Roundtest RA-2100 Series - Mitutoyo Scandinavia AB

Roundtest RA-2100 Series - Mitutoyo Scandinavia AB

Roundtest RA-2100 Series - Mitutoyo Scandinavia AB

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

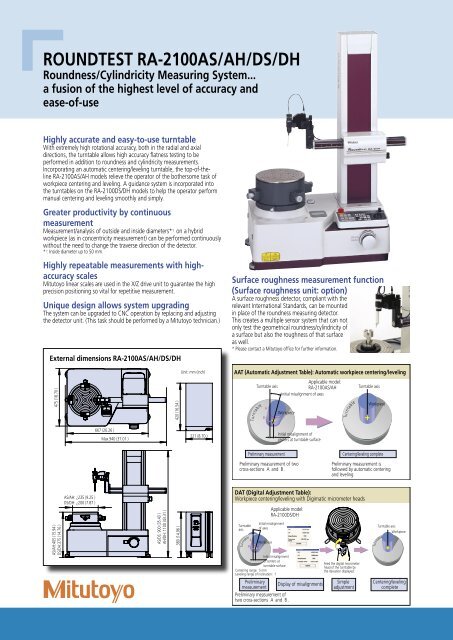

ROUNDTEST <strong>RA</strong>-<strong>2100</strong>AS/AH/DS/DHRoundness/Cylindricity Measuring System...a fusion of the highest level of accuracy andease-of-useHighly accurate and easy-to-use turntableWith extremely high rotational accuracy, both in the radial and axialdirections, the turntable allows high accuracy flatness testing to beperformed in addition to roundness and cylindricity measurements.Incorporating an automatic centering/leveling turntable, the top-of-theline<strong>RA</strong>-<strong>2100</strong>AS/AH models relieve the operator of the bothersome task ofworkpiece centering and leveling. A guidance system is incorporated intothe turntables on the <strong>RA</strong>-<strong>2100</strong>DS/DH models to help the operator performmanual centering and leveling smoothly and simply.Greater productivity by continuousmeasurementMeasurement/analysis of outside and inside diameters* 1 on a hybridworkpiece (as in concentricity measurement) can be performed continuouslywithout the need to change the traverse direction of the detector.* 1 : Inside diameter up to 50 mm.Highly repeatable measurements with highaccuracyscales<strong>Mitutoyo</strong> linear scales are used in the X/Z drive unit to guarantee the highprecision positioning so vital for repetitive measurement.Unique design allows system upgradingThe system can be upgraded to CNC operation by replacing and adjustingthe detector unit. (This task should be performed by a <strong>Mitutoyo</strong> technician.)External dimensions <strong>RA</strong>-<strong>2100</strong>AS/AH/DS/DHSurface roughness measurement function(Surface roughness unit: option)A surface roughness detector, compliant with therelevant International Standards, can be mountedin place of the roundness measuring detector.This creates a multiple sensor system that can notonly test the geometrical roundness/cylindricity ofa surface but also the roughness of that surfaceas well.* Please contact a <strong>Mitutoyo</strong> office for further information.475 (18.70 )420 (16.54 )Unit: mm (inch)AAT (Automatic Adjustment Table): Automatic workpiece centering/levelingApplicable model:Turntable axis<strong>RA</strong>-<strong>2100</strong>AS/AHInitial misalignment of axesAWorkpieceBleTurn tableTu rn tabTurntable axisWorkpiece667 (26.26 )Max.940 (37.01 )221 (8.70 )Initial misalignment ofcenters at turntable surfacePreliminary measurementPreliminary measurement of twocross-sections A and B .Centering/leveling completePreliminary measurement isfollowed by automatic centeringand levelingAS/AH:405 (15.94 )DS/DH:375 (14.76 )AS/AH: ¿235 (9.25 )DS/DH: ¿200 (7.87 )AS/DS: 900 (35.43 )AH/DH: 1100 (43.31 )380 (14.96 )DAT (Digital Adjustment Table):Workpiece centering/leveling with Digimatic micrometer headsTurntableaxisInitial misalignmentof axesWorkpieceApplicable model:<strong>RA</strong>-<strong>2100</strong>DS/DHInitial misalignmentof centers atturntable surfaceCentering range: 5 mmLeveling range of inclination: 1PreliminarymeasurementPreliminary measurement oftwo cross-sections A and B .Display of misalignmentsFeed the digital micrometerhead of the turntable bythe deviation displayed.SimpleadjustmentTurntable axisWorkpieceCentering/levelingcomplete6