Technical Data Sheet - Simpson Strong-Tie

Technical Data Sheet - Simpson Strong-Tie

Technical Data Sheet - Simpson Strong-Tie

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

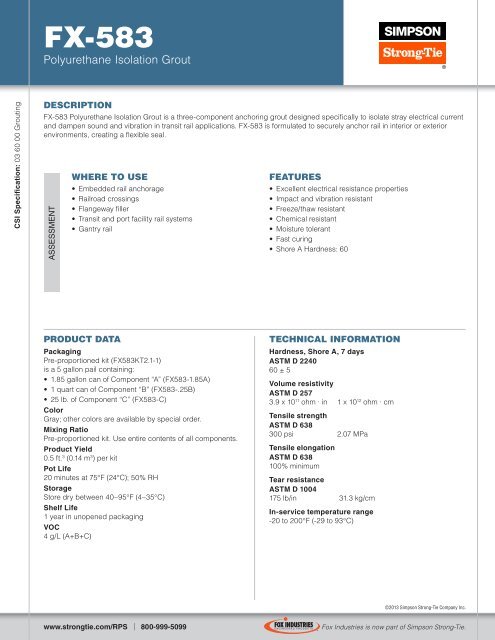

FX‐583Polyurethane Isolation GroutCSI Specification: 03 60 00 GroutingDESCRIPTIONFX‐583 Polyurethane Isolation Grout is a three-component anchoring grout designed specifically to isolate stray electrical currentand dampen sound and vibration in transit rail applications. FX‐583 is formulated to securely anchor rail in interior or exteriorenvironments, creating a flexible seal.ASSESSMENTWHERE TO USE• Embedded rail anchorage• Railroad crossings• Flangeway filler• Transit and port facility rail systems• Gantry railFEATURES• Excellent electrical resistance properties• Impact and vibration resistant• Freeze/thaw resistant• Chemical resistant• Moisture tolerant• Fast curing• Shore A Hardness: 60PRODUCT DATAPackagingPre-proportioned kit (FX583KT2.1-1)is a 5 gallon pail containing:• 1.85 gallon can of Component “A” (FX583-1.85A)• 1 quart can of Component “B” (FX583-.25B)• 25 lb. of Component “C” (FX583-C)ColorGray; other colors are available by special order.Mixing RatioPre-proportioned kit. Use entire contents of all components.Product Yield0.5 ft. 3 (0.14 m 3 ) per kitPot Life20 minutes at 75°F (24°C); 50% RHStorageStore dry between 40–95°F (4–35°C)Shelf Life1 year in unopened packagingVOC4 g/L (A+B+C)TECHNICAL INFORMATIONHardness, Shore A, 7 daysASTM D 224060 ± 5Volume resistivityASTM D 2573.9 x 10 11 ohm ∙ in 1 x 10 12 ohm ∙ cmTensile strengthASTM D 638300 psi 2.07 MPaTensile elongationASTM D 638100% minimumTear resistanceASTM D 1004175 lb/in 31.3 kg/cmIn-service temperature range-20 to 200°F (-29 to 93°C)©2013 <strong>Simpson</strong> <strong>Strong</strong>‐<strong>Tie</strong> Company Inc.www.strongtie.com/RPS | 800-999-5099FOX INDUSTRIESENGINEERED PRODUCTS®Fox Industries is now part of <strong>Simpson</strong> <strong>Strong</strong>‐<strong>Tie</strong>.

FX‐583 Polyurethane Isolation Grout2PLANNINGLimitations• Do not apply to surfaces below 40°F (4°C).• Do not apply to surfaces above 90°F (32°C)• Do not thin with solvents• Minimum application thickness is 1/4 in.(0.6 cm) when used as a topping• Maximum installation thickness is 1 in. (2.5 cm)• Material is a vapor barrier after cure.Concrete surface to receive grout must notexhibit an active moisture vapor drive.• Resistance to in-service chemical exposure mustbe confirmed for compatibility prior to applicationPlease note: This product has not been evaluated for resisting long-term sustained loads in anchor applications.Refer to the current Anchoring and Fastening Systems for Concrete and Masonry catalog or www.strongtie.comfor code-listed structural anchoring adhesives.PREPARATIONSurface PreparationConcrete must be sound, clean, and free of all contaminants that could impair product adhesion or performance.Concrete should be a minimum of 28 days old or substantially cured to the equivalent design strength prior to FX-583installation.Anchor Grouting: Drill hole to specified diameter and depth using a rotary hammer drill with a carbide tip. Blow the holeclean for a minimum of 4 seconds using 80 psi (min.) oil-free, compressed air to remove dust from hole. Brush the holeclean for a minimum of 4 cycles using with a nylon brush such as ETB6 (See www.strongtie.com for appropriate brushsize). Blow again for a minimum of 4 seconds to remove remaining dust.Floor topping: Prepare surface by abrasive blasting or other mechanical means to achieve an open pore structure andsurface profile per ICRI Guideline 310.2 CSP 5-9, taking care to avoid micro-cracking. Remove all cleaning media anddebris by vacuum or blowing with high-pressure, oil-free air.MixingFor optimal product performance, condition individual components to 70°F (21°C) and stir thoroughly prior to use.Do not mix partial units. Remove all Components from the pail. Add the entire contents of Component “A” andComponent “B” into the pail. Mix thoroughly with a low-speed (300–600 rpm) drill and mixing paddle for 3 minutes,scraping unmixed material from sides and bottom of mixing container as needed. Slowly add entire contents ofComponent “C” to the mixture, continuously mixing to avoid clumping. Mix until uniform consistency is achieved,(approximately 2 minutes) scraping unmixed material from the sides and bottom of mixing container as needed. Takemeasures to prevent entrapping air into mix. Place immediately.EXECUTIONApplicationAnchor Grouting: Fill hole by pumping or pouring properly mixed FX-583 approximately 1/2 to 2/3 full. If pumping,withdraw nozzle as the hole fills up taking care to avoid entrapping air. Insert clean, oil-free anchor, turning slowly until itbottoms out. Strike off any excess material with a steel trowel or putty knife. Do not disturb until fully cured.Floor Topping: Pour mixed material into place. Screed to desired elevation. Finish with a steel trowel. Xylene may beused as a troweling aid.Allow FX-583 to fully cure prior to placing into service.www.strongtie.com/RPS | 800-999-5099©2013 <strong>Simpson</strong> <strong>Strong</strong>-<strong>Tie</strong> Company Inc.

FX‐583 Polyurethane Isolation Grout3CAUTIONComponent “A”: Causes severe eye irritation. May cause allergic skin reaction.Component “B”: Harmful if inhaled. May cause respiratory tract irritation. May cause allergic respiratory reaction. Maycause skin irritation. May cause allergic skin reaction. May cause eye irritation.Component “C”: May cause eye irritation or damage. A single exposure will not result in serious adverse healtheffects.Protective Measures: The use of safety glasses and chemically resistant gloves is recommended. Use appropriateclothing to minimize skin contact. The use of a NIOSH-approved respirator is required to protect respiratory tract whenventilation is not adequate to limit exposure below the PEL. Refer to Material Safety <strong>Data</strong> <strong>Sheet</strong> (MSDS) available atwww.strongtie.com/msds for detailed information.SAFETYFIRST AIDEye Contact: Immediately flush eyes with plenty of cool water for at least 15 minutes while holding the eyes open.If redness, burning, blurred vision, or swelling persists, CONSULT A PHYSICIAN.Skin Contact: Remove product and wash affected area with soap and water. Do not apply greases or ointments.Remove contaminated clothing. Wash clothing with soap and water before reuse. If redness, burning, or swellingpersists, CONSULT A PHYSICIAN.Ingestion: DO NOT INDUCE VOMITING. CONSULT A PHYSICIAN OR POISON CONTROL CENTERIMMEDIATELY FOR CURRENT INFORMATION. Never administer anything by mouth to an unconscious person.Rinse mouth out with water. Never leave patient unattended. If vomiting occurs spontaneously, lay individual on theirside, keeping head below hips to prevent aspiration of material into lungs.Inhalation: Move to an area free from further exposure. SEEK IMMEDIATE MEDICAL ATTENTION. Administer oxygenor artificial respiration as needed. Asthmatic symptoms may develop and may be immediate or delayed up to severalhours. Extreme asthmatic reactions can be life threatening.CLEAN UPSpillsLiquid or mixed material spills: Construct a dike to prevent spreading. Soak up with absorbent material such asclay, sand or other non-reactive material. Place in leak-proof containers. Keep out of sewers, storm drains, surfacewaters, and soils.Powder Spills: Sweep or vacuum material and place in a suitable container. Keep out of sewers, storm drains,surface waters, and soils.Surface CleanLiquid or mixed material: Wipe up uncured material with cotton cloths. If desired scrub area with abrasive, waterbasedcleaner and flush with water. If approved, solvents such as FX-Epoxy Cleaner, ketones (MEK, acetone, etc.),or adhesive remover can be used. Cured material can only be removed by mechanical means.Powder: Remove any residue with hot soapy water.Tools and EquipmentLiquid or mixed material: Remove uncured material with FX-Epoxy Cleaner, ketones (MEK, acetone, etc.), oradhesive remover. Cured material can only be removed by mechanical means.Powder: Clean with hot soapy water immediately after use.Skin: Use a non-toxic pumice-based soap, citrus-based hand cleaner, or waterless hand cleaner towel. Never usesolvents to remove product from skin.Disposal: Dispose of container and unused contents in accordance with federal, state, and local requirements.Containers may be recycled; consult local regulations for exceptions.DistributorIMPORTANT INFORMATIONIt is the responsibility of each purchaser and user of each product to determine the suitability of the product for its intended use. Prior to using any product, consult a qualified design professional foradvice regarding the suitability and use of the product, including whether the capacity of any structural building element may be impacted by a repair. As jobsite conditions vary greatly, a small-scale testpatch is required to verify product suitability prior to full-scale application. The installer must read, understand and follow all written instructions and warnings contained on the Limited Warranty, productlabel(s), Product <strong>Data</strong> <strong>Sheet</strong>(s), Material Safety <strong>Data</strong> <strong>Sheet</strong>(s) and the www.strongtie.com website prior to use. For industrial use only by qualified applicators. KEEP OUT OF REACH OF CHILDREN!Proposition 65: Products contained within this document contain materials listed by the state of California as known to cause cancer, birth defects, or reproductive harm.www.strongtie.com/RPS | 800-999-5099 ©2013 <strong>Simpson</strong> <strong>Strong</strong>-<strong>Tie</strong> Company Inc. T-R-FX583 | 9/13UPDATED | 12/18/13