Orkot Marine Bearings: Engineering Manual - Trelleborg.com.au

Orkot Marine Bearings: Engineering Manual - Trelleborg.com.au

Orkot Marine Bearings: Engineering Manual - Trelleborg.com.au

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

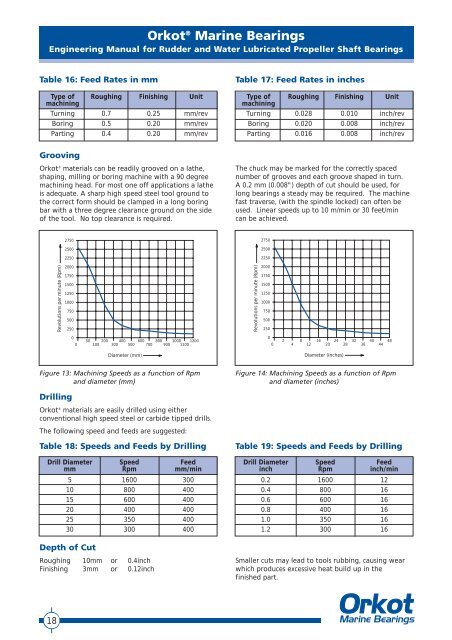

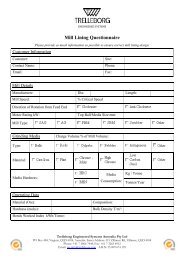

<strong>Orkot</strong> ® <strong>Marine</strong> <strong>Bearings</strong><strong>Engineering</strong> <strong>Manual</strong> for Rudder and Water Lubricated Propeller Shaft <strong>Bearings</strong>Table 16: Feed Rates in mmType of Roughing Finishing UnitmachiningTurning 0.7 0.25 mm/revBoring 0.5 0.20 mm/revParting 0.4 0.20 mm/revTable 17: Feed Rates in inchesType of Roughing Finishing UnitmachiningTurning 0.028 0.010 inch/revBoring 0.020 0.008 inch/revParting 0.016 0.008 inch/revGrooving<strong>Orkot</strong> ® materials can be readily grooved on a lathe,shaping, milling or boring machine with a 90 degreemachining head. For most one off applications a latheis adequate. A sharp high speed steel tool ground tothe correct form should be clamped in a long boringbar with a three degree clearance ground on the sideof the tool. No top clearance is required.The chuck may be marked for the correctly spacednumber of grooves and each groove shaped in turn.A 0.2 mm (0.008") depth of cut should be used, forlong bearings a steady may be required. The machinefast traverse, (with the spindle locked) can often beused. Linear speeds up to 10 m/min or 30 feet/mincan be achieved.275025002250275025002250Revolutions per minute (Rpm)20001750150012501000750500250Revolutions per minute (Rpm)20001750150012501000750500250050 200 400 600 800 1000 12000 100 300 500 700 900 110002 8 16 24 32 40 480 4 12 20 28 36 44Diameter (mm)Diameter (inches)Figure 13: Machining Speeds as a function of Rpmand diameter (mm)Figure 14: Machining Speeds as a function of Rpmand diameter (inches)Drilling<strong>Orkot</strong> ® materials are easily drilled using eitherconventional high speed steel or carbide tipped drills.The following speed and feeds are suggested:Table 18: Speeds and Feeds by DrillingDrill Diameter Speed Feedmm Rpm mm/min5 1600 30010 800 40015 600 40020 400 40025 350 40030 300 400Table 19: Speeds and Feeds by DrillingDrill Diameter Speed Feedinch Rpm inch/min0.2 1600 120.4 800 160.6 600 160.8 400 161.0 350 161.2 300 16Depth of CutRoughing 10mm or 0.4inchFinishing 3mm or 0.12inchSmaller cuts may lead to tools rubbing, c<strong>au</strong>sing wearwhich produces excessive heat build up in thefinished part.18