oakite® draw clean vo - Industrial Cleaning Supply

oakite® draw clean vo - Industrial Cleaning Supply

oakite® draw clean vo - Industrial Cleaning Supply

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

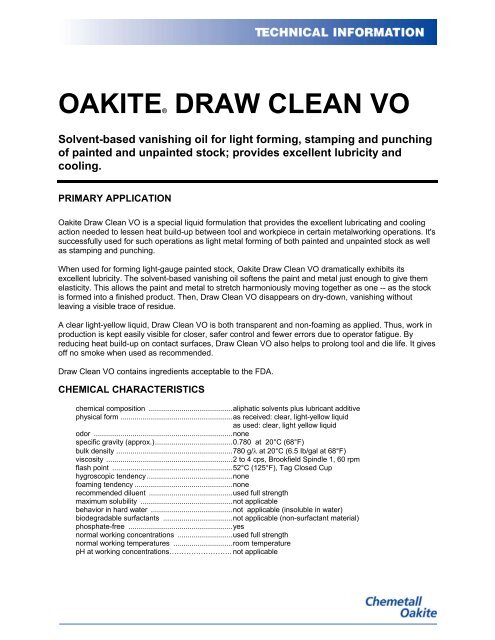

OAKITE® DRAW CLEAN VOSolvent-based vanishing oil for light forming, stamping and punchingof painted and unpainted stock; provides excellent lubricity andcooling.PRIMARY APPLICATIONOakite Draw Clean VO is a special liquid formulation that provides the excellent lubricating and coolingaction needed to lessen heat build-up between tool and workpiece in certain metalworking operations. It'ssuccessfully used for such operations as light metal forming of both painted and unpainted stock as wellas stamping and punching.When used for forming light-gauge painted stock, Oakite Draw Clean VO dramatically exhibits itsexcellent lubricity. The solvent-based vanishing oil softens the paint and metal just enough to give themelasticity. This allows the paint and metal to stretch harmoniously moving together as one -- as the stockis formed into a finished product. Then, Draw Clean VO disappears on dry-down, vanishing withoutleaving a visible trace of residue.A clear light-yellow liquid, Draw Clean VO is both transparent and non-foaming as applied. Thus, work inproduction is kept easily visible for closer, safer control and fewer errors due to operator fatigue. Byreducing heat build-up on contact surfaces, Draw Clean VO also helps to prolong tool and die life. It givesoff no smoke when used as recommended.Draw Clean VO contains ingredients acceptable to the FDA.CHEMICAL CHARACTERISTICSchemical composition .........................................aliphatic solvents plus lubricant additivephysical form .......................................................as received: clear, light-yellow liquidas used: clear, light yellow liquidodor ....................................................................nonespecific gravity (approx.)......................................0.780 at 20°C (68°F)bulk density .........................................................780 g/λ at 20°C (6.5 Ib/gal at 68°F)viscosity ..............................................................2 to 4 cps, Brookfield Spindle 1, 60 rpmflash point ...........................................................52°C (125°F), Tag Closed Cuphygroscopic tendency ..........................................nonefoaming tendency ................................................nonerecommended diluent .........................................used full strengthmaximum solubility .............................................not applicablebehavior in hard water ........................................not applicable (insoluble in water)biodegradable surfactants ..................................not applicable (non-surfactant material)phosphate-free ...................................................yesnormal working concentrations ...........................used full strengthnormal working temperatures .............................room temperaturepH at working concentrations…………………….. not applicable

F17001/01/02Printed in the USAAPPLICATION PROCEDUREApplicable on most ferrous and non ferrous metals, Oakite Draw Clean VO is used full strength beforeforming, stamping or punching operations. It's applied by the flow on method directly on parts to beworked. Since it leaves no residue on dry down that would interfere with subsequent finishing operations,such as painting, there's usually no need to rinse the worked surfaces. And usually no need to <strong>clean</strong>them before they're shipped.Solution Control: No titration procedure is needed for Oakite Draw Clean VO.NOTES ON USE(See Material Safety Data Sheet)Keep away from heat, sparks, open flames and strong oxidants.SAFETY AND HANDLINGPrior to handling and use of any of the materials referenced in this document, theMaterial Safety Data Sheet should be read and understood by all personnel in contactwith the materials.KEEP OUT OF REACH OF CHILDRENSTORAGEDry indoor storage at temperatures between 40ºF and 100ºF is recommended, away from anyincompatible materials referenced in Material Safety Data Sheets. All containers should be kept tightlyclosed when not in use.DISPOSALAny disposal of the materials referenced in this document should be in accordance with all applicablefederal, state, and local regulations. Process solutions can contain components other than those presentin the materials as supplied. Analysis of process solutions may be required prior to disposal.