TIMREX® Graphites and Cokes for Friction Materials - Timcal

TIMREX® Graphites and Cokes for Friction Materials - Timcal

TIMREX® Graphites and Cokes for Friction Materials - Timcal

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

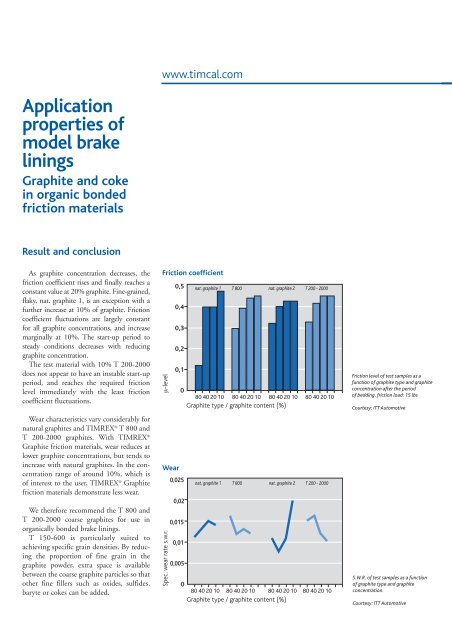

www.timcal.comApplicationproperties ofmodel brakeliningsGraphite <strong>and</strong> cokein organic bondedfriction materialsResult <strong>and</strong> conclusionAs graphite concentration decreases, thefriction coefficient rises <strong>and</strong> finally reaches aconstant value at 20% graphite. Fine-grained,flaky, nat. graphite 1, is an exception with afurther increase at 10% of graphite. <strong>Friction</strong>coefficient fluctuations are largely constant<strong>for</strong> all graphite concentrations, <strong>and</strong> increasemarginally at 10%. The start-up period tosteady conditions decreases with reducinggraphite concentration.The test material with 10% T 200-2000does not appear to have an instable start-upperiod, <strong>and</strong> reaches the required frictionlevel immediately with the least frictioncoefficient fluctuations.Wear characteristics vary considerably <strong>for</strong>natural graphites <strong>and</strong> TIMREX ® T 800 <strong>and</strong>T 200-2000 graphites. With TIMREX ®Graphite friction materials, wear reduces atlower graphite concentrations, but tends toincrease with natural graphites. In the concentrationrange of around 10%, which isof interest to the user, TIMREX ® Graphitefriction materials demonstrate less wear.We there<strong>for</strong>e recommend the T 800 <strong>and</strong>T 200-2000 coarse graphites <strong>for</strong> use inorganically bonded brake linings.T 150-600 is particularly suited toachieving specific grain densities. By reducingthe proportion of fine grain in thegraphite powder, extra space is availablebetween the coarse graphite particles so thatother fine fillers such as oxides, sulfides,baryte or cokes can be added.<strong>Friction</strong> coefficientµ-level0,50,40,30,20,1WearSpec. wear rate s.w.r.0,0250,0150,010,005nat. graphite 1 T 800 nat. graphite 2 T 200 - 2000080 40 20 10 80 40 20 10 80 40 20 10 80 40 20 10Graphite type / graphite content (%)0,020nat. graphite 1 T 800 nat. graphite 2 T 200 - 200080 40 20 10 80 40 20 10 80 40 20 10 80 40 20 10Graphite type / graphite content (%)<strong>Friction</strong> level of test samples as afunction of graphite type <strong>and</strong> graphiteconcentration after the periodof bedding, friction load: 15 lbsCourtesy: ITT AutomotiveS.W.R. of test samples as a functionof graphite type <strong>and</strong> graphiteconcentration.Courtesy: ITT Automotive