Orkot Marine Bearings: Engineering Manual - Trelleborg.com.au

Orkot Marine Bearings: Engineering Manual - Trelleborg.com.au

Orkot Marine Bearings: Engineering Manual - Trelleborg.com.au

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

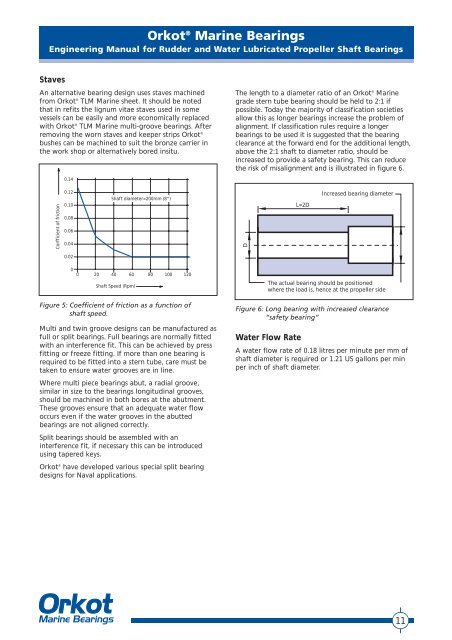

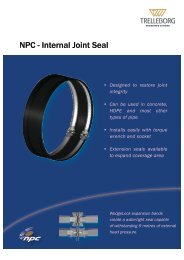

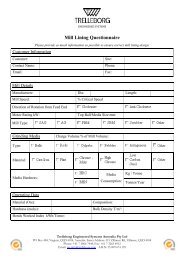

<strong>Orkot</strong> ® <strong>Marine</strong> <strong>Bearings</strong><strong>Engineering</strong> <strong>Manual</strong> for Rudder and Water Lubricated Propeller Shaft <strong>Bearings</strong>StavesAn alternative bearing design uses staves machinedfrom <strong>Orkot</strong> ® TLM <strong>Marine</strong> sheet. It should be notedthat in refits the lignum vitae staves used in somevessels can be easily and more economically replacedwith <strong>Orkot</strong> ® TLM <strong>Marine</strong> multi-groove bearings. Afterremoving the worn staves and keeper strips <strong>Orkot</strong> ®bushes can be machined to suit the bronze carrier inthe work shop or alternatively bored insitu.0.14The length to a diameter ratio of an <strong>Orkot</strong> ® <strong>Marine</strong>grade stern tube bearing should be held to 2:1 ifpossible. Today the majority of classification societiesallow this as longer bearings increase the problem ofalignment. If classification rules require a longerbearings to be used it is suggested that the bearingclearance at the forward end for the additional length,above the 2:1 shaft to diameter ratio, should beincreased to provide a safety bearing. This can reducethe risk of misalignment and is illustrated in figure 6.Corfficient of friction0.120.100.080.060.04Shaft diameter=200mm (8")DL=2DIncreased bearing diameter0.0200 20 40 60 80 100 120Shaft Speed (Rpm)The actual bearing should be positionedwhere the load is, hence at the propeller sideFigure 5: Coefficient of friction as a function ofshaft speed.Multi and twin groove designs can be manufactured asfull or split bearings. Full bearings are normally fittedwith an interference fit. This can be achieved by pressfitting or freeze fitting. If more than one bearing isrequired to be fitted into a stern tube, care must betaken to ensure water grooves are in line.Where multi piece bearings abut, a radial groove,similar in size to the bearings longitudinal grooves,should be machined in both bores at the abutment.These grooves ensure that an adequate water flowoccurs even if the water grooves in the abuttedbearings are not aligned correctly.Split bearings should be assembled with aninterference fit, if necessary this can be introducedusing tapered keys.<strong>Orkot</strong> ® have developed various special split bearingdesigns for Naval applications.Figure 6: Long bearing with increased clearance“safety bearing”Water Flow RateA water flow rate of 0.18 litres per minute per mm ofshaft diameter is required or 1.21 US gallons per minper inch of shaft diameter.11