Statement of Basis Vigor Shipyards Inc. - Puget Sound Clean Air ...

Statement of Basis Vigor Shipyards Inc. - Puget Sound Clean Air ...

Statement of Basis Vigor Shipyards Inc. - Puget Sound Clean Air ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

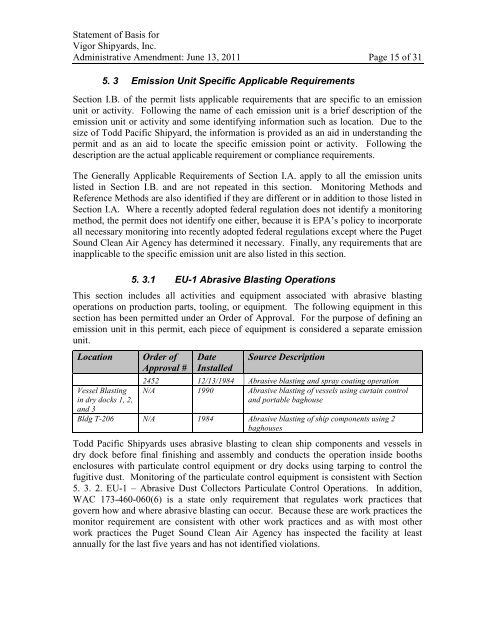

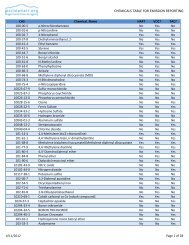

<strong>Statement</strong> <strong>of</strong> <strong>Basis</strong> for<strong>Vigor</strong> <strong>Shipyards</strong>, <strong>Inc</strong>.Administrative Amendment: June 13, 2011 Page 15 <strong>of</strong> 315. 3 Emission Unit Specific Applicable RequirementsSection I.B. <strong>of</strong> the permit lists applicable requirements that are specific to an emissionunit or activity. Following the name <strong>of</strong> each emission unit is a brief description <strong>of</strong> theemission unit or activity and some identifying information such as location. Due to thesize <strong>of</strong> Todd Pacific Shipyard, the information is provided as an aid in understanding thepermit and as an aid to locate the specific emission point or activity. Following thedescription are the actual applicable requirement or compliance requirements.The Generally Applicable Requirements <strong>of</strong> Section I.A. apply to all the emission unitslisted in Section I.B. and are not repeated in this section. Monitoring Methods andReference Methods are also identified if they are different or in addition to those listed inSection I.A. Where a recently adopted federal regulation does not identify a monitoringmethod, the permit does not identify one either, because it is EPA’s policy to incorporateall necessary monitoring into recently adopted federal regulations except where the <strong>Puget</strong><strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency has determined it necessary. Finally, any requirements that areinapplicable to the specific emission unit are also listed in this section.5. 3.1 EU-1 Abrasive Blasting OperationsThis section includes all activities and equipment associated with abrasive blastingoperations on production parts, tooling, or equipment. The following equipment in thissection has been permitted under an Order <strong>of</strong> Approval. For the purpose <strong>of</strong> defining anemission unit in this permit, each piece <strong>of</strong> equipment is considered a separate emissionunit.LocationVessel Blastingin dry docks 1, 2,and 3Order <strong>of</strong>Approval #DateInstalledSource Description2452 12/13/1984 Abrasive blasting and spray coating operationN/A 1990 Abrasive blasting <strong>of</strong> vessels using curtain controland portable baghouseBldg T-206 N/A 1984 Abrasive blasting <strong>of</strong> ship components using 2baghousesTodd Pacific <strong>Shipyards</strong> uses abrasive blasting to clean ship components and vessels indry dock before final finishing and assembly and conducts the operation inside boothsenclosures with particulate control equipment or dry docks using tarping to control thefugitive dust. Monitoring <strong>of</strong> the particulate control equipment is consistent with Section5. 3. 2. EU-1 – Abrasive Dust Collectors Particulate Control Operations. In addition,WAC 173-460-060(6) is a state only requirement that regulates work practices thatgovern how and where abrasive blasting can occur. Because these are work practices themonitor requirement are consistent with other work practices and as with most otherwork practices the <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency has inspected the facility at leastannually for the last five years and has not identified violations.