed given in this catalogue are maximum values determined in the laboratory. Duringpractical applications it should be remembered that due to the interaction of the operating parameters, the maximum values must be setcorrespondingly lower. For exceptional operating conditions, please contact us.This edition supersedes all previous brochures.© Smiths Group Plc / <strong>Orkot</strong> ® <strong>Marine</strong> <strong>Bearings</strong> 2003. All rights reserved.This brochure, or any part thereof, may not be reproduced without our permission.Non Smiths Group trade marks are referred to for technical advice only and do not express any preference to the use of these products. Thegenuine rights and liability of the owners of these trade marks are applicable.Araldite ® is a trade mark of Ciba-Geigy.Bisonite ® is a trade mark of the Bolton Group.Belzona ® is a trade mark of Belzona Molocular Ltd.Chockfast ® is a trade mark of ITW Philadelphia Resins Corporation.Epocast ® is a trade mark of Springer <strong>Marine</strong>+Industrial Services GmbHInconel ® is a trade mark of INCO Alloys International, Inc.Loctite ® is a trade mark of Loctite Corporation.<strong>Orkot</strong> ® is a trade mark of Polymer Sealing Solutions Ltd.Permabond ® a trade mark of Permabond Europe, a division of National Starch & Chemical.Stellite ® is a trade mark of Deloro Stellite.26

For further information visit: www.orkotmarine.usEurope, Africa, Asia<strong>Orkot</strong> CompositesBradmarsh Business ParkRotherhamS60 1BXUnited KingdomTel: +44 (0)1709 789 828Fax: +44 (0)1709 789 802Email: enquiries@orkotmarine.<strong>com</strong>24 Hour Emergency Line: +44 (0)1709 789 840North & South America<strong>Orkot</strong> Composites2535 Prairie RoadEugeneOregon, 97402USATel: +1 (541) 688 5529Fax: +1 (541) 688 2079Email: inquiries.americas@orkotmarine.<strong>com</strong>24 Hour Emergency Line: +1 (800) 546 7568© Smiths Group Plc / <strong>Orkot</strong> <strong>Marine</strong> <strong>Bearings</strong> 2003. All rights reserved designed & produced by visualsource.co.uk