LEESON Basic Training - iProcesSmart.com

LEESON Basic Training - iProcesSmart.com

LEESON Basic Training - iProcesSmart.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

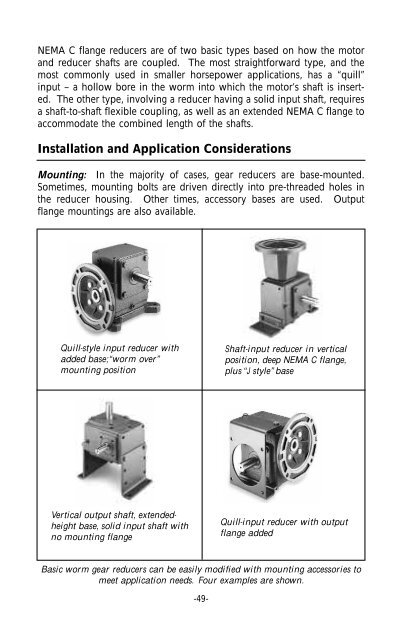

NEMA C flange reducers are of two basic types based on how the motorand reducer shafts are coupled. The most straightforward type, and themost <strong>com</strong>monly used in smaller horsepower applications, has a “quill”input – a hollow bore in the worm into which the motor’s shaft is inserted.The other type, involving a reducer having a solid input shaft, requiresa shaft-to-shaft flexible coupling, as well as an extended NEMA C flange toac<strong>com</strong>modate the <strong>com</strong>bined length of the shafts.Installation and Application ConsiderationsMounting: In the majority of cases, gear reducers are base-mounted.Sometimes, mounting bolts are driven directly into pre-threaded holes inthe reducer housing. Other times, accessory bases are used. Outputflange mountings are also available.Quill-style input reducer withadded base;“worm over”mounting positionShaft-input reducer in verticalposition, deep NEMA C flange,plus “J style” baseVertical output shaft, extendedheightbase, solid input shaft withno mounting flangeQuill-input reducer with outputflange added<strong>Basic</strong> worm gear reducers can be easily modified with mounting accessories tomeet application needs. Four examples are shown.-49-