Statement of Basis Vigor Shipyards Inc. - Puget Sound Clean Air ...

Statement of Basis Vigor Shipyards Inc. - Puget Sound Clean Air ...

Statement of Basis Vigor Shipyards Inc. - Puget Sound Clean Air ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

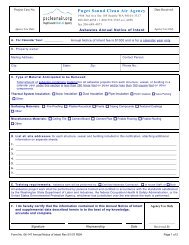

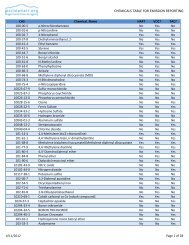

<strong>Statement</strong> <strong>of</strong> <strong>Basis</strong><strong>Vigor</strong> <strong>Shipyards</strong> <strong>Inc</strong>.Administrative Amendment, June 13, 20111. Purpose <strong>of</strong> the <strong>Statement</strong> <strong>of</strong> <strong>Basis</strong>This document summarizes the legal and factual bases for the permit conditions in the airoperating permit to be issued to the Todd Pacific <strong>Shipyards</strong> under the authority <strong>of</strong> theWashington <strong>Clean</strong> <strong>Air</strong> Act, Chapter 70.94 Revised Code <strong>of</strong> Washington (RCW), Chapter173-401 <strong>of</strong> the Washington Administrative Code (WAC), and <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong>Agency (previously known as <strong>Puget</strong> <strong>Sound</strong> <strong>Air</strong> Pollution Control Agency (PSAPCA))Regulation I, Article 7. Unlike the permit, this document is not legally enforceable. Itincludes references to the applicable statutory or regulatory provisions that relate to ToddPacific <strong>Shipyards</strong> air emissions and provides a description <strong>of</strong> Todd Pacific Shipyard’sactivities, including a compliance history.2. Source Description2. 1 Why Todd Pacific <strong>Shipyards</strong> is an <strong>Air</strong> Operating Permit SourceThe Todd Pacific <strong>Shipyards</strong> qualifies as a major source and is required to obtain an airoperating permit because it exceeded the 10 tons per year or more <strong>of</strong> any singlehazardous air pollutant (single HAP-xylene) for 1996. Todd Shipyard received Notice <strong>of</strong>Violation Nos. 36729 and 36730, issued on July 9, 1999, for exceeding its syntheticminor cap. The major sources <strong>of</strong> emissions are from the use <strong>of</strong> solvents and coatingsused to support cleaning and coating operations associated with ship building and repair.2. 2 Emission InventoryThe emission inventory is listed in Attachment A. The attached emission inventoryincludes a breakdown <strong>of</strong> the total annual emissions listed by chemical name, CASnumber, and the sources <strong>of</strong> the listed emissions. In 1996, the Todd Pacific <strong>Shipyards</strong>emitted more than ten tons per year <strong>of</strong> the following Hazardous <strong>Air</strong> Pollutants (HAPs):Xylene, Methyl isobutyl ketone (MIBK; Hexone) and Naphthalene. In the last 5 years(1996–2000), Todd Pacific <strong>Shipyards</strong> has demonstrated over a 40% reduction in HAPemissions and a 30% reduction in volatile organic compounds (VOC) emissions. Thisreduction may be related to the cyclical nature <strong>of</strong> the business.The following table summarizes the reported HAP and VOC emissions from ToddPacific <strong>Shipyards</strong> over the last 5 years. However, for 1996, 1997 and 1998, Todd PacificShipyard’s actual emissions placed Todd Pacific <strong>Shipyards</strong> in the major source category.The information in the table is presented in tons per year.

<strong>Statement</strong> <strong>of</strong> <strong>Basis</strong> for<strong>Vigor</strong> <strong>Shipyards</strong>, <strong>Inc</strong>.Administrative Amendment: June 13, 2011 Page 2 <strong>of</strong> 31Pollutant 1996Tons1997Tons1998Tons1999Tons2000TonsVOC (Reported) 36 27 31 23 25HAP (Singlereported)12 6 7 7 72. 3 Process DescriptionTodd Pacific <strong>Shipyards</strong> is located at 1801 16 th Ave SW in Seattle, Washington. ToddPacific <strong>Shipyards</strong> is a full service shipyard specializing in commercial and military vesselrepair and overhaul. The shipyard is the largest commercial shipyard in the <strong>Puget</strong> <strong>Sound</strong>region. It is located on the northwest corner <strong>of</strong> Harbor Island in Seattle, Washington atthe intersection <strong>of</strong> 16th Avenue SW and SW Florida Street and is accessed from Seattlevia S. Spokane Street. The facility is approximately 23 acres in size, not including pierareas. The shipyard consists <strong>of</strong> three dry docks and associated piers located on the northend <strong>of</strong> Harbor Island, two shipways located in the southwest portion <strong>of</strong> the facility <strong>of</strong>f theWest Waterway <strong>of</strong> the Duwamish River, and nine wet moorage berths located adjacent tothe shipyard’s piers.Todd Pacific <strong>Shipyards</strong> currently provides repair and overhaul services to approximately275 vessels a year, including Navy vessels, Coast Guard vessels, passenger ferries,barges, fishing vessels, cruise ships, tank vessels, and tugs. The hulls <strong>of</strong> these vessels aregenerally constructed <strong>of</strong> steel. The services include electrical and machine work,carpentry, steel fabrication, pipe-fitting, painting, abrasive grit blasting, and pressurewashing. Operational facilities include shops for abrasive grit blasting and painting, pipetreatment and fabrication, rigging, carpentry, welding, machining, plate bending,electrical, and copper work. Support facilities include storage and warehouse buildings;sheds for compressors, heating and power plants, and tools; administrative <strong>of</strong>fices; firstaid <strong>of</strong>fice; and fuel storage.

<strong>Statement</strong> <strong>of</strong> <strong>Basis</strong> for<strong>Vigor</strong> <strong>Shipyards</strong>, <strong>Inc</strong>.Administrative Amendment: June 13, 2011 Page 3 <strong>of</strong> 31Dry dock #1 is a steel dry dock located on the northwest corner <strong>of</strong> the property. It is 598feet long, 87 feet wide and can hold up to 17,500 tons. Dry dock #2 is a wooden drydock located east <strong>of</strong> Dry dock #3. It is 412 feet long and 66 feet wide and holds up to5,700 tons. Dry dock #3, the largest dry dock, is located between #1 and #2. Dry dock#3 is 873 feet long, 137 feet wide and can hold up to 40,000 tons. Dry docks #1 and #2are owned by the Navy and are operated by Todd Pacific <strong>Shipyards</strong>.Todd Pacific <strong>Shipyards</strong> used approximately 3,900 tons <strong>of</strong> abrasive grit blasting materialin 1998. More than 35% <strong>of</strong> the vessels hauled out (dry docked) require partial orcomplete hull blasting, accounting for 80% <strong>of</strong> the grit used. About 10% is used in theabrasive blast shed on shore. The remaining 10% is used in ship holds and shipsuperstructures. Spent grit is removed from the dry docks prior to launching a vessel.Spent grit is stored in a covered area prior to being hauled to Lafarge Cement for re-usein the manufacture <strong>of</strong> cement.Todd Pacific <strong>Shipyards</strong> applies paint to nearly every vessel it services. Approximately47,700 gallons <strong>of</strong> paint were used at the shipyard in 1998. The primary types <strong>of</strong> paintused are solvent based epoxy paints, solvent based non-epoxy paints, solvent based zincpaints, and solvent based anti-foulant paints. Painting operations occur both indoors andoutdoors at the shipyard. Vessel components small enough to be moved or separatedfrom a vessel can be painted indoors in one <strong>of</strong> several “paint shops”. Vessel paintingoccurs outdoors when the vessels are in dry dock (below water line work andsuperstructure painting) or are berthed adjacent to one <strong>of</strong> the shipyard’s piers(superstructure and above water line painting). The majority <strong>of</strong> air emissions from theshipyard originate from painting operations. Todd Pacific <strong>Shipyards</strong> uses VOCcompliant paints per Shipbuilding and Repair NESHAPS. [40 CFR part 63 Subpart II]3. Review <strong>of</strong> Permit ApplicationAn air operating permit application was received by the <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agencyfrom Todd Pacific <strong>Shipyards</strong> on May 4, 2000. The <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agencyacknowledged that the application was complete in a letter to Todd Pacific <strong>Shipyards</strong>dated June 19, 20004. Compliance HistoryTodd Pacific <strong>Shipyards</strong> has been inspected by the Agency annually over the past fiveyears. During this time the Agency issued three Notices <strong>of</strong> Violations for exceeding thelimits <strong>of</strong> the synthetic minor emissions cap and one Notice <strong>of</strong> Violation for smokeemissions from a barge at the dock. These violations and their resolutions are discussedin further detail below.The Agency issued Notice <strong>of</strong> Violation (NOV) No. 36728 for violation <strong>of</strong> Regulation ISection 9.03(a), emissions greater than 20% opacity for more than 3 minutes in any onehour, on April 26, 1999. The emissions were from a diesel-oil fired power generationunit exhaust stack <strong>of</strong> the barge 'Margarita'. Both Todd <strong>Shipyards</strong> and the vessel owner,Man B&W Diesel AG, were cited. The Agency issued civil Penalty No. 9015 on Sept.

<strong>Statement</strong> <strong>of</strong> <strong>Basis</strong> for<strong>Vigor</strong> <strong>Shipyards</strong>, <strong>Inc</strong>.Administrative Amendment: June 13, 2011 Page 5 <strong>of</strong> 315. 1 Applicable RequirementsTodd Pacific <strong>Shipyards</strong> is subject to all the requirements listed in all the tables containedin Section I <strong>of</strong> the permit. Section I.A. contains the requirements that are applicablefacility-wide. The <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency did not repeat the facility-widerequirements listed in Section I.A in Section I.B unless the monitoring method wasspecific to the listed emission unit. Section I.B. contains the Emission Unit SpecificApplicable Requirements and Section I.C. contains Operations without SpecificApplicable Requirements.The tables in Section I.A list the citation for the “applicable requirement” in the secondcolumn. The third column, “Date,” contains the adoption or effective date <strong>of</strong> therequirement. In some cases, the effective dates <strong>of</strong> the “Federally EnforceableRequirement” and the “State Only Requirement” may be different because only rulesapproved by EPA through Section 110, 111, and 112 <strong>of</strong> the federal <strong>Clean</strong> <strong>Air</strong> Act arefederally enforceable and either the state has not submitted the regulation to the EPA orthe EPA has not approved it.The first column is used as an identifier for the requirement, and the fourth “RequirementParaphrase” column paraphrases the requirement. The first and fourth columns are forinformation only and are not enforceable conditions <strong>of</strong> this permit. The actualenforceable requirement is embodied in the requirement cited in the second and thirdcolumns.The fifth column, “Monitoring, Maintenance & Recordkeeping Method,” identifies themethods described in Section II <strong>of</strong> the permit. Following these methods is an enforceablerequirement <strong>of</strong> this permit. The sixth column, “Emission Standard Period,” identifies theaveraging time for the emission standard and/or the minimum length <strong>of</strong> one referencemethod run. Section V.N.1 <strong>of</strong> the permit identifies the number <strong>of</strong> separate runs fordetermining compliance using the reference method. The last column, “Reference TestMethod,” identifies the reference method associated with an applicable emission limitthat is to be used if and when a source test is required. In some cases where theapplicable requirement does not cite a test method, one has been added. This is called“gapfilling” and is authorized under WAC 173-401-615.The permit identifies a specific method and the adoption date. <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong>Agency Regulation I, Section 3.07(a) states that testing for compliance must follow thecurrent EPA approved methods unless specific methods have been adopted by the <strong>Puget</strong><strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency Board <strong>of</strong> Directors. WAC 173-400-105(4) allows either EPA40 CFR 60 Appendix A or procedures in Ecology’s “Source Test Manual – Proceduresfor Compliance Testing” as <strong>of</strong> July 12, 1990. These three requirements may conflict ifthe current method is not listed in the permit. However, EPA seldom significantlychanges the Reference Methods and the current method could be used as credibleevidence <strong>of</strong> an emission violation. Finally, major changes in the Reference Test Methodmay necessitate reopening the permit.In case <strong>of</strong> conflict or omission between the information contained in the fourth columnand the actual statue or regulation cited in the second column, the requirements andlanguage <strong>of</strong> the actual statute or regulation cited shall govern. For more information

<strong>Statement</strong> <strong>of</strong> <strong>Basis</strong> for<strong>Vigor</strong> <strong>Shipyards</strong>, <strong>Inc</strong>.Administrative Amendment: June 13, 2011 Page 6 <strong>of</strong> 31regarding any <strong>of</strong> the requirements cited in the second and third columns, refer to theactual requirements cited.Recently amended <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency Regulations. The <strong>Puget</strong> <strong>Sound</strong><strong>Clean</strong> <strong>Air</strong> Agency Board <strong>of</strong> Directors has recently amended several sections <strong>of</strong> itsregulations. These amended sections are listed as “State Only” in the permit. Thatmeans they are not federally enforceable. They are enforceable only by <strong>Puget</strong> <strong>Sound</strong><strong>Clean</strong> <strong>Air</strong> Agency and the Washington State department <strong>of</strong> Ecology. However, theserequirements will become federally enforceable if they are adopted in the SIP 1 .5. 2 Section I. A. (Facility-Wide)5. 2.1 Requirement I.A.1Both WAC 173-400-040(1) and <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency Regulation I,Section 9.03 standards are 20% opacity and apply to all stationary sources. Although thepermit lists all these requirements together, Todd Pacific <strong>Shipyards</strong> must comply witheach.The monitoring method is based on visible emission inspections <strong>of</strong> the facility at leastonce per week. Todd Pacific Ship Yards shall conduct opacity determinations on shipslocated at the yard during startup and shut down activities. Inspections are to beperformed while the facility is in operation during daylight hours. If visible emissionsother than uncombined water are observed from a single unit or activity, Todd Pacific<strong>Shipyards</strong> shall, as soon as possible but within 24 hours <strong>of</strong> the initial observation, takecorrective action until there are no visible emissions or, alternatively, record the opacityusing the reference test method WDOE Method 9A, or shut down the unit or activity untilit can be repaired. If Todd Pacific <strong>Shipyards</strong> corrects the visible emissions within 24hours <strong>of</strong> initial observation or shuts down the unit or activity within 24 hours until it isrepaired or corrected, Todd Pacific <strong>Shipyards</strong> does not need to report the deviation underSection V.M. (Compliance Certifications) or Section V.Q. (Reporting). However, ifTodd Pacific <strong>Shipyards</strong> does not take appropriate action within 24 hours, Todd Pacific<strong>Shipyards</strong> must report the deviation. The <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency has determinedthat the monitoring should be weekly for the reasons listed below.1) Compliance. Generally, none <strong>of</strong> the emission units at Todd Pacific <strong>Shipyards</strong>normally have visible emissions. The emission units are also unlikely to generatevisible emissions except under the most unusual circumstances. In addition, the1 “SIP” is an abbreviation for “state implementation plan” which is a plan for improvingor maintaining air quality and complying with the Federal <strong>Clean</strong> <strong>Air</strong> Act. The Federal<strong>Clean</strong> <strong>Air</strong> Act requires states to submit these plans to the US EPA for its review andapproval. This plan must contain the rules and regulations <strong>of</strong> the state agency or local airauthority necessary to implement the programs mandated by Federal law. Once the EPAadopts the plan or elements <strong>of</strong> it, the plan and its requirements become “federallyenforceable” by EPA. New or modified state or local rules are not federally enforceableuntil they are “adopted into the SIP” by the EPA.

<strong>Statement</strong> <strong>of</strong> <strong>Basis</strong> for<strong>Vigor</strong> <strong>Shipyards</strong>, <strong>Inc</strong>.Administrative Amendment: June 13, 2011 Page 7 <strong>of</strong> 31<strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency has inspected this facility at least annually since 1986and has not identified opacity issues, nor has Todd Pacific <strong>Shipyards</strong>. Therefore, weconclude that it is generally in compliance with the opacity requirement and themargin <strong>of</strong> compliance is large. In addition, the monitoring method is designed so thatTodd Pacific <strong>Shipyards</strong> will take corrective action before a violation occurs, furtherenhancing the compliance margin.2) Variability <strong>of</strong> process and emissions. Generally, none <strong>of</strong> the processes at ToddPacific <strong>Shipyards</strong> normally emit visible emissions, except as noted above. Whilemany <strong>of</strong> the processes are variable or batch operations, the most likely cause <strong>of</strong>visible emissions would be a significant change in the process, one that would requireapproval from the <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency, or major equipment failure. Thespecific emission units that are most likely to fail and have significant visibleemissions, such as the boilers, spray booths- and baghouses, are addressed elsewherein the permit.3) Environmental impacts <strong>of</strong> problems. Observed opacity is generally related toemissions <strong>of</strong> particulate matter or finely divided liquid droplets. The manufacturingactivities at Todd Pacific <strong>Shipyards</strong> typically do not generate significant quantities <strong>of</strong>particulate matter. Hence, the environmental impacts <strong>of</strong> the emissions are smallespecially considering the amount <strong>of</strong> land on which the facility is located. Amaintenance problem is unlikely to result in emissions that would have a significantenvironmental impact.4) Technical considerations. The emission units that are likely to generate visibleemissions are addressed elsewhere in the permit.5. 2.2 Requirement I.A.2Both <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency Regulation I, Section 9.07 and WAC 173-400-040(6) are equivalent requirements (SO 2 emissions not to exceed 1000 ppmv), except forthe second paragraph <strong>of</strong> the WAC, which is not in the <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agencyregulation. The second paragraph <strong>of</strong> WAC 173-400-040(6), which is not federallyenforceable, allows for exceptions to this requirement if the source can demonstrate thatthere is no feasible method <strong>of</strong> reducing the SO 2 concentrations to 1000 ppm. Since the<strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency’s rules are more stringent, this exception is not availableto Todd Pacific <strong>Shipyards</strong> and the second paragraph does not apply to Todd Pacific<strong>Shipyards</strong>.Todd Pacific <strong>Shipyards</strong> burns only pipeline grade natural gas in all combustion emissionunits except for Boiler No.1 (has diesel oil standby fuel).All the natural gas burned at Todd Pacific <strong>Shipyards</strong> must be pipeline quality, thecontents <strong>of</strong> which the Washington Utilities and Transportation Commission regulates tocontain less than 2000 grains <strong>of</strong> sulfur per million cubic feet. 2000 grains <strong>of</strong> sulfur permillion cubic feet is equivalent to approximately 3.4 parts <strong>of</strong> sulfur per million cubic feet<strong>of</strong> natural gas, as shown in the following calculation:

<strong>Statement</strong> <strong>of</strong> <strong>Basis</strong> for<strong>Vigor</strong> <strong>Shipyards</strong>, <strong>Inc</strong>.Administrative Amendment: June 13, 2011 Page 8 <strong>of</strong> 312,000 gr S 1lb385 31,000,000 ft nat.gas 7000 gr 323ftmoleSlbmoleS3.44106ft33ft S3.44nat.gasppmdvSAccording to Perry’s Chemical Engineer’s Handbook, each cubic foot <strong>of</strong> natural gasrequires approximately 10 cubic feet <strong>of</strong> air for combustion, yielding approximately 11cubic feet <strong>of</strong> combustion exhaust gases, consisting mostly <strong>of</strong> nitrogen, water vapor, andcarbon dioxide. The sulfur in the natural gas will almost all be converted to sulfurdioxide, with each cubic foot <strong>of</strong> sulfur producing the same volume <strong>of</strong> sulfur dioxide.Since each cubic foot <strong>of</strong> natural gas contains 3.44 10 -6 cubic foot <strong>of</strong> sulfur, each cubicfoot <strong>of</strong> stack exhaust will contain approximately:3.44106ft333ft S 1 ft SO3nat.gas 1 ft S231 ft nat.gas311 ft stack exhaust 3.13107ft3ft3SO2stack exhaustThis is equivalent to 0.31 ppmdv SO 2 . Note that this estimated value is less than onetenth<strong>of</strong> one percent <strong>of</strong> the 1,000 ppm SO 2 standard. Therefore, it is reasonable to assumethat combustion units that are fired on natural gas cannot exceed the 1,000 ppm SO 2limits in <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency Regulation I, Section 9.07 and WAC 173-400-040(6). The other emission units are not capable <strong>of</strong> generating SO 2 emissions aspermitted. Therefore, the permit does not contain additional monitoring requirements forthe natural gas usage.5. 2.3 Requirement I.A.3<strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency Regulation I, Section 9.09 limits particulate emissions to0.05 gr/dscf from equipment used in a manufacturing process. WAC 173-400-060 limitsparticulate emissions to 0.1 gr/dscf from general process units (i.e., units using aprocedure or a combination <strong>of</strong> procedures for the purpose <strong>of</strong> causing a change in materialby either chemical or physical means, excluding combustion).The monitoring method is based on weekly visual inspections <strong>of</strong> the facility for visibleemissions, opacity monitoring as a surrogate to performing a Method 5 test with ToddPacific <strong>Shipyards</strong> taking corrective action if any visible emissions are noted. As withRequirement I.A.1, the <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency has determined through itsinspections and permitting that it is unlikely that Todd Pacific <strong>Shipyards</strong> will have anyvisible emissions or exceed the particulate limit. Recording <strong>of</strong> visible emissions is notnecessarily a deviation <strong>of</strong> the particulate concentration standard because the threshold forobserving visible emissions occurs at a particulate concentration <strong>of</strong> less than 0.05 gr/dscf.However, failure to take timely corrective action, as defined in the permit, is a deviationfrom the specific permit requirement and must be reported to the <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong>Agency. Taking corrective action does not relieve Todd Pacific <strong>Shipyards</strong> from theobligation to comply with the particulate concentration standard itself. The <strong>Puget</strong> <strong>Sound</strong><strong>Clean</strong> <strong>Air</strong> Agency has determined that the monitoring should be quarterly for the reasonslisted above in Section 5. 25. 2.2.

<strong>Statement</strong> <strong>of</strong> <strong>Basis</strong> for<strong>Vigor</strong> <strong>Shipyards</strong>, <strong>Inc</strong>.Administrative Amendment: June 13, 2011 Page 9 <strong>of</strong> 315. 2.4 Requirement I.A.4<strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency Regulation I, Section 9.11 and WAC 173-400-040(5) aresimilar requirements that address emissions that may be environmentally detrimental orcause a nuisance. Although the permit lists all these requirements together, Todd Pacific<strong>Shipyards</strong> must comply with each. The monitoring method for all is based on respondingto complaints and general inspections <strong>of</strong> the facility to identify any emissions that arelikely to be injurious to human health, plant or animal life, or property, or thatunreasonably interfere with enjoyment <strong>of</strong> life and property. For the following reasons,the <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency has determined that the monthly facility-wideinspections required in Section II.A.1(c) <strong>of</strong> the permit are sufficient to monitor forchanges that would cause a fugitive emission or unexpected buildup <strong>of</strong> dust on theroadways and plant grounds.1) Initial compliance. The <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency has received complaintsconcerning overspray from the spray coating operations at Todd Pacific <strong>Shipyards</strong>(fugitive dust or odor emissions); however, over the past five years <strong>Puget</strong> <strong>Sound</strong><strong>Clean</strong> <strong>Air</strong> Agency has not observed visible or odorous emissions from plant activitiesduring any inspection, nor has Todd Pacific Shipyard; therefore, we conclude that it isgenerally in compliance with the nuisance requirements.2) Margin <strong>of</strong> compliance. Because the Agency has not observed nuisance problems, andthe fact that the current operations are unlikely to cause nuisance problems, the <strong>Puget</strong><strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency has determined that the margin <strong>of</strong> compliance is sufficientto only require monthly inspections and response to complainants as necessary. Theemission <strong>of</strong> fugitive dust or odor is unlikely to generate <strong>of</strong>f-site fallout or complaintsexcept under the most unusual circumstances.3) Variability <strong>of</strong> process and emissions. Todd Pacific <strong>Shipyards</strong> does have emissionunits that have the potential to generate emissions causing nuisance complaints.However, in the past 5 years no odor complaints have been received. In addition,Todd Pacific <strong>Shipyards</strong> is unlikely to install such emission units during the life <strong>of</strong> thepermit.4) Environmental impacts <strong>of</strong> problems. Nuisance emissions can cause personaldiscomfort; however, by their nature do not result in exceedances <strong>of</strong> federal emissionsor ambient standards. By responding quickly to complaints and identifying problemsbefore they cause complaints, the environmental impact <strong>of</strong> nuisances should be small.5) Technical considerations. Catastrophic failures <strong>of</strong> one <strong>of</strong> the boilers, a large dustcollector, or spray booth, are the only likely causes <strong>of</strong> a nuisance causing a deviationat Todd Pacific <strong>Shipyards</strong>. Boilers at Todd Pacific <strong>Shipyards</strong> are fueled on naturalgas and in accordance with an acceptable O&M plan, thereby minimizing theprobability <strong>of</strong> any nuisance emission. The dust collectors and spray booths areequipped with high efficiency filters and are monitored at least daily, monthly orquarterly by Todd Pacific Shipyard, thereby minimizing the chance <strong>of</strong> generatingemissions that may cause a nuisance. The permit requires Todd Pacific <strong>Shipyards</strong> to

<strong>Statement</strong> <strong>of</strong> <strong>Basis</strong> for<strong>Vigor</strong> <strong>Shipyards</strong>, <strong>Inc</strong>.Administrative Amendment: June 13, 2011 Page 10 <strong>of</strong> 31both look for possible nuisances on a regular basis and handle upset emissions <strong>of</strong>nuisance causing particulate or odor bearing contaminants more frequently on an asneededbasis. This minimizes the probability <strong>of</strong> causing an emission that could beinjurious to health, plant or animal life, or property; or that unreasonably interfereswith the enjoyment <strong>of</strong> life and property. The monitoring method is designed so thatTodd Pacific <strong>Shipyards</strong> will take corrective action before a violation occurs. Inaddition, in the past five years the <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency has not noted norreceived complaints about Todd Pacific <strong>Shipyards</strong> causing emissions that are likely tobe injurious to health, plant or animal life, or property or that unreasonably interferewith enjoyment <strong>of</strong> life and property. Therefore, the <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agencyhas determined that monthly monitoring is adequate. Receiving complaints does notnecessarily mean Todd Pacific <strong>Shipyards</strong> is in violation <strong>of</strong> this requirement, but ToddPacific <strong>Shipyards</strong> has a responsibility to investigate complaints and take correctiveaction if necessary. Failure to take timely corrective action, as defined by themonitoring method, is a deviation <strong>of</strong> the specific permit term. Taking correctiveaction does not relieve Todd Pacific <strong>Shipyards</strong> from the obligation to comply with thenuisance requirement itself.5. 2.5 Requirements I.A.5 through I.A.7The fugitive dust requirements are in I.A 5 through I.A.7 and addressed in Regulation I,Section 9.15 and WAC 173-400-040(3). The <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency Board <strong>of</strong>Directors made significant revisions to Regulation I, Section 9.15 on March 11, 1999.The amended version will be forwarded to EPA as a SIP amendment. Upon approval <strong>of</strong>the SIP changes, the revised version <strong>of</strong> Regulation I, Section 9.15 will be federallyenforceable, and the old version will no longer apply. The revised rule requires the use <strong>of</strong>reasonable precautions for fugitive dust. We have included both versions <strong>of</strong> Section 9.15because they are significantly different. The Monitoring, Maintenance, andRecordkeeping Methods are the same as those listed in I.A.5 through I.A.7.The SIP version <strong>of</strong> <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency Regulation I, Section 9.15 requiresbest available control technology (BACT) for all fugitive dust, limits vehicle dust trackout,and limits fugitive dust from manufacturing and control equipment. The currentversion <strong>of</strong> Section 9.15 and WAC 173-400-040(3) requires reasonable precautions tominimize or prevent fugitive emissions. The <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency’s currentrule also describes specific examples <strong>of</strong> reasonable precautions. There is no differencebetween the current and SIP versions <strong>of</strong> WAC 173-400-040(3).All the fugitive emission regulations have common monitoring methods <strong>of</strong> responding tocomplaints and looking for fugitive emissions. The <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency hasdetermined that monitoring should be monthly for the reasons listed below.1) Initial compliance. The <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency has not observed fugitiveemissions during any inspection in the past five years, nor has Todd Pacific Shipyard;however, Todd Pacific <strong>Shipyards</strong> has received some complaints <strong>of</strong> overspray onvehicles located in the area in the past 5 years. The parking lots are paved withasphalt and should not have any visible emissions. Tarps are put down in abrasive

<strong>Statement</strong> <strong>of</strong> <strong>Basis</strong> for<strong>Vigor</strong> <strong>Shipyards</strong>, <strong>Inc</strong>.Administrative Amendment: June 13, 2011 Page 11 <strong>of</strong> 31blasting areas in the dry docks to keep the dust contained to the dry dock area.Therefore, we conclude that it is generally in compliance with this requirement.2) Margin <strong>of</strong> compliance. For known sources <strong>of</strong> potential fugitive dust, the buildings atTodd Pacific <strong>Shipyards</strong> are enclosed and all <strong>of</strong> the yard roadways are paved andreasonably maintained. All the significant air pollution generating equipment has airpollution control devices and is inspected by Todd Pacific <strong>Shipyards</strong> periodically andmaintained on a regular basis. The overspray problems experienced by Todd Pacific<strong>Shipyards</strong> in the past have not occurred recently. Hence, the margin <strong>of</strong> compliance isconsidered large enough to warrant monthly and as needed inspections.3) Variability <strong>of</strong> process and emissions. While many <strong>of</strong> the processes are variable orrelated to number <strong>of</strong> ship repairs being conducted at any specific time, few if any arelikely to cause fugitive emissions. The most likely cause <strong>of</strong> fugitive emissions wouldbe a significant change in the process, one that would require approval from the <strong>Puget</strong><strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency, or major equipment failure.4) Environmental impacts <strong>of</strong> problems. Because Todd Pacific <strong>Shipyards</strong> employsBACT for fugitive dust control, the likelihood <strong>of</strong> fugitive dust is very low. Anyfugitive dust emissions are likely to be small and without significant environmentalimpact.5) Technical considerations. The most likely causes <strong>of</strong> fugitive emissions at ToddPacific <strong>Shipyards</strong> would be failure <strong>of</strong> existing control equipment or vehicle track-outduring construction. Equipment failure is likely to be identified by some otherinspection or complaints. Track-out is minimized because all the roadways arepaved and maintained.5. 2.6 Requirement I.A.8<strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency Regulation I, Section 9.20 requires Todd Pacific<strong>Shipyards</strong> to maintain equipment in good working order. Section 9.20(a) applies tosources that received a Notice <strong>of</strong> Construction Order <strong>of</strong> Approval under <strong>Puget</strong> <strong>Sound</strong><strong>Clean</strong> <strong>Air</strong> Agency Regulation I, Article 6. Section 9.20(b) applies to equipment notsubject to Section 9.20(a). Section II, Monitoring, Maintenance and RecordkeepingProcedures, <strong>of</strong> the permit identifies the minimum monitoring criteria for maintainingequipment in good working order. The section identifies both facility-wide criteria andspecific criteria for the emission units and activities. In addition, the facility-wideinspections provide monitoring <strong>of</strong> the general effectiveness <strong>of</strong> Todd Pacific Shipyard’sOperation and Maintenance Plan. The <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency chose to list all <strong>of</strong>Section II as the monitoring method because many parts <strong>of</strong> Section II apply to severalemission units and activities. Where there are specific monitoring requirements forspecific emission units, the <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency has listed them in SectionII.A.2. The <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency has determined that following therequirements <strong>of</strong> Section II <strong>of</strong> the permit provides sufficient monitoring criteria to certifythat the equipment has been maintained in good working order. However, the <strong>Puget</strong>

<strong>Statement</strong> <strong>of</strong> <strong>Basis</strong> for<strong>Vigor</strong> <strong>Shipyards</strong>, <strong>Inc</strong>.Administrative Amendment: June 13, 2011 Page 12 <strong>of</strong> 31<strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency reserves the right to evaluate the maintenance <strong>of</strong> each piece <strong>of</strong>equipment to determine if it has been maintained in good working order.5. 2.7 Requirement I.A.9In accordance with <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency Regulation I, Section 7.09(b), ToddPacific <strong>Shipyards</strong> is required to develop and implement an Operation and MaintenancePlan (O&M Plan) to assure continuous compliance with <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> AgencyRegulations I, II, and III. The requirement specifies that the plan shall reflect goodindustrial practice, but does not define how to determine good industrial practice. Toclarify the requirement, the <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency added that, in most instances,following the manufacturer’s operations manual or equipment operational schedule,minimizing emissions until the repairs can be completed and taking measures to preventrecurrence <strong>of</strong> the problem may be considered good industrial practice. This language isconsistent with a Washington Department <strong>of</strong> Ecology requirement in WAC 173-400-101(4). The <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency also added language establishing criteria fordetermining if good industrial practice is being used. These include monitoring results,opacity observations, review <strong>of</strong> operations and maintenance procedures, and inspections<strong>of</strong> the emission unit or equipment. The <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency added thiswording in response to Washington State court decision, Longview Fibre Co. v. DOE, 89Wn. App. 627 (1998), which held that similar wording was not vague and gave sufficientnotice <strong>of</strong> the prohibited conduct.<strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency Regulation I, Section 7.09(b) also requires Todd Pacific<strong>Shipyards</strong> to promptly correct any defective equipment. However, the underlyingrequirement in most instances does not define “promptly”; hence for significant emissionunits and applicable requirements that Todd Pacific <strong>Shipyards</strong> has a reasonablepossibility <strong>of</strong> violating or that a violation would cause an air quality problem, the <strong>Puget</strong><strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency added clarification that “promptly” usually means within 24hours. For many insignificant emission units and equipment not listed in the permit,“promptly” cannot be defined because the emission sources and suitable pollution controltechniques vary widely, depending on the contaminant sources and the pollution controltechnology employed. However, the permit identifies a means by which to identify ifTodd Pacific <strong>Shipyards</strong> is following good industrial practice.As described in Section V.Q, Todd Pacific <strong>Shipyards</strong> must report to the <strong>Puget</strong> <strong>Sound</strong><strong>Clean</strong> <strong>Air</strong> Agency any instances where it failed to promptly repair any defectiveequipment, both equipment that received approval from the Agency and that which didnot. In addition, Todd Pacific <strong>Shipyards</strong> has the right to claim certain problems were aresult <strong>of</strong> an emergency (Section V.S) or unavoidable (Section V.T).Following these requirements demonstrates that Todd Pacific <strong>Shipyards</strong> has properlyimplemented the O&M Plan, but it does not prohibit the <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agencyor EPA from taking any necessary enforcement action to address violations <strong>of</strong> theunderlying applicable requirements after proper investigation. However, not followingits own O&M Plan is an indication that Todd Pacific <strong>Shipyards</strong> was not using goodindustrial practice.

<strong>Statement</strong> <strong>of</strong> <strong>Basis</strong> for<strong>Vigor</strong> <strong>Shipyards</strong>, <strong>Inc</strong>.Administrative Amendment: June 13, 2011 Page 13 <strong>of</strong> 315. 2.8 Requirement I.A.10<strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency Regulation I, Section 9.10 specifies that HCl emissionsshall not exceed 100 ppm (dry) corrected to 7% O 2 for combustion sources. Since ToddPacific <strong>Shipyards</strong> burns only pipeline grade natural gas and distillate fuel oil and theother processes do not use chlorine in a form likely to emit HCl, it is incapable <strong>of</strong>violating this standard while complying with the other requirements in the permit.Refer to the “Conversion Factors for Concentration” table in Section 2 <strong>of</strong> ReferenceMethod 19 to compute value for C d . Note that this factor is equal to molecular weight <strong>of</strong>the pollutant divided by 10 6 , and then divided by 385.3 ft 3 per mole. The conversionfactor for HCl is 36.4610 -6 /385.3 ft 3 = 9.46310 -8 lb/dscf-ppmdv. One part per million<strong>of</strong> HCl is equivalent to 9.46310 -8 lb HCL per dry standard cubic foot <strong>of</strong> stack gas.Residual oil:EquationEquation 1According to AP-42, Section 1.3:• Burning 1,000 gallons <strong>of</strong> No. 6 “residual” oil produces 0.347 pound <strong>of</strong>chloride. Assume all <strong>of</strong> the chloride is emitted in the form <strong>of</strong> hydrogenchloride.• There are 150 MMBtu/10 3 gallons <strong>of</strong> No. 6 oil.Equation converts the emission factor for chloride in Table 1.3-11 frompounds <strong>of</strong> HCl per 1,000 gallons <strong>of</strong> oil burned to pounds per million Btu.3lb10 gallbE 0.347 0.3470.00231310 gal 150 MMBtu MMBtuAccording to Table 19.1 <strong>of</strong> EPA Reference Method 19:• Burning a million Btu <strong>of</strong> oil produces 9,190 dry standard cubic feet <strong>of</strong>stack gas.• One part per million HCl is equivalent to 9.46310 -8 pound <strong>of</strong> HydrogenChloride per dry standard cubic foot.Equation 1 is derived from Equation 19-1 from EPA Reference Method 19,which may be used to calculate parts per million HCl, corrected to 7% O 2 ,from HCL emissions in lb/MMBtu.Cd E20 .9%O2( dry)20.9 7 20.9Fd 0.00231lbMMBtu8MMBtudscf ppmdv20.9dscf lb9,1909.4610Therefore, based on the AP-42 emission factor for HCl (expressed aschloride) from new residual oil, the concentration <strong>of</strong> HCl in the boilerexhaust will be less than 2% <strong>of</strong> the regulatory limit <strong>of</strong> 100 ppmdv,corrected to 7% O 2 , 1.77ppmdv

<strong>Statement</strong> <strong>of</strong> <strong>Basis</strong> for<strong>Vigor</strong> <strong>Shipyards</strong>, <strong>Inc</strong>.Administrative Amendment: June 13, 2011 Page 14 <strong>of</strong> 31There are no AP-42 emission factors for HCl for #2 diesel fuel used inboilers. HCl is not a significant component <strong>of</strong> diesel fuel.Therefore, the permit does not contain additional monitoring requirements.5. 2.9 Requirement I.A.11WAC 173-400-040(4) addresses odors. The monitoring method is based on respondingto complaints and general inspections <strong>of</strong> the facility to identify emissions <strong>of</strong> odor-bearingcontaminants. Receiving complaints does not necessarily mean Todd Pacific <strong>Shipyards</strong>is in violation <strong>of</strong> this requirement, since the regulation does not prohibit the emission <strong>of</strong>odors, but prohibits the emissions <strong>of</strong> odors if reasonable control measures are notemployed. Complaints will trigger action by Todd Pacific <strong>Shipyards</strong> to investigate andprevent a violation. Since the <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency and Todd Pacific<strong>Shipyards</strong> have not received odor complaints concerning Todd Pacific Shipyard, the<strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency has determined that responding to complaints withinthree working days is appropriate.5. 2.10 Requirement I.A.12WAC 173-400-040(2) prohibits the emission <strong>of</strong> particulate matter from the facility to bedeposited beyond the property line in sufficient quantity as to unreasonably interfere withthe use and enjoyment <strong>of</strong> the property upon which the material is deposited. Themonitoring method is based on responding to complaints and general inspections <strong>of</strong> thefacility to identify any particulate emissions or deposition <strong>of</strong> particulate that mayunreasonably interfere with the use and enjoyment <strong>of</strong> property. Receiving complaintsdoes not necessarily mean Todd Pacific <strong>Shipyards</strong> is in violation <strong>of</strong> this requirement, buttriggers action by the source to prevent a violation.5. 2.11 Requirement I.A.13RCW 70.94.040 is similar to <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency Regulation I, Section 9.11and is listed separately here because it is not a federally enforceable requirement.5. 2.12 Requirement I.A.14Todd Pacific <strong>Shipyards</strong> is subject to the Ship Building and Repair NESHAP 40 CFRSubpart II. Option No. 2 was chosen as their compliance strategy for the NESHAP. Alist <strong>of</strong> the applicable sections <strong>of</strong> 40 CFR Subpart II is in the <strong>Air</strong> Operating Permit SectionII. The table lists the Federal NESHAP requirement, adoptive or effective date, therequirement paraphrased, monitoring method, emission standard (if any) and a referencetest method if required.

<strong>Statement</strong> <strong>of</strong> <strong>Basis</strong> for<strong>Vigor</strong> <strong>Shipyards</strong>, <strong>Inc</strong>.Administrative Amendment: June 13, 2011 Page 15 <strong>of</strong> 315. 3 Emission Unit Specific Applicable RequirementsSection I.B. <strong>of</strong> the permit lists applicable requirements that are specific to an emissionunit or activity. Following the name <strong>of</strong> each emission unit is a brief description <strong>of</strong> theemission unit or activity and some identifying information such as location. Due to thesize <strong>of</strong> Todd Pacific Shipyard, the information is provided as an aid in understanding thepermit and as an aid to locate the specific emission point or activity. Following thedescription are the actual applicable requirement or compliance requirements.The Generally Applicable Requirements <strong>of</strong> Section I.A. apply to all the emission unitslisted in Section I.B. and are not repeated in this section. Monitoring Methods andReference Methods are also identified if they are different or in addition to those listed inSection I.A. Where a recently adopted federal regulation does not identify a monitoringmethod, the permit does not identify one either, because it is EPA’s policy to incorporateall necessary monitoring into recently adopted federal regulations except where the <strong>Puget</strong><strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency has determined it necessary. Finally, any requirements that areinapplicable to the specific emission unit are also listed in this section.5. 3.1 EU-1 Abrasive Blasting OperationsThis section includes all activities and equipment associated with abrasive blastingoperations on production parts, tooling, or equipment. The following equipment in thissection has been permitted under an Order <strong>of</strong> Approval. For the purpose <strong>of</strong> defining anemission unit in this permit, each piece <strong>of</strong> equipment is considered a separate emissionunit.LocationVessel Blastingin dry docks 1, 2,and 3Order <strong>of</strong>Approval #DateInstalledSource Description2452 12/13/1984 Abrasive blasting and spray coating operationN/A 1990 Abrasive blasting <strong>of</strong> vessels using curtain controland portable baghouseBldg T-206 N/A 1984 Abrasive blasting <strong>of</strong> ship components using 2baghousesTodd Pacific <strong>Shipyards</strong> uses abrasive blasting to clean ship components and vessels indry dock before final finishing and assembly and conducts the operation inside boothsenclosures with particulate control equipment or dry docks using tarping to control thefugitive dust. Monitoring <strong>of</strong> the particulate control equipment is consistent with Section5. 3. 2. EU-1 – Abrasive Dust Collectors Particulate Control Operations. In addition,WAC 173-460-060(6) is a state only requirement that regulates work practices thatgovern how and where abrasive blasting can occur. Because these are work practices themonitor requirement are consistent with other work practices and as with most otherwork practices the <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency has inspected the facility at leastannually for the last five years and has not identified violations.

<strong>Statement</strong> <strong>of</strong> <strong>Basis</strong> for<strong>Vigor</strong> <strong>Shipyards</strong>, <strong>Inc</strong>.Administrative Amendment: June 13, 2011 Page 16 <strong>of</strong> 315. 3.2 E-1 Abrasive Dust Collectors and Other ParticulateControl OperationsThis section includes all activities and equipment associated with abrasive blastingoperations on Vessels in dry dock, and component parts or equipment in specificenclosures.Todd Pacific <strong>Shipyards</strong> uses abrasive blasting to clean vessels, component parts andequipment before final finishing and assembly and conducts the operation inside boothsenclosures with particulate control equipment or in dry docks equipped with tarping tocontrol fugitive dust. Monitoring <strong>of</strong> the particulate control equipment is consistent withSection II <strong>of</strong> the <strong>Air</strong> Operating Permit. In addition, WAC 173-460-060(6) is a state onlyrequirement that regulates work practices that govern how and where abrasive blastingcan occur. Because these are work practices, the monitoring requirements are consistentwith other work practices and as with most other work practices, the <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong><strong>Air</strong> Agency has inspected the facility at least annually for the last five years and has notidentified violations.The <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency has determined the monitoring frequency based onthe following.Initial compliance. The <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency has not observed visibleemissions from any <strong>of</strong> these activities during any inspection in the last five years;therefore, we conclude that Todd Pacific <strong>Shipyards</strong> is generally in compliance withthe particulate and opacity requirements.Margin <strong>of</strong> compliance. Because <strong>of</strong> the type <strong>of</strong> process (woodworking, grinding andmachining) and the control equipment (baghouses and cyclones), the <strong>Puget</strong> <strong>Sound</strong><strong>Clean</strong> <strong>Air</strong> Agency expects the concentration <strong>of</strong> particulate to be much less than thestandard when there is no visible emission, fallout or fugitive emissions.Variability <strong>of</strong> process and emissions. Although the equipment runs periodically, theactual emissions are not significant and not likely to cause a nuisance.Environmental impacts <strong>of</strong> problems. These are small dust collectors that combinednormally emit less than a ton <strong>of</strong> particulate per year. A maintenance problem isunlikely to result in emissions that would have a significant environmental impact.Technical considerations. The mostly likely type <strong>of</strong> problem would be a gradualequipment failure like normal wear and tear. Such failure could easily be detected bychecking for visible emissions, fugitive emissions, fallout, and pressure drop acrossthe control equipment. Because <strong>of</strong> the nature <strong>of</strong> the potential problems, <strong>Puget</strong> <strong>Sound</strong><strong>Clean</strong> <strong>Air</strong> Agency has determined that the units should be divided into those systemsthat should be checked for visible emissions weekly and fugitive dust monthly.5. 3.3 EU 2 – Spray Coating OperationsThis section includes all activities and equipment associated with surface coating,operations for both Vessel repair and ship building activities. These operations includecoating mixing, application, drying, and curing; spray gun cleaning; solvent wipe and

<strong>Statement</strong> <strong>of</strong> <strong>Basis</strong> for<strong>Vigor</strong> <strong>Shipyards</strong>, <strong>Inc</strong>.Administrative Amendment: June 13, 2011 Page 17 <strong>of</strong> 31solvent flush; and material and waste handling. The activities included in this section areconducted throughout the facility and the dry docks 1, 2, and 3. For the purpose <strong>of</strong>defining an “emission unit” in the permit, each piece <strong>of</strong> equipment listed below isconsidered a separate emission unit. The last column in this list indicates whether ShipBuilding and Repair NESHAP-regulated coatings are sprayed in the unit. However, fromtime to time Todd Pacific <strong>Shipyards</strong> may change the type <strong>of</strong> coatings applied or the partscoated.Order <strong>of</strong>ApprovalNo. Date Installed Source Description2277 10/15/1981 Paint spay booth Yes2452 12/21/1983 Paint spray booth and Yesabrasive blasting booth5671 11/22/1994 Outdoor spray coating Yesoperation7069 3/10/1998 Spray Booth T-230 in PaintShed #2YesShip Building and RepairNESHAP Coatings Used(a) Ship Building and Repair NESHAPS40 CFR 63 Subpart II requires Todd Pacific <strong>Shipyards</strong> use coatings to comply with theVOHAPS listed in table 2 <strong>of</strong> the rule. Option No. 2 was selected by Todd Pacific<strong>Shipyards</strong> to comply with the rule. This means that the volume <strong>of</strong> allowed thinners andVOHAPS in a coating category is compared with the actual facility usage each month.The actual usage cannot exceed the allowable usage <strong>of</strong> coatings and thinners in thecoating category.(b) Local RequirementsThe federally enforceable version <strong>of</strong> <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency Regulation I,Section 9.16 requires that all spray coating operations be conducted inside an enclosurewith overspray controls and a vertical stack approved by the <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong>Agency. It allows for some exemptions such as hand-held aerosol cans and largestationary objects like bridges and buildings. It also allows the Control Officer toapprove spray coating objects that cannot be reasonably handled in an enclosed sprayarea. The requirement is also listed in Section IV <strong>of</strong> the permit as an activity requiringadditional approval. <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency has recently changed Section 9.16<strong>of</strong> Regulation I to exempt activities that must comply with the aerospace NESHAP. IfEPA approves this amended rule as a SIP change, this section will no longer apply whenTodd Pacific <strong>Shipyards</strong> conducts activities that must comply with the aerospaceNESHAP.The booths were approved by NOC Orders <strong>of</strong> Approval. The <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong>Agency has determined, in addition to the Order <strong>of</strong> Approval Notice <strong>of</strong> Completion,Todd Pacific <strong>Shipyards</strong> will conduct periodic facility-wide inspections that includelooking for spray coating operations that do not comply with the requirements <strong>of</strong> Section9.16.

<strong>Statement</strong> <strong>of</strong> <strong>Basis</strong> for<strong>Vigor</strong> <strong>Shipyards</strong>, <strong>Inc</strong>.Administrative Amendment: June 13, 2011 Page 18 <strong>of</strong> 315. 3.4 EU-3 Small Gas-Fired Boilers and One Boiler withdiesel Standby(a) Visible EmissionsBoth WAC 173-400-040(1) and <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency Regulation I,Section 9.03 standards are 20% opacity and apply to the fuel burning equipment at ToddPacific <strong>Shipyards</strong>. Although the permit lists all these requirements together, Todd Pacific<strong>Shipyards</strong> must comply with each.The fuel burning equipment at Todd Pacific <strong>Shipyards</strong> can only burn natural gas exceptone boiler that has diesel fuel as a standby. The monitoring method requires checking forvisible emissions once per quarter, and the frequency was determined based on thefollowing.1) Compliance. None <strong>of</strong> the fuel burning equipment at Todd Pacific <strong>Shipyards</strong> normallyhas visible emissions. The <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency has inspected this facilityat least annually since 1997 and has not identified opacity issues at the fuel burningequipment, nor has Todd Pacific <strong>Shipyards</strong>. Therefore, we conclude that it isgenerally in compliance with the opacity requirement and the margin <strong>of</strong> compliance islarge. In addition, the monitoring method is designed so that Todd Pacific <strong>Shipyards</strong>will take corrective action before a violation occurs, further enhancing the compliancemargin.2) Variability <strong>of</strong> process and emissions. The equipment burns natural gas. The steamand heat demand at Todd Pacific <strong>Shipyards</strong> fluctuates throughout the day and fromseason-to-season, causing variations in load on the equipment. These boilers are onlyshut down completely for annual maintenance or if a problem occurs where morefrequent maintenance is required. Typically, one boiler is in operation while the othertwo are in "hot stand-by" mode, meaning the unit is still under pressure and theburner modulates to maintain a set pressure level. Once per year, the boilers aretaken down to undergo pressure vessel testing. However, the demand is verypredictable and seldom changes quickly.3) Environmental impacts <strong>of</strong> problems. Observed opacity is generally related toemissions <strong>of</strong> particulate matter or finely divided liquid droplets. The fuel burningactivities at Todd Pacific <strong>Shipyards</strong> typically do not generate significant quantities <strong>of</strong>particulate matter, typically less than one ton per year. Hence, the environmentalimpacts <strong>of</strong> the emissions are small especially considering the amount <strong>of</strong> land onwhich the facility is located. A maintenance problem is unlikely to result inemissions that would have a significant environmental impact.4) Technical considerations. Although the opacity standard is 20%, the monitoringmethod requires corrective action, or Reference Method testing, upon detection <strong>of</strong>visible emissions. This will provide an added margin <strong>of</strong> compliance.

<strong>Statement</strong> <strong>of</strong> <strong>Basis</strong> for<strong>Vigor</strong> <strong>Shipyards</strong>, <strong>Inc</strong>.Administrative Amendment: June 13, 2011 Page 19 <strong>of</strong> 31(b) Fuel Burning Particulate<strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency Regulation I, Section 9.09 also limits particulateemissions to 0.05 gr/dscf corrected to 7% oxygen from fuel burning equipment (i.e.,equipment that produces hot air, hot water, steam, or other heated fluids by externalcombustion <strong>of</strong> fuel) combusting natural gas. WAC 173-400-050(1) limits particulateemissions to 0.1 gr/dscf corrected to 7% O 2 from all combustion units (i.e., units usingcombustion for steam production or other process requirements, excluding open burning).Todd Pacific <strong>Shipyards</strong> burns only pipeline grade natural gas. It can be shown for SO 2 ,that if fuels are properly burned, Todd Pacific <strong>Shipyards</strong> is incapable <strong>of</strong> violating thisstandard while complying with the other requirements such as the fuel content andopacity requirements. Improper fuel burning that would result in high particulateemissions would also cause opacity problems and would be detected by the Fuel BurningOpacity monitoring requirement.(c) Fuel StandardsThe permit does not contain <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency Regulation I, Section 9.08(a)and RCW, 70.94.610 “Burning used fuel oil in land-based facilities” because ToddPacific <strong>Shipyards</strong> does not and cannot burn such oil.(d) Federal Standards<strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency Regulation I, Section 6.11 and WAC 173 400-115 bothadopt by reference the federal new source performance standards in 40 CFR Part 60.5. 3.5 EU-4 Gasoline Underground Storage TankTodd Pacific <strong>Shipyards</strong> has one underground gasoline storage tank used for fuelequipment used on site. Because, the motor vehicles are used on site and not on publicroads, the tank is not subject to Regulation II Section 2.07. However, the undergroundgasoline storage tank is subject to the registration (Regulation I Article 5) and new sourcereview (Regulation I Article 6). The notice <strong>of</strong> construction approval required the sourceto inspect the stage 1 vapor recovery equipment after each fuel delivery. Theunderground gasoline storage tank at Todd Pacific <strong>Shipyards</strong> can only be used for yardequipment that is not licensed to travel on public roadways.5. 3.6 EU-5 Ground Water Remediation EquipmentOver the years, Todd Pacific <strong>Shipyards</strong>’ soil has been contaminated with solvents. Thegroundwater remediation system draws water from all areas at the facility. Water isextracted and a solvent such as benzene is separated from the water. <strong>Air</strong> from thestripper is passed through an afterburner where the benzene and other solvents aredestroyed (turned into water and carbon dioxide). Less than 25,000 gallons <strong>of</strong> waterpassed through the system. The after burner operates at greater than 1,400 degrees F.Currently the system is shut down because the afterburner has failed and cannot be

<strong>Statement</strong> <strong>of</strong> <strong>Basis</strong> for<strong>Vigor</strong> <strong>Shipyards</strong>, <strong>Inc</strong>.Administrative Amendment: June 13, 2011 Page 20 <strong>of</strong> 31repaired. A consultant is working on sizing a new afterburner that would be moreefficient than the existing unit.5. 3.7 Operations without Specific Applicable RequirementsThis emission activity consists <strong>of</strong> any equipment and associated activities that generateair contaminants that do not have specific applicable requirements as listed elsewhere inthis permit.Todd Pacific <strong>Shipyards</strong> may conduct operations at Todd Pacific <strong>Shipyards</strong> that do nothave specific applicable requirements but are still subject to the generally applicablerequirements listed in Section I.A. <strong>of</strong> the permit. Most <strong>of</strong> those activities are listed underthis emission unit. Todd Pacific <strong>Shipyards</strong> requested that the <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong>Agency include this emission unit to ensure that these activities are listed in the permitand protected by the permit shield. The <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency concluded thatthe permit contains all the applicable requirements elsewhere in the permit andrecognizes that Todd Pacific <strong>Shipyards</strong> may conduct these activities. By listing theseemission units and activities, the <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency is not implying that theother requirements <strong>of</strong> the permit do not apply. For example, if Todd Pacific <strong>Shipyards</strong>were to modify an activity, listed in this emission activity, in such a way that requirednew source review under Section IV.A. <strong>of</strong> the permit, the <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agencywould require a Notice <strong>of</strong> Construction.5. 3.8 Inapplicable Orders <strong>of</strong> ApprovalThe following Orders <strong>of</strong> Approval are no longer applicable to Todd Pacific <strong>Shipyards</strong> forthe following reasons.Order <strong>of</strong>DescriptionReasonApprovalPrevious7253(11/14/00)Groundwater Remediation/Soil Vapor Extractor System Order <strong>of</strong> Approval No.7253 (11/14/00) wasSuperceded by Order <strong>of</strong>Approval No. 7253 toinstall newer control5671,7069 and7070One Binks Dry Filter Spray Coating Booth (T- 199,Paint Shop #3),Spray Coating Room (T-230, Shop#2),Outdoor Spray Coating for Large Fabrications up to40” x 60” that could weigh 80 tons that cannot be SprayCoated in existing Spray Booths and Rooms.Designated Spray coating areas are located behind Paintshop No. 2, in front <strong>of</strong> Paint Shop 1 and 2, Pier 3 Slab,between Buildings T-201 and T-114 and Building Ways(existing).equipment.Replaced obsoleteconditions with new Order<strong>of</strong> Approval No. 8678(6/10/02)

<strong>Statement</strong> <strong>of</strong> <strong>Basis</strong> for<strong>Vigor</strong> <strong>Shipyards</strong>, <strong>Inc</strong>.Administrative Amendment: June 13, 2011 Page 21 <strong>of</strong> 316. Monitoring, Maintenance and Recordkeeping ProceduresMany <strong>of</strong> the procedures in Section II <strong>of</strong> the permit are grouped according to types <strong>of</strong>activities or the Todd Pacific <strong>Shipyards</strong> organizational unit responsible for performingthe procedure. For example, the activities in Section II.A.2(e) Equipment Maintenanceare normally performed by maintenance personnel while the other activities in SectionII.A <strong>of</strong> the permit are normally performed by operators or environmental staff. Forexample, maintenance staff checks to see that the pressure drop gauge on a spray booth isoperating properly and that the acceptable ranges are marked, but the operator isresponsible for logging the pressure drop.6. 1 Following Monitoring, Maintenance and RecordkeepingProceduresTodd Pacific <strong>Shipyards</strong> must follow the procedures contained in Section II <strong>of</strong> the permit,Monitoring, Maintenance and Recordkeeping Procedures. Failure to follow arequirement in Section II may not necessarily be a deviation <strong>of</strong> the underlying applicableemission standard in Section I. However, not following a requirement <strong>of</strong> Section II is adeviation <strong>of</strong> Section II and Todd Pacific <strong>Shipyards</strong> must report such violations, as well asdeviations from any other permit condition, as a deviation under Section V.Q.1 <strong>of</strong> thepermit. In addition, all information collected as a result <strong>of</strong> implementing Section II canbe used as credible evidence under Section V.N.2. <strong>of</strong> the permit. Reporting a permitdeviation and taking corrective action does not relieve Todd Pacific <strong>Shipyards</strong> from itsobligation to comply with the underlying applicable requirement.6. 2 Standard Approval ConditionsA standard <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency Notice <strong>of</strong> Construction Order <strong>of</strong> Approvalcondition, Condition No. 1, requires that the equipment, device or process be installedaccording to plans and specifications submitted to the <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency.Once the equipment is installed, the <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency requires certificationby the applicant that the installation was as approved; this is usually done with a Notice<strong>of</strong> Completion. Normally within six months to a year after receiving a Notice <strong>of</strong>Completion, a <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency inspector verifies by inspection that theequipment was installed as specified and in accordance with the Order <strong>of</strong> Approval.While the Notice <strong>of</strong> Completion is a one-time requirement that Todd Pacific <strong>Shipyards</strong>has complied with, Todd Pacific <strong>Shipyards</strong> cannot change the approved equipment insuch a manner that requires an NOC Order <strong>of</strong> Approval without first obtaining an NOCOrder <strong>of</strong> Approval which is addressed in Section IV.A <strong>of</strong> the permit.6. 3 Work Practice InspectionsThe permit requires Todd Pacific <strong>Shipyards</strong> to conduct quarterly work practiceinspections. These inspections are to ensure that the work practices required by thepermit are being followed. The <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency determined the frequency<strong>of</strong> these inspections after considering the potential for emissions, the lack <strong>of</strong> federallyrequired monitoring, Todd Pacific <strong>Shipyards</strong> in-house training practices and similar

<strong>Statement</strong> <strong>of</strong> <strong>Basis</strong> for<strong>Vigor</strong> <strong>Shipyards</strong>, <strong>Inc</strong>.Administrative Amendment: June 13, 2011 Page 22 <strong>of</strong> 31factors. If problems are identified, Todd Pacific <strong>Shipyards</strong> has the responsibility to makea record <strong>of</strong> the problem, correct the specific problem, and adjust the work practices andtraining to prevent future problems.6. 4 Monitoring FrequencyIn determining the appropriate monitoring frequency, the <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agencyconsidered several factors including the following:Todd Pacific <strong>Shipyards</strong> compliance history and the likelihood <strong>of</strong> violating theapplicable requirement;The complexity <strong>of</strong> the emission unit including the variability <strong>of</strong> emissions overtime;The likelihood that the monitoring would detect a compliance problem;The likely environmental impacts <strong>of</strong> a deviation;Whether add-on controls are necessary for the unit to meet the emission limit;Other measures that Todd Pacific <strong>Shipyards</strong> may have in place to identifyproblems;The type <strong>of</strong> monitoring, process, maintenance, or control equipment data alreadyavailable for the emissions unit;The technical and economic considerations associated with the range <strong>of</strong> possiblemonitoring methods; andThe kind <strong>of</strong> monitoring found on similar emissions units.6. 5 Operation and Maintenance (O&M) Plan RequirementsTodd Pacific <strong>Shipyards</strong> O&M Plan shall include equipment operation and maintenanceprocedures specifying how Todd Pacific <strong>Shipyards</strong> will assure continuous compliancewith <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency Regulations I, II and III.

<strong>Statement</strong> <strong>of</strong> <strong>Basis</strong> for<strong>Vigor</strong> <strong>Shipyards</strong>, <strong>Inc</strong>.Administrative Amendment: June 13, 2011 Page 23 <strong>of</strong> 317. Prohibited ActivitiesSome <strong>of</strong> the requirements Todd Pacific <strong>Shipyards</strong> identified in the operating permitapplication are included in Section III as prohibited activities. Since these activities areprohibited, routine monitoring <strong>of</strong> parameters is not appropriate. Instead, the <strong>Puget</strong> <strong>Sound</strong><strong>Clean</strong> <strong>Air</strong> Agency has listed these activities in this section to highlight that they cannotoccur at the facility. Personnel that perform the facility-wide inspections, required inSection II <strong>of</strong> the permit, should be aware <strong>of</strong> these requirements and if they find anyevidence that any <strong>of</strong> these activities are being conducted, they should take appropriateaction to investigate them and take corrective action if necessary.7. 1 Requirement III.B Open Burning<strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency Regulation I, Article 8 prohibits most open burning inmost areas within the Agency's jurisdiction. However, Regulation I, Section 8.07specifically allow fire extinguisher training under certain conditions.7. 2 Requirement III.D & E. Concealment and Masking<strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency Regulation I, Section 9.13, and WAC 173-400-040(7)contain similar requirements addressing concealment and masking <strong>of</strong> emissions.Although the effective dates for the federally enforceable and the state-only versions <strong>of</strong>WAC 173-400-040(7) differ, the actual wording <strong>of</strong> the two versions are the same.8. Activities Requiring Additional ApprovalSome <strong>of</strong> the requirements Todd Pacific <strong>Shipyards</strong> identified in the operating permitapplication are included in Section IV as activities that require additional approval.8. 1 Requirement IV.A. New Source ReviewFor new source review, the permit language has been simplified. Chapter 173-460 WAC(State-Only) and <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency Regulation I, Article 6 New SourceReview Programs require approval to construct, install, establish, or modify an aircontaminant source. All these requirements apply, but the language in these requirementshas been incorporated into one section to simplify the permit language. WAC 173-400-110 applies statewide, yet defers to local authority programs which provide the same,equivalent function. Since <strong>Puget</strong> <strong>Sound</strong> <strong>Clean</strong> <strong>Air</strong> Agency has had a New SourceReview Program under Regulation I, Article 6 for many years, the regulatory programused to review activities for this purpose is that Regulation and not the statewide versionmanaged by the Washington Department <strong>of</strong> Ecology. New and modified sources arerequired to apply Best Available Control Technology (BACT), and BACT is defined toinclude all requirements in the NSPS and NESHAP. Therefore, the NESHAPrequirements for new and reconstructed sources (procedural requirements included in thegeneral provisions in 40 CFR 63.5) are covered by this language as are the requirementsin 40 CFR 60.7, 60.14, and 60.15.