Specifications

Specifications

Specifications

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

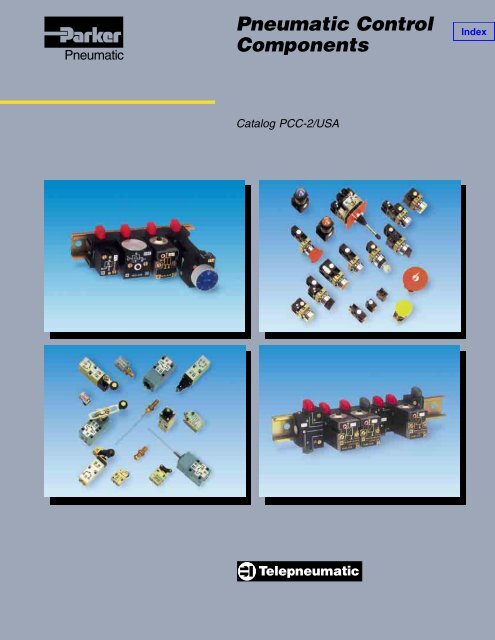

Pneumatic ControlComponentsIndexCatalog PCC-2/USA

Catalog PCC-2/USAIndexPart Number to Page IndexPneumatic Control ComponentsContentsIndexLogicModular Sequencer • Logic Elements • Time Delay Relays • Memory Relays •Amplifier and Sensor Relays • Solenoid Actuators • 4-Way Valve Unit • Pulse Units •Air Regulator • Pressure Switches • Impulse Counters • Timers • Subbases •Logic Processing Spare PartsMan / Machine DialogPush Buttons • Selector Switches • Visual Indicators •Rotary Selector Switches • Joystick Controllers •Two-hand Controls • Foot SwitchesSensingMechanical Limit Switches • Pressure Switches • Vacuum Switches •Threshold Sensors • Bleed Sensors • Fluidic Proximity SensorsABCAccessoriesMounting Accessories • Tubing AccessoriesDOffer of SalePneumatic1Parker Hannifin CorporationPneumatic DivisionRichland, Michigan

Parker Hannifin CorporationPneumatic DivisionRichland, MichiganPneumatic2Pneumatic Control ComponentsProduct ReferenceCatalog PCC-2/USAIndex7097J03711A22AF1EA51D4AK2LA34D5AM1DE200A36, D4AZ1CA04D4AZ1CA029123D4BAC3P10A29BAC7P10A29BAESP20A29BIC3P10A28BIC7P10A28BNC3P10A28BNC3P20A28BPB3P10A28BPB3P20A28CBP101B9CBP501B9CBL101B9CBL501B9FR3P10A26LA9D901A12LAAN10/1A19LAAY10/1A19LFAY10/0A17LFAY10/1A17LFPUL10/0.5A24LFPUL10/1A24LNOTPS10A22LPG10/0A24LPG10/1A24LPS10/2A22LPS10/3A22LPSV10A22LT10.AA12LT10.CA12LTN10.0A12LTN10.1A12LTN10.2A12LTN10.3A12LTN10.PANA12LTY1.EXTA12LTY10.0A12LTY10.1A12LTY10.2A12LTY10.3A12MEM7P10A15P6T-MC04N04-025D5P6T-MC04N07-025D5PCMC11A32PCMD11A32PCME11A32PCPA11A32PCTA11A32PCTB11A32PLEB12A9PLJC10A10PLKA11A8PLKA15A8PLKB12A9PLKC10A10PLLA11A8PLLA15A8PLLB12A9PLLC10A10PLMA10A13PLMA12A13PLNB12A9PLNC10A10PLNC12A10PLND10A10PLND12A10PPRL01A34PPRL02A35PPRL04A35PPRL05A35PPRL06A34PPRL07A35PPRL08A35PPRL09A34PPRL10A34PPRL11A34PPRL15B15PPRL20A35PPRL23A35PRD3P10A26PRDA10A16PRDA111C19PRDA12A16, C19PREA10A20PREA12A20PRFA10A16PRFA12A16, C17PRSA121BA18PRSA121FA18PRSA122BA18PRSD10A18PRTA10A12PRTA12A12PRTB10A12PRTC10A12PRTD10A12PRTE10A12PRTF10A12PS1P1081A19PS1P1091A19PSBA12A6PSDA12A6PSDB12A6PSEA127A6PSMA10A6PSMB10A6PSVA12A6PVAF101BA18PVAF101EA18PVAF101FA18PVAF101MA18PVAF102BA18PVAF102EA18PWSB1227C16PWSB1337C16PWSB1557C16PWSB1887C16PWSB1997C16PWSM1012C16PWSP111C16PXBB1011B5PXBB1011BA2B4PXBB1011BA3B4PXBB1011BA4B4PXBB1011BC2B4PXBB1011BC4B4PXBB1011BD2B4PXBB1011BT4B4PXBB1015B5PXBB1021B5PXBB1021BT4B4PXBB1025B5PXBB1111BD2B4PXBB1111BD3B4PXBB1111BJ5B4PXBB1121BA2B4PXBB1121BD2B4PXBB1121BD3B4PXBB1121BT4B4PXBB1221BJ5B4PXBB1911B5PXBB1911SEB5PXBB1912B5PXBB1915B5PXBB1921B5PXBB1921SEB5PXBB1922B5PXBB1925B5PXBB2011B5PXBB2011BA2B4PXBB2011BA3B4PXBB2011BA4B4PXBB2011BC2B4PXBB2011BC4B4PXBB2011BD2B4PXBB2011BT4B4PXBB2015B5PXBB2021B5PXBB2021BT4B4PXBB2025B5PXBB2111BD2B4PXBB2111BD3B4PXBB2111BJ5B4PXBB2121BA2B4PXBB2121BD2B4PXBB2121BD3B4PXBB2121BT4B4PXBB2221BJ5B4PXBB2911B5PXBB2915B5PXBB2921B5PXBB2925B5PXBDD104B12PXBDD508B12PXBDD512B12PXBGA8211B13PXBGA8221B13PXBGA8411B13PXBGA8421B13PXCA1A32PXCB1A32PXCJ117C12PXCJ11701C12PXCJ11705C12PXCJ127C12PXCJ12701C12PXCJ12705C12PXCK211C9PXCK21100C9PXCK2110031 C8PXCK2110041C8PXCK21101C8PXCK21102C8PXCK21106C8PXCK21121C8PXCK221C9PXCK22100C9PXCK2210031C8PXCK2210041C8PartNumberPagePartNumberPagePartNumberPagePartNumberPageIndex

3 Parker Hannifin CorporationPneumatic DivisionRichland, MichiganPneumaticPneumatic Control ComponentsProduct ReferenceCatalog PCC-2/USAIndexPXCK22101C8PXCK22102C8PXCK22106C8PXCK22121C8PXCM111C4PXCM115C4PXCM121C4PXCM125C4PXCM521C4PXCM601A102C5PXCM601A103C5PXCM601A110C5PXCZ11C4PXCZ12C4PXDA111C17PXFA111C18PXFA121C18PXFA131C18PXPA11B15PXPC111B15PXPEA110B14PXPEM110B14PXPEM510B14PXVF111B10PXVF1211B10PXVF1213B10PXVF1214B10PXVF1215B10PXVF1216B10PXVF131B10PXVF141B10PXVF151B10PXVF161B10PZCB244D4PZCB2268D4PZCM994D5PZCM996D5PZCM888D5PZML199A8PZTX05D5PZUA12A27PZUB12A27PZUC12A27PZUE12A27TR3P10A26VLF3P4-302B9XCMZ24C5ZB2BA2B6ZB2BA3B6ZB2BA4B6ZB2BA5B6ZB2BA6B6ZB2BC2B6ZB2BC3B6ZB2BC4B6ZB2BD2B7ZB2BD3B7ZB2BD4B7ZB2BD5B7ZB2BD7B7ZB2BD8B7ZB2BE101B5ZB2BE1016B5ZB2BE102B5ZB2BE1026B5ZB2BG2B7ZB2BG3B7ZB2BG4B7ZB2BG5B7ZB2BG7B7ZB2BJ2B7ZB2BJ3B7ZB2BJ4B7ZB2BJ5B7ZB2BL2B6ZB2BL3B6ZB2BL4B6ZB2BL5B6ZB2BP2B6ZB2BP3B6ZB2BP4B6ZB2BR2B6ZB2BR3B6ZB2BR4B6ZB2BS14B6ZB2BS24B6ZB2BS54B6ZB2BS64B6ZB2BT2B6ZB2BT4B6ZB2BX2B6ZB2BX4B6ZB2BY2002B11ZB2BY2004B11ZB2BY2101B11ZB2BY2303B11ZB2BY2304B11ZB2BY2305B11ZB2BY2306B11ZB2BY2307B11ZB2BY2308B11ZB2BY2309B11ZB2BY2310B11ZB2BY2311B11ZB2BY2312B11ZB2BY2313B11ZB2BY2314B11ZB2BY2321B11ZB2BY2323B11ZB2BY2326B11ZB2BY2327B11ZB2BY2328B11ZB2BY2330B11ZB2BY2334B11ZB2BY2335B11ZB2BY2336B11ZB2BY2337B11ZB2BY2338B11ZB2BY2339B11ZB2BY2362B11ZB2BY2365B11ZB2BY2367B11ZB2BY2369B11ZB2BY2370B11ZB2BY2371B11ZB2BY2372B11ZB2BY2376B11ZB2BY2380B11ZB2BY2381B11ZB2BY2384B11ZB2BY2387B11ZB2BY2388B11ZB2BY2389B11ZB2BY2503B11ZB2BY4001B11ZB2BY4005B11ZB2BY4101B11ZB2BY5101B11ZB2BY8330B11ZB2BZ009B5ZB2BZ19B6ZB2BZ41B6ZB2SZ3B6ZC2JE01C12ZC2JE02C12ZC2JE03C12ZC2JE05C12ZC2JE09C12ZC2JE61C12ZC2JE62C12ZC2JE63C12ZC2JE64C12ZC2JE65C12PartNumberPagePartNumberPagePartNumberPageZC2JE70C12ZC2JY11C12ZC2JY12C12ZC2JY13C12ZC2JY21C12ZC2JY22C12ZC2JY23C12ZC2JY31C12ZC2JY41C12ZC2JY51C12ZC2JY61C12ZC2JY71C12ZC2JY81C12ZC2JY91C12ZCKD02C9ZCKD06C9ZCKD10C9ZCKD21C9ZCKD23C9ZCKG00C9ZCKY11C9ZCKY13C9ZCKY41C9ZCKY43C9ZCKY51C9ZCKY52C9ZCKY81C9ZCKY91C9PartNumberPageIndex

Catalog PCC-2/USANotesPneumatic Control ComponentsIndexPneumatic4Parker Hannifin CorporationPneumatic DivisionRichland, Michigan

Catalog PCC-2/USAIndexPneumatic Control ComponentsLogicIndexALogicLogicBasic Features ............................................................................................................................... 2-5Modular Sequencers ....................................................................................................................... 6-7Inline Logic ElementsAND, OR & Mounting Clip ............................................................................................................. 8Integrated Logic ElementsAND, OR, NOT, Head / Tail Plate (With 5/32" Swivel Connections) ................................................................................. 9Subbase Mounted Logic ElementsAND, OR, YES, & NOT Modular Sequencers (For Mounting on 3-Port Subbases) .................................................10Pressures, <strong>Specifications</strong> & Dimensions ..................................................................................... 11Time Delay Relays, Memory Relays and 4-Way Valve .............................................................. 12-15Sensor & Amplifier Relays ............................................................................................................... 16Signal Amplifier Relays .................................................................................................................... 17Solenoid Relays ............................................................................................................................... 18Pressure Switches ...................................................................................................................... 19-23Pulse Units .................................................................................................................................. 24-25Regulators / Flow Control ................................................................................................................ 263 & 4-Port Modular Subbases .......................................................................................................... 27Independent Subbases .................................................................................................................... 28Subbases / Conversion Kits ............................................................................................................. 29Technical Information .................................................................................................................. 30-31Impulse Counters & Dial Timers ................................................................................................. 32-33Logic & Processing Spare Parts ................................................................................................. 34-35DIN Rail & Replacement Screws ..................................................................................................... 36Pneumatic1Parker Hannifin CorporationPneumatic DivisionRichland, Michigan

Catalog PCC-2/USABasic FeaturesLogicModular SequencerIndexVirtually all production machines usingpneumatic actuators operate in adedicated and repeatable sequence orcycle. The purpose of any controlmethod is to insure that all steps of themachine’s cycle occur as intended.The sequencer constitutes the backboneof a Telepneumatic control circuit. Thesequencer’s poppet design provides longlife using only shop air.Since it is modular, the sequencer caneasily be configured to any applicationcycle requirement. Logic elements andsupporting relays provide for otherapplication needs such as safetyconditions, operating modes and timedelays.The Telepneumatic sequencereliminates the need for solenoidoperated valves.COMPOSITIONA sequencer is comprised of a Numberof step modules, each correspondingto a defined step in the machine’scycle according to the applicationrequirements.HeadModuleStepModuleDeviationModuleTailModuleLogicThe head / tail module peforms thefunction of locking the easily stackedstep modules to the 35 mm DIN railwhile also supplying connection to thestack as follows: (1) supply pressure,(2) starting condition and (3) generaland emergency resets. A deviation moduleis placed between step modules toprovide for variation to the normalsequence of events such as skips,repeats, multi line cycles and resets.STEP MODULEOutput SignalTest PointAt the heart of the sequencer, the stepmodule is the decision making elementthat will read the necessary inputs andprovide output commands as needed.The step module consists of the followingparts:• Input/output via 5/32" instant swivelswith test points• Visual indicator, defining status• Both on and off manual overrides• Step reference marking to assist insequence diagnostics• Stackable subbase with special internalpiping.AutomaticConnectionsBetweenStep ModulesInput SignalManual Override “On”Manual Override“Off”loop BVisual IndicatorStep ReferenceMarkingBRPA1 2 6 7BAloop APneumatic2Parker Hannifin CorporationPneumatic DivisionRichland, Michigan

Catalog PCC-2/USABasic FeaturesLogicModular SequencerIndexGRAFCETAThe use of a function flow diagramallows the designers of machine toolautomation to organize applicationrequirements in a simple sequentialflow. The GRAFCET flow diagrambecomes a snapshot of the machine’spositions and conditions. This simplifiesunderstanding and modification of thespecific application.CONTROL LOOPa +a 1ALogicTo understand the operating cycle, wefirst define each actuator motion insequence. We will address each actuatorwith a letter starting with A. For a cylinderas shown to the right, the motion requiredis the extension of the cylinder. This actionwill now be known as A+. The “+” indicatesthe extension of a cylinder, or the turningof an actuator that is digital (on / off).When the cylinder reaches the end of itsstroke, it will trigger a limit switch. Thissignal is an input (transition) that we call“a1". The “a” defines the actuator, and “1”defines its active state. This completes astep consisting of a command and atransition.COMBINATIONWe can now combine additional actuatorsand reciprocal motions to create a totalcontrol package. To the right are twoactuators A and B. “A” is a transfercylinder that will move parts into theworkspace. “B” is a press that will formthe parts.The GRAFCET flow diagram in the upperleft shows the required actions and thecorresponding limit switch feedbacksignals to indicate the actions arecomplete. When the machine starts, thetransfer (A) will extend (+), placing a partin the nest. Feedback (a1) states thatthe action is complete and initiatesretraction (A-). Feedback (a0) confirmsthe action is complete and initiates thenext motion. The press (B) will extenddownward (+) until reaching the end ofstroke sensor (b1) which confirms theaction and initiates the final step thatreturns the press to its home condition(B-). The sensor (b0) confirms when (B)is home and signals end of cycle.a0A +1 A+a12 A-a03 B+b14 B-b0.m(b0 and m)ABRPAa1A -B +B -A+ A– B+ B–1 2 3 4a1 a0 b1b0&BABstarting cyclemb0b1Pneumatic3Parker Hannifin CorporationPneumatic DivisionRichland, Michigan

Catalog PCC-2/USABasic FeaturesLogicLogic ElementsIndexIN-LINE MOUNTEDLOGIC ELEMENTSThese logic elements can be either flushmounted on any flat surface, 35mm DINrail mounted with the addition of a springclip or hung from the tubing.In-line elements are available in two logicstatements: AND and OR.INTEGRATEDLOGIC ELEMENTSThese elements can be combined witheach other, allowing the creation of stringstatements in a compact footprint whilereducing the piping required. There arethree logic functions available in thisconfiguration: AND, OR and NOT.Each element is supplied with an integrallocking key which allows each logic unitto lock to the next element to the right.In addition, each element includes amode selector which enables the user toselect either cascade (series) or common(parallel) cilrcuitry.Cascade mode determines that the outputof a logic element will feed the nextdownstream logic element, while thecommon mode feeds its supply to thenext component. These units aredesigned for 35mm DIN rail mountingand are supplied with the internal pipingdiagram printed on the face of the device.This internal piping is field convertable.Selector inCascade Positions s s& 1 &b a a aSelector inCommon PositionLogicSUBBASE MOUNTINGLOGIC ELEMENTSAll logic devices are designed to mounton 3-port subbases. The 3-port subbaseis available in two styles (common inputand cascade input) and are manifoldablewith each other as well as the 4-portsubbases for relays. A stand alone3-port (1/8" pipe) metal subbase is alsoavailable. There are 5 logic elements forsubbase mounting: AND, OR, YES, NOTand THRESHOLD NOT.Pneumatic4Parker Hannifin CorporationPneumatic DivisionRichland, Michigan

Catalog PCC-2/USABasic FeaturesLogicRelays on Stacking SubbasesIndexRELAYSThese components provide additionalcapability to the pneumatic logic system.Types available are: Time Delay, Memory,Amplifier, Sensor, Solenoid, and PressureSwitch (both pneumatic and electric).Depending on function, a 3 or 4-portsubbase is used.ALogic3-PORT SUBBASESThese stackable subbases are designedfor the mounting of:• logic devices• timers• bleed sensor relays• threshold NOT relays• E/P and P/E interfaces.They are stackable with the 4-portsubbases below and are available incommon input or cascade input styles.4-PORT SUBBASESThese stackable subbases are designedfor the mounting of:• memory relays• amplifier relays for use with proximitysensors.They are stackable with the 3-portsubbases above.STACK ASSEMBLYThe drawing to the right explains theprocedure for asembling subbasemounted logic components and relays.Note: The subbases are supplied with anintegral key that must be pulled upward(1) to release the blanking plug (2). Nowthe downstream subbase can bepositioned (3) then locked by returningthe integral key back to its original position(4). After this process is complete,the relay or logic element are mounted ontop.AirPressureSupplyIntegralLocking ofKeythe Key bytheComponent 14BlankingPlug23Pneumatic5Parker Hannifin CorporationPneumatic DivisionRichland, Michigan

Catalog PCC-2/USAPart NumbersLogicModular SequencersIndexStep ModulePart NumberPSMA10PSMB10PSMA12PSMB12DescriptionWith Manual Override, Less BaseWithout Manual Override, Less BasePSMA10 on PSBA12 BasePSMB10 on PSBA12 BasePSMA10Head / Tail Set(For 35mm DIN Rail Mounting)Part NumberPSEA127DescriptionRequired to assemble ModularSequencerProvides Inlet & Signal PortsLogicBRPABAPSEA127Deviation ModelsBABRAStandardBlocked PortPSDB12Part NumberPSDA12PSDB12DescriptionStandard:- Parallel Sequences- Selection Sequences- Repeat Sequences- Skip StepsBlocked Port:For the Remote Reinitialization ofthe Blocked PortStep Module SubbasePart NumberPSBA12DescriptionFor Mounting with PSM•10Step ModulesPSBA12Step Module InterlockPart NumberPSVA12DescriptionMounted between the Subbase andthe Step Module to Interruptthe Sequence if a SensorSignal is Faulty.PSVA12Pneumatic6Parker Hannifin CorporationPneumatic DivisionRichland, Michigan

Catalog PCC-2/USATechnical InformationLogicModular SequencersIndexPilot & Depilot PressuresReset Signal always takes priority over Set Signal.PSI bar75 560 445 330 2Pressures X and YDepilot ThresholdPilot ThresholdA151Air Supply Pressure P1 2 3 4 5 6 7 8 bar15 30 45 60 75 90 105 120 PSILogic<strong>Specifications</strong>Air QualityStandard Shop Air, Lubricated or Dry,40 µm FiltrationCv (kv)0.14 (1.8)Flow rate at 90 PSI (6 bar) in SCFM(l/mn ANR)6.4 (180)Function3-Way, Double Air operated Valvewith priority reset (Reset signaltakes precedence over set signal).Materials- Body ............................... Polyamide- Poppet ....................... Polyurethane- Seals ...................... Nitrile (Buna N)Number of Operations with Dry Airat 90 PSI and 70°F – Frequency 1 Hz10 MillionOperating Pressure40 to 115 PSIG (3 to 8 bar)PortsPSEA127: Supply 1/4", All Others 5/32"PSDA12, PSDB12, PSBA12, PSVA12:All 5/32Use Semi- Rigid Nylon orPolyurethane TubeResponse Time2 to 3 msecTemperatureOperating32°F to 122°F (0°C to +50°C)Storage-22°F to 140°F (-30°C to +60°C)DimensionsPSEA127PSMA10PSEA127PSVA12PSMA10.55(14)PSMA12PSDA12PSDB12.55(14)2.17 (55)2.17 (55)2.17 (55)1.73 (44)RPBABARBABA2.17 (55).59(15).87(22)1.91 (48.5)2.78 (70.5).59(15).87(22)1.06(27) 1.91 (48.5)3.84 (97.5).55(14)1.4 (35.5) 1.26 (32) 1.73 (44) 1.73 (44) 1.26 (32) 1 (25.5)Instant connection Ø 1/4" Instant connection Ø 5/32".55(14)Pneumatic7Parker Hannifin CorporationPneumatic DivisionRichland, Michigan

Catalog PCC-2/USAPart NumbersLogicInline Logic ElementsIndexAND ElementPart NumberPLLA11PLLA15Description5/32" Instant10-32 UNFOutput (S or 3)&Signal 1(P or 2)Signal 2(a or 1)PLLA11LogicOR ElementPart NumberPLKA11PLKA15Description5/32" Instant10-32 UNFOutput (S or 3)1Signal 1(P or 2)Signal 2(a or 1)PLKA11Mounting Clip AssemblyPart NumberPZML199Description1 Set of 10 Clip AssembliesPZML199M4 Screw5/32" InstantFittings1.38 (35).47(12)1ø.17 (4.2)PZML199.63(16).63(16).63(16).87(22)<strong>Specifications</strong>Air QualityStandard Shop Air, Lubricated or Dry,40 µm FiltrationCv (kv)0.14 (1.8)Flow rate at 90 PSI (6 bar) in SCFM(l/mn ANR)6.4 (180)Materials- Body ............................... Polyamide- Poppet ....................... Polyurethane- Seals ...................... Nitrile (Buna N)MountingInline or 35mm DIN RailNumber of Operations with Dry Airat 90 PSI and 70°F – Frequency 1 Hz10 MillionOperating PositionsAll PositionsOperating Pressure40 to 115 PSIG (3 to 8 bar)PortsStandard: 5/32" Instant for Semi-Rigid Nylon or Polyurethane Tube10-32 UNF AvailableResponse Time2 to 3 msecTemperatureOperating32°F to 122°F (0°C to +50°C)Storage-22°F to 140°F (-30°C to +60°C)Pneumatic8Parker Hannifin CorporationPneumatic DivisionRichland, Michigan

Catalog PCC-2/USAPart NumbersLogicIntegrated Logic ElementsIndexWith 5/32" Instant Swivel Connections and Pressure IndicatorsAND ElementOR ElementOutput(S or 3 - Red)Signal 2(a or 1- Green)&Signal 1(P or 2- Green)Output(S or 3 - Red)Signal 2(a or 1- Green)1Signal 1(P or 2- Green)APart NumberPLLB12PLLB12DescriptionWith Integral Circuit Selector forCascade or Common Mode SelectionPart NumberPLKB12PLKB12DescriptionWith Integral Circuit Selector forCascade or Common Mode SelectionLogicNOT ElementHead / Tail Plate SetOutput(S or 3 - Red)&Signal(a or 1- Green)Supply(P or 2- Green)Part NumberPLNB12<strong>Specifications</strong>Air QualityStandard Shop Air, Lubricated or Dry,40 µm FiltrationCv (kv)0.14 (1.8)Flow rate at 90 PSI (6 bar) in SCFM(l/mn ANR)6.4 (180)Materials- Body ............................... Polyamide- Poppet ....................... Polyurethane- Seals ...................... Nitrile (Buna N)PLNB12DescriptionWith Integral Circuit Selector forCascade or Common Mode SelectionPart NumberPLEB12MountingInline or 35 mm DIN RailNumber of Operations with Dry Airat 90 PSI and 70°F – Frequency 1 Hz10 MillionOperating PositionsAll PositionsOperating Pressure40 to 115 PSIG (3 to 8 bar)PLEB12DescriptionMounts on DIN Rail, Required withIntegrated Logic Elements toComplete Stack AssemblyPortsStandard: 5/32" Instant for Semi-Rigid Nylon or Polyurethane Tube10-32 UNF AvailableResponse Time2 to 3 msecTemperatureOperating32°F to 122°F (0°C to +50°C)Storage-22°F to 140°F (-30°C to +60°C)DimensionsPLN - NOT.55 (14)1.58 (40).55 (14)Clip.59 .87(15) (22)PressureIndicator5/32" InstantConnections.24(6)1.10 (28).31 (8)ø.17(4.2).28 (7).87(22).55 (14)&.87(22)1.87(22)&1.02(26).26(6.5)PSI7560453015bar543210Pressure Signal a(Ratio = 7:4.5)Pilot ThresholdDepilot Threshold(Ratio = 7:1.5)Air Supply Pressure P1 2 3 4 5 6 7 8 bar15 30 45 60 75 90 105 120 PSIPneumatic9Parker Hannifin CorporationPneumatic DivisionRichland, Michigan

Catalog PCC-2/USAPart NumbersLogicSubbase Mounted Logic ElementsIndexFor Mounting On 3 Port SubbasesAND Element&Output(S or 3- Red)Part NumberPLLC10DescriptionLess BaseSupply(P or 2- Black/None)Signal(a or 1- Green)OR ElementOutput(S or 3- Red)PLLC10Part NumberPLKC10DescriptionLess BaseLogic1Supply(P or 2- Black/None)Signal(a or 1- Green)PLKC10YES ElementOutput(S or 3- Red)Part NumberPLJC10DescriptionLess BaseSupply(P or 2- Black/None)Signal(a or 1- Green)PLJC10NOT ElementsSupply(P or 2- Black/None)Output(S or 3- Red)Standard&Signal(a or 1- Green)PLNC10Part NumberPLNC10PLNC12PLND10PLND12DescriptionLess BasePLNC10 on PZUA12 SubbaseLess BasePLND10 on PZUA12 Subbase&Output(S or 3- Red)ThresholdSupply(P or 2- Black/None)Signal(a or 1- Green)PLND10Pneumatic10Parker Hannifin CorporationPneumatic DivisionRichland, Michigan

Catalog PCC-2/USATechnical InformationPilot and Depilot PressuresPLN and PLJ - NOT and YESLogicSubbase Mounted Logic ElementsPLND - Threshold NOTIndexPSI7560453015bar543210Pressure Signal aPilot ThresholdDepilot Threshold1 2 3 4 5 6 7 8(Ratio = 7:4.5)(Ratio = 7:1.5)Air Supply Pressure PbarPSI bar90 675 560 445 330 215 1Pressure Signal aPilot ThresholdDepilot Threshold(Ratio = 7:4.5)(Ratio = 7:1)Air Supply Pressure PALogic15 30 45 60 75 90 105 120 PSI01 2 3 4 5 6 7 8 bar15 30 45 60 75 90 105 120 PSI<strong>Specifications</strong>Air QualityStandard Shop Air, Lubricated or Dry,40 µm FiltrationCv (kv)PLNC, PLJC,PLL & PLK PLND0.14 (1.8) 0.08 (1.0).14 (1.8)Flow rate at 90 PSI (6 bar) in SCFM(l/mn ANR)PLNC, PLJC,PLL & PLK PLND6.4 (180) 3.2 (906.4 (180)Materials- Body ............................... Polyamide- Poppet ....................... Polyurethane- Seals ...................... Nitrile (Buna N)Mounting3-Port SubbaseNumber of Operations with Dry Airat 90 PSI and 70°F – Frequency 1 HzPLNDPLL & PLK PLNC / PLJC100 Million 10 MillionOperating PositionsAll PositionsOperating Pressure40 to 115 PSIG (3 to 8 bar)PortsStandard: 5/32" Instant for Semi-Rigid Nylon or Polyurethane Tube10-32 UNF AvailableResponse Time2 to 3 msecTemperatureOperating32°F to 122°F (0°C to +50°C)Storage-22°F to 140°F (-30°C to +60°C)DimensionsPLKC10, PLLC10PLNC10, PLND10, PLJC10Output IndicatorOutput IndicatorSignal Indicator1.11 (28)1.19 (30).97 (25)M41.25 (32)1.34 (34).97 (25)M41.25 (32)1.34 (34)Pneumatic11Parker Hannifin CorporationPneumatic DivisionRichland, Michigan

Catalog PCC-2/USAPart NumbersLogicTime Delay RelaysIndexTime Delay RelaysFor Mounting On Any 2* or 3-Port SubbaseUsing Atmospheric Air for ControlSingle Turn AdjustmentSupply(P or 2- Black/None)Supply(P or 2- Black/None)t 1 0t 1 0Output(S or 3- Red)Signal(a or 1- Green)Output(S or 3- Red)Signal(a or 1- Green)ON DelayOFF DelayPRTA10Part NumberDescriptionPRTE10 ON Delay 0.1 to 3 sPRTA10 ON Delay 0.1 to 30 sPRTB10 ON Delay 10 to 180 sPRTF10 OFF Delay 0.1 to 3 sPRTC10 OFF Delay 0.1 to 30 sPRTD10 OFF Delay 10 to 180 sPRTA12 PRTE10 on PZUA12 SubbaseLA9D901 Tamperproof CapLogicTime Delay RelaysFor Mounting On Any 2* or 3-Port SubbaseUsing Pressurized Air for ControlMultiple Turn AdjustmenttSignal(a or 1- Green)Output(S or 3- Red)Supplyo(P or 2ON Delay- Black/None)Output(S or 3- Red)Supply OFF Delayt o (P or 2- Black/None)Signal(a or 1- Green)LTY / LTN AccessoriesLTY10/3Part NumberDescriptionLTY10/0 ON Delay 0.18 to 1.8LTY10/1 ON Delay 0.40 to 3.0LTY10/2 ON Delay 1.0 to 10.0LTY10/3 ON Delay 5.0 to 40.0LTY/EXT ON Delay VariableLTN10/0 OFF Delay 0.14 to 1.4LTN10/1 OFF Delay 0.25 to 2.0LTN10/2 OFF Delay 0.50 to 6.0LTN10/3 OFF Delay 2.50 to 25.0LTY / EXTThis unit is the same as a standard LTY10/3 with an additionalvolume added to the body, and has a time delay of 45 to 80seconds as shipped. A barbed fitting (.129” 3.3mm diameter)on the side of the timer allows connection of an externalvolume to increase the time delay. See specifications for howto determine the amount of volume necessary.Part NumberLTN10/PANLT10/CLT10/ADescriptionPanel Mounting Adapter KitTamperproof KitCounting Dial KitLT10/CLT10/A2.16 (55) Square2 Holes1.66(42) Dia.1 Hole.472(11.9) Dia..590(150).905 (23)*Function Must Be Checked.Faceplate.08(2) Max.Panel Thickness2 Holes .098(2.48) Dia.(Use faceplateas template)Panel Cutout DetailPneumatic12Parker Hannifin CorporationPneumatic DivisionRichland, Michigan

Catalog PCC-2/USATechnical InformationLogicTime Delay RelaysIndexFunctionPressure<strong>Specifications</strong>0Adjustable timeAir Quality - PRTStandard Shop Air, Lubricated or Dry,40 µm FiltrationAir Quality - LTY/LTNStandard Shop Air, Dry, 20 µmFiltrationCv (kv) - PRT0.14 (1.8)Cv (kv) - LTY, LTN0.19 (2.4)Filter - PRTa-PPRL23Vent - PPRL20Filter - LTY, LTN35 Micron Internal Filter fitted toSignal Port 1DimensionsTimeWithONdelayFlow rate at 90 PSI (6 bar) in SCFM(l/mn ANR) - PRT6.4 (180)Flow rate at 90 PSI (6 bar) in SCFM(l/mn ANR) - LTY, LTN9.3 (262)Interchangable 50 µm Filter(PRT Only)a (Input) ......................... PPRL23Input Cylinder ................ PPRL20Materials- Body ............................... Polyamide- Poppet ....................... Polyurethane- Seals ...................... Nitrile (Buna N)Mounting2 or 3-Port SubbasePressureLTY / EXTThe time delay per unit volume is 295 sec/in 3 at 80 psig (18 sec/cc at 5.5 bar).The volume of the timer as shipped is .305 in 3 (5 cc).Example: Required 10-minute time delay at 80 psig (5.5 bar).Total volume will be 10 min x 60 sec/min x 1 in 3 /295 sec = 2.03 in 3 (10x60/18 = 33 cc).The additional volume that will be required will be 2.03 - .305 = 1.725 in 3 (33-5 = 28 cc).PRT•10PRTEPRTAPRTBLTY10PRTFPRTCPRTDLTN10Key:Control signal aOutput signal S - - - - - -0Adjustable timeTimeWithOFFdelayNumber of Operations with Dry Airat 90 PSI and 70°F – Frequency 1 Hz10 MillionOperating PositionsAllOperating Pressure40 to 115 PSIG (3 to 8 bar)Repeatability - PRT±5% / 5 OperationsResponse Time - PRT2 to 3 msecResponse Time - LTY,LTNTypical Reset Time less than100msecTemperatureOperating32°F to 122°F (0°C to +50°C)Storage-22°F to 140°F (-30°C to +60°C)ALogic1.91 (48)1.31(33) Dia..56 (14)M41.41 (36)BAC0DFLTY10 / LTN10OutputIndicator1.00 (25) (Red)3.39 (86)Locating pin0.112 Dia. x .06 LongSupply(P or 2Black/None)Output(S or 3Red)1.30 (33)M4.90 (23)LTY / EXTOutputIndicator1.00 (25) (Red)3.98 (101)Locating pin0.112 Dia. x .06 LongSupply(P or 2Black/None)Output(S or 3Red).23(6)1.30 (33)M4.90 (23).23(6)E1.66 (42)3.84 (98)Input Indicator(Green).08 (2)Tamperproof CoverLT10/C (Optional)3.98 (101).138 (3.5).59 (15)Signal(a or 1Green)Input Indicator(Green).08 (2)Tamperproof CoverLT10/C (Optional)3.98 (101).138 (3.5).59 (15)Signal(a or 1Green)Counting DialLT10/A (Optional)Counting DialLT10/A (Optional)Pneumatic13Parker Hannifin CorporationPneumatic DivisionRichland, Michigan

Catalog PCC-2/USAPart NumbersLogicMemory RelayIndexMemory RelayWithout SubbaseFor Mounting On 4-Port Modular SubbaseSPPart NumberPLMA10PLMA12Description3-Way Double Air Pilot OperatedValve. Reset Signal Y Always HasPriority Over Set Signal X.With Manual OverridePLMA10 on PZUB12 SubbaseXYPLMA10Logic<strong>Specifications</strong>Air QualityStandard Shop Air, Lubricated or Dry,40 µm FiltrationCv (kv)0.14 (1.8)Flow rate at 90 PSI (6 bar) in SCFM(l/mn ANR)6.4 (180)Materials- Body ............................... Polyamide- Poppet ....................... Polyurethane- Seals ...................... Nitrile (Buna N)Mounting4-Ported SubbaseNumber of Operations with Dry Airat 90 PSI and 70°F – Frequency 1 Hz10 MillionOperating PositionsAllOperating Pressure40 to 115 PSIG (3 to 8 bar)Response Time2 to 3 msecTemperatureOperating32°F to 122°F (0°C to +50°C)Storage-22°F to 140°F (-30°C to +60°CDimensionsPLMA12Pilot & Depilot PressuresReset Signal Y always takes priority over Set Signal X..51 (13)1.50 (38)PSI bar75 5Pressures X and Y1.58 (40)1.59 (40)1.93 (49)604530432Depilot ThresholdPilot Threshold.51 (13).59 (15).87 (22)1.94 (49)1.19 (30)151Air Supply Pressure P1 2 3 4 5 6 7 8 bar15 30 45 60 75 90 105 120 PSIPneumatic14Parker Hannifin CorporationPneumatic DivisionRichland, Michigan

Catalog PCC-2/USAPart NumbersLogic4-Way Valve UnitIndex4-Way Valve UnitFor Mounting On 5-Ported SubbasePart NumberMEM7P10Description4-Way Double Air Pilot OperatedValve. 2-Position, Dual Exhaust PortsaA BbAPMEM7P10Logic<strong>Specifications</strong>Air QualityStandard Shop Air, Lubricated or Dry,40 µm FiltrationFlow8.5 SCFM at 100 PSIGFunctionWhen pilot pressure is applied, thevalve shifts and remains in positionuntil an opposing signal is appliedand the initiating signal is lost. Thiscreates a “memory” or latchingfunction.Materials- Body ............................... Polyamide- Poppet ....................... Polyurethane- Seals ...................... Nitrile (Buna N)Minimum Pilot Pressure30 PSIGMounting BaseBAC7P10, BIC7P10Mounting5-Ported SubbaseOperating Pressure30 to 115 PSIG (2 to 8 bar)Operating PositionsAllPorts“a” and “b” ......................... Pilot PortsA and B.......................... Output PortsSingle Supply PortDual Exhaust PortsTemperatureOperating32°F to 122°F (0°C to +50°C)Storage-22°F to 140°F (-30°C to +60°C)Dimensions(Not including Mounting Base)2.125 (54)Pop-Up Indicator1.181 (30)1.575 (40).120 (3) .180 (5)2.680 (68)M4Pneumatic15Parker Hannifin CorporationPneumatic DivisionRichland, Michigan

Catalog PCC-2/USAPart NumbersLogicSensor & Amplifier RelaysIndexSensor RelayFor Mounting On Any 3-Port BaseSupply(P or 2- Black/None)Output(S or 3- Red)Signal(a or 1- Green)Part NumberPRFA10PRFA12DescriptionProvides a supply to a bleed sensor*and generates an output signal whenoperated.*See Bleed Sensors in Sensing SectionPRFA10 on PZUA12 SubbasePRFA10Amplifier RelayFor Mounting On 4-Port BaseSupplyPOutput SSignal aAuxillarySupplyPx<strong>Specifications</strong>Air QualityStandard Shop Air, Lubricated or Dry,40 µm FiltrationCv (kv)0.14 (1.8)Flow rate at 90 PSI (6 bar) in SCFM(l/mn ANR)6.4 (180)Function3-Way Normally ClosedNNPYesMaterials- Body ............................... Polyamide- Poppet ....................... Polyurethane- Seals ...................... Nitrile (Buna N)DimensionsPRDA12PRDA10MountingSensor: 3-Ported SubbaseAmplifier: 4-Ported SubbaseNozzle Consumption0.00487ft 3 /PSI Min(2 l/bar - Min ANR)LFAY10/1 - 0.04 l/s (0.08 SCFM)Nozzle Ø (Of Sensor)1/32" (3mm)Number of Operations with Dry Airat 90 PSI and 70°F – Frequency 1 Hz10 MillionOperating PositionsAllOperating Pressure40 to 115 PSIG (3 to 8 bar)Part NumberDescriptionAmplifies the low pressureWith signal coming from a fluidicPRDA10 Manual proximity sensor* to aOverride usable level.* See Fluidic Proximity Sensors in SensingPRDA12 PRDA10 on PZUB12 SubbasePRFA10Response Time2 to 3 msecTemperatureOperating32°F to 122°F (0°C to +50°C)Storage-22°F to 140°F (-30°C to +60°C)PRD - Amplifier Relay OnlyAir Signal Pressure (a).007 to .03 PSI (0.5 to 2 mbar)Auxiliary Supply Pressure (Px)1.5 to 3 PSI (100 to 200 mbar)ConsumptionAt 1.5 PSI (100mbar) with a= 0: 0.1 SCFM (3Nl/mn)Maximum Operating Frequency10 HzManual ControlPRDALogic1.58 (40)1.11 (28).51 (13).51 (13)1.50 (38).59 (15).87 (22)1.56 (40)1.46 (37).97 (25)M41.25 (32)1.34 (34)Pneumatic16Parker Hannifin CorporationPneumatic DivisionRichland, Michigan

Catalog PCC-2/USAPart NumbersLogicSignal Amplifier RelaysIndexSignal Amplifier RelayFor Mounting On Any 3-Port Subbase Part Number Description331122Sensitive AmplifierStandard AmplifierLFAY10/1Sensitive Amplifier A low pressureLFAY10/0 .15 to 5.00 PSIG signal at Port 1(.01 to .34 bar) allows a higherStandard Amplifier pressure signalLFAY10/1 1.10 to 115 PSIG to pass from(.08 to 8 bar) Port 2 to Port 3ALogic<strong>Specifications</strong>Air QualityStandard Shop Air, Lubricated or Dry,40 µm FiltrationCv (kv)0.19 (2.4)Flow rate at 90 PSI (6 bar) in SCFM(l/mn ANR)9.3 (262)Function3-Way Normally ClosedNNPYesMaterials- Body ...................................... Acetal- Poppet ................................... Acetal- Seals ...................... Buna N (Nitrile)Mounting3-Ported SubbaseNozzle ConsumptionLFAY10/0 - 0.7 l/s (0.15 SCFM)LFAY10/1 - 0.04 l/s (0.08 SCFM)Nozzle Ø (Of Sensor).007" (0.18mm)Number of Operations with Dry Airat 90 PSI and 70°F – Frequency 1 Hz10 MillionOperating PositionsAllOperating Pressure30 to 115 PSIG (2 to 8 bar)Pressure Signal RangeLFAY10/0 - .15 to 5.00 PSIG(.01 to .34 bar)LFAY10/1 - 1.10 to 115 PSIG(.08 to 8 bar)Response TimeTypical Reset Time less than 100msTemperatureOperating32°F to 122°F (0°C to +50°C)Storage-22°F to 140°F (-30°C to +60°C)DimensionsLFAY10/0OutputIndicator1.00 (25) (Red) .08 (2)Locating pin0.112 Dia. x .06 Long2.19 (56)Output (3)Supply (2)LFAY10/1OutputIndicator1.00 (25) (Red) .08 (2)Locating pin0.112 Dia. x .06 Long1.69 (43)Output (3)Supply (2)1.30 (33)M4.23(6).90 (23)1.30 (33)M4.23(6).90 (23)Input Indicator(Green).12 (3) .59 (15)Pilot (1)Input Indicator(Green).12 (3).59 (15)Pilot (1)Pneumatic17Parker Hannifin CorporationPneumatic DivisionRichland, Michigan

Catalog PCC-2/USAPart NumbersLogicSolenoid RelaysIndexSolenoid RelayWith PZUA12 SubbaseSupply(P or 2- Black/None)Output(S or 3- Red)Solenoid CoilWith Plunger and Plug-inDIN Connector (22 x 30mm)ABWith manual override and plug-inDIN connector 22 x 30 mm (43650Form B Industrial)PRSA121BPVAF10●●LogicPart NumberDescriptionPRSA121B 24VAC 50/60 Hz 6VAPRSA121F 120VAC 60 Hz 6VAPRSA122B 24VDC 5WDimensionsPRSA121BPart NumberDescriptionPVAF102B 24VDC 5WPVAF102E 48VDC 5WPVAF101B 24VAC 50/60 Hz 6VAPVAF101E 48VAC 50/60 Hz 6VAPVAF101F 120VAC 60 Hz 6VAPVAF101M 240VAC 60 Hz 6VA1.50 (38)Coil MountFor Mounting On Any 2 or 3-Port Subbase.55 (14)1.58 (40).55 (14).59 (15).87 (22)1.94 (49)3.25 (83)1.38 (35)Part NumberPRSD10PRSD10DescriptionFor mounting the Solenoid Coil andPlunger on a 3-Port SubbaseWith Manual Override<strong>Specifications</strong>Air QualityStandard Shop Air, Lubricated or Dry,40 µm FiltrationConsumptionDirect Current: Holding = 5 WAlternating Current: Holding = 6 VA;Inrush = 20 VACv (kv)0.05 (0.65)Degree of ProtectionIP 65Electrical ConnectionPlug-in Connector, 22-30 mm,Ø 9 mm Cable Entry, TerminalCapacity 1.5 mm 2PneumaticFlow rate at 90 PSI (6 bar) in SCFM(l/mn ANR)2.1 (60)Manual ControlYesMaterials- Body ............................... Polyamide- Poppet ....................... Polyurethane- Seals ...................... Nitrile (Buna N)Mounting3-Ported SubbaseNumber of Operations with Dry Airat 90 PSI and 70°F – Frequency 1 Hz10 MillionOperating PositionsAll Positions18Operating Pressure40 to 115 PSIG (3 to 8 bar)Rated Insulation Voltage660V AC or DCDuty Rating100 %Response Time8 to 12 msecStandard Voltages24 VDC; 48 VDC ; 24 VAC ; 48 VAC;120 VAC; 240 VACTemperatureOperating32°F to 122°F (0°C to +50°C)Storage-22°F to 140°F (-30°C to +60°C)Parker Hannifin CorporationPneumatic DivisionRichland, Michigan

Catalog PCC-2/USAPart NumbersLogicPressure SwitchesIndexPneumatic Pressure Level SwitchWithout SubbaseFor Mounting On Any 3-Port BaseOutput(S or 3- Red)Part NumberLAAY10/1LAAN10/1DescriptionSenses Change in Rising Pressurefrom a Adjustable Level and Provides aPneumatic OutputSenses Change in Falling Pressurefrom a Adjustable Level and Provides aPneumatic OutputASignal(a or 1- Green)Supply(P or 2- Black/None)LogicLAA*10/1<strong>Specifications</strong>Air QualityStandard Shop Air, Lubricated or Dry,40 µm FiltrationCv (kv)0.19 (2.4)Flow rate at 90 PSI (6 bar) in SCFM(l/mn ANR)9.3 (262)Materials- Body ............................... Polyamide- Poppet ....................... Polyurethane- Seals ...................... Nitrile (Buna N)Mounting3-Ported SubbaseNumber of Operations with Dry Airat 90 PSI and 70°F – Frequency 1 Hz10 MillionOperating PositionsAll PositionsOperating Pressure115 PSIG Max. (8 bar)Pilot PressureAdjustable 7 to 130 PSI (0.5 to 8 bar)Switching Differential (On Off)

Catalog PCC-2/USAPart NumbersLogicPressure SwitchesIndexPressure SwitchWithout SubbaseFor Mounting On Any 2 or 3-Port BasePart NumberPREA10PREA12DescriptionWith Manual Override and Plug-inDIN Connector 22 x 30 mmPREA10 on PZUA12 SubbaseABSignal(a or 1- Green)LogicPREA10<strong>Specifications</strong>Air QualityStandard Shop Air, Lubricated or Dry,40 µm FiltrationDegree of ProtectionIP 65Depilot Pressure30 to 37 PSI (2 to 2.6 bar)Electrical CharacteristicsN.O. (NNP) Contact, 5A / 660VElectrical ConnectionPlug-in Connector, 22-30 mm,Ø 9 mm Cable Entry,Terminal Capacity 1,5 mm 2FunctionNO ContactInsulation Voltage Rating660V AC or DCMaterials- Body ........................ Polyamide- Poppet ................. Polyurethane- Seals ............... Nitrile (Buna N)Maximum Operating Frequency10 HzMechanical LifeVA400030002000900 1000700 800600500400300200100Volt Ampère510million2 million operationsmillionlth 10 Aoperationsoperations24 48 110 220 380VoltsMounting2 or 3-Ported SubbaseNominal Current Rating10 ANumber of Operations with Dry Airat 90 PSI and 70°F – Frequency 1 Hz10 MillionOperating PositionsAll PositionsOperating Pressure115 PSIG Max. (8 bar)Response Time2 to 3 msecTemperatureOperating32°F to 122°F (0°C to +50°C)Storage-22°F to 140°F (-30°C to +60°C)Trip Pressure32 to 40 PSI (2.2 to 3 bar)DimensionsPREA10ManualOverride1.57 (40)1.34 (34)2.00 (51)1.38 (35) 1.25 (32)1.00 (25)Pneumatic20Parker Hannifin CorporationPneumatic DivisionRichland, Michigan

Catalog PCC-2/USAPart NumbersLogicPressure SwitchesIndexLine Mounted Pressure Switch(Includes Manual Override andVisual Indicator)24 1PressureSignalFixedPart NumberPS1P1081PS1P1091DescriptionElectrical Pneumatic1SPDT Contact5A / 250V1SPDT Contact5A / 250V20PSI FixedSwitchingPressure30-75 PSIAdjustableSwitchingPressureA24 1PressureSignalAdjustableLogicPS1P1091<strong>Specifications</strong>Adjustable Trip Pressure30 to 75 PSI (2 to 5 bar)Air QualityStandard Shop Air, Lubricated or Dry,40 µm FiltrationDegree of ProtectionIP 40Electrical ConnectionsScrew TerminalsFixed Trip Pressure≥20 PSI (1.3 bar)FunctionSPDT ContactsInsulation Voltage Rating250V AC or DCMaterials- Body ........................ Polyamide- Poppet ................. Polyurethane- Seals ............... Nitrile (Buna N)Maximum Operating Frequency10 HzMountingInline or 35 mm DIN RailNominal Current Rating5 ANumber of Operations with Dry Airat 90 PSI and 70°F – Frequency 1 Hz10 MillionElectrical LifeType of CircuitAC (Switching Capacity in VA) DC (Switching Capacity in W)12V 24V 48V 120V 220V 12V 24V 48V 110V 220VFor 1 Million AC 15 25 56 115 140 17 24 37 50 54Operations DC 54 86 190 370 440 42 58 88 115 105For 2 Million AC - - - - - 10 14 25 40 23Operations DC - - - - - 30 43 70 100 90For 5 Million AC 8 10 14 19 21 - - - - -Operations DC 21 35 82 160 200 - - - - -Operating PositionsAll PositionsOperating Pressure115 PSIG Max. (8 bar)Ports5/32" Instant for Semi- Rigid Nylon orPolyurethane TubeResponse Time2 to 3 msecTemperatureOperating32°F to 122°F (0°C to +50°C)Storage-22°F to 140°F (-30°C to +60°C)DimensionsDIN rail1 (Common)4 (NNP Contact) 2 (NP Contact)3.05(77.5)Pneumaticconnection1.59(40.5)A A n. modules AA = .69 (17.5)ø3 mmadjusting screw(PS1P1091 only)Pneumatic21Parker Hannifin CorporationPneumatic DivisionRichland, Michigan

Catalog PCC-2/USAPart NumbersLogicPressure SwitchesIndexWith Electrical, Electrical & Pneumatic and Pneumatic OutputElectrical Pressure SwitchWithout SubbaseFor Mounting On Any 2 or 3-Port Base32 1Signal(a or 1- Green)LPS10/2, LPS10/33132 1LNOTPS101 2LPS10/*Part NumberDescription1.5 to 30 PSIG AdjustableLPS10/2 Senses Presence of Air Pressure toprovide Electrical Switching10 to 100 PSIG AdjustableLPS10/3 Senses Presence of Air Pressure toprovide Electrical SwitchingSenses Absence of Air Pressure,LNOTPS10 Provides Electrical and PneumaticSwitchingUnits supplied with 3 crimp-on electrical terminals withinsulators.Electrical Characteristics5A / 250V, 1 N.O. or 1 N.C. (SPDT) ContactTerminalDescriptionNumber LPS10 LNOTPS1 Common Common2 Normally Passing Normally Non-Passing3 Normally Non-Passing Normally PassingLogicVacuum SwitchFor Mounting On Any 2 or 3-Port Base32 1Signal(a or 1- Green)LPSV10Part NumberDescriptionLPSV10 Senses Presence of VacuumUnits supplied with 3 crimp-on electrical terminals withinsulators.Electrical Characteristics5A / 250V, 1 N.O. or 1 N.C. (SPDT) ContactTerminalDescriptionNumber1 Common2 Normally Non-Passing3 Normally PassingCablePart Number7097J03711DescriptionOptional for LPS10 / LPSV7097J03711TerminalNumber1 Brown2 Blue3 BlackWire ColorPneumatic22Parker Hannifin CorporationPneumatic DivisionRichland, Michigan

Catalog PCC-2/USAPart NumbersLogicPressure SwitchesIndex<strong>Specifications</strong>LPS & LPSVAir QualityStandard Shop Air, Lubricated or Dry,40 µm FiltrationDegree of ProtectionIP40 with Molded ConnectorDepilot PressureDifferential less than 25% ofmaximum rangeElectrical ConnectionSpade Connectors or Molded CableFunctionSPDT Contacts (NO or NC)Insulation Voltage Rating250V AC or DCMaterials- Body ............................... Polyamide- Poppet ................................... Acetal- Seals ...................... Nitrile (Buna N)Maximum Operating Frequency2 HzMechanical Life10 Million OperationsMounting2 or 3-Port SubbaseNumber of Operations with Dry Airat 90 PSI and 70°F – Frequency 1 Hz10 MillionOperating PositionsAll PositionsOperating Pressure115 PSIG (8 bar Max.)Rated Current5A (3A with 7097J03711 Cable)TemperatureOperating32°F to 122°F (0°C to +50°C)Storage-22°F to 140°F (-30°C to +60°C)Trip PressureLPS10/2 - 1.5 to 30 PSI (0.1 to 2 barAdjustableLPS10/3 - 10 to 100 PSI (0.7 to 7 barAdjustableALogic<strong>Specifications</strong>LNOTPSAir QualityStandard Shop Air, Lubricated or Dry,40 µm FiltrationCv0.19 (2.4)Degree of ProtectionIP40 with Molded ConnectorDepilot Pressure7% of Supply PressureElectrical ConnectionSpade Connectors or Molded CableFlow rate at 90 PSI (6 bar) in SCFM(l/mn ANR)9.3 (262)FunctionSPDT Contacts (NO or NC)Insulation Voltage Rating250V AC or DCMaterials- Body ............................... Polyamide- Poppet ................................... Acetal- Seals ...................... Nitrile (Buna N)Mechanical Life10 Million OperationsMounting3-Ported SubbaseNumber of Operations with Dry Airat 90 PSI and 70°F – Frequency 1 Hz10 MillionOperating PositionsAll PositionsOperating Pressure40 to115 PSIG (3 to 8 bar)Rated Current5A (3A with 7097J03711 Cable)TemperatureOperating32°F to 122°F (0°C to +50°C)Storage-22°F to 140°F (-30°C to +60°C)Trip Pressure36% of Supply PressureDimensionsLPS10 / LPSV101.00 (25) .16 (4)Locating pin0.112 Dia. x .06 Long2.87 (73)LNOTPS101.00 (25).16 (4)2.87 (73)Locating pin0.112 Dia. x .06 LongSupply(P or 2)Output(S or 3)2131.30 (33)M4.90 (23).23(6)1.30 (33)M4.90 (23).23(6).216 (5).59 (15)Signal(a or 1)AdjustingScrew.216 (5) .59 (15)Supply(a or 1)Pneumatic23Parker Hannifin CorporationPneumatic DivisionRichland, Michigan

Catalog PCC-2/USAPart NumbersLogicPulse UnitsIndexFixed Pulse Unit*Mounts On Any 2-Port Base (3-Port basemay be used if Inlet and Signal Ports areexternally connected or by using LT10/POL Pulse Conversion Kit)Output(S or 3- Red)Fixed Time DurationPart NumberLFPUL10/0.5LFPUL10/1Description0.5 Second PulseProvides a short duration PneumaticPulse when a Pneumatic Signal isapplied.1.0 Second PulseProvides a short duration PneumaticPulse when a Pneumatic Signal isapplied.Signal(P & aor 2 & 1)LogicLFPUL10/1Variable Pulse Unit*Mounts On Any 2-Port Base (3-Port basemay be used if Inlet and Signal Ports areexternally connected or by using LT10/POL Pulse Conversion Kit)Part NumberLPG10/0LPG10/1Description1 to 10 Pulse per SecondProvides continuous pulses which areuser set for pulse frequency.Pulse every 1 to 10 SecondsProvides continuous pulses which areuser set for pulse frequency.Output(S or 3- Red)Signal(P & aor 2 & 1)Variable PulseLPG10/0Pneumatic24Parker Hannifin CorporationPneumatic DivisionRichland, Michigan

Catalog PCC-2/USATechnical InformationLogicPulse UnitsIndex<strong>Specifications</strong>LFPULAir QualityStandard Shop Air, Lubricated or Dry,20 µm FiltrationConnectionsSubbaseCv (kv)0.19 (2.4)Flow rate at 90 PSI (6 bar) in SCFM(l/mn ANR)9.3 (262)Materials- Body ............................... Polyamide- Poppet ................................... Acetal- Seals ...................... Nitrile (Buna N)MountingAll PositionsNumber of Operations with Dry Airat 90 PSI and 70°F – Frequency 1 Hz10 MillionOff TimeLFPUL10/0.5 - 0.5 Secs ±15%LFPUL10/1 - 1.0 Secs ±15%Operating PositionsAll PositionsOperating Pressure30 to 115 PSIG (2 to 8 bar)Reset TimeLFPUL10/0.5 -

Catalog PCC-2/USADimensionsLogicRegulators / Flow ControlIndexAir RegulatorMounts On Any 2 or 3-Port BaseOutput(S or 3- Red)Part NumberPRD3P10DescriptionRegulate Air PressureUnit is Base MountedPressure ControlInput(a or 1-Green)Flow ControlMounts On Any 2 or 3-Port BaseOutput(S or 3- Red)Input(a or 1-Green)Flow ControlPRD3P10Part NumberTR3P10DescriptionFine Adjustable RestrictorFull Reverse Flow(Grey Knob)Course Adjustable RestrictorFR3P10 Full Reverse Flow(Black Knob)Logic<strong>Specifications</strong>Air QualityStandard Shop Air, Lubricated or Dry,40 µm FiltrationControl RangeTR3P10 - 0.002 to 0.1 SCFMFR3P10 - 0.020 to 3.0 SCFMFlow rate at 90 PSI (6 bar) in SCFM(l/mn ANR) - PRD35.2 (147)Flow rate at 90 PSI (6 bar) in SCFM(l/mn ANR) - TRP3, FR3PMax Reverse Flow - 3 SCFMMaterials - PRD3- Body ................Anodized Aluminum- Seals ...................... Nitrile (Buna N)Materials - TRP3, FR3P- Body ............................... Polyamide- Poppet ................................... Acetal- Seals ...................... Nitrile (Buna N)TR3P10Mounting2 or 3-Ported SubbaseOperating PositionsAll PositionsOperating Pressure - PRD3120 PSI (8.5 bar Max.)Operating Pressure - TRP3, FR3P30 to 115 PSI (2 to 8 bar)Pneumatic Characteristics - PRD3120 PSI Maximum Pressure7 to 105 PSI Reduction Range6 SCFM Flow at 85 PSIPort 1 - Not UsedPort 2 - Air SupplyPort 3 - Reduced Output PressurePneumatic Characteristics - TR3P30 to115 PSIG Pressure Range0 to 0.1 Flow at 100 PSIG (Port 1 toPort 3)5 SCFM Max. Reverse Flow (Port 3 toPort 1)Pneumatic Characteristics - FR3P30 to115 PSIG Pressure Range0.2 to 3.0 Flow at 100 PSIG (Port 1 toPort 3)5 SCFM Max. Reverse Flow (Port 3 toPort 1)TemperatureOperating32°F to 122°F (0°C to +50°C)Storage-22°F to 140°F (-30°C to +60°C)DimensionsPRD3P10.95 (24)1.26 (33).95 (24)1.34 (34)Max.Locating pin0.112 Dia. x .06 Long.826 (21)Output (3)M4.905 (23).23(6)PRD3P10, FR3P10.95 (24)1.26 (40).6 Dia. (15)1.56 (40)Locating pin0.112 Dia. x .06 Long.89 (23)M4Output (3).90 (23).23(6)Adjusting KnobLocknut.197 (5)Supply (2).59 (15)Indicator.291 (7,4) .59 (15)Input (1)Pneumatic26Parker Hannifin CorporationPneumatic DivisionRichland, Michigan

Catalog PCC-2/USAPart NumbersLogic3 & 4-Port Modular SubbasesIndexFor Mounting Logic Elements And Relays3-Port SubbasesWith 5/32" Instant Swivel Connections,Pressure Indicators and Integral Lock forStacking4-Port SubbasesWith 5/32" Instant Swivel Connections,Pressure Indicators and Integral Lock forStackingACommon InputPZUA12LogicPZUB12CascadePart NumberPZUB12DescriptionCommon InputPZUC12Part NumberPZUA12PZUC12DescriptionCommon InputCascadeEntry ModuleWith Integral Lock for Stacking<strong>Specifications</strong>MaterialsPolyamide and BrassPorts5/32" Instant for Semi- Rigid Nylon orPolyurethane TubePart NumberPZUE12DimensionsPZUE12DescriptionRelay Entry Module ( Used withPZUA12, PZUB12 and PZUC12 BasesNotes:1. Can be used as individual units or in stackingassemblies.2. May be DIN rail mounted using spring clip or surfacemounted using 2 socket head cap screws.3. PZUA12, PZUB12 and PZUC12 can be mountedtogether in the same assembly.4. Units interconnect with 5/32" Tube. For replacement use1" (25mm), 5/32" semi-rigid nylon or polyurethane.PZUE12, PZUC12, PZUA12A1.58(40)5/32"Instantø.17 (4,2) Thruø.27 (7,0) C' Borex 0.185 (4,7) DeepCBB1.18(30)PZUB12ø.17 (4,2) Thruø.27 (7,0) C' Borex 0.185 (4,7) DeepD.98(25)5/32"Instant1.18(30)inch mmA .55 14B .39 10C .59 15D .47 12E .20 5F .59 15AEClipF.87(22)5/32"Instant.91(23)1.34(34)1.34(34)ClipF.87(22)5/32"Instant1.50(38)Pneumatic27Parker Hannifin CorporationPneumatic DivisionRichland, Michigan

Catalog PCC-2/USAPart NumbersIndependent BasesLogicIndependent SubbasesIndependent 2-Port Pulse BasesIndexBNC3P10BPB3P10BIC3P10BNC3P20BPB3P20BIC7P10Part# ofDescriptionNumberPortsBNC3P10 1/8" NPT, Individual Mount 3BPB3P10 5/32" Instant Fitting*, Machine Mount 3BIC3P10 5/32" Instant Fitting*, DIN Rail Mount 3BIC7P105/32" Instant Swivel Fitting*,DIN Rail Mount for MEM7P105* Use Semi- Rigid Nylon or Polyurethane TubePart NumberDescriptionBNC3P20 1/8" NPT, Port 1 and 2 CommonBPB3P205/32" Instant Fitting*, Machine Mount,Port 1 and 2 Common* Use Semi- Rigid Nylon or Polyurethane Tube<strong>Specifications</strong>MaterialsBIC Units .......................................... Polyamide and BrassBNC Units ........................................................ Plated ZincBPB Units .......................................................... AluminiumLogicDimensionsBNC3P10BNC3P20112 Mtg. holes .17 Dia. thruC'bore .29 Dia. x .19 deep.08 (2).197 (5).63 (16).90 (23)3 PortsTapped 1/8.08 (2).45 (11).197 (5).63 (16).90 (23).216(5)3.59(15)1.00 (25)2 Mtg. holes .17 Dia. thruC'bore .29 Dia. x .19 deep.216(5)33 holes .118 Dia.1 hole .130 Dia. x .138 deep.22(6)21 2.67(17).08 (2).63(16)2 Mtg. holesM4 x 0.7x .236 deep.22(6).08 (2).63(16)21 2.67(17)3.63(16)31.61 (41)3 holes .118 Dia.1 hole .130 Dia. x .138 deep1.61 (41)BPB3P10BPB3P20.24 (6)1.70 (43).24 (6)1.70 (43).44 (11).44 (11).24 Dia.thru typ..45 (11).24 Dia.thru typ..45 (11)325/32Instant1.00 (25) .75 (19) .50 (13)35/32Instant1.00 (25) .75 (19) .50 (13)112.19 (56)2.19 (56)BIC3P103 PortsTapped 1/85/32"Instant(Typ).45 (11)Input 2(Black)Input 1(Green)1.615 (41)1.06 (27)2.677 (68)2 Mtg. holes .18 Dia. thruC'bore .29 Dia. x .14 deepOutput(Red).87 (22).59(15)1.00 (25)2 Mtg. holesM4 x 0.7x .236 deep.71 (18)1.515 (38).63(16)Port 2PluggedBIC7P10Input ‘a’(Green)5/32"Instant(Typ)SupplyPressure(Black)1.00 (25)Input ‘b’(Black)1.575 (40)2.677 (68)3 Mtg. holes .18 Dia. thruC'bore .29 Dia. x .14 deepOutput A(Red)2.95 (75)Input B(Black).87 (22)1.00 (25)Pneumatic28Parker Hannifin CorporationPneumatic DivisionRichland, Michigan

Catalog PCC-2/USAPart NumbersPolylog Manifold Mounting BaseBAC3P10Conversion KitsLT10/PUL<strong>Specifications</strong>MaterialsPolyamide and BrassPortsAll are 5/32" Instant except for supply on BAESP20which is 1/4" Instant. Use Semi- Rigid Nylon orPolyurethane TubeBAC7P10PI•23P10LogicSubbases / Conversion KitsPart NumberBAC3P10*BAESP20BAC7P10*Description3-Port Modular Base,5/32" Instant Swivel Fitting,DIN Rail MountEnd Plate Kit2 Pieces - Supply Base andOutput Base5/32" Instant DIN Rail Base,5-Port Modular BaseFor MEM7P10. Use withBAESP20 End Plates* BAC3P10 and BAC7P10 can be assembled in the same manifoldassemblyPulse Conversion KitPart NumberDescriptionConverts a 3-Port Base intoLT10/PUL a 2-Port Base -Combines Ports P and a or 1 and 2Unit ships with (2) 40mm long screws for use with LTY, LTN, LPG andLFPUL10/0.5. For additional screws, see Spare Parts at the end of thisSection.Port InverterPart NumberPI123P10PI233P10Includes threaded screw extensions.DescriptionInverts Ports 1 or a and 2 or PInverts Ports 2 or P and 3 or SIndexALogicDimensionsBAC3P10BAC7P10LT10/PULInput(Green)2.125 (54)Input(Green)2.125 (54)Output(Red)5/32"Instant(Typ).87 (22)3.12 (79)1.30 (33)Output(Red)1.08(27)5/32"Instant(Typ)1.42 (36)3.12 (79)1.57 (40)1.00 (25)2.76 (7)1.25 (32).94 (24)BAESP201/4"Instant1.00 (25)Input2.13 (54)Output5/32"Instant(Typ)PI123P10, PI223P10.58 (15)1.00 (25)2.24 (57).87 (22).87 (22)3.12 (79)1.08 (27)1.25 (32).94 (24)Pneumatic29Parker Hannifin CorporationPneumatic DivisionRichland, Michigan

Catalog PCC-2/USATechnical InformationLogicLogic ComponentsIndexBase Usage - Shows which components can be mounted with which base types.Base Description / Part NumberType 2-Port 3-Port 4-Port 5-Port 6-PortStacking PZUA12 PZUB12 BAC7P10 PSBA12Element Part No. Stacking PZUC12StackingBAC3P10Inline BNC3P20 BNC3P10 BIC7P10Inline BPB3P20 BPB3P10InlineBIC3P10Step ModuleStep Module w/Overrides PSMA10 XStep Module w/o Overrides PSMB10 XLogicAND PLLC10 XOR PLKC10 XYES PLJC10 XNOT PLNC10 XThreshold NOT PLND10 XRelaysSensor PRFA10 XSolenoid PRSA10 X XSignal Amplifier LFAY10 XElectric Pressure Switch PREA10 X XE/P Pressure Switch LNOTPS10 XElectric Pressure Switch LPS10 X XVacuum/Electric LPSV10 X XPneumatic/Pneumatic LAAY10 XPneumatic/Pneumatic LAAN10 XTimersTimer (NNP) Relay PRTA10 X* XTimer (NNP) Relay PRTB10 X* XTimer (NNP) Relay PRTE10 X* XTimer (NP) Relay PRTC10 X* XTimer (NP) Relay PRTD10 X* XTimer (NP) Relay PRTF10 X* XTimer (NNP) Relay LTY10 X* XTimer (NP) Relay LTN10 X* XOther RelaysMemory Relay PLMA10 XAmplifer Relay PRDA10 XValves4 Way Valve MEM7P10 XPulse GeneratorsPulse Generator Fixed LPG10 X X**Pulse Generator Variable LFPUL X X**AccessoriesAir Pressure Regulator PRD3P10 X XFlow Control (Fine) TR3P10 X XFlow Control (Single Turn) FR3P10 X X* Functionality must be checked** Must be used with LT10/PULPort Label ColorSupply P 2 Black/NoneSignal a 1 GreenOutput S 3 RedEntry End Head /Module Plate TailPZUE12 BAE3SP20 PSEA127Used PZUA12 BAC3P10 PSBA12With PZUC12 BAC7P10Base PZUB12LogicPneumatic30Parker Hannifin CorporationPneumatic DivisionRichland, Michigan

BCatalog PCC-2/USATechnical InformationLogicLogic ComponentsIndex! CAUTION: The logic and relay units shown on the rightcan be improperly assembled to the bases shown on theleft. For proper assembly, the locators shown should beoriented towards port 3 on the subbases.Port 3ABNC3P10BNC3P201LogicPort 3LocatorBPB3P10BPB3P20132Port 3PLLC10PLKC10PLJC10PLNC10PLND10PRFA10LocatorBIC3P10321(Red)Port 3LocatorAC0DFEPRT*10BAC3P10PRSD10(Green)(Green)LocatorBAC3P10(Inverted)Port 3PREA10(Red)Pneumatic31Parker Hannifin CorporationPneumatic DivisionRichland, Michigan

Catalog PCC-2/USAPart NumbersLogicImpulse Counters & Dial TimersIndexWith 5/32" Instant Straight ConnectionsTotalizing CountersPCTa11= 1.5 (38) =1.06(27)==3 x ø .16 (4)ZY3.15 (80)3.94 (100)3.54 (90)ZY==PCTA11 PCTB11Part NumberDescriptionPCTA11 0 to 999,999 Surface Mount0 to 99,999 Panel Mount withPCTB1160 x 50 mm Bezel(Lockable cover available, see below)PCTB11=2 x ø .18 (4.5)=1.5 (38)1.97 (50)=2.07(53)=5/32"instant connections5/32" Instant Connections=1.02(26)=.63(16)ZY==Logic=1.97 (50)2.36 (60)=.35(9)1.28(32.5)2.46(62.5)=1.26(32)=Predetermined CountersPCPA112 x ø .18 (4.5)ZAY0PPart NumberPCPA11PCPA11Description0 to 99,999 Panel Mount with60 x 75 mm Bezel(Lockable cover available, see below)= =2.36 (60)=2.46 (62.5)=2.95 (75).53(13.5)1.28(32.5)2.46(62.5)=2 (51)=ZPYA=== 1.26 =(32)5/32"instant connections.91(23)Lockable CoverPart NumberPXCA1PXCB1DescriptionFor 60 x 50 mm BezelFor 60 x 75 mm BezelPXCA1Timers with Calibrated Dial21M1241M12Part NumberPCMC11PCMD11PCME11Description3 to 100 Seconds, With Reset0.3 to 10 Seconds, With Reset3 to 100 Minutes, With ResetPCMC11PCMC11, PCMD11, PCME112.83 (72)2.83 (72).91(23)1 mini5.04 (128)5.95 (151)2.64 (67)2 45 1 312Pneumatic32Parker Hannifin CorporationPneumatic DivisionRichland, Michigan

Catalog PCC-2/USATechnical InformationLogicImpulse Counters & Dial TimersIndex<strong>Specifications</strong>PCTA PCTB PCPA PCMC, PCMD & PCMEConnectionsStandard: 5/32" Instant for Semi-rigid Tube (Nylon and Polyurethane).IP55 with IP55 withDegree of Protection —Lockable Cover Lockable Cover —Function — —NNPor NPMaximum Operating Frequency 20 Hz with Mark / Space Ratio of 1/1 — —Mechanical Life (Number ofoperations) with Dry Air at 90 PSI 10 Million 10 Millionand 70°F – Frequency 1 HzMounting Surface Mount Panel Mount Panel Mount Panel MountOperating Positions All Positions All Positions All Positions All PositionsOperating Pressure 40 to 130 PSI (3 to 9 bar) 40 to 130 PSI (3 to 9 bar)Operating Temperature 32°F to 140°F (0°C to 60°C) 32°F to 122°F (0°C to +50°C)Pneumatic Reset Time 150 ms 150 ms 150 ms 200 msSetting Accuracy — — — —Storage Temperature -40°F to 160°F (-40°C to 70°C) -22°F to 140°F (-30°C to +60°C)Timing Accuracy — — — ± 2%Type of Air Dry with 40 µm Filtration Dry with 5 µm FiltrationOperating CharacteristicsPCTA11 and PCTB11PCPA11PCMC11, PCMD11 and PCME11NNPCount and display the Number of impluses received.Pulse input at Port Z.Pneumatic reset at Port Y.Supplies a signal at A when the preselected Number of pulses has been reached.The required Number of impulses is preselected using the keys associated with thelower display, which remains unchanged during counting.The pulses to be counted are applied to Port Z. Signal A is given as soon as the twodisplays show the same value.Port Y is used to reset the counter with a single pulse. (1)The required time is preselected directly on the dial, by moving the preselectionpointer to the required position.Timing starts when a signal appears at 12.This signal must be maintained continuously until the output signal appears at 2.Signal 2 is given at the end of the timing period.The output signal is “on delay” if connected to 2 and “off delay” if connected to 4.The timer is reset by breaking the command signal at 12.Units have constant bleed rate of 0.14 SCFM @ 72 PSIG (4Nl/min @ 5 bar)(1) Note: “Output” may not be used as the reset signal.ALogicPneumatic33Parker Hannifin CorporationPneumatic DivisionRichland, Michigan

Catalog PCC-2/USAPart NumbersFor Modular Sequencer and Logic ElementsLogicLogic Processing Spare PartsIndexGaskets For Step Module andInterlock ModulePart BaseNumber Component DescriptionPSMA12PPRL01PSMB12PSVA12PSBA121 Set of 10 Flat GasketsLogicPPRL01Head And Tail ModuleRail Clamping ComponentsPart BaseNumber Component Description1 Set Comprising Of:PPRL09 PSEA12- 20 Hooks- 20 Screws- 20 SpringsPPRL09O-rings For SequencerComponents and CombinableLogic ElementsPPRL11Part BaseNumber Component DescriptionPLEB12PLKB12PLLB12PPRL11PLNB121 Set of 100 O-ringsPSMA12For Use With SubbasesPSMB12PSDA12PSDB12PSBA12Locks & Circuit SelectorsFor Combinable Logic RelaysPPRL06PPRL10Part BaseNumber Component DescriptionPLEB12PPRL06PLKB12PLLB121 Set of 50 Intermodule LocksPLNB12PSMA12 1 Set of 50 Circuit SelectorsPPRL10 PSMB12 For Cascade orPSDA12 “Common Input”Pneumatic34Parker Hannifin CorporationPneumatic DivisionRichland, Michigan

Catalog PCC-2/USAPart NumbersFor Logic Elements, Subbases and RelaysAccessories & Spare PartsLogic Processing Spare PartsIndexO-rings For Subbase MountedLogic RelaysPPRL04Part BaseNumber Component DescriptionPLJC10PLKC10 1 Set of 100 O-rings:PLLC10 - 10 O-rings For PortPPRL04 PLNC10 WithFilterPSND10 - 90 O-rings For PortPRT••• Without FilterPRFA10LTYLTNLAAYLAANLPS1091500/1007 LNOTPS10 1 O-ringTR3P10FR3P10LFPULLPG10PRD3PFlat Gaskets For4-Port SubbasesSubbase Plugs For 3 or 4-PortSubbasesPart BaseNumber Component DescriptionPZUA12PPRL05 PZUB12 1 Set of 50 Subbase PlugsPZUC12Intermodule Locks For 3 or 4-PortSubbasesPart BaseNumber Component DescriptionPZUA12PPRL07 PZUB12 1 Set of 50 Intermodule LocksPZUC12Mylar Diaphragms For AmplifierRelaysPart BaseNumber Component DescriptionPPRL08PRDA10PRDA121 Set of 10 Mylar DiaphragmsNote: To obtain 1 set of 10 Mylar Diaphragms for PRDA10,order 1 of PPRL08.FiltersPPRL05PPRL07ALogicPPRL02Part BaseNumber Component DescriptionPRDA12PPRL02 PLMA12 1 Set of 10 Flat GasketsPZUB12PPRL23Part BaseNumber Component DescriptionPPRL20 PRT•••1 Set of 2050µm Input FiltersPPRL23 PRT•••1 Set of 2050µm FiltersPneumatic35Parker Hannifin CorporationPneumatic DivisionRichland, Michigan

Catalog PCC-2/USAPart NumbersLogicDIN Rail / Replacement ScrewsIndexDIN RailPart NumberAM1DE200Description6 Foot Rail Length.59(15mm)1.38(35mm).06(1.5mm)Base Mounted Component Screws M4 x 0.7 With 7mm Head DiameterLogicPart Screw Replacement For Use WithNumber Element Length Part Number LT10/PULFR3P10 Flow Control 25 mm K05M11040025 —LAAN10 Pneumatic/Pneumatic 45 mm K05M11040045 —LAAY10 Pneumatic/Pneumatic 45 mm K05M11040045 —LFAY10/0 Signal Amplifier 55mm K05M11040055 —LFAY10/1 Signal Amplifier 45 mm K05M11040045 —LFPUL10/0.5 Pulse Generator fixed 30 mm K05M11040030 K05M11040040LFPUL10/1 Pulse Generator fixed 45 mm K05M11040045 K05M11040055LNOTPS10 E/P Pressure Switch 70mm K05M11040070 —LPG10 Pulse Generator Variable 30 mm K05M11040030 K05M11040040LPS10 Electric Pressure Switch 40 mm K05M11040040 —LPSV10 Vacuum/Electric 40 mm K05M11040040 —LTN10 Timer (NP) Relay 30 mm K05M11040030 K05M11040040LTY10 Timer (NNP) Relay 30 mm K05M11040030 K05M11040040MEM7P10 4 Way Valve 40 mm K05M11040040 —PLJC10 YES 31 mm K05M11040032F —PLKC10 OR 31 mm K05M11040032F —PLLC10 AND 31 mm K05M11040032F —PLMA10 Memory Relay 50 mm K05M11040050 —PLNC10 NOT 31 mm K05M11040032F —PLND10 Threshold NOT 31 mm K05M11040032F —PRD3P10 Air Pressure Regulator 22.5 mm K05M11040025 —PRDA10 Amplifer Relay 45 mm K05M11040045 —PREA10 Electric Pressure Switch 12 mm K05M11040012 —PRFA10 Sensor 31 mm K05M11040032F —PRSA10 Solenoid 18 mm K05M11040020 —PRTA10 Timer (NNP) Relay 12 mm K05M11040012 K05M11040020PRTB10 Timer (NNP) Relay 12 mm K05M11040012 K05M11040020PRTC10 Timer (NP) Relay 12 mm K05M11040012 K05M11040020PRTD10 Timer (NP) Relay 12 mm K05M11040012 K05M11040020PRTE10 Timer (NNP) Relay 12 mm K05M11040012 K05M11040020PRTF10 Timer (NP) Relay 12 mm K05M11040012 K05M11040020PSMA10 Step Module w/Overrides 50 mm K05M11040050 —PSMB10 Step Module w/o Overrides 50 mm K05M11040050 —TR3P10 Flow Control 25 mm K05M11040025 —Pneumatic36Parker Hannifin CorporationPneumatic DivisionRichland, Michigan

Catalog PCC-2/USANotesLogicIndexALogicPneumatic37Parker Hannifin CorporationPneumatic DivisionRichland, Michigan

Catalog PCC-2/USANotesLogicIndexLogicPneumatic38Parker Hannifin CorporationPneumatic DivisionRichland, Michigan

Catalog PCC-2/USAIndexPneumatic Control ComponentsMan / Machine DialogIndexBManMan / Machine DialogBasic Features ................................................................................................................ 2-3Part NumbersPush Button Assembly, 22mm (7/8")................................................................................4Push Button Bodies ..........................................................................................................5Operating Heads, 22mm (7/8") ..................................................................................... 6-8Valves ...............................................................................................................................9Visual Indicators 22mm (7/8")......................................................................................... 10Legend Plates ................................................................................................................. 11Rotary Selector Switches, 22mm (7/8").......................................................................... 12Joystick Operators .......................................................................................................... 13Foot Pedal Operated Switches ....................................................................................... 14Two-Hand Controls ......................................................................................................... 15Pneumatic1Parker Hannifin CorporationPneumatic DivisionRichland, Michigan

Catalog PCC-2/USABasic FeaturesMan / Machine DialogPneumatic Push Button & Visual IndicatorsIndexMAN-MACHINE DIALOG requiresdevices such as push buttons andselector switches to provide commandinputs. A wide variety of these devicesis available to meet most applicationneeds. Both pneumatic and electricalswitch bodies are available to matchsystem technology. All of these devicesuse the 22 mm (7/8") mounting standard.PNEUMATIC VISUALINDICATORSManAn indicator ball is rotated by a pneumaticinput, changing the visible color. Theball sits behind a clear plastic window,providing a wide field of view. The visualindicators are available in five brightlycolored Day-Glow paints for increasedvisibility. Like push buttons and selectorswitches, visual indicators use the 22mm(7/8") mounting standard.Unactuated StateActuated StateFOOT PEDALSWITCHESWhen the application requires the use offoot pedals, these devices can be usedto initiate a cycle or a step within a cycle.A metal foot pedal is available withprotective guard.Metal ModelPlastic ModelPneumatic2Parker Hannifin CorporationPneumatic DivisionRichland, Michigan

Catalog PCC-2/USABasic FeaturesMan / Machine DialogPneumatic Push Button & Visual IndicatorsIndexMODULARPNEUMATIC/ELECTRICPUSH BUTTONSAs with electrical contact switches,pneumatic valve modules can bemounted on a number of differentoperating heads.• Pneumatic normally non passing(NNP) is equivalent to electricalnormally open (N.O.).• Pneumatic normally passing (NP) isequivalent to electrical normally closed(N.C.).Note: Electrical switches can be stacked,but the rear connection on pneumaticswitches prevents stacking. Therefore,when mixing electrical and pneumaticswitch bodies on the same operator, thepneumatic switch must be mounted last.P2 Pneumatic ValvesHeavy Duty, 1/8" I.D.Normally Non-PassingPneumatic SwitchStandard DutyDirect Acting1/16" I.D.PS2 Pneumatic ValvesStandard Duty, 1/16"I.D.Normally PassingPneumatic Switch2 Electrical Contacts“N/O”, “N/C”10A Form “C”BManStandardPush ButtonPush ButtonsSpring Return or LatchingMushroom Headed Push ButtonsSelector Switches2 or 3 Positions,Fixed orReturnTo CenterPneumatic3Parker Hannifin CorporationPneumatic DivisionRichland, Michigan

Catalog PCC-2/USAPart NumbersMan / Machine DialogPush Button Assembly, 22mm (7/8")IndexWith 3/2 Valve Bodies5/32" Instant Straight ConnectionsFlush Push ButtonsPart Part Type ofNumber Number Color Function Switching*PXBB1011BA2 PXBB2011BA2 BlackPXBB1011BA3 PXBB2011BA3 Green Spring Return NNPPXBB1011BA4 PXBB2011BA4 RedPXBB1121BA2 PXBB2121BA2 Black Spring Return NNP+NPPXBB1011BA2PXBB2011BA2Mushroom Head Push Buttons(40mm Diameter)PXBB1021BT4PXBB2021BT4Part Part Type ofNumber Number Color Function Switching*PXBB1011BC2 PXBB2011BC2 BlackPXBB1011BC4 PXBB2011BC4 RedSpring Return NNPPXBB1011BT4 PXBB2011BT4 Red Push-Pull NNPPXBB1021BT4 PXBB2021BT4 Red Push-Pull NPPXBB1121BT4 PXBB2121BT4 Red Push-Pull NNP+NPManSelector SwitchesPXBB1121BD2PXBB2121BD2Part Part Type ofNumber Number Color Function Switching*PXBB1011BD2 PXBB2011BD2 Black 2 Maintained NNPPXBB1111BD2 PXBB2111BD2 Black Positions with NNP+NNPPXBB1121BD2 PXBB2121BD2 Black Std. Handle NNP+NPPXBB1111BD3 PXBB2111BD3 Black3 Maintained NNP+NNPPositions withPXBB1121BD3 PXBB2121BD3 Black Std. Handle NNP+NPPXBB1111BJ5 PXBB2111BJ5 Black3 Positions,Spring Return NNP+NNPPXBB1221BJ5 PXBB2221BJ5 Blackto Center withLong HandleNNP+NP* NNP: Normally Non-Passing.NP: Normally Passing.NNP + NNP: Double Switch Body, Both Normally Non-Passing.NNP + NP: Normally Non passing and Normally-Passing.NP + NP: Both Normally Passing.MountingPneumatic4Parker Hannifin CorporationPneumatic DivisionRichland, Michigan

Catalog PCC-2/USAPart NumbersMan / Machine DialogPush Button BodiesIndexFor Use With 22mm (7/8") Operating Heads5/32" Instant Connections3/2 Valve Bodies withMounting Ring Part PartNumber NumberType ofConnections Function1/16" ID 1/8" ID Switching*Body BodyPXBB1011 PXBB2011 5/32" Instant 3/2 NNPPXBB1021 PXBB2021 5/32" Instant 3/2 NPPXBB1011PXBB1021BPXBB2011PXBB2021Additional Valve BodiesPXBB1911 PXBB1922 PXBB2911AccessoriesPart PartNumber NumberType ofConnections Func.1/16" ID 1/8" ID Switching*Body BodyPXBB1911 PXBB2911 5/32" Instant StraightPXBB1912 — 5/32" Instant Swivel 3/2 NNPPXBB1915 PXBB2915 10-32 UNF ThreadedPXBB1921 PXBB2921 5/32" Instant StraightPXBB1922 — 5/32" Instant Swivel 3/2 NPPXBB1925 PXBB2925 10-32 UNF ThreadedPXBB1911SE — 5/32" Instant Straight NNP2/2PXBB1921SE — 5/32" Instant Swivel NPManZB2BE101Electrical Switch BodiesWhen combined with pneumatic these contact blocks allowdifferent forms of power to be vided from asingle pushbutton. Can be mounted with both types ofvalves PXBB1•• and PXBB2••Electrical Specification: 240V, 10AmpPartType ofNumberContactZB2BE101Normally Open (NO)ZB2BE1016 (Gold Leaf) †ZB2BE102Normally Closed (NC)ZB2BE1026 (Gold Leaf) †† For Low VoltagePneumatic5ZB2BZ009Mounting Ring for Valve Bodies, Switch Bodies andOperating HeadsTo make up a complete pushbutton with one or twoswitching elements with 5/32" instant connections,use this mounting block and select the operatingheads and bodies in this Section.PartNumberZB2BZ009* NNP: Normally Non-Passing.NP: Normally Passing.Parker Hannifin CorporationPneumatic DivisionRichland, Michigan

Catalog PCC-2/USAPart NumbersMan / Machine DialogOperating Heads, 22mm (7/8")IndexFor Use With PXBB Valve Bodies and ZB2BE Electrical Switch BodiesUsing ZB2BZ009 Mounting RingPush Buttons1.13(29)ZB2BA21.13(29)ZB2BL31.13(29).50.38.63(13)(10)(16)Flush Extended BootedPartNumber Color Function DescriptionZB2BA2 BlackZB2BA3 GreenZB2BA4 Red Spring Return FlushZB2BA5 YellowZB2BA6 BlueZB2BL2 BlackZB2BL3 GreenZB2BL4 RedSpring Return ExtendedZB2BL5 YellowZB2BP2 BlackZB2BP3 Green Spring Return BootedZB2BP4 RedMushroom Head Push ButtonsSpringReturnZB2BC41.25(32)1.50(38)1.38(35)ZB2BR22.38(60)Push /PullPartNumber Color Function DescriptionZB2BC2 BlackZB2BC3 Green Spring ReturnZB2BC4 Red Ø 40mm HeadZB2BT2 Black LatchingZB2BT4 Red Push-PullZB2BR2 BlackZB2BR3 Green Spring ReturnZB2BR4 Red Ø 60mm HeadZB2BX2 Black LatchingZB2BX4 Red Push-PullManMushroom Head Push Buttonswith Key Sellect1.38(35)2.38(60)ZB2BS24Mounting Accessories.157 (4)Dia.2.17(55)3 (76)Dia.1.50(38)ZB2BZ19PartNumber Color Function DescriptionZB2BS54 RedLatchingTurn to Release Ø 40mm HeadZB2BS14 RedKeyLatchingZB2BS64 RedLatchingTurn to Release Ø 60mm HeadZB2BS24 RedKeyLatchingPartNumber Color DescriptionZB2BZ19 Black PlasticGuard for 60mmMushroom HeadsZB2BZ41 —Adapter for Mounting 22mmDevice in 30mm OpeningZB2SZ3 Black Plastic Blanking Plate for 7/8" Dia.Pneumatic6Parker Hannifin CorporationPneumatic DivisionRichland, Michigan

Catalog PCC-2/USAPart NumbersMan / Machine DialogOperating Heads, 22mm (7/8")IndexFor Use With PXBB Variable Composition Switch BodiesSelector SwitchesStandard Black HandlePartNumber Description FunctionZB2BD2MaintainedZB2BD3 ZB2BJ31.06(27)1.13(29)Standard Selector.94(24)1.06(27)Knob Lever1.50(38)ZB2BD4Spring Return2-Positionsfrom Right to LeftZB2BD3MaintainedZB2BD5Spring Return to Center 3-Positionsfrom Left and RightMaintained RightZB2BD7 Spring Return from 3-PositionsLeft to CenterMaintained LeftZB2BD8 Spring Return from 3-PositionsRight to CenterLong Black HandleZB2BJ2MaintainedZB2BJ4Spring Return2-Positionsfrom Right to LeftZB2BJ3MaintainedZB2BJ5Spring Return to Center 3-Positionsfrom Left and RightBManKey Operated Selectors1.19(30)1.13(29).88(22)ZB2BG7Key OperatedPartNumber Key Withdrawal FunctionZB2BG2 Left 2 MaintainedZB2BG4 Left and Right PositionsZB2BG3 Center 3 MaintainedZB2BG5 Left and Right Positions3 PositionsZB2BG7 Center 2 Spring Returnto CenterPneumatic7Parker Hannifin CorporationPneumatic DivisionRichland, Michigan

Catalog PCC-2/USATechnical InformationMan / Machine Dialog<strong>Specifications</strong> & DimensionsIndex<strong>Specifications</strong>Air QualityStandard Shop Air, Lubricated or Dry,40 µm FiltrationFlow at 90 PSI (6 bar)in SCFM (l/mn ANR)PXBB1• ................................. 1.8 (50)PXBB2• ............................... 8.5 (240)MaterialsBody .................................. PolyamideOperating Head ... Zinc Alloy & PlasticNominal Bore Ø in Inches (mm)PXBB1• ............................. 1/16" (1.5)PXBB2• .................................. 1/8" (3)Number of Operations withDry Air at 90 PSI (6 bar) and68°F (20°C) - Frequency 1 Hz1 million Operations. Mushroom Head= 300,000 OperationsOperating PositionsAll PositionsOperating PressurePXBB1• - 15 to 115 PSIG (1 to 8 bar)PXBB2• - 40 to 115 PSIG (3 to 8 bar)PortsStandard: 5/32" Instant for Semi-Rigid Nylon or Polyurethane Tube10-32 UNF AvailableTemperatureOperating32°F to 122°F (0°C to + 50°C)Storage-22°F to 140°F (-30°C to +60°C)Operator <strong>Specifications</strong>Maximum Travel (B)at 90 PSIG (6 bar)Minimum Pre-Travel (A)at 90 PSIG (6 bar)Minimum Operating Forceat 90 PSI (6 bar)Operating DiagramMushroom Head Spring Return Mushroom Head Latching Spring ReturnPush Buttons PXBB Push Buttons PXBB Push Buttons PXBB3/16" (4.8 mm) 3/16" (4.8 mm) 3/16" (4.8 mm)7/64" (3 mm) 9/64" (3.5 mm) 7/64" (3 mm)4.0 lb (18 N) 11.2 lb(50 N) 2.9 lb (13 N)ManRestOperationABMaximum TravelDimensionsPXBB1●●●1.58 (40).06 to .25(1.5 to 6)* 1.69 (43)* Bending radius5/8" minimum1.18(30)ø.89 (22.5)**1.58(40)Minimumdistancebetweencenters** Mounting width1.18" (30 mm)PXBB2●●●PXBB2912, PXBB2922 ZB2BE10●with straight connections with swivel connections1.58 (40)*.06 to .25(1.5 to 6)2.52 (64)1.73 (44).55(14).06 to .25 (1.5 to 6)1.58 (40)1.69 (43)Pneumatic8Parker Hannifin CorporationPneumatic DivisionRichland, Michigan

Catalog PCC-2/USAPart NumbersMan / Machine DialogManual ValvesIndexLow Operating ForcePush Button ValvePart Button Type ofNumber Color Description Switching*Designed to reducestraining injuriesVLF3P4-302 Green associated with NNPrepetitive operations.Built-in guard to preventaccidental operation.VLF3P4-302<strong>Specifications</strong>Dimensions2.93 (74).53(13).67 (17)1.64 (42).95 (24) 1.26 (32)1.57 (40)Miniature Pilot ValvesM30 x 1.5Thread1.77 (45)1.57(40)Hole Dia.1.20 (30.5)+.05-0Air Bleed0.085 SCFMAir QualityStandard Shop Air, Lubricated or Dry, 40 µm FiltrationFlow @ 100 PSI10.6 SCFMMaterialsBody ......................................... AcetalMounting Ring .......................... AcetalOperating Force Required4.5 ozOperating Pressure29 to 115 PSI (2 to 8 bar)Ports5/32" Instant for Semi-Rigid Nylon or Polyurethane TubeTemperature RatingOperating32°F to 122°F (0°C to + 50°C)Storage-22°F to 140°F (-30°C to +60°C)PartType ofNumber Connection Actuator Switching*CBP101 5/32" InstantCBP501 10-32 UNFPush Button NNPCBL101 5/32" InstantCBL501 10-32 UNFToggle Lever NNPBMan<strong>Specifications</strong>CBP101Dimensions2.30 (58)CBP1011.32 (34)41.71 (18).79 (20) Dia..48 (12)ExhaustOutletSupplyCBL1011.32 (34) 1.52 (39).2 (5)CBL10160°411.22 (31)2.40 (61).48 (12)ExhaustOutletSupply2.84 (72)Air QualityStandard Shop Air, Lubricated or Dry, 40 µm FiltrationFlow @ 80 PSI10 SCFM / .14CvMaterialsBody ............................................ ZincOperator ............................ PolyamideOperating Pressure0 to 115 PSIG (0 to 8 bar)Ports5/32" Instant for Semi-Rigid Nylon or Polyurethane TubeTemperature RatingOperating32°F to 122°F (0°C to + 50°C)Storage-22°F to 140°F (-30°C to +60°C)* NNP: Normally Non-Passing.Pneumatic9Parker Hannifin CorporationPneumatic DivisionRichland, Michigan

Catalog PCC-2/USAPart NumbersMan / Machine DialogVisual Indicators, 22mm (7/8")IndexWith 5/32" Instant Connections22mm Visual IndicatorsPXVF131Black Plastic BezelPart Number Part Number“ON” Indicator “OFF” Indicator ColorPXVF131 PXVF1213 GreenPXVF141 PXVF1214 RedPXVF151 PXVF1215 YellowPXVF161 PXVF1216 BluePXVF111 PXVF1211 WhiteNotes:The Pneumatic Indicators are black in one position andcolored in the other. The colored position correspondseither to the presence of a pressure (“ON” Indicator) or theabsence of pressure (“OFF” Indicator).ManMounting<strong>Specifications</strong>Air QualityStandard Shop Air, Lubricated or Dry,40µm FiltrationMaterialsBody: .................................. PolyamideOperating Head: ... Zinc Alloy & PlasticNumber of Operations withDry Air at 90 PSI (6 bar) and68°F (20°C) - Frequency 1 Hz1 million Operations.Mushroom Head= 300,000 OperationsOperating PositionsAll PositionsOperating Pressure15 to 115 PSIG (1 to 8 bar)PortsStandard: 5/32" Instant for Semi-Rigid Nylon or Polyurethane Tube10-32 UNF Available.TemperatureOperating32°F to 122°F (0°C to + 50°C)Storage-22°F to 140°F (-30°C to +60°C)DimensionsPXVF1●●.06 to .25(1.5 to 6)ø.89 (22.5)1.10(28)1.58(40)Minimum distancebetween centers2.09 (53).63(16)1.18(30)Pneumatic10Parker Hannifin CorporationPneumatic DivisionRichland, Michigan

Catalog PCC-2/USAPart NumbersMan / Machine DialogLegend PlatesIndexFor Push Buttons and Visual IndicatorsLegend Plates for PXBB Devices(22mm)Legend Plates for PXBB Devices(22mm)ZB2BY●●●●Part NumberDescriptionWithout Text For Customer EngravingZB2BY2101 Black / Red Background (White Letters)ZB2BY4101 Yellow / White Background (Black Letters)With Text For Push ButtonsZB2BY2303StartZB2BY2304StopZB2BY2305ForwardZB2BY2306ReverseZB2BY2307UpZB2BY2308DownZB2BY2309RightZB2BY2310LeftZB2BY2311OnZB2BY2312OffZB2BY2313OpenZB2BY2314CloseZB2BY2321InchZB2BY2323ResetZB2BY2326Power onZB2BY2327SlowZB2BY2328FastZB2BY2330Emergency stopZB2BY2334RunZB2BY2335RaiseZB2BY2336LowZB2BY2337LowerZB2BY2338HighZB2BY2339OutZB2BY2380Jog RevZB2BY2381Jog ForZB2BY2503InPart NumberBlank Legend Plates forInscriptionFor PXBB Devices (2 lines of 11 characters maximum)Please indicate the required text when ordering.(Allow 3 weeks for delivery)Part NumberDescriptionZB2BY2002 Black Background / White LettersBlank Legend PlatesPart NumberZB2BY5101DescriptionWith Text For 2-Position SelectorsZB2BY2362 Stop StartZB2BY2365 Run JogZB2BY2367 Off OnZB2BY2369 High LowZB2BY2370 Up DownZB2BY2371 For RevZB2BY2372 Manual AutoZB2BY2376 Open CloseWith Text For 3-Position SelectorsZB2BY2384 For O RevZB2BY2387 Hand Off AutoZB2BY2388 Open O CloseZB2BY2389 Up O DownWith Text For Mushroom Head OperatorZB2BY8330 Emergency Stop (90mm round)DescriptionRectangular for Mushroom HeadBManPneumatic11Parker Hannifin CorporationPneumatic DivisionRichland, Michigan