Air Operating Permit - Puget Sound Clean Air Agency

Air Operating Permit - Puget Sound Clean Air Agency

Air Operating Permit - Puget Sound Clean Air Agency

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

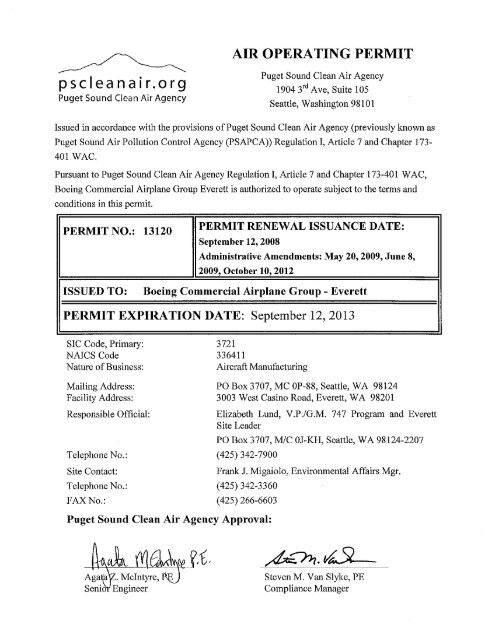

AIR OPERATING PERMITpscleanair.org<strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> <strong>Agency</strong><strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> <strong>Agency</strong>1904 3'd Ave, Suite 105Seattle, Washington 98101Issued in accordance with the provisions of <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> <strong>Agency</strong> (previously known as<strong>Puget</strong> <strong>Sound</strong> <strong>Air</strong> Pollntion Control <strong>Agency</strong> (PSAPCA)) Regulation I, Article 7 and Chapter 173-401 WAC.Pursuant to <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> <strong>Agency</strong> Regulation I, Article 7 and Chapter 173-401 WAC,Boeing Commercial <strong>Air</strong>plane Group Everett is authorized to operate subject to the terms andconditions in this permit.PERMIT NO.: 13120PERMIT RENEWAL ISSUANCE DATE:September 12, 2008Administrative Amendments: May 20, 2009, June 8,2009, October 10, 2012ISSUED TO:Boeing Commercial <strong>Air</strong>plane Group - EverettPERMIT EXPIRATION DATE: September 12,2013SIC Code, Primary:NArcs CodeNature of Business:Mailing Address:Facility Address:Responsible Official:Telephone No.:Site Contact:Telephone No.:FAX No.:3721336411<strong>Air</strong>craft ManufacturingPO Box 3707, MC OP-88, Seattle, WA 981243003 West Casino Road, Everett, WA 98201Elizabeth Lund, V.P.lG.M. 747 Program and EverettSite LeaderPO Box 3707, MlC OJ-KH, Seattle, WA 98124-2207(425) 342-7900Frank J. Migaiolo, Environmental Affairs Mgr.(425) 342-3360(425) 266-6603<strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> <strong>Agency</strong> Approval:Aga a ~. McIntyre, p~Senio EngineerSteven M. Van Slyke, PECompliance Manager

<strong>Permit</strong> No. 13120Expiration Date: September 12, 2013Page 20f291TABLE OF CONTENTSI. EMISSION LIMITS AND PERFORMANCE STANDARDS 6A. FACILITY-WIDE APPLICABLE REQUIREMENTS 7B. EMISSION UNIT SPECIFIC APPLICABLE REQUIREMENTS 151. Halogenated Solvent Vapor Degreasing and Cold Solvent <strong>Clean</strong>ing Operations 162. Chemical Process Tankline Operations 173. Coating, <strong>Clean</strong>ing, and Depainting Operations 184. NSPS - Fuel Burning Equipment 945. NON NSPS - Fuel Burning Equipment 1186. Waste Water Trealment Operations 1237. Cyclones, Baghouses, and Other Particulate Control Operations 1298. Composite Processing Operations 1369. Abrasive Blasting Operations 15610. Motor Vehicle Fueling Operations 16011. Storage Tanks 16712. Graphic Arts Operations 17013. Laser Operations 17214. Drying and Curing Operations 17315. Wood Furniture 17616. Site Remediation 17717. Stationary Internal Combustion Engines Subject to NSPS and/or NESHAP 178II. MONITORING, MAINTENANCE AND RECORDKEEPING PROCEDURES 187A. Minimum Monitoring and Maintenance Requirements 187I. Facility-Wide Monitoring2. Specific Monitoring187192B. Operation and Maintenance (O&M) Plan Requirements. 231232A. Adjustment for Atmospheric Conditions 232Boeing-Everett <strong>Permit</strong>, issued September 12, 2008; Administrative Amendment 3: October 10, 2012

<strong>Permit</strong> No. 13120Expiration Date: September 12,2013Page 30f291B.Outdoor Burning232C.Refnse Burning232D.1.2.ConcealmentGeneralNSPS232232233E.Masking233F.Tampering233C.False Statements233IV.ACTIVITIES REQUIRING ADDITIONAL APPROVAL 234A.New Source Review 234n.Replacement or Substantial Alteration of Emission Control Technology 235C.Asbestos 236D.V.Spray Coating 236STANDARD TERMS AND CONDITIONS 238A.Duty to comply 238B.<strong>Permit</strong> actions 238C.Property rights 238D.Duty to provide information 238E.<strong>Permit</strong> fees 239F.Emissions trading 239C.H.Severability 239<strong>Permit</strong> appeals 239Boeing-Everett <strong>Permit</strong>, issued September f 2, 2008; Administrative Amendment 3: October 10, 20 J 2

<strong>Permit</strong> No. 13120Expiration Date: September 12,2013Page 40f291J.<strong>Permit</strong> continuation240J.Federal enforceability240K.Inspection and entry240L.Compliance requirements241M.Compliance certifications241N.1.2.3.4.Compliance determinationEmission Testing - GeneralEmission Testing - New Source Performance TestsTesting - Gasoline StationCredible Evidence242242243245245O.1.2.RecordkeepingGeneralSpecific246246248P.1.2.3.Data recoveryGeneral Data RecoveryData Recovery ExceptionsCEMS Data Recovery250250250251Q. Reporting2521.2.3.4.5.6.7.8.9.10.General ReportsAnnual Emission Inventory ReportingAerospace Manufacturing and Rework Facilities NESHAP -- Reporting/NotificationMethod 9 A ReportsReport of Problems not Corrected Within 24 HoursNSPS Fuel Burning Equipment Reporting RequirementsReinforced Plastic Composites NESHAP Reporting/NotificationRegulation I, Article 12Summmy of Required Applications, Reports, and Compliance CertificationsNotification Requirements252254255258258259263267267272R.Emergencies 276Boeing-Everett <strong>Permit</strong>, issued September 12, 2008,' Administrative Amendment 3: October 10,2012

<strong>Permit</strong> No. 13120Expiration Date: September 12, 2013Page 50f291S. Unavoidable excess emissions276T. Need to halt or reduce activity not a defense277U. Stratospheric ozone and climate protection277V. RACT satisfied278W. Risl{ Management Programs278X. Definitions279Y. Duty to supplement or correct application279Z. Insignificant emission units and activities279VI.PERMIT ACTIONS280A. <strong>Permit</strong> Renewal, Revocation and Expiration280B. Administrative <strong>Permit</strong> Amendments280C. Changes not Reqniring <strong>Permit</strong> Revisions282D. Off <strong>Permit</strong> Changes283E. <strong>Permit</strong> Modification284F. Reopening for Cause287VII.PERMIT SHIELD288VIII.APPENDIXES289A. Reference Method Titles and Ave"aging Periods289B. Source Test Method 99 Fuel Oil Analyses291Boeing~Everett <strong>Permit</strong>, issued September 12, 2008,' Administrative Amendment 3: October J 0, 20 J 2

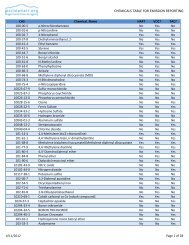

<strong>Permit</strong> No. 13120Expiration Date: September 12, 2013Page 60f291I. EMISSION LIMITS AND PERFORMANCE STANDARDSThe following tables list the citation for the "applicable requirement" in the second column. Thethird column (Date) contains the adoption or effective date of the requirement. In some cases,the effective dates of the "Federally Enforceable" requirement and the "State Only" requirementare different because either the state (or local authority) has not submitted the regulation to theEPA for approval into the State Implementation Plan (SIP), or the state (or local authority) hassubmitted it and the EPA has not yet approved it. "STATE ONLY" adoption dates are in italicizedfont. When the EPA does approve the new requirement into the SIP, the old requirement will bereplaced and superseded by the new requirement. This replacement will take placeautomatically, with no changes being made to this permit until the permit is renewed. The newrequirement will be enforceable by the EPA as well as the <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> <strong>Agency</strong> fromthe date that it is adopted into the SIP, and the old requirement will no longer be an applicablerequirement.The first column is used as an identifier for the requirement, and the fourth (RequirementParaphrase) column paraphrases the requirement. The first and fourth columns are forinformation only and are not enforceable conditions of this permit. The actual enforceablerequirement is embodied in the requirement cited in the second and third columns.The fifth column (Monitoring, Maintenance & Recordkeeping Method) identifies the methodsdescribed in Section II of the permit. Following these methods is an enforceable requirement ofthis permit.The sixth (Emission Standard Period) column identifies the averaging time for the reference testmethod. The last column (Reference Test Method) identifies the reference method associatedwith an applicable emission limit that is to be used when a source test is required. In some caseswhere the applicable requirement does not cite a test method, one has been added.In the event of conflict or omission between the information contained in the fourth and sixthcolumns and the actual statute or regulation cited in the second column, the requirements andlanguage of the actual statute or regulation cited shall govern. For more information regardingany of the requirements cited in the second and third columns, refer to the actual requirementscited.Boeing-Everett <strong>Permit</strong>, issued September 12, 2008,' Administrative Amendment 3: October lO, 2012

Facility-Wide Applicable Requirements<strong>Permit</strong> No. 13120Expiration Date: September 12,2013Page 70f291A. FACILITY-IDE APPLICABLE REQUIREMENTSThe requirements in this section apply facility-wide to all the emission units regulated by this permit except that monitoring methodsspecified elsewhere in the permit for specific applicable requirements for specific emission units or activities supersede the generalmonitoring requirements listed in Section LA.Table 1 Facility-Wide Applicable RequirementsReqmt. Enforceable Adoption or Requirement Paraphrase Monitoring, Emission ReferenceNo. Requirement Effective Date .(Information Only) Maintenance & Standard Period Test MethodRecordkeeping Method(See Section II)LA. 1<strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Shall not emit air contaminants in More than 3 Ecology<strong>Agency</strong> Reg I: 9.03 This 3111/1999 excess of 20% opacity for more than 3 II.A. 1 (a) Opacity min in any 1 hr Method 9Arequirement will be minutes per hour Monitoring(See Sectionsuperseded upon adoptionVIII)of the 3125104 version ofReg 1: 9.03 into the SIPII.A. I (b) Complaint<strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong>3/25/2004 Response<strong>Agency</strong> Reg. I: 9.03 (StateOnly). This requirementwill become federallyII.A.1 (c) Facilityenforceable upon adoptionInspectionsinto the SIP and will replacethe 3111/99 version of Reg I:9.03WAC 173-400-040(1) Thisrequirement will besuperseded upon adoptionof the 2110/05 version ofWAC /73-400-040(1) intothe SIPWAC 173-400-040(1) (StateOnly). This requirementwill become federallyeriforceable upon adoptioninto the SIP and will replace09/2011993Boeing-Everett <strong>Permit</strong>, issued September 12, 2008; Administrative Amendment 3: October 10, 2012

Facility-Wide Applicable RequirementsReqmt. Enforceable Adoption or Requirement ParaphraseNo. Requirement Effective Date (Information Only)the 912011993 version ofWAC 173-400-040(1) 211012005<strong>Permit</strong> No. 13120Expiration Date: September 12, 2013Page 80f291Monitoring, Emission ReferenceMaintenance & Standard Period Test MethodRecordkeeping Method(See Section II)l.A.2<strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong>Shall not emit particulate matter in<strong>Agency</strong> Reg I: 9.09 04/0911998 excess of 0.05 gr/dscffrom equipmentused in a manufacturing process,uncorrected for excess airIl.A.I(a) OpacityMonitoringII.A. I (b) ComplaintResponseAt least I -br perrun<strong>Puget</strong> <strong>Sound</strong><strong>Clean</strong> <strong>Air</strong><strong>Agency</strong>MethodS(See SectionVIII)Il.A.I(c) FacilityInspectionsl.A.3WAC 173-400-060 ThisShall not emit particulate matter inrequirement shall be 312211991 excess of O. I gr/dscf from generalsuperseded by the 21fOI05process units, uncorrected for excessversion of WAC 173-400-air060 upon its adoption intothe SIPWAC 173-400-060 (StateOnly). This requirementwill become federallyenforceable upon adoptioninto the SIP and will replacethe 3122191 version of WAC173-400-06021fOI2005II.A. I (a) OpacityMonitoringII.A. I (b) ComplaintResponseIl.A. I (c) FacilityInspectionsAt least I -br perrunEPA Method5(See SectionVIII)Boeing-Everett <strong>Permit</strong>, issued September 12, 2008; Administrative Amendment 3: October 10, 2012

Facility-Wide Applicable RequirementsReqmt Enforceable .. Adoption or.Requirement ParaphraseNo. Requirement Effective Date (Information Only)l.AA<strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong>Shall not emit particulate matter in<strong>Agency</strong> Reg l: 9.09 04/0911998 excess of 0.05 gr/dscfcorrected to 7%0, from fuel burning equipmentburning fuel other than wood, coal, orother solid fossil fuel (applies to theequipment that produces hot air, hotwater, steam, or other heated fluids byextemal combustion of fuel. Examplesinclude indirect-fired drying ovens andspace heaters and water heaters)<strong>Permit</strong> No. 13120Expiration Date: September 12,2013Page 90[291- Monitoring, Emission ReferenceMaintenance & Standard Period Test MethodRecordkeeping Method(See Section IT)At least I-br per <strong>Puget</strong> <strong>Sound</strong>Il.A.I(a) Opacity run <strong>Clean</strong> <strong>Air</strong>Monitoring<strong>Agency</strong>MethodS(See SectionIl.A.I (b)ComplaintVIII)ResponseIl.A.I(c) FacilityInspectionslASWAC 173-400-050 (I) &Shall not emit particulate matter in(3) This requirement will be 3/22/91 excess of 0.10 gr/dscfcorrected to 7%superseded upon adoptionO 2 from combustion and incinerationof the 2110105 version ofunits except for emission unitsWAC 173-400-050 into thecombusting wood derived fuels for theSIPproduction of steam.. (Applies to unitsusing combustion for waste disposal,WAC 173-400-050 (1) & (3)steam production, chemical recovery(State Only) Thisor other process requirements; butrequirement will be 2110105excludes outdoor burning.)federally enforceable uponadoption into the SIP andwill replace the 3122191Shall not emit particulate matter inversion of WAC 173-400-excess of 0.2 gr/dscf at standard050conditions.At least I-br per EPA MethodIl.A.I(a) Opacity run 5 (See 40MonitoringCFR60Appendix A,July I, 2004)II.A.I (b)ComplaintResponseILA.I(c) FacilityInspectionsBoeing-Everett <strong>Permit</strong>, issued September 12, 2008; Administrative Amendment 3: October 10, 2012

Facility-Wide Applicable RequirementsReqmt. - Enforceable Adoption or Requirement ParaphraseNo. Requirement--Effective Date (Information Only)l.A.6 <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> 0411411994<strong>Agency</strong> Reg I: 9.07WAC 173-400-040(6) firstparagraph only. Thisrequirement shall besuperseded by the 2/fO/05version of WAC 173-400-040(6) upon its adoptioninto the SIPWAC 173-400-040(6) (StateOnly). This requirementwill become federallyenforceable upon adoptioninto the SIP and will replacethe 9/20/93 version of WAC173-400-040(6)9/20119932/fO/2005Shall not emit SO, in excess of 1,000ppmv (dry) corrected to 7% O 2 for fuelburning equipment<strong>Permit</strong> No. 13120Expiration Date: September 12,2013Page 100f291Monitoring, Emission ReferenceMaintenance & Standard Period Test MethodRecordkeeping Method(See Section II)Il.A.2(f) Fuel Oil At least I-br perEPA Method6CSulfur Content run (See 40 CFRMonitoring ProcedurePart 60,Appendix A,July 1,2004)Boeing-Everett <strong>Permit</strong>, issued September 12, 2008; Administrative Amendment 3: October 10, 2012

Facility-Wide Applicable Requirements<strong>Permit</strong> No. 13120Expiration Date: September 12,2013Page 11 of291ReqmL Enforceable Adoption or Requirement ParaphraseNo. Requirement ... Effective (Information Only). ..Date.LA.7 <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> <strong>Agency</strong> 0311111999Shall not emit aircontaminants in sufficientReg I: 9.II(a) (State Only)quantities and of suchcharacteristics and durationWAC 173-400-040(5) Thisas is, or is likely to be,requirement will be supersededinjurious to human health,upon adoption of the 2110105plant or animal life, orversion of WAC 173-400-040(5)9/2011993 property, or whichinto the SIPunreasonably interferes withWAC 173-400-040(5) (Stateenjoyment oflife andOnly). This requirement willpropertybecome federally enforceableupon adoption into the SIP andwill replace the 9/20/93 versionof WAC 173-400-040(5)2/1012005Monitoring, Emission ReferenceMaintenance.& Standard Test MethodRecordkeepmg Method Period(See Section II). .H.A.I (b) Complaint N/A N/AResponse;ILA.1 (c) FacilityInspectionsBoeing-Everett <strong>Permit</strong>, issued September 12, 2008; Administrative Amendment 3: October 10, 2012

Facility-Wide Applicable RequirementsReqmt. Enforceable Adoption or Requirement ParaphraseNo. Requirement Effective (Information Only)I DateI.A.8<strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> <strong>Agency</strong>Reg I: 9.15It shall be unlawful for any03/11/1999 person to cause or allowvisible emissions of fugitivedust unless reasonableprecautions are employed tominimize the emissions.Reasonable precautionsinclude, but are not limitedto, the following:.(l) The use of controlequipment, enclosures, andwet (or chemical) suppressiontechniques, as practical, andcurtailment during highwinds;(2) Surfacing roadways andparking areas with asphalt,concrete, or gravel;(3) Treating temporary, lowtrafficareas (e.g.,construction sites) with wateror chemical stabilizers,reducing vehicle speeds,constructing pavement or riprap exit aprons, and cleaningvehicle undercarriages beforethey exit to prevent the trackoutof mud or dirt onto pavedpublic roadways; or(4) Covering or wetting truckloads or allowing adequatefreeboard to prevent theescape of dust-bearingmaterials<strong>Permit</strong> No. 13120Expiration Date: September 12,2013Page 120f291Monitoring, Emission ReferenceMaintenance & Standard Test MethodRecordkeeping Method Period(See Section II)ILA.I (b) Complaint N/A N/AResponse;II.A.I (c) FacilityInspectionsILA.I(f) Fugitive Dust,Track-Out, and OdorBearing ContaminantsBoeing-Everett <strong>Permit</strong>, issued September 12, 2008; Administrative Amendment 3: October 10, 2012

Facility-Wide Applicable RequirementsReqmt. Enforceable Adoption or Requirement Para phraseNo. Requirement Effective (Information Only)Dilte. .LA.12 WAC 173-400-040(4) (State 211012005 Must use recognized goodOnly)practice and procedures toreduce odors which mayurueasonably interfere withany other property owners'use and enjoyment of theirpropertyIAl3 WAC 173-400-040(2) (State 211012005 Shall not deposit particulateOnly)matter beyond propertyboundary in sufficientquantity to interfereurueasonably with the useand enjoyment of thepropertyLA.14 <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> <strong>Agency</strong> 0610911988 Shall not emit HCI in excessReg I: 9.10(a) (State Only)of 100 ppm (dry) corrected to7% O 2 for combustionsourcesLA.IS RCW 70.94.040 1980 Shall not cause air pollution(State Only)in violation of70.94 RCW orany ordinance, resolution,rule or regulation adoptedthereunder<strong>Permit</strong> No. l3120Expiration Date: September 12,2013Page 14of29lMonitoring, Emission ReferenceMaintenance & Standard Test MethodRecordkeeping Method Period(See Section II)ILA.l(b) Complaint N/A N/AResponse;IIAI(c) FacilityInspectionsII.A.I (b )Complaint N/A N/AResponse;ILA.I( c) FacilityInspectionsNo monitoring required At least EPA Methodthree I-hr 26A (See 40runs CFR Part 60,Appendix A; July1,2000)No monitoring required N/A N/ANI A ~ Not ApplicableBoeing-Everett <strong>Permit</strong>, issued September 12, 2008; Administrative Amendment 3: October 10. 2012

EMISSION UNIT SPECIFIC REQUIREMENTS<strong>Permit</strong> No. 13120Expiration Date: September 12, 2013Page 15 of291B. EMISSION UNIT SPECIFIC APPLICABLE REQUIREMENTSThe requirements in Section LB. only apply to the specific emission units cited; however, therequirements in Section LA. also apply to the specific emission units or activities described inSection LB. If a requirement in Section LA. is repeated in this section, then the monitoring,maintenance, and recordkeeping method specified in this section supersedes the monitoring,maintenance, and recordkeeping method specified in Section LA.The first part of each subsection in Section LB. lists a description of the emission activity andidentifYing information about each specific emission point or unit. The identifYing informationincludes the building number, the colunm and door number (grid system for locating points withinthe buildings), a Boeing inventory control identification number (MSS/ID#), the Notice ofConstruction (NOC) number for equipment that has gone through the new source review process,the installation date and a short description of the emission unit. This information, which is initalics, is not an enforceable part of the permit. Because of the size of Boeing and its complexity,the information is provided as an aid in understanding the permit and locating the specificemission point or activity.The following tables list the citation for the "applicable requirement" in the second column.The third column (Requirement Paraphrase) paraphrases the requirements and is not anenforceable condition of this permit. The actual enforceable requirement is embodied in therequirement cited in the second column.The fourth column (Monitoring, Maintenance and Recordkeeping Method) identifies the activitiesthat Boeing shall use to monitor compliance with the applicable requirements identified in thesecond colunm. These methods are described in Section II of this permit. Following the method isa requirement of this permit. In some cases where the applicable requirement does not cite a testmethod, one has been added.Boeing is subject to all the requirements in all the tables listed below. The paraphrasing containedin the third column below is intended to generally state the relevant requirements for the purposesof the table, but is not intended in any way to alter or change the meaning of any requirementreferenced in the second column.In the event of conflict or omission between the information contained in the third column and theactual statute or regulation cited in the second column, the requirements and language of the actualstatute or regulation cited shall govern. For more information regarding any of the requirementscited in the second colunm, refer to the actual requirements cited.Boeing-Everett <strong>Permit</strong>, issued September 12, 2008; Administrative Amendment 3: October 10, 20 J 2

PennitNo.13120EMISSION UNIT SPECIFIC REQUIREMENTS Expiration Date: September 12, 2013LB.1 Vapor Degreasing and Cold Solvent <strong>Clean</strong>ing Operations1.OperationsHalogenated Solvent Vapor Degreasing and Cold Solvent <strong>Clean</strong>ingRESERVEDBoeing-Everett <strong>Permit</strong>, issued September 12, 2008; Administrative Amendment 3: October 10, 2012

EMISSION UNIT SPECIFIC REQUIREMENTS1.B.2 Chemical Process Tankline Operations<strong>Permit</strong> No. 13120Expiration Date: September 12,2013Page 17 of2912. Chemical Process Tankline OperationsRESERVEDBoeing-Everett <strong>Permit</strong>, issued September J 2, 2008; Administrative Amendment 3: October 10, 2012

EMISSION UNIT SPECIFIC REQUIREMENTSI.B.3 Coating, <strong>Clean</strong>ing, and Depainting Operations<strong>Permit</strong> No. 13120Expiration Date: September 12,2013Page 18 of2913. Coating, <strong>Clean</strong>ing, and Depainting OperationsDESCRIPTION: This section includes all activities and equipment associated with surfacecoating, cleaning, and depainting operations that have specific applicablerequirements other than the general requirements in Section LAoTheseoperations include coating mixing, application, drying, and curing; spray guncleaning; solvent wipe and solvent flush cleaning; de painting; and materialand waste handling.Examples of equipment involved in these activitiesinclude spray booths, paint hangars, solvent cleaning benches, and guncleaning units. Note that small buckets, pails, and beakers with a capacity of2 gallons or less usedfor cleaning with acetone are exempt from WAC 173-460-060(5). I In addition, cold solvent cleaners using solvents that meet thevolatility thresholds in <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> <strong>Agency</strong> Regulation I Section6.03(c)(53) are exempt from WAC 173-460-060 since they are exempt fromreview under <strong>Agency</strong> Regulation 1 Section 6.03.(WAC 173-460 is asupplemental regulation which does not apply to units that are exempt fromreview under <strong>Agency</strong> Regulation I Section 6.03).2<strong>Clean</strong>ing, primer application, and topcoat application operations su~ject tothe Aerospace NESHAP (40 CFR Part 63 Subpart GG) are included in thissection. Currently, the Everett facility depaints 6 or less completed aircrqfieach calendar year. Therefore, the de painting requirements of the AerospaceNESHAP do not apply to the facility. However, under the Alternate <strong>Operating</strong>Scenario shown below, the Everett facility would depaint more than 6completed aircraft in a calendar year and thus be subject to the depaintingrequirements. Chemical milling maskant application operations subject to theAerospace NESHAP are not conducted at the Everett facility and, therefore,are not included in this section.I August 10, 19991eller from David Kircher, <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> <strong>Agency</strong>, to Charles Austin, Boeing.2 February 24,2005 email/rom Steve Van Slyke, <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> <strong>Agency</strong>, to John Fosberg, Boeing.Boeing-Everett <strong>Permit</strong>, issued September 12, 2008,' Administrative Amendment 3: October 10, 20 J 2

EMISSION UNIT SPECIFIC REQUIREMENTSLB.3 Coating, <strong>Clean</strong>ing, and Depainting Operations<strong>Permit</strong> No. 13120Expiration Date: September 12, 2013Page 19 of291The table below includes those spray coating units and solvent cleaningbenches that have received Orders of Approval or were registered with the<strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> <strong>Agency</strong>. This table does not necessarily include allunits that may be subject to the requirements of this section; units that havenot received an Order of Approval or were not previously registered with the<strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> <strong>Agency</strong> are not included in the table. The last columnin the table indicates whether Aerospace NESHAP-regulated coatingscontaining inorganic HAPs are sprayed in the unit at the time of permitissuance. However, any of the booths listed below may have such coatingssprayed in them in the future, and in some cases an amendment ormodification to the existing permits may not be needed.Most of the spray coating units listed below are used in aerospace componentcoating operations. The units with an asterisk (*) next to their description arenot normally used in aerospace component coating operations, but may be inthe future.40-04 A-7B214 4123 4193 777 wing spar dry booth # 1 Yes40-04 A-7B214 4124 4193 777 wing spar dry booth #2 Yes40-04 A-7B214 4125 4193 777 wing spar dry booth #3 Yes40-04 A-7B214 4126 4193 777 wing spar dry booth #4 Yes40-10 G-22089459 3371 2190 Wet booth- No40-21 B-8B946 3918 5192 747 HS GIG dry filter exhaust Nosystem40-22 DIE-l 0B243 None 1968 747 wing stub dry booth YesBoeing--Everett <strong>Permit</strong>, issued September 12, 2008; Administrative Amendment 3: October 10, 2012

EMISSION UNIT SPECIFIC REQUIREMENTSLB.3 Coating, <strong>Clean</strong>ing, and Depainting Operations<strong>Permit</strong> No. 13120Expiration Date: September 12,2013Page 20 of291Aerospace NESirAPregulated Coatingswith Inorganic HAPUsed in Unit?40-22 D-6.518 1165201 3926 2192 747 FBJ CIC dry filter exhaust NoG90551B927system40-22 DlE-lO 712343/ 3924 5/92 747 WBJ CIC dry filter exhaust YesBII3system40-22 G-3.5, 018790 8292 3101 Dry booth No2ndfir40-23 G-IO B234/ 3922 4/93 747 J&I CIC dry filter exhaust NoB946system. BS 46-48. NW & NE40-23 G-9 B233/ 3923 4193 747 J&I CIC dry filter exhaust NoB2351system. BS 46-48. Sw. & BSB946 44/4540-23 G-9 B233/ 7067 2198 Additionalfilter boxes and NoE2351B946exhaust fans for the 747 J&ICIC dry filter exhaust system,BS46-48, SW40-24 I/J-IO GOOl71 3874 12/91 767 FBJ CIC dry filter exhaust NoB583-6 system, west40-24 1-415.25 B240, 3914 11192 767 J&I CIC dry filter exhaust NoB2411 system, 46-48GOOl7Boeing-Everett <strong>Permit</strong>, issued September 12, 2008,' Administrative Amendment 3: October 10, 2012

EMISSION UNIT SPECIFIC REQUIREMENTSLB.3 Coating, <strong>Clean</strong>ing, and Depainting Operations<strong>Permit</strong> No. 13120Expiration Date: September 12,2013Page 21 of29140-24 1-718 B2391 3913 5192 767 J CIC dry filter exhaust NoGOO17 system. BS 41-4340-25 LlM-9 B215 4127 11/93 777 wing stub" dry booth res40-25 LlM-8 ETOl421 4075 2194 777 FBJ CIC dry filter exhaust NoBI54system40-25 K-IO 0/0357 6690 3197 Solvent cleaning bench No40-25 LlM-1 NIA 4274 2194 777 Final Assembly CIC NotoLlM-640-26 N-IO Not Yet 9252 Not Yet 777 Wing Body Join YesInstalledInstalled40-30 G-2 0174851 8761 5103 M&PT dry booth No172940-31 A-16 701500 REG 1968 Wet booth Yes40-33 G/H-14 B247 4006 8192 767 wing stub dry booth Yes40-33 G-14 8581 5913 1981 767 wing panel dry booth No40-33 H-12113 B1I71 3915 5192B1I81GOO17767 WSIWBJ CIC dryfilterexhaust systemNol3oeing~Everett <strong>Permit</strong>, issued September 12, 2008; Administrative Amendment 3: October 10, 2012

EMISSION UNIT SPECIFIC REQUIREMENTSLB.3 Coating, <strong>Clean</strong>ing, and Depainting Operations<strong>Permit</strong> No. 13120Expiration Date: September 12, 2013Page 22 of29140-33 G-J4 1657351 6691 1994 Solvent cleaning benches (3) No361371G602040-33 G-II.5 B946 8315 767 wing stub buildup CIC dry Nofilter exhaust system40-33 H-14.5 BI09 3913 5192 767 HS CIC dry filter exhaust Nosystem40-34 J-14 B684 4119 4193 777 wing panel dry booth #1 No40-34 J-14 B684 4120 4193 777 wing panel dlY booth #2 No40-34 J-14 B684 4121 4193 777 wing panel dry booth #3 No40-34 J-14 B684 4122 4/93 777 wing panel dry booth #4 No40-34 J-12 4247 6/93 777 Wing Major Tool Positions No(8)40-37 C.8- 060201 5070 9/93 Solvent cleaning benches (3) No11/13 148006107/1640-37 B.8- 86631 9058 9/93 77741/43 CIC dry booth No10.6 B7023107040Boeing-Everett <strong>Permit</strong>, issued September 12, 2008,' Administrative Amendment 3: October J 0, 2012

EMISSION UNIT SPECIFIC REQUIREMENTSI.BJ Coating, <strong>Clean</strong>ing, and Depainting Operations<strong>Permit</strong> No. 13120Expiration Date: September 12,2013Page 23 of 29140-37 B.8- 8669/ 5054 9193 777 41143 dry booth Yes13.8 870231G704040-37 8.8- 86641 9058 9/93 77744145 C1C dry booth Yes11.2 870231G704040-37 8.5- 86701 5060 9193 777 44145 dry booth Yes13.8 870231G704040-37 8.8-11 86651 9058 10193 77746147148 C1C dry booth No870231G704040-37 8.2- 86681 5051 9/93 777 46147148 dry booth Yes13.8 870231G704040-37 C.6- 86711 5061 10193 777 dolly parts dry booth Yes12.6 B70231G704040-37 8.3- 86671 9058 10193 777 hariz. stab. C1C dry booth No10.2 870231G7040Boeing--Everett <strong>Permit</strong>, issued September 12, 2008,' Administrative Amendment 3: October !OJ 2012

EMISSION UNIT SPECIFIC REQUIREMENTSLBJ Coating, <strong>Clean</strong>ing, and Depainting Operations<strong>Permit</strong> No. 13120Expiration Date: September 12, 2013Page 24 of291.. .erospadeNESl{AP~egulated Coatings~kh jnQrga~icUsed.in Unit?40-37 B.8-/2 B675/ 5059 8/93 777 vert. wing dry booth resB7023/0704040-37 B.5- B662/ 9058 9/93 777 wing laydown CIC dry res10.2 B7023/ booth0704040-37 B.5-/3 B676/ 5063 8/93 777 wing laydown dry booth #1 resB7023/G704040-37 B.5-13 B677/ 5063 8/93 777 wing laydown dry booth #2 resB7023/0704040-37 B.5-/3 B678/ 5063 8/93 777 wing laydown dry booth #3 resB7023/0704040-37 B.5-/3 B679/ 5063 8/93 777 wing laydown dry booth #4 YesB7023/G7040Boeing-Everett <strong>Permit</strong>, issued September 12,2008; Administrative Amendment 3: October 10, 2012

EMISSION UNIT SPECIFIC REQUIREMENTSLB.3 Coating, <strong>Clean</strong>ing, and Depainting Operations<strong>Permit</strong> No. 13120Expiration Date: September 12, 2013Page 25 of 29140-51 B9311 7637 1969 40-51 highboy spray coating YesB9301B027IB0281B0291B0301B0311G0108areas with 7 dry filter units40-51 A-2.5 7084701 8250 1968 Dry booth YesG900240-51 A-213 7084691 8249 1968 Dry booth YesG900240-51 A-3 7084711 8251 1968 Dry booth YesG900240-51 8-5 1541481 4250 12/93 Vertical wing dry booth. North YesET008440-51 8-4 1541451 4249 3193 Vertical wing dry booth, South YesETOl6440-51 Bd-2 227615 8246 1101 Dry booth Yes40-54 F-3.6 PBOO131 9705 2108 Dry booth Yes8676040-56 S-5 384615 2139 7180 Dry booth YesBoeing-Everett <strong>Permit</strong>, issued September J 2,2008; Administrative Amendment 3: October la, 2012

EMISSION UNIT SPECIFIC REQUIREMENTSI.B.3 Coating, <strong>Clean</strong>ing, and Depainting Operations<strong>Permit</strong> No. 13120Expiration Date: September 12, 2013Page 26 of29140-56 D-8 135463 3986 8192 Dry booth res40-56 D-9 135464 3988 8/92 Dry booth No40-56 K-7.5 088265 3990 9/92 Dry booth Yes40-56 J.5-3 135465 3992 8/92 Dry booth res40-56 J. 5-8. 5 126452 5840 4192 Dry booth No40-56 88-4 135469 3997 3/93 Dry booth No40-56 B-4 110226/ 3999 2/92 Dry booth No/1022540-56 F-3.5 018148 7744 9100 Dry booth No40-56 G-7 018700 8282 12/00 Dry booth No40-56 J-7.5 018699 8283 12/00 Dry booth No40-56 J-7.5 110244 9571 4/07 Dry booth No45-01 8056 7210 1968 Paint hangar Yes45-01 l-5 8057 8603 1987 <strong>Air</strong> lock dry booth Yes45-01 South G80/l1 None Unknown Solvent cleaning bench No08854445-02 E-I0 165336 7509 5/94 Dry booth YesBoeing-Everett <strong>Permit</strong>, issued September 12, 2008,' Administrative Amendment 3: October 10, 2012

EMISSION UNIT SPECIFIC REQUIREMENTSI.B.3 Coating, <strong>Clean</strong>ing, and Depainting Operations<strong>Permit</strong> No. 13120Expiration Date: September 12, 2013Page 27 of29145-03 B058 7217 9/81 Paint hangar, 45-03 Yes45-03 M-5 ET0417 5903 1981 Spray booth, dry Yes45-04 B685 3763 10/93 Paint hangar, 45-04 Yes45-04 Q-I0 B685/ 4501 4/93 Rudder/elevator dry booth YesET040145-04 Q-10 B685/ 4502 4/93 Rudder/elevator dry booth YesET040345-04 G8012/ None 1993 Solvent cleaning benches (2) No1647191164720Data in italics are for information only and not enforceable conditions of this permit.Boeing-Everett <strong>Permit</strong>, issued September 12, 2008,' Administrative Amendment 3: October 10, 2012

EMISSION UNIT SPECIFIC REQUIREMENTSI.BJ Coating, <strong>Clean</strong>ing, and Depainting Operations<strong>Permit</strong> No. 13120Expiration Date: September 12, 2013Page 28 of291EU3. I40CFR63.I(c)(1),63.4 (4/5/02)Aerospace operations must comply with 40 CFR 63Subpart A and GG.NMR40CFR63.741 (b)(9/1/98)EU 3. 240 CFR 63.5(4/5/02)Boeing shall comply with preconstruction reviewrequirements.NMREU3.340 CFR63.6(b)(2)(4120106)New and reconstructed affected sources that have aninitial startup after the effective date of 40 CFR 63Subpart GG must comply with the requirements of 40CFR 63 Subpart GG upon startup.NMREU 3. 440CFR63.6(e)(I)(4120106)At all times, including startup, shutdown andmalfunction, must operate and maintain affectedsources consistent with safety and good air pollutioncontrol practice for minimizing emissions.Malfunctions must be corrected as soon as practicableafter their occurrence. During periods of startup,shutdown, or malfunction, reduce emissions to thegreatest extent which is consistent with safety andgood air pollution control practices.Il.A.2(d)(ii)Spray Boothsand OtherParticulateControlBoothsII.A.2(i)AerospaceNESHAPPressureDroplWaterFlow RateMonitoringandRecordkeepingBoeing-Everett <strong>Permit</strong>, issued September 12, 2008; Administrative Amendment 3: October 10, 2012

EMISSION UNIT SPECIFIC REQUIREMENTSLB.3 Coating, <strong>Clean</strong>ing, and Depainting Operations<strong>Permit</strong> No. 13120Expiration Date: September 12, 2013Page 29 of291EU 3.5 40CFR If control equipment is used to control HAPs, Boeing II.A.2(c)63.6(e)(3) shall develop and implement a Startup, Shutdown and Documentation(4120/06) Malfunction Plan (SSMP), except for dry filters when on FileBoeing follows the manufacturer's instructions. TheSSMP does not need to address any scenario thatwould not cause the source to exceed an applicableemission limitation in the relevant standard.(Note that additional O&M provisions are includedunder 40 CFR 63.743(b).)EU 3. 6 40 CFR The nOllop.city emission standards set forth in 40 NMR63.6(t) CFR 63 shall apply at all times except during periods(4/20/06) of startup, shutdown and malfunction as set forth in 40CFR Subpart A and 00. If a startup, shutdown, ormalfunction of one portion of an affected source doesnot affect the ability of particular emission pointswithin other portions of the affected source to complywith the non-opacity emission standards set forth inthis part, then that emission point must still complywith the non-opacity emission standards and otherapplicable requirements.EU 3. 7 40CFR Conduct monitoring. Monitoring shall be conducted I1.A.2(d)(ii)63.8(b)(41201 as set forth in Subpart A and GO. Spray Booths06) and OtherParticulateControlBooths1I.A.2(i)AerospaceNESHAPPressureDrop/WaterFlow RateMonitoringandRecordkeepingEU 3. 8 40CFR Boeing must receive permission from the <strong>Puget</strong> <strong>Sound</strong> NMR63.8(t) <strong>Clean</strong> <strong>Air</strong> <strong>Agency</strong> before using an alternative(4/20/06) monitoring procedure.Boeing-Everett <strong>Permit</strong>, issued September 12, 2008; Administrative Amendment 3: October J 0, 2012

EMISSION UNIT SPECIFIC REQUIREMENTSI.B.3 Coating, <strong>Clean</strong>ing, and Depainting Operations<strong>Permit</strong> No. 13120Expiration Date: September 12, 2013Page 30 of291EU3.9 40CFR Boeing shall notify the <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> <strong>Agency</strong> NMR63.9(b)(5/301 if it constructs or reconstructs a new affected source,03)EU 3.10 40CFR Adjustment to time periods or postmark deadlines for NMR63.9(i) submittal and review of required communications may(5/30103) be requested from and approved by the <strong>Puget</strong> <strong>Sound</strong><strong>Clean</strong> <strong>Air</strong> <strong>Agency</strong>.EU 3. II 40CFR Notification requirements. Any change in information NMR63.90) already provided under 40 CFR 63.9 shall be sent to(5/30103) the <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> <strong>Agency</strong> within 15 days.EU 3.12 40CFR Must send reports to the <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> NMR63.10(a)(3)- <strong>Agency</strong> according to 40 CFR 63.1 0(a)(3)-(7) and may(7) (4120106) request changes to report due dates.EU 3.13 40 CFR Boeing shall retain records for five years. Ata II.A.2(c)63.10(b) (I) minimum, the most recent two years of data shall be Documentation(4120106) retained on site. The remaining three years of data on Filemay be off site.EU 3.14 40CFR Boeing shall maintain relevant records of startups, Il.A.2(c)63.10(b)(2) shutdowns, malfunctions, maintenance, corrective Documentation(4/20106) actions, monitoring, measurements, and testing in on Fileaccordance with the rule.Boeing-Everett <strong>Permit</strong>, issued September 12, 2008; Administrative Amendment 3: October 10,2012

EMISSION UNIT SPECIFIC REQUIREMENTSI.B. 3 Coating, <strong>Clean</strong>ing, and Depainting Operations<strong>Permit</strong> No. 13120Expiration Date: September 12, 2013Page 31 of291EU 3.15 40CFR If Boeing determines that the facility emits (or has the II.A.2(c)63.1O(b)(3) potential to emit, without considering controls) one or Documentation(4/20106) more hazardous air pollutants is not subject to a on Filerelevant standard or other requirement establishedunder 40 CFR part 63, Boeing shall keep a record ofthe applicability determination on site at the source fora period of 5 years after the determination, or until thesource changes its operations to become an affectedsource, whichever comes fIrst. The record of theapplicability determination shall include an analysis(or other information) that demonstrates why Boeingbelieves the source is unaffected (e.g., because thesource is an area source). The analysis (or otherinformation) shall be suffIciently detailed to allow theAdministrator to make a fInding about the source'sapplicability status with regard to the relevant standardor other requirement. If relevant, the analysis shall beperformed in accordance with requirementsestablished in subparts of this part for this purpose forparticular categories of stationary sources. If relevant,the analysis should be performed in accordance withEPA guidance materials published to assist sources inmaking applicability determinations under section112, ifany.EU 3. 16 40CFR Boeing shall submit reports in accordance with 40 NMR63.10(d)(I) CFR 63 Subpart GG.(4/20106)EU 3. 17 40CFR Boeing must comply with the recordkeeping and NMR63.10(!) reporting requirements in40 CFR 63.10, unless a(4/20106) waiver is granted by the <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong><strong>Agency</strong>.Boeing-Everett <strong>Permit</strong>, issued September 12, 2008; Administrative Amendment 3: October J 0, 2012

EMISSION UNIT SPECIFIC REQUIREMENTSI.B.3 Coating, <strong>Clean</strong>ing, and Depainting Operations<strong>Permit</strong> No. 13120Expiration Date: September 12, 2013Page 32 of291EU 3.1840CFR63.741(b)(9/1198)Boeing must comply with Subparts GG and A, exceptas specified in 40 CFR 63.743(a) and Table I ofSubpartGG.NMREU 3.1940CFR63.741 (a)-(d)(9/1198)Affected sources are specified in 40 CFR 63.74 I (c)(1 )through (7). The activities subject to the AerospaceNESHAP requirements are limited to the manufactureor rework of aerospace vehicles or components asdefined in the regulation. Where a dispute arisesrelating to the applicability of Subpart GG to aspecific activity, Boeing shali demonstrate that theactivity is not regulated under Subpali GG.NMR3 January 15, 1998 letter from Neal Shulman, <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> <strong>Agency</strong>, to David Moore,Boeing.Boeing-Everett <strong>Permit</strong>, issued September 12, 2008,' Administrative Amendment 3: October 10, 2012

EMISSION UNIT SPECIFIC REQUIREMENTSLB.3 Coating, <strong>Clean</strong>ing, and Depainting Operations<strong>Permit</strong> No. 13120Expiration Date: September 12,2013Page 33 of291EU 3.20 40CFR The Aerospace NESHAP requirements are not NMR63.741(e), (t) applicable to: RCRA hazardous waste, specialty(9/1/98) coatings, adhesives, adhesive bonding primers,sealant, research and development, quality control,laboratory testing activities, chemical milling, metalfinishing, electrodeposition (except of paints),composites processing (except cleaning and coating ofcomposite parts or components that become part of anaerospace vehicle or component as well as compositetooling that comes in contact with such compositeparts or components prior to cure), electronic partsand assemblies (except cleaning and topcoating ofcompleted assemblies), manufacture of aircrafttransparencies, wastewater operations, parts andassemblies not critical to the vehicle's structuralintegrity or flight performance. Not applicable toprimers, topcoats, chemical milling maskants,strippers and cleaning solvents with HAP and VOCJess than 0.1 percent for carcinogens or 1.0 percent fornoncarcinogens as detennined from manufacturer'srepresentations.EU 3. 21 40CFR The requirements for primers, topcoats, and chemical NMR63.741(g) milling maskants in 40 CFR 63.745 and 40 CFR(9/1/98) 63.747 do not apply to the use of low-volume coatingsin these categories for which the annual total of eachseparate formulation used at a facility does not exceed189 liter (L) (50 gallons [gal]), and the combinedannual total of all such primers, topcoats, andchemical milling maskants used at a facility does notexceed 757 L (200 gal).EU 3. 22 40 CFR Regulated activities associated with space vehicles are NMR63.741(h) exempt from the requirements of the Aerospace(911/98) NESHAP, except for depainting operations in 40 CFR63.746.EU 3. 23 40CFR Waterborne coatings are exempt from 40 CFR NMR63.741(i) 63.745(d)-(e), 63.747(d)-(e), 63.749(d) and (h),(9/1/98) 63.750(c)-(h) and (k)-(m), 63.752(c) and (t), and63.753(c) and (e).EU 3. 24 40CFR Aerospace NESHAP does not apply to rework on NMR63.7410) antique vehicles.(9/1/98)Boeing-Everett <strong>Permit</strong>, issued September 12, 2008,' Administrative Amendment 3: October 10, 2012

EMISSION UNIT SPECIFIC REQUIREMENTSI.B.3 Coating, <strong>Clean</strong>ing, and Depainting Operations<strong>Permit</strong> No. 13120Expiration Date: September 12,2013Page 34 of 291EU 3. 25 40CFR Requirements for the use of air pollution control NMR63.743(c) device not listed in this subpart.(4/20106)EU 3.26 40 CPR Facilities may choose to comply with averaging provisions Il.A.2(h)63.743(d) herein rather than individual coating limits in 40 CPR Aerospace(4/20106) 63.745 and 40 CFR 63.747. If choosing to comply with NESHAPaveraging provisions, Boeing shall use any combination Coatingof primers, topcoats (including self-priming topcoats), Type MonitoringI chemical milling maskants, or Type II chemical millingandmaskants such that the monthly volume-weighted averageRecordkeepingorganic HAP and VOC contents ofthe combination ofprimers, topcoats, Type I chemical milling maskants, or ProcedureType 11 chemical milling maskants, as determined inaccordance with the applicable procedures set forth in 40CFR 63.750, complies with the specified content limits in40 CPR 63.745(c) and 40 CFR 63.747(c).Averaging is allowed only for uncontrolled primers,topcoats (including self-priming topcoats), Type Ichemical milling maskants, or Type II chemicalmilling maskan!s.Averaging is not allowed between primers andtopcoats (including self-priming topcoats); norbetween Type I and Type II chemical millingmaskants; nor between primers and chemical millingmaskallts; nor between topcoats and chemical millingEU 3. 27 40CFR Aerospace NESHAP depainting requirements in 40 NMR63.746(a) CFR 63.746 do not apply to a facility that depaints six(911198) or less completed aerospace vehicles in a calendaryear.EU 3. 28 40CFR New and reconstructed affected sources that have an NMR63.749(a) initial startup after the effective date of 40 CPR 63(3/27/98) Subpart GG must comply with the requirements of 40CFR 63 Subpart GG upon startup.EU 3. 29 40CFR Boeing must receive permission from the <strong>Puget</strong> <strong>Sound</strong> NMR63.75 I (e) <strong>Clean</strong> <strong>Air</strong> <strong>Agency</strong> before using an alternative(12/8/00) monitoring procedure.Boeing~Everett <strong>Permit</strong>, issued September 12, 2008; Administrative Amendment 3: October 10, 2012

EMISSION UNIT SPECIFIC REQUIREMENTSI.B.3 Coating, <strong>Clean</strong>ing, and Depainting Operations<strong>Permit</strong> No. 13120Expiration Date: September 12,2013Page 35 of291EU 3. 3040 CFR63.751(t)(12/8/00)Reduction of monitoring data. All emission data shallbe converted into units specified in this subpart forreporting purposes. After conversion into unitsspecified in this subpart, the data may be rounded tothe same number of significant digits as used in thissubpart to specify the emission limit.NMREU 3. 3140 CFR63.744 Table1 (6/23/03)Aqueous cleaners are :::80 percent water, have flashpoints> 200°F and are miscible with water.Hydrocarbon based cleaners are mixtures ofphotochemically reactive hydrocarbons andoxygenated hydrocarbons, have a maximum vaporpressure of7 nun Hg at 20°C, and contain no HAP.NMREU 3. 3240CFR63.744(a)(6/23/03)Must comply with housekeeping measures forcleaning operations unless using solvents that areidenti±led in Table I of 40 CPR 63.744 as aqueouscleaners or hydrocarbon cleaners, or that meet the 40CFR 63.741(t) de minimis levels.NMREU 3. 3340CFR63.744(a)(1)(6/23/03)Place cleaning solvent-laden cloth, paper, or any otherabsorbent applicators used for cleaning in bags orother closed containers upon completing their use. Usebags and containers of such design so as to contain thevapors of the cleaning solvent. "Completing theiruse" means when cleaning operation is completed orbefore leaving for a break or end shift, whichevercomes first.II.A.I (d)Work PracticeInspectionEU 3. 3440 CFR63.744(a)(1)(6/23/03)Cotton-tipped swabs used for very small cleaningoperations are exempt from the requirements of 40CFR 63.744(a)(1).NMREU 3. 3540CFR63.744(0)(2)(6/23/03)Fresh and spent cleaning solvents must be stored inclosed containers.II.A. 1 (d)Work PracticeInspectionBoeing-Everett <strong>Permit</strong>, issued September J 2, 2008; Administrative Amendment 3: October 10, 2012

EMISSION UNIT SPECIFIC REQUIREMENTSLB.3 Coating, <strong>Clean</strong>ing, and Depainting Operations<strong>Permit</strong> No. 13120Expiration Date: September 12, 2013Page 36 of291EU 3. 3640 CFR63.744(a)(3)(6/23/03)Handling and transfer of cleaning solvents must beconducted in a manner as to minimize spills.Il.A.I(d)Work PracticeInspectionEU 3. 3740 CFR63.744(b)(6/23/03)<strong>Clean</strong>ing solvent solutions that contain HAP or VOCbelow the de minimis levels specified in 40 CFR63.741(f) are exempt from the requirements inparagraphs (b)(l), (b)(2), and (b)(3).NMREU 3. 3840CFR63.744(b)(l)& (2)(6/23/03)Hand-wipe cleaning solvent must meet the aqueous orhydrocarbon-based composition "equirements, or havecomposite v.p. of 45 mm Hg or less @20'C.II.A.2(g)AerospaceNESHAPSolvent<strong>Clean</strong>erMonitoringandRecordkeepingProcedure40CFR63.750(a),63.750(b)EU 3. 3940CFR63.744(c)(6/23/03)Must use one or more of the following techniques, ortheir equivalent, to clean spray guns:• Enclosed system cleaning; clean spray gun in anenclosed system that is closed at all times except wheninserting or removing the spray gun. <strong>Clean</strong>ing shallconsist of forcing solvent through gun.• Nonatomized cleaning: clean spray gun by placingcleaning solvent in the pressure pot and forcing itthrough the gun with the atomizing cap in place. Noatomizing air is to be used. Direct the cleaningsolvent from the gun into a vat, drum, or the wastecontainer that is closed when not in use.• Disassembled cleaning: disassemble the spray gunand clean the components by hand in a vat, whichshall remain closed at all times except when in use; orsoak components in a vat, which shall remain closedduring the soaking period and when not inserting orremoving components.Il.A.l(d)Work PracticeInspectionH.A.2( d)(i)Enclosed Gun<strong>Clean</strong>ingSystems• Atomizing cleaning: <strong>Clean</strong> spray gun by forcingthe cleaning solvent through the gun and directing theresulting atomized spray into a waste container that isfitted with a device designed to capture the atomizedcleaning solvent emissions.of nozzleof automatedBoeing-Everett <strong>Permit</strong>, issued September 12, 2008; Administrative Amendment 3: October J 0, 2012

EMISSION UNIT SPECIFIC REQUIREMENTSLB.3 Coating, <strong>Clean</strong>ing, and Depainting Operations<strong>Permit</strong> No. 13120Expiration Date: September 12, 2013Page 37 of291systems, except for robotic systems programmed tospray into a closed container, are exempt ITom therequirements of paragraphs c(1)-(4).<strong>Clean</strong>ing solvent solutions that contain HAP or VOCbelow the de minimis levels specified in 40 CFR63.741(f) are exempt ITom the requirements inparagraphs (c)(I)-(4).<strong>Clean</strong>ing procedures used in Safety Kleen gun cleanermodels 1107 and 1111 are generally equivalent tothose specified in 40 CFR 63.744(c)(2) and (3).4EU 3. 4040 CFR63.744(d)(6/23/03)Flush cleaning operations, excluding those in whichTable I or semi-aqueous cleaning solvents are used;Boeing shall empty the used cleaning solvent eachtime aerospace parts, assembJies, or components of acoating unit (with the exception of spray guns) areflush cleaned into an enclosed container or collectionsystem that is kept closed when not in use or into asystem with equivalent emission control.II.A.I(d)Work PracticeInspectionEU 3. 4140 CFR63.744(e)(6/23/03)The following cleaning operations are exempt fromthe requirements of40 CFR 63.744(b) for hand-wipecleaning:NMR(1) <strong>Clean</strong>ing during the manufacture, assembly,installation, maintenance, or testing of components ofbreathing oxygen systems that are exposed to thebreathing oxygen;(2) <strong>Clean</strong>ing during manufacture, assembly,installation maintenance or testing of parts,subassemblies, or assemblies that are exposed tostrong oxidizers or reducers (e.g., nitrogen tetraoxide,liquid oxygen, or hydrazine);(3) <strong>Clean</strong>ing and surface activation prior to adhesivebonding;4 June 14, 2000 letter from Jay Willenberg, Pugel <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> <strong>Agency</strong>, 10 Robin Bennett. Boeing.Boeing-Everett <strong>Permit</strong>, issued September 12,2008; Administrative Amendment 3: October 10,2012

EMISSION UNIT SPECIFIC REQUIREMENTSLB.3 Coating, <strong>Clean</strong>ing, and Depainting Operations<strong>Permit</strong> No. 13120Expiration Date: September 12, 2013Page 38 of291containing electronic parts;(5) <strong>Clean</strong>ing of aircraft and ground support equipmentfluid systems that are exposed to the fluid, includingair-to-air heat exchangers and hydraulic fluid system;(6) <strong>Clean</strong>ing of fuel cells, fuel tanks, and confInedspaces;(7) Surface cleaning of solar cells, coated optics, andthermal control surfaces;(8) <strong>Clean</strong>ing during fabrication, assembly, installationand maintenance of upholstery, curtains, carpet, andother textile materials used in the interior of theaircraft;(9) <strong>Clean</strong>ing of metallic and nonmetallic materialsused in honeycomb cores during the manufacture ormaintenance of these cores, and cleaning of thecompleted cores used in the manufacture of aerospacevehicles or components;(10) <strong>Clean</strong>ing of aircraft transparencies,polycarbonate, or glass substrates;(11) <strong>Clean</strong>ing and cleaning solvent usage associatedwith research and development, quality control, andlaboratory testing;(12) <strong>Clean</strong>ing operations, using nonflammable liquids,conducted within fIve feet of energized electricalsystems. Energized electrical systems means any ACor DC electrical circuit on an assembled aircraft onceelectrical power is connected, including interiorpassenger and cargo areas, wheel wells and tailsections; and;(13) <strong>Clean</strong>ing operations identifIed as essential usesunder the Montreal Protocol for which theAdministrator has allocated essential use allowancesor exemption in 40 CFR 82.4.Boeing-Everett <strong>Permit</strong>, issued September 12, 2008,' Administrative Amendment 3: October 10, 2012

EMISSION UNIT SPECIFIC REQUIREMENTSLB.3 Coating, <strong>Clean</strong>ing, and Depainting Operations<strong>Permit</strong> No. 13120Expiration Date: September 12, 2013Page 39 of 291EU 3. 42 40CFR Boeing shall demonstrate compliance with solvent NMR63.750(a) composition using manufacturer's data. The data shall(JO/l7/00) identify all components of the cleaning solvent andshall demonstrate that one ofthe approvedcomposition definitions is met.EU 3. 43 40CFR Boeing shall follow 40 CFR 63.750(b) to determine NMR63.750(b) the vapor pressure of cleaning solvents.(10/17/00)EU 3. 44 40CFR Boeing shall record the name, vapor pressure, and II.A.2(g)63.752(b)(I) documentation showing the organic HAP constituents Aerospace(9/1/98) of each cleaning solvent used for affected cleaning NESHAPoperations at the facility.Solvent<strong>Clean</strong>erMonitoringandRecordkeepingProcedureEU 3. 45 40CFR For complying with hand-wipe cleaner composition II.A.2(g)63.752(b)(2) requirements specified in 63.744(b)(I), or for semi- Aerospace(9/1/98) aqueous cleaning solvent for flush cleaning, Boeing NESHAPshall keep records of name, data/calculations, andaIillual volumes on file.Solvent<strong>Clean</strong>erMonitoringandRecordkeepingProcedureEU 3. 46 40 CFR For complying with hand-wipe cleaner vapor pressure II.A.2(g)63.752(b)(3) limit (not complying with the composition Aerospace(9/\/98) requirements specified in 63. 744(b)(1 », Boeing must NESHAPkeep records of name, vapor pressure,Solventdata/calculations/test results, and monthly volumes on <strong>Clean</strong>erfile for five years (the most recent two years must bekept on site) as required by 40 CFR 63.1 O(b)(\).MonitoringandRecordkeepingProcedureBoeing-Everett <strong>Permit</strong>, issued September 12, 2008; Administrative Amendment 3: October J 0, 2012

EMISSION UNIT SPECIFIC REQUIREMENTSLB.3 Coating, <strong>Clean</strong>ing, and Depainting Operations<strong>Permit</strong> No. 13120Expiration Date: September 12,2013Page 40 of291EU 3.47 40CFR For using noncompliant hand-wipe cleaning solvent in Il.A.2(g)63.752(b)(4) exempt cleaning operations specified in 40 CPR Aerospace(9/1198) 63.744(e), Boeing shall keep records on monthly NESHAPvolumes by operation and a master list of processes onfile.Solvent<strong>Clean</strong>erMonitoringandRecordkeepingProcedureEU 3. 48 40CFR Boeing shall keep a record of all leaks from enclosed II.A.2( d)(i)63.752(b)(5) spray gun cleaners identified pursuant to 63.751(a) Enclosed Gun(9/1198) that includes the source identification, date leak was <strong>Clean</strong>ingdiscovered and date leak was repaired for each leak Systemsfound.5 February 19, 1999 letter ji'om J. M. Willenberg, <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> <strong>Agency</strong>, to Robin Bennett, Boeing, andApril 2, 1999 letter from Bonnie Thie, EPA, to Robin Bennett, Boeing.Boeing-Everett <strong>Permit</strong>, issued September J 2, 2008; Administrative Amendment 3: October 10, 2012

EMISSION UNIT SPECIFIC REQUIREMENTSI.B.3 Coating, <strong>Clean</strong>ing, and Depainting Operations<strong>Permit</strong> No. 13120Expiration Date: September 12, 2013Page 41 of291EU 3. 49 40CFR For exempt waterborne coatings, Boeing shall II.A.2(c)63.741(i) maintain manufacturer's data on HAP/VOC content Documentation(911198) and annual purchase records for 5 years. on FileEU 3.50 40CFR Aerospace equipment that is no longer operational, NMR63.745(a) intended for public display, and not easily capable of(12/8/00) being moved is exempt from the requirements of 40CFR 63.745, EU 3.51 through EU 3.55.EU 3. 51 40CFR Boeing shall conduct handling and transfer of HAP- IT.A.l (d)63.745(b) containing primers and topcoats in such a manner to Work Practice(12/8/00) minimize spills. InspectionEU 3. 52 40CFR Boeing shall limit primer organic HAP/VOC content II.A.2(h) EPA63.745(c) to 350 gil or 650 gil for large commercial aircraft and Aerospace Method 24(12/8/00) their components; iopcoat organic HAP/vOC content NESHAP (See 40to 420 gil. Coating CFRPartMonituring 60,andAppendixRecordkeeping A, July 1,Procedure 2001)40CFR63.750(c)-(I)EU 3.53 40CFR Compliance with the organic HAP and VOC content Il.A.2(h)63.745(e) limits specified in 40 CFR 63.745(c)(1) through Aerospace(12/8/00) (c)(4), EU 3.52, shall be accomplished by using the NESHAPmethods specified in 40 CFR63.745(e)(1) and (e)(2) Coatingeither by themselves or in conjunction with one Monitoringanother.and(1) Use pi"imers and topcoats (including self-priming Recordkeepingtopcoats) with HAP and VOC content levels equal to Procedureor less than the limits specified in 40 CFR63.745(c)(1) through (c)(4); or(2) Use the averaging provisions described in 40 CPR63.743(d), EU 3. 26.EU 3.54 40CFR Specific primerltopcoat application techniques II.A.1(d)63.745(1)(1), identified in 40 CFR 63.745(f)(1) are required; must Work Practice(2)(12/8/00) be operated according to company procedures, locally Inspectionspecified operating procedures, or manufacturer'sspecifications whichever is most stringent. Modifiedguns must maintain transfer efficiency equivalent toHVLP.Boeing-Everett <strong>Permit</strong>, issued September 12, 2008,' Administrative Amendment 3: October 10. 2012

EMISSION UNIT SPECIFIC REQUIREMENTSI.B.3 Coating, <strong>Clean</strong>ing, and Depainting Operations<strong>Permit</strong> No. 13120Expiration Date: September 12,2013Page 42 of291EU 3. 5540CFR63.745(t)(3)(12/8/00)Certain situations are exempt from the requirements of40 CFR 63.745(t)(1), including the use of airbrushequipment, band-held aerosol cans, and touch-up andrepair operations.NMRPreval hand-held aerosol cans with a non-refillablepressurized portion qualify for the exemption under 40CFR 63.741(t).6EU 3. 5640CFR63.750(i)(10/17/00)Boeing may apply for alternative application methodsfor primers and topcoats by following procedures in40 CFR 63.750(i).NMREU 3.57EU 3. 5840 CFR63.752(c)(I)(9/1/98)40 CFR63.752(c)(2)(9/1/98)Boeing must keep records of name and VOC contentfor all primers and topcoat~ as received and asapplied.II.A.2(b)AerospaceNESHAPCoatingMonitoringandRecordkeepingProcedureFor compliant coatings, Boeing must keep records on II.A.2(h)organic HAP and VOC contents, as applied, Aerospacedata/calculations or Method 24 used to determine NESHAPthem, and monthly usage.CoatingMonitoringandRecordkeepingProcedure6 October 14. 1998 letter from Douglas Hardesty, EPA, 10 Jay Willenberg, Pugel <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> <strong>Agency</strong>.Boeing-Everett <strong>Permit</strong>, issued September 12,2008; Administrative Amendment 3: October 10,2012

EMISSION UNIT SPECIFIC REQUIREMENTSI.B.3 Coating, <strong>Clean</strong>ing, and Depainting Operations<strong>Permit</strong> No .. 13120Expiration Date: September 12, 2013Page 43 of291EU 3. 5940CFR63.752(c)(3)(9/1/98)For low-HAPIVOC uncontrolled primers as applied:«~250 giL HAP less water as applied) and VOC«~250 giL VOC less water & exempt solvents); sitemust keep annual purchase records, anddatalcalculations or Method 24 used to determineorganic HAP content on file.II.A.2(h)AerospaceNESHAPCoatingMonitoringandRecordkeepingProcedureEU 3. 6040CFR63.752(c)(4)(9/1198)For primers and topcoats complying with the organicHAPIVOC content level by averaging, site must keepmonthly volume-weighted average masses of organicHAPIVOC emitted per unit volume of coating asapplied as determined by procedures in 40 CFR63.750(d) and (t), and all data, calculations, and testresults used to determine these values.II.A.2(h)AerospaceNESHAPCoatingMonitoringandRecordkeepingProcedureEU 3. 6140CFR63.743(a)(10)(4/20106)Boeing shall notify the Administrator and the <strong>Puget</strong><strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> <strong>Agency</strong> on or before March 1 ofeach year requirements for (re)construction of boothsor hangars, during the prior calendar year, withpotential to emit less than 10 tonslyr of an individualinorganic HAP or less than 25 tons/yr of all inorganicHAP combined. Submission of a Notice ofConstruction and Application for Approval to the<strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> <strong>Agency</strong> fulfills the abovementionedinitial notification requirements.II.A.2(a)Approval by the<strong>Puget</strong> <strong>Sound</strong><strong>Clean</strong> <strong>Air</strong><strong>Agency</strong>, viaNOCIOrder ofApprovalBoeing-Everett <strong>Permit</strong>, issued September 12, 2008,' Administrative Amendment 3: October 10, 2012

EMISSION UNIT SPECIFIC REQUIREMENTSI.B.3 Coating, <strong>Clean</strong>ing, and Depainting Operations<strong>Permit</strong> No. 13120Expiration Date: September 12,2013Page 44 of291EU 3. 6240 CFR63.743(b)(4/20/06)Boeing must prepare a startup, shutdown and ILA.2( c)malfunction plan required for water wash booths and Doctunentationdry particulate filter systems not operated per the on Filemanufacturer's instructions. 1n addition to theinformation required in 40 CFR 63.6, this plan shallalso include the following provisions:(1) The plan shall specify the operation andmaintenance criteria for each air pollution contToldevice or equipment and shall include a standardizedchecklist to document the operation and maintenanceof the requirement;(2) The plan shall include a systematic procedure foridentifying malfunctions and for reporting themimmediately to supervisory personnel: and(3) The plan shall specify procedures to be followed toensure that equipment or process malfunctions due topoor maintenance or other preventable conditions donot occur.EU 3. 6340CFR63.743(b)(4120/06)Dry particulate filter systems operated per themanufacturer's instructions are exempt from a startup,shutdown and malfunction plan required by 40 CFR63.6(e)(3).NMREU 3. 6440CFR63.745(g)(1)(12/8/00)Boeing shall apply aerospace primers and topcoats ina booth or hangar with airflow directed downward,onto or across and exhausted through one or moreoutlets.II.A.I(c)FacilityInspectionsEU 3. 6540 CFR63.745(g)(2)(i)(A)(12/8/00)For existing booths or hangars where primers ortopcoats containing inorganic HAPs are spray applied,the air stream must be exhausted through a dryparticulate filter system certified using Method 319 tomeet or exceed the efficiency data points in Tables Iand 2. Alternatively, may choose to comply with 40CFR 63.745(g)(2)(i)(B), EU 3.66, or (C), EU 3. 67.1I.A.2(c)Documentationon FileEPAMethod319 (See40 CFRPart 63,AppendixA, July I,2001)Boeing-Everett <strong>Permit</strong>, issued September 12, 2008,' Administrative Amendment 3: October la, 2012

EMISSION UNIT SPECIFIC REQUIREMENTSLB.3 Coating, <strong>Clean</strong>ing, and Depainting Operations<strong>Permit</strong> No. 13120Expiration Date: September 12,2013Page 45 of 291EU 3. 66EU3.67EU 3. 68EU 3. 69EU 3. 7040CFR63.745(g)(2)(i)(B)(12/8/00)40CFR63.745(g)(2)(i)(C)(12/8/00)40 CFR63.745(g)(2)(ii)(A)(12/8/00)40 CFR63.745(g)(2)(ii)(B)(12/8/00)40CFR63.745(g)(2)(iii) (12/8/00)For existing booths 01' hangars where primers ortopcoats containing inorganic HAPs are spray applied,the air stream must be exhausted through a waterwashsystem that remains in operation during all coatingapplication operations. Alternatively, may choose tocomply with 40 CFR 63.745(g)(2)(i)(A), EU 3. 65, 01'40 CFR 63.745(g)(2)(i)(C), EU 3. 67.For existing booths or hangars where primers ortopcoats containing inorganic HAPs are spray applied,the ail' stream must be exhausted through an airpollution control system that meets or exceeds theefficiency data points in Tables I and 2 and isapproved by the permitting authority. Alternatively,may choose to comply with 40 CFR63.745(g)(2)(i)(A), EU 3. 65,01' (B), EU 3. 66.11.A.2(i)AerospaceNESHAPPressureDroplWaterFlow RateMonitoring andRecordkeepingProcedureI1.A.2(c)Documentationon FileFor new booths or hangars where primers or topcoats II.A.2(c) 319containing inorganic HAPs are spray applied, the air Documentationstream must be exhausted through a dry particulate on Filefilter system that is certified using Method 319 to meetor exceed the efficiency data points in Tables 3 and 4.Altcrnatively, may choose to comply with 40 CFR63.745(g)(2)(ii)(B), EU 3.69.For new booths or hangars where primers or topcoatscontaining inorganic HAPs are spray applied, the airstTeam must be exhausted through an air pollutioncontrol system that meets or exceeds the efficiencydata points in Tables 3 and 4 and is approved by thepermitting authority. Alternatively, may choose tocomply with 40 CFR 63.745(g)(2)(ii)(A), EU 3. 68.Alternate control technology options for sources forwhich construction commenced after June 6, 1994, butbefore October 29, 1996.ILA.2(a)Approval by the<strong>Puget</strong> <strong>Sound</strong><strong>Clean</strong> <strong>Air</strong><strong>Agency</strong>. viaNOCIOrder ofApprovalIl.A.2(a)Approval by the<strong>Puget</strong> <strong>Sound</strong><strong>Clean</strong> <strong>Air</strong><strong>Agency</strong>, viaNOCIOrder ofApprovalBoeing-Everett <strong>Permit</strong>, issued September 12, 2008; Administrative Amendment 3: October J 0, 2012

EMISSION UNIT SPECIFIC REQUIREMENTSLB.3 Coating, <strong>Clean</strong>ing, and Depainting Operations<strong>Permit</strong> No. 13120Expiration Date: September 12, 2013Page 46 of291EU 3. 71EU 3. 72EU 3. 73EU 3.7440CFR63.745(g)(2)(iv) (12/8/00)40CFR63.745(g)(3)(12/8/00)40CFR63.745(g)(4)(12/8/00)40CFR63.745(g)(2)(v) (12/8/00)For dry filter system, must maintain in good workingorder, Boeing must install a differential pressuregauge, continuously monitor the pressure drop acrossthe tilter and record once per shift, and take correctiveaction if outside the limits.Boeing must shut down the spray operation if thepressure drop (as recorded pursuant to 63.752(d)(l))or water flow (as recorded pursuant to 63.752(d)(2))go outside of the range or if Boeing does not doscheduled maintenance. The operation shall not beresumed until the pressure drop or water flow rate isreturned within the specified limit(s).When water wash is used to control inorganic HAPemissions fyom the booth, Boeing must continuouslymonitor water flow rate and record once per shift.II.A.2( d)(ii)Spray Boothsand OtherParticulateControl Booths,I1.A.2(i)AerospaceNESHAPPressureDrop/WaterFlow RateMonitoring andRecordkeepingProcedureII.A.2(i)AerospaceNESHAPPressureDrop/WaterThe requirements of paragraphs (g)(l), EU 3. 64, NMRthrough (g)(3), EU 3. 72, do not apply to: touchup ofscratched surfaces or damaged paint; hole daubing forfasteners; touchup of trimmed edges; coating prior toJommg dissimilar metal components; stenciloperations performed by brush or air brush; sectionjoining; touchup of bushing and other similar parts;sealant detackifying; painting parts in an areaidentified in a Title V permit, where the <strong>Puget</strong> <strong>Sound</strong><strong>Clean</strong> <strong>Air</strong> <strong>Agency</strong> has determined that it is nottechnically feasible to paint the parts in a booth; and,use of hand-held spray can application methods.Flow RateMonitoring andRecordkeepingProcedureI1.A.2(i)AerospaceNESHAPPressul'eDrop/WaterFlow RateMonitoring andRecordkeepingProcedureBoeing-Everett <strong>Permit</strong>, issued September 12, 2008; Administrative Amendment 3: October J 0, 2012

EMISSION UNIT SPECIFIC REQUIREMENTSI.E.3 Coating, <strong>Clean</strong>ing, and Depainting Operations<strong>Permit</strong> No. 13120Expiration Date: September 12,2013Page 47 of291EU 3. 7540CFR63.750(0)(10/17/00)When dry filters are used to control inorganic HAPemissions from the booth, the filters must be certifiedusing Method 319.II.A.2(c)Documentationon FileEU 3. 7640 CFR63.751(c)(I)(12/8/00)When dry filters are used to control inorganic HAP,while primer 01' topcoat application operations areoccurring, Boeing shall continuously monitor pressuredrop 01' water flow rate as applicable across the systemand read and record the pressure drop once pel' shiftfollowing the recordkeeping requirements of 40 CFR63.752(d).II.A.2(i)AerospaceNESHAPPressureDrop/WaterFlow RateMonitoring andRecordkeepingProcedureEU 3. 7740CFR63.751(c)(2)(12/8/00)When water wash is used to control inorganic HAPemissions from the booth, while primer and topcoatapplication operations are occurring, Boeing shallcontinuously monitor the water flow rate through thesystem and read and record the water flow rate onceper shift following the recordkeeping requirements of40 CFR 63.752(d).II.A.2(i)AerospaceNESHAPPressureDrop/WaterFlow RateMonitoring andRecordkeepingProcedureEU 3. 7840 CFR63.752(d)(9/1/98)Boeing shall record pressure drop or water flow onceeach shift. Log shall include limits.Il.A.2(i)AerospaceNESHAPPressureDrop/WaterFlow RateMonitoring andRecordkeepingProcedureEU 3. 79----'40CFR63.748(9/1/96)Except as provided in EU 3. 20, Boeing shall conducthandling and transfer of HAP-containing wastes insuch a manner to minimize spills.II.A.I(d)Work PracticeInspectionBoeing-Everett <strong>Permit</strong>, issued September 12,2008,' Administrative Amendment 3: October 10, 2012

EMISSION UNIT SPECIFIC REQUIREMENTSLBJ Coating, <strong>Clean</strong>ing, and Depainting Operations<strong>Permit</strong> No. 13120Expiration Date: September 12, 2013Page 48 of291EU 3. 80WAC 173-401-650(a)(1114/93)Boeing shall, contemporaneously with making achange from one operating scenario to another, recordin a log at the permitted facility a record of thescenario under which it is operating.II.A.2(1)AerospaceNESHAPDepaintingMonitoringandRecordkeepingProcedureEU 3. 8140 CFR63.746(a)(1)(9/1/98)40 CFR 63.746, EU 3. 81 to EU 3. 86, applies todepainting of outer surface areas of completedaerospace vehicles. Does not apply to the depaintingof parts or units normally removed from the aerospacevehicle for depainting. Wings and stabilizers arealways subject to the requirements of this sectionregardless of whether their removal is considerednormal practice for depainting.NMREU 3.8240 CFR63.746(a)(2)(9/1/98)Aerospace vehicles or components that are intendedfor public display, no longer in operation, and noteasily capable of being moved are exempt from therequirements of this section.NMREU 3.8340CFR63.746(a)(3)(9/1/98)The following depainting operations are exempt fromthe requirements of 40 CFR 63.746, EU 3.81 to EU 3.86:(i) depainting ofradomes, and(ii) depainting of parts, subassemblies, .nd assembliesnormally removed from the primary aircraft structurebefore dep.inting.NMRBoeing-Everett <strong>Permit</strong>, issued September 12, 2008; Administrative Amendment 3: October J 0, 2012

EMISSION UNIT SPECIFIC REQUIREMENTSl.B.3 Coating, <strong>Clean</strong>ing, and Depainting Operations<strong>Permit</strong> No. 13120Expiration Date: September 12, 2013Page 49 of291EU 3.8440CFR63.746(b)(I)(9/1/98)New or existing aerospace depainting operations shallemit no organic HAP from chemical strippingformulations and agents 01' chemical paint softeners.I!.A.2(l)AerospaceNESHAPDepaintingMonitoringandRecordkeepingProcedureEU 3. 8540CFR63.746(b)(3)(9/1/98)New or existing depainting operations shall not, on an I1.A.2(l)annual average basis, use more than 26 gallons of Aerospaceorganic HAP-containing chemical strippers or NESHAPalternatively 190 pounds of organic HAP pel' Depaintingcommercial aircraft depainted; 01' more than 50 Monitoringgallons of organic HAP-containing chemical stTippers andor alternatively 365 pounds of organic HAP pel' Recordkeepingmilitary aircraft depainted for spot stripping and decal Procedureremova!.40CFR63.750(j)EU 3.8640 CFR63.746(b)(5)(9/1198)Mechanical and hand sanding operations are exemptfrom the requirements in 40 CFR 63.746(b)(4)NMREU 3.8740CFR63.750(j)(10117/00)For sources complying with 40 CFR 63.746(b)(3), EU3. 85, must determine volume of organic HAPcontainingchemical strippers or alternatively theweight of organic I-lAP used per aircraft using theprocedures specified in 40 CFR 63.750(j)(1) through(3).NMREU 3.8840CFR63.752(e)(I)(911/98)For all chemical strippers used in depaintingoperations subject to 40 CFR 63.746, EU 3.81 to EU3. 86, record the name of each chemical stTipper andthe monthly volumes of each organic HAP containingstripper used or monthly weight of organic HAPmaterialused for spot stripping and decalremova!.II.A.2(l)AerospaceNESHAPDepaintingMonitoringandRecordkeepingProcedureBoeing-Everett <strong>Permit</strong>, issued September 12, 2008; Administrative Amendment 3: October J 0, 2012

EMISSION UNIT SPECIFIC REQUIREMENTSLBJ Coating, <strong>Clean</strong>ing, and Depainting Operations<strong>Permit</strong> No. 13120Expiration Date: September 12, 2013Page 50 of291EU 3.8940CFR63.752(e)(4)(9/1/98)For each type of aircraft depainted, a listing of theparts, subassemblies, and assemblies normallyremoved from the aircraft before depainting.Prototype, test model or aircraft that exist in lownumbers are exempt from this requirement.ILA.2(l)AerospaceNESHAPDepaintingMonitoringandRecordkeepingProcedureEU 3.9040CFR63.752(e)(6)(9/l/98)For spot stripping and decal removal, the volume oforganic HAP-containing chemical stripper or weightof organic HAP used, the annual average volume ororganic HAP-containing chemical stripper or weightof organic HAP used per aircraft, the annual numberof aircraft stripped, and all data and calculations used.II.A.2(l)AerospaceNESHAPDepaintingMonitoringandRecordkeepingProcedureEU 3. 91<strong>Puget</strong> <strong>Sound</strong><strong>Clean</strong> <strong>Air</strong><strong>Agency</strong> RegII: 3.09(a)(12/9/93)Regulation II: 3.09 applies to operations in whichcoatings are applied to aerospace components.Aerospace component means the fabricated part,assembly of parts, or completed unit of any aircraft,helicopter, missile, or space vehicle.NMRBoeing-Everett <strong>Permit</strong>, issued September 12, 2008; Administrative Amendment 3: October 10, 2012