Technical guidance GRAPHIC CHEMICALS

Technical guidance GRAPHIC CHEMICALS

Technical guidance GRAPHIC CHEMICALS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

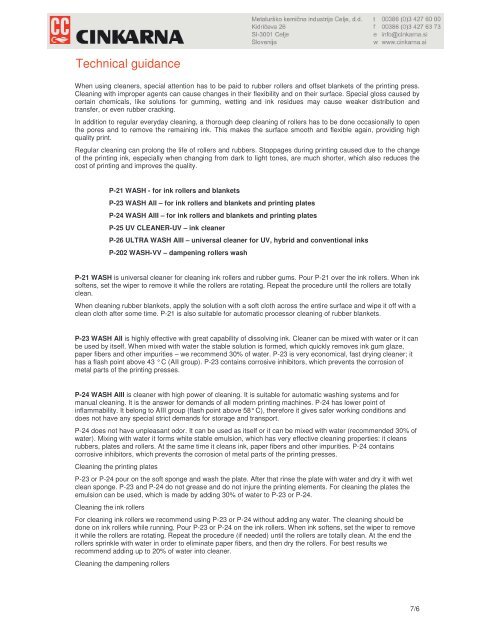

<strong>Technical</strong> <strong>guidance</strong>When using cleaners, special attention has to be paid to rubber rollers and offset blankets of the printing press.Cleaning with improper agents can cause changes in their flexibility and on their surface. Special gloss caused bycertain chemicals, like solutions for gumming, wetting and ink residues may cause weaker distribution andtransfer, or even rubber cracking.In addition to regular everyday cleaning, a thorough deep cleaning of rollers has to be done occasionally to openthe pores and to remove the remaining ink. This makes the surface smooth and flexible again, providing highquality print.Regular cleaning can prolong the life of rollers and rubbers. Stoppages during printing caused due to the changeof the printing ink, especially when changing from dark to light tones, are much shorter, which also reduces thecost of printing and improves the quality.P-21 WASH - for ink rollers and blanketsP-23 WASH AII – for ink rollers and blankets and printing platesP-24 WASH AIII – for ink rollers and blankets and printing platesP-25 UV CLEANER-UV – ink cleanerP-26 ULTRA WASH AIII – universal cleaner for UV, hybrid and conventional inksP-202 WASH-VV – dampening rollers washP-21 WASH is universal cleaner for cleaning ink rollers and rubber gums. Pour P-21 over the ink rollers. When inksoftens, set the wiper to remove it while the rollers are rotating. Repeat the procedure until the rollers are totallyclean.When cleaning rubber blankets, apply the solution with a soft cloth across the entire surface and wipe it off with aclean cloth after some time. P-21 is also suitable for automatic processor cleaning of rubber blankets.P-23 WASH AII is highly effective with great capability of dissolving ink. Cleaner can be mixed with water or it canbe used by itself. When mixed with water the stable solution is formed, which quickly removes ink gum glaze,paper fibers and other impurities – we recommend 30% of water. P-23 is very economical, fast drying cleaner; ithas a flash point above 43 ° C (AII group). P-23 contains corrosive inhibitors, which prevents the corrosion ofmetal parts of the printing presses.P-24 WASH AIII is cleaner with high power of cleaning. It is suitable for automatic washing systems and formanual cleaning. It is the answer for demands of all modern printing machines. P-24 has lower point ofinflammability. It belong to AIII group (flash point above 58° C), therefore it gives safer working conditions anddoes not have any special strict demands for storage and transport.P-24 does not have unpleasant odor. It can be used as itself or it can be mixed with water (recommended 30% ofwater). Mixing with water it forms white stable emulsion, which has very effective cleaning properties: it cleansrubbers, plates and rollers. At the same time it cleans ink, paper fibers and other impurities. P-24 containscorrosive inhibitors, which prevents the corrosion of metal parts of the printing presses.Cleaning the printing platesP-23 or P-24 pour on the soft sponge and wash the plate. After that rinse the plate with water and dry it with wetclean sponge. P-23 and P-24 do not grease and do not injure the printing elements. For cleaning the plates theemulsion can be used, which is made by adding 30% of water to P-23 or P-24.Cleaning the ink rollersFor cleaning ink rollers we recommend using P-23 or P-24 without adding any water. The cleaning should bedone on ink rollers while running. Pour P-23 or P-24 on the ink rollers. When ink softens, set the wiper to removeit while the rollers are rotating. Repeat the procedure (if needed) until the rollers are totally clean. At the end therollers sprinkle with water in order to eliminate paper fibers, and then dry the rollers. For best results werecommend adding up to 20% of water into cleaner.Cleaning the dampening rollers7/6