New evidence for the suitability of EMAT inspection technology in ...

New evidence for the suitability of EMAT inspection technology in ...

New evidence for the suitability of EMAT inspection technology in ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

6<br />

RECOGNIZED AS A MAJOR<br />

<strong>in</strong>tegrity threat s<strong>in</strong>ce <strong>the</strong><br />

1970s, <strong>the</strong> phenomenon <strong>of</strong> stress<br />

corrosion crack<strong>in</strong>g (SCC) now<br />

<strong>for</strong>ms an important part <strong>of</strong><br />

<strong>in</strong>tegrity management programs<br />

worldwide. Whereas SCC has<br />

conventionally been detected with<br />

liquid coupled ultrasonic<br />

<strong>technology</strong>, advances made <strong>in</strong><br />

recent years <strong>in</strong> ultrasonic systems<br />

based on an electro-magnetic<br />

acoustic transducer (<strong>EMAT</strong>) mean<br />

that this <strong>technology</strong> now has <strong>the</strong><br />

potential to be established as a<br />

preferable alternative: dispens<strong>in</strong>g<br />

entirely with <strong>the</strong> need <strong>for</strong> a liquid<br />

coupl<strong>in</strong>g, <strong>EMAT</strong> is a highly costeffective<br />

<strong><strong>in</strong>spection</strong> method <strong>for</strong> gas<br />

pipel<strong>in</strong>es <strong>in</strong> particular. This paper<br />

presents a summary <strong>of</strong> <strong>the</strong> field<br />

tests conducted to establish <strong>the</strong><br />

<strong>suitability</strong> <strong>of</strong> high-resolution<br />

<strong>EMAT</strong> <strong>technology</strong> <strong>in</strong> assess<strong>in</strong>g<br />

SCC and similar threats <strong>in</strong><br />

pipel<strong>in</strong>es.<br />

Test approach and nature<br />

<strong>of</strong> <strong>EMAT</strong><br />

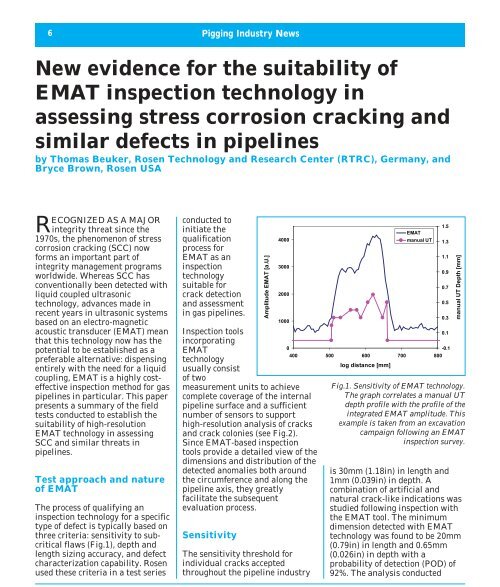

The process <strong>of</strong> qualify<strong>in</strong>g an<br />

<strong><strong>in</strong>spection</strong> <strong>technology</strong> <strong>for</strong> a specific<br />

type <strong>of</strong> defect is typically based on<br />

three criteria: sensitivity to subcritical<br />

flaws (Fig.1), depth and<br />

length siz<strong>in</strong>g accuracy, and defect<br />

characterization capability. Rosen<br />

used <strong>the</strong>se criteria <strong>in</strong> a test series<br />

Pigg<strong>in</strong>g Industry <strong>New</strong>s<br />

<strong>New</strong> <strong>evidence</strong> <strong>for</strong> <strong>the</strong> <strong>suitability</strong> <strong>of</strong><br />

<strong>EMAT</strong> <strong><strong>in</strong>spection</strong> <strong>technology</strong> <strong>in</strong><br />

assess<strong>in</strong>g stress corrosion crack<strong>in</strong>g and<br />

similar defects <strong>in</strong> pipel<strong>in</strong>es<br />

by Thomas Beuker, Rosen Technology and Research Center (RTRC), Germany, and<br />

Bryce Brown, Rosen USA<br />

conducted to<br />

<strong>in</strong>itiate <strong>the</strong><br />

qualification<br />

process <strong>for</strong><br />

<strong>EMAT</strong> as an<br />

<strong><strong>in</strong>spection</strong><br />

<strong>technology</strong><br />

suitable <strong>for</strong><br />

crack detection<br />

and assessment<br />

<strong>in</strong> gas pipel<strong>in</strong>es.<br />

Inspection tools<br />

<strong>in</strong>corporat<strong>in</strong>g<br />

0<br />

<strong>EMAT</strong><br />

<strong>technology</strong><br />

usually consist<br />

<strong>of</strong> two<br />

measurement units to achieve<br />

complete coverage <strong>of</strong> <strong>the</strong> <strong>in</strong>ternal<br />

pipel<strong>in</strong>e surface and a sufficient<br />

number <strong>of</strong> sensors to support<br />

high-resolution analysis <strong>of</strong> cracks<br />

and crack colonies (see Fig.2).<br />

S<strong>in</strong>ce <strong>EMAT</strong>-based <strong><strong>in</strong>spection</strong><br />

tools provide a detailed view <strong>of</strong> <strong>the</strong><br />

dimensions and distribution <strong>of</strong> <strong>the</strong><br />

detected anomalies both around<br />

<strong>the</strong> circumference and along <strong>the</strong><br />

pipel<strong>in</strong>e axis, <strong>the</strong>y greatly<br />

facilitate <strong>the</strong> subsequent<br />

evaluation process.<br />

Sensitivity<br />

Amplitude <strong>EMAT</strong> [a.U.]<br />

4000<br />

3000<br />

2000<br />

1000<br />

The sensitivity threshold <strong>for</strong><br />

<strong>in</strong>dividual cracks accepted<br />

throughout <strong>the</strong> pipel<strong>in</strong>e <strong>in</strong>dustry<br />

<strong>EMAT</strong><br />

manual UT<br />

400 500 600<br />

log distance [mm]<br />

700 800<br />

-0.1<br />

is 30mm (1.18<strong>in</strong>) <strong>in</strong> length and<br />

1mm (0.039<strong>in</strong>) <strong>in</strong> depth. A<br />

comb<strong>in</strong>ation <strong>of</strong> artificial and<br />

natural crack-like <strong>in</strong>dications was<br />

studied follow<strong>in</strong>g <strong><strong>in</strong>spection</strong> with<br />

<strong>the</strong> <strong>EMAT</strong> tool. The m<strong>in</strong>imum<br />

dimension detected with <strong>EMAT</strong><br />

<strong>technology</strong> was found to be 20mm<br />

(0.79<strong>in</strong>) <strong>in</strong> length and 0.65mm<br />

(0.026<strong>in</strong>) <strong>in</strong> depth with a<br />

probability <strong>of</strong> detection (POD) <strong>of</strong><br />

92%. The analysis conducted<br />

1.5<br />

1.3<br />

1.1<br />

0.9<br />

0.7<br />

0.5<br />

0.3<br />

0.1<br />

manual UT Depth [mm]<br />

Fig.1. Sensitivity <strong>of</strong> <strong>EMAT</strong> <strong>technology</strong>.<br />

The graph correlates a manual UT<br />

depth pr<strong>of</strong>ile with <strong>the</strong> pr<strong>of</strong>ile <strong>of</strong> <strong>the</strong><br />

<strong>in</strong>tegrated <strong>EMAT</strong> amplitude. This<br />

example is taken from an excavation<br />

campaign follow<strong>in</strong>g an <strong>EMAT</strong><br />

<strong><strong>in</strong>spection</strong> survey.

Fig.2. RoCD2 <strong>EMAT</strong> <strong>in</strong>-l<strong>in</strong>e <strong><strong>in</strong>spection</strong><br />

tool dur<strong>in</strong>g <strong>the</strong> launch process.<br />

proves conclusively that <strong>the</strong><br />

sensitivity <strong>of</strong> <strong>EMAT</strong> is comparable<br />

to more established <strong><strong>in</strong>spection</strong><br />

technologies and notably that <strong>the</strong><br />

target <strong>for</strong> detect<strong>in</strong>g subcritical<br />

flaws is met.<br />

Depth and length siz<strong>in</strong>g<br />

capabilities<br />

A depth siz<strong>in</strong>g model based on<br />

electro-magnetic acoustic<br />

<strong><strong>in</strong>spection</strong> was developed by<br />

Rosen as part <strong>of</strong> <strong>the</strong> test project.<br />

This model <strong>in</strong>corporated a<br />

quantitative multi-parameter<br />

process whereby various<br />

parameters derived from <strong>the</strong><br />

datasets, e.g. amplitude and<br />

frequency content <strong>of</strong> <strong>the</strong> different<br />

wave modes, were correlated to<br />

<strong>the</strong> depth <strong>of</strong> a crack <strong>in</strong>dication.<br />

This model was <strong>the</strong>n applied to<br />

artificial crack-like flaws as well<br />

as natural cracks and SCC (see<br />

Figs 3 and 4). The accuracy levels<br />

achieved <strong>in</strong> <strong>the</strong>se tests was found<br />

to be +/- 0.64mm (0.025<strong>in</strong>) with a<br />

confidence level <strong>of</strong> 90%. This<br />

result is comparable to that <strong>of</strong><br />

widely accepted crack evaluation<br />

processes based on o<strong>the</strong>r<br />

<strong><strong>in</strong>spection</strong> technologies.<br />

Beside <strong>the</strong> depth <strong>of</strong> a crack, its<br />

length is an essential parameter<br />

<strong>for</strong> <strong>in</strong>tegrity assessment. A<br />

threshold criterion is used on <strong>the</strong><br />

signal amplitude to determ<strong>in</strong>e <strong>the</strong><br />

length <strong>of</strong> a flaw. Siz<strong>in</strong>g results <strong>for</strong><br />

INNOVATION.<br />

www.rosen<strong><strong>in</strong>spection</strong>.net<br />

<strong>EMAT</strong> Depth [mm]<br />

Pigg<strong>in</strong>g Industry <strong>New</strong>s 7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0<br />

0 1 2 3 4 5 6<br />

Given Depth [mm]<br />

Fig.3. Application <strong>of</strong> <strong>the</strong> <strong>EMAT</strong> siz<strong>in</strong>g<br />

to a population <strong>of</strong> artificial flaws <strong>in</strong> a<br />

16<strong>in</strong> test jo<strong>in</strong>t.<br />

artificial defects <strong>of</strong><br />

different length are<br />

shown below; even<br />

<strong>for</strong> short defects, a<br />

stable length siz<strong>in</strong>g<br />

can be achieved.<br />

However, due to <strong>the</strong><br />

physical size <strong>of</strong> <strong>the</strong><br />

applied shear wave,<br />

short features result<br />

<strong>in</strong> a slightly larger<br />

scatter<strong>in</strong>g <strong>of</strong> <strong>the</strong><br />

length measurement.<br />

The length<br />

determ<strong>in</strong>ation<br />

accuracy <strong>of</strong> <strong>EMAT</strong> is<br />

similar to <strong>the</strong> results<br />

furnished by<br />

magnetic particle<br />

<strong><strong>in</strong>spection</strong> (MPI)<br />

<strong>technology</strong>.<br />

Defect characterization<br />

and coat<strong>in</strong>g assessment<br />

Over and above <strong>the</strong> criteria <strong>of</strong><br />

sensitivity, depth and length<br />

siz<strong>in</strong>g, <strong>the</strong> Rosen test program<br />

also <strong>in</strong>vestigated <strong>the</strong> ability <strong>of</strong><br />

<strong>EMAT</strong> to characterize different<br />

types <strong>of</strong> defects. S<strong>in</strong>ce both risk<br />

assessment and corrective<br />

measures directly depend on <strong>the</strong><br />

types <strong>of</strong> defects present <strong>in</strong> a<br />

<strong>EMAT</strong> Depth [mm]<br />

4.0<br />

3.5<br />

3.0<br />

2.5<br />

2.0<br />

1.5<br />

1.0<br />

0.5<br />

0.0<br />

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0<br />

Manual UT Depth [mm]<br />

Fig.4. Two sets <strong>of</strong> natural defects were<br />

sized us<strong>in</strong>g <strong>the</strong> <strong>EMAT</strong> siz<strong>in</strong>g model.<br />

The depth has been verified us<strong>in</strong>g an<br />

NSDS (near side detection and siz<strong>in</strong>g)<br />

UT probe.<br />

Fig.5. Top half: photograph <strong>of</strong> coal tar<br />

coat<strong>in</strong>g disbondment; bottom half:<br />

<strong>EMAT</strong> representation <strong>of</strong> <strong>the</strong> same<br />

feature follow<strong>in</strong>g a 16<strong>in</strong> <strong>in</strong>-l<strong>in</strong>e<br />

<strong><strong>in</strong>spection</strong>.<br />

pipel<strong>in</strong>e, <strong>the</strong>ir reliable<br />

identification plays a vital part <strong>in</strong><br />

asset <strong>in</strong>tegrity management.<br />

Adopt<strong>in</strong>g a multi-parameter<br />

correlation model (MPC) tak<strong>in</strong>g<br />

<strong>in</strong>to account <strong>the</strong> distribution <strong>of</strong> <strong>the</strong><br />

responses to a particular feature<br />

type, <strong>EMAT</strong> was applied to a<br />

EMPOWERED BY<br />

TECHNOLOGY

8<br />

sample set <strong>of</strong> 315 crack-type and<br />

non-crack-type defects. Field<br />

verification subsequently revealed<br />

that <strong>the</strong> probability <strong>of</strong><br />

identification (POI) <strong>for</strong> <strong>the</strong>se flaws<br />

was as high as 91 percent.<br />

Apart from direct defect<br />

characterization, <strong>the</strong> ability to<br />

identify pipel<strong>in</strong>e coat<strong>in</strong>g types is<br />

helpful, s<strong>in</strong>ce some coat<strong>in</strong>g types<br />

are more prone to stress corrosion<br />

crack<strong>in</strong>g (SCC) than o<strong>the</strong>rs.<br />

Additional <strong>in</strong><strong>for</strong>mation on <strong>the</strong><br />

condition <strong>of</strong> <strong>the</strong> coat<strong>in</strong>g is also<br />

directly relevant to crack-type<br />

defects, s<strong>in</strong>ce coat<strong>in</strong>g disbondment<br />

is demonstrably a precursor <strong>of</strong><br />

SCC. The tests revealed that <strong>the</strong><br />

<strong>EMAT</strong> <strong><strong>in</strong>spection</strong> system is<br />

Pigg<strong>in</strong>g Industry <strong>New</strong>s<br />

capable <strong>of</strong> provid<strong>in</strong>g dependable<br />

<strong>in</strong><strong>for</strong>mation on both coat<strong>in</strong>g type<br />

and condition. Identified on <strong>the</strong><br />

basis <strong>of</strong> changes <strong>in</strong> transmission<br />

amplitude received through<br />

multiple signal channels, <strong>the</strong><br />

precise position and even lateral<br />

dimensions <strong>of</strong> disbonded areas is<br />

reported (see Fig.5).<br />

Conclusion<br />

For <strong>the</strong> purpose <strong>of</strong> <strong>in</strong>itiat<strong>in</strong>g <strong>the</strong><br />

qualification process <strong>for</strong> <strong>EMAT</strong> as<br />

an adequate <strong><strong>in</strong>spection</strong> method <strong>for</strong><br />

crack detection <strong>in</strong> gas pipel<strong>in</strong>es,<br />

Rosen conducted a series <strong>of</strong><br />

empirical tests. These tests<br />

confirmed <strong>the</strong> high sensitivity <strong>of</strong><br />

<strong>EMAT</strong> even to sub-critical flaws<br />

and its excellent depth and length<br />

siz<strong>in</strong>g capabilities which are on a<br />

par with well established<br />

technologies. In addition, <strong>EMAT</strong><br />

accurately characterized defects<br />

and furnished precise and<br />

dependable <strong>in</strong><strong>for</strong>mation on <strong>the</strong><br />

type and condition <strong>of</strong> pipel<strong>in</strong>e<br />

coat<strong>in</strong>g encountered. In sum, <strong>the</strong><br />

sensitivity and accuracy <strong>of</strong> <strong>EMAT</strong><br />

<strong><strong>in</strong>spection</strong> systems are <strong>the</strong> basis<br />

<strong>for</strong> a subsequent application <strong>of</strong><br />

<strong>in</strong>tegrity management programs.<br />

This has been discussed<br />

exemplary us<strong>in</strong>g <strong>the</strong> API 579<br />

assessment standard.●