You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

GENERAL SAFETY INSTRUCTIONSFOR MACHINESExtreme caution should be used when operating all power tools. Know your powertool, be familiar with its operation, read through the owner’s manual and practice safeusage procedures at all times.ALWAYS read and understand theuser manual before operating themachine.CONNECT your machine ONLY to thematched and specific power source.ALWAYS wear safety glassesrespirators, hearing protection andsafety shoes, when operating yourmachine.DO NOT wear loose clothing orjewelry when operating your machine.Wear protective hair covering.A SAFE ENVIRONMENT isimportant. Keep the area free of dust,dirt and other debris in the immediatevicinity of your machine.BE ALERT! DO NOT use prescriptionor other drugs that may affect yourability or judgment to safely use yourmachine.DISCONNECT the power source whenchanging drill bits, hollow chisels,router bits, shaper heads, blades,knives or making other adjustments orrepairs.NEVER leave a tool unattended while itis in operation.NEVER allow unsupervised or untrainedpersonnel to operate the machineNEVER reach over the table when thetool is in operation.ALWAYS keep blades, knives and bitssharpened and properly aligned.ALL OPERATIONS MUST BEperformed with the guards in place toensure safety.ALWAYS use push sticks and featherboards to safely feed your work throughthe machine.ALWAYS make sure that any tools usedfor adjustments are removed beforeoperating the machine.ALWAYS keep bystanders safely awaywhile the machine is in operation.NEVER attempt to remove jammedcutoff pieces until the blade has come toa full stop.3

<strong>CT171</strong> - 10” WET BENCHTOP GRINDERSPECIFIC SAFETY INSTRUCTIONSALWAYS read and understand theuser manual before operating thegrinder.MAKE SURE you are wearing safetyglasses while operating the grinder.The small particles becoming airborneduring grinding operation can seriouslydamage your eyes.ALWAYS wear a dust mask or arespirator while grinding. The dustproduced during grinding process canlead to serious respiratory problems ifinhaled.MAKE SURE before making anyadjustments, servicing or installingparts, the switch is in the “OFF”position, and the cord is un-pluggedfrom the power source.MAKE SURE the RPM of the wheelyou are installing on the grinder isequal to or higher than the speed ofthe grinder. Operating wheels at ahigher speed than rated for may causethe wheel to lie apart, fly or break.MAKE SURE to keep your hands at asafe distance from the wheel.NEVER LEAVE the grinder unattendedwhile it is running.MAKE SURE to do a test on thegrinding wheels before installation.Wheels that do not pass the test are notsafe to use. See page-8 for details.ALWAYS stand to the side of thegrinder when turning it ON and let thewheel reach full speed. Stand at leastone minute to the side of the grinderafter startup. A damaged wheel canbreak apart and fly shortly after startingthe grinder.DO NOT grind on the side of the wheel,unless the wheel is rated for sidegrinding.ALWAYS keep the tool rest within 1/8”distance from the wheel while operatingthe grinder.MAKE SURE you have read andunderstood all the safety instructions inthe manual and you are familiar withyour grinder, before operating it. If youfail to follow the instructions given in thisuser manual, serious injury could occur.WARNINGThe safety instructions given above can not be complete because the environment inevery shop is different. Always consider safety first as it applies to your individualworking conditions.4

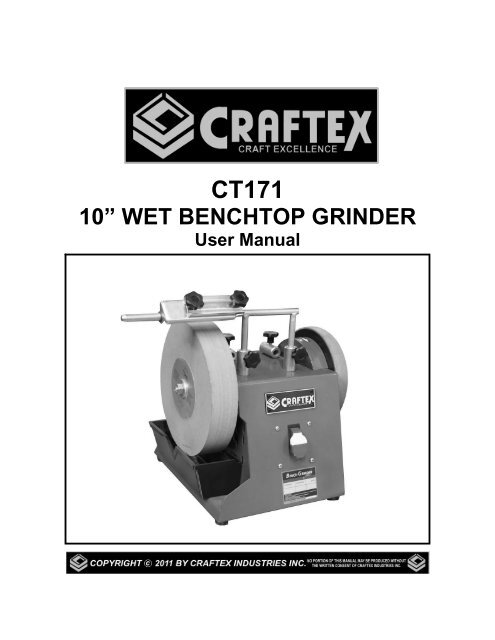

<strong>CT171</strong> – WET BENCHTOP GRINDERFEATURESMODEL <strong>CT171</strong> - 10” WET BENCHTOP GRINDERAs part of the growing line of Craftex woodworking equipment, we are proud to offer the<strong>CT171</strong>, a 10” Wet Benchtop Grinder. The Craftex name guarantees Craft Excellence. Byfollowing the instructions and procedures laid out in this user manual, you will receive years ofexcellent service and satisfaction. The C171 is a professional tool and like all power tools,proper care and safety procedures should be adhered to.Motor ................................... .......... 1/4-HP, 110-Volts, Single Phase, 60-Hz, 1725 RPMAmps ................................... .......... 3 AmpsGrinding Wheel Diameter .... .......... 10"Grinding Wheel Thickness... .......... 2”Grinding Wheel Material ...... .......... Aluminum OxideGrinding Wheel Grit ............. .......... 220Arbor Diameter .................... .......... 1/2"Stropping Wheel Diameter... .......... 8"Stropping Wheel Thickness. .......... 1-3/16”Stropping Wheel Material .... .......... LeatherWheel Speed ....................... .......... 70 RPMWidth ................................... .......... 17”Height .................................. .......... 13”Weight ................................. .......... 42 lbsWarranty.............................. .......... 2 Years5

<strong>CT171</strong> - 10” WET BENCHTOP GRINDERPHYSICAL FEATURES6

PROPER GROUNDINGGrounding provides a path of leastresistance for electric current to reduce therisk of electric shock.Make sure the cord is plugged into aproperly installed and grounded poweroutlet. To prevent electrical hazards, have aqualified electrician ensure that the line isproperly wired.Make sure that the appliance is connectedto an outlet having the same configurationas the plug. If an adaptor plug is used, itmust be attached to the metal screw of thereceptacle.It is strongly recommended not to useextension cords with your <strong>CT171</strong>. Alwaystry to position your machine close to thepower source so that you do not need touse extension cords.In case if you really find it necessary to usean extension cord, make sure the extensioncord does not exceed 50-feet in length andthe cord is 14-gauge to prevent motordamage.WARNINGImproper connection of the equipmentgroundingconductor can result in a riskof electric shock. Check with a qualifiedelectrician if you are in doubt as towhether the outlet is properly grounded.Figure-1 110-Volts outlet for <strong>CT171</strong>7

UNPACKINGThe machine is properly packaged andshipped completely in carton for safetransportation. When unpacking, carefullyinspect the carton and ensure that nothinghas been damaged during transit. Open thecarton and check that the grinder and theparts are in good condition.While doing inventory, if you can not findany part, check if the part is alreadyinstalled on the machine. Some of the partscome preassembled with the machinebecause of shipping purposes.Figure-2 Tapping locations on the grindingstone when inspecting for internal damageGRINDING WHEELThe <strong>CT171</strong> comes with a 10” diameter, 220grit aluminum oxide grinding wheel. Thegrinding wheel should be inspectedproperly before installation.Clean the dust and/or dirt from the surfaceof the wheel and inspect it for any cracks,dents, chips, or any kind of externaldamage.To inspect the wheel for any internaldamages:Take the wheel up with a finger through thehole located in the middle of the wheel andtap it using a wooden mallet or a light nonmetallic object as shown in figure-2.WARNINGTapping the wheel with heavy or metallicobjects can damage the grinding wheel.Tapping the wheel with the mallet willcreate a sound, based on which you will beable to know if the wheel is damaged ornot.If the wheel is undamaged, the soundomitted will have a clear or “ping” sound. Ifthe wheel is damaged the sound will haveno clear tone.GRINDING SURFACEThe grinding surface of the wheel should beparallel with the universal support.Make sure the switch is in the OFF positionand the cord is disconnected from thepower source.Lower the universal support 1/8” above thegrinding wheel and check if the grindingsurface of the wheel is parallel to theuniversal support by rotating the wheelslowly with your hands.8

WATER RESERVOIRThe <strong>CT171</strong> is a wet grinder and is equippedwith a water reservoir. Do no attempt toperform grinding on this machine withoutwater. If the grinder is used without water, itwill either damage the grinding wheel or thetool you are grinding.Figure-3 Checking the grinder wheelsurface parallelism with universal supportTEST RUNOnce you have assembled and inspectedthe machine it is then time to do a test runand see if the machine powers up and runsproperly.All the tools and objects used forassembling the machine should beremoved and cleared away during test run.Connect the machine to the correct powersource and start the machine. During thetest run if there is any unusual noise orvibration, disconnect the machine from thepower source immediately. Check all theparts you have assembled, once again andtry to find out the problem.The water reservoir is equipped withmounting tabs used to hook to the slots onthe grinder body.The water reservoir can be attached to thelower slots of the grinder body when thegrinder is not in use while it is attached tothe upper slots, (filled with clean water)when in use.Make sure not to keep the grinding wheelinside the water when the grinder is notused for a long period of time. Failure to doso, can cause the wheel becomeunbalanced and break off easily whilegrinding. The reservoir should be emptiedand attached to the lower mounting slotswhen the grinder is not used.During the test run make sure the start/stopbutton and all the safety features on thegrinder are working properly.WARNINGDo not make any adjustments while themachine is running. Turn the machineOFF and un-plug from the power sourcebefore making any adjustments. Failure todo so may cause serious personal injury.Figure-4 Installing the water reservoir9

UNIVERSAL SUPPORTThe <strong>CT171</strong> is equipped with a universalsupport which can be mounted on thegrinder in horizontal or vertical positiondepending on the grinding job. The verticaland horizontal position of the universalsupport allows grinding with the handagainst the rotation of the wheel.GRINDING WITH THE ROTATIONOF THE WHEELGrinding with the rotation of the wheelremoves small amount of material andprovides a smooth result. This method isused for blades, chisels, knives, etc...To set the universal support for grindingwith the rotation of the wheel:GRINDING AGAINST THEROTATION OF THE WHEELGrinding against the rotation of the wheelremoves a large amount of material in avery short time and finally the result will notbe very smooth. Coarse tools aresharpened against the rotation of the wheel.To set the universal support for grindingagainst the rotation of the wheel:Turn the switch to OFF position and makesure the cord is unplugged from the powersource.Install the universal support through thevertical mounts on the grinder and secure itby tightening the knobs properly as shownin figure-6.Turn the switch to OFF position and makesure the cord is unplugged from the powersource.Install the universal support through thehorizontal mounts on the grinder andsecure it by tightening the knobs properlyas shown in figure-5.Figure-6 Installing the universal supportvertically for grinding against the rotationthe wheelFigure-5 Installing the universal supporthorizontally for grinding with the rotation ofthe wheelWARNINGDo not perform any sharpening job onthe leather honing wheel against itsdirection of rotation. Failure to do so willseriously damage the leather honingwheel.10

ANGLE GUIDEYour <strong>CT171</strong> grinder comes with an angleguide allowing you to find the cutting angleof your tools.Using the angle guide is simple and easy. Itfeatures 2 angle measuring notches oneach side.Figure-8 Using angle guideAdjust the universal support or the tool sothat the sharpened edge of the tool is flatagainst the grinding wheel and the angleguide.Figure-7 Angle guide measuring notchesTo find the cutting angle on your tool usingangle guide:Place the sharpened edge of the tool intoeach measuring notches and find the notchbest fits the tool you want to grind.Position the angle guide on the grindingwheel with the side having the best fitmeasuring notch as shown in figure-8.HONING COMPOUNDThe <strong>CT171</strong> comes with honing compoundused on the leather honing wheel to givesmooth and razor sharp edge results whensharpening tools.Make sure the switch is in the OFF positionand the cord is disconnected from thepower sourc.First, apply a light coat of machine oil onthe leather honing wheel and then apply athin coat of the abrasive honing paste.Spread the paste on the wheel properlywith your hand.11

Plug the cord into the power source andturn the machine ON distributing the pasteevenly on the wheel using a spreader.Figure-10 Nut and washer holding thewheelFigure-9 Honing compoundREPLACING THEGRINDING WHEELMake sure the switch is in the OFF positionand the cord is disconnected from thepower sourc.Loosen the nut (shown in figure-10)securing the grinding wheel by holding thewheel with one hand.Remove the nut, washer, and grindingwheel and replace the wheel with a newone.Make sure to inspect the new grindingwheel properly before installation. Fordetails see “GRINDING WHEEL” on page-8.12

WARRANTYCRAFTEX 2 YEARS LIMITED WARRANTYCraftex warrants every product to be free from defects in materials and agrees to correct such defects whereapplicable. This warranty covers two years for parts and 90 days for labor (unless specified otherwise), to theoriginal purchaser from the date of purchase but does not apply to malfunctions arising directly or indirectly frommisuse, abuse, improper installation or assembly, negligence, accidents, repairs or alterations or lack ofmaintenance.Proof of purchase is necessary.All warranty claims are subject to inspection of such products or part thereof and Craftex reserves the right toinspect any returned item before a refund or replacement may be issued.This warranty shall not apply to consumable products such as blades, bits, belts, cutters, chisels, punchesetceteras.Craftex shall in no event be liable for injuries, accidental or otherwise, death to persons or damage to property orfor incidental contingent, special or consequential damages arising from the use of our products.RETURNS, REPAIRS AND REPLACEMENTSTo return, repair, or replace a Craftex product, you must visit the appropriate <strong>Busy</strong> <strong>Bee</strong> <strong>Tools</strong> showroom or call 1-800-461-BUSY. Craftex is a brand of equipment that is exclusive to <strong>Busy</strong> <strong>Bee</strong> <strong>Tools</strong>.For replacement parts directly from <strong>Busy</strong> <strong>Bee</strong> <strong>Tools</strong>, for this machine, please call 1-800-461-BUSY (2879), andhave your credit card and part number handy. All returned merchandise will be subject to a minimum charge of 15% for re-stocking and handling with thefollowing qualifications. Returns must be pre-authorized by us in writing. We do not accept collect shipments.Items returned for warranty purposes must be insured and shipped pre-paid to the nearest warehouseReturns must be accompanied with a copy of your original invoice as proof of purchase. Returns must be inan un-used condition and shipped in their original packaging a letter explaining your reason for the return.Incurred shipping and handling charges are not refundable.<strong>Busy</strong> <strong>Bee</strong> will repair or replace the item at our discretion and subject to our inspection.Repaired or replaced items will be returned to you pre-paid by our choice of carriers.<strong>Busy</strong> <strong>Bee</strong> reserves the right to refuse reimbursement or repairs or replacement if a third party without ourprior authorization has carried out repairs to the item.Repairs made by <strong>Busy</strong> <strong>Bee</strong> are warranted for 30 days on parts and labour.Any unforeseen repair charges will be reported to you for acceptance prior to making the repairs.The <strong>Busy</strong> <strong>Bee</strong> Parts & Service Departments are fully equipped to do repairs on all products purchased from uswith the exception of some products that require the return to their authorized repair depots. A <strong>Busy</strong> <strong>Bee</strong>representative will provide you with the necessary information to have this done.For faster service it is advisable to contact the nearest <strong>Busy</strong> <strong>Bee</strong> location for parts availability prior tobringing your product in for repairs.15