LEESON Basic Training - iProcesSmart.com

LEESON Basic Training - iProcesSmart.com

LEESON Basic Training - iProcesSmart.com

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

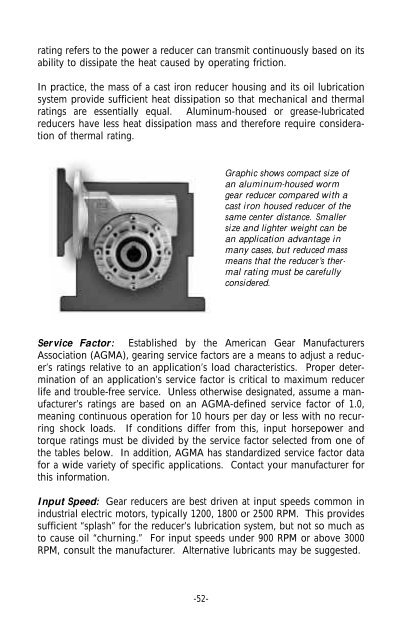

ating refers to the power a reducer can transmit continuously based on itsability to dissipate the heat caused by operating friction.In practice, the mass of a cast iron reducer housing and its oil lubricationsystem provide sufficient heat dissipation so that mechanical and thermalratings are essentially equal. Aluminum-housed or grease-lubricatedreducers have less heat dissipation mass and therefore require considerationof thermal rating.Graphic shows <strong>com</strong>pact size ofan aluminum-housed wormgear reducer <strong>com</strong>pared with acast iron housed reducer of thesame center distance. Smallersize and lighter weight can bean application advantage inmany cases, but reduced massmeans that the reducer’s thermalrating must be carefullyconsidered.Service Factor: Established by the American Gear ManufacturersAssociation (AGMA), gearing service factors are a means to adjust a reducer’sratings relative to an application’s load characteristics. Proper determinationof an application’s service factor is critical to maximum reducerlife and trouble-free service. Unless otherwise designated, assume a manufacturer’sratings are based on an AGMA-defined service factor of 1.0,meaning continuous operation for 10 hours per day or less with no recurringshock loads. If conditions differ from this, input horsepower andtorque ratings must be divided by the service factor selected from one ofthe tables below. In addition, AGMA has standardized service factor datafor a wide variety of specific applications. Contact your manufacturer forthis information.Input Speed: Gear reducers are best driven at input speeds <strong>com</strong>mon inindustrial electric motors, typically 1200, 1800 or 2500 RPM. This providessufficient “splash” for the reducer’s lubrication system, but not so much asto cause oil “churning.” For input speeds under 900 RPM or above 3000RPM, consult the manufacturer. Alternative lubricants may be suggested.-52-