thermoforming - McElroy Metal

thermoforming - McElroy Metal

thermoforming - McElroy Metal

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

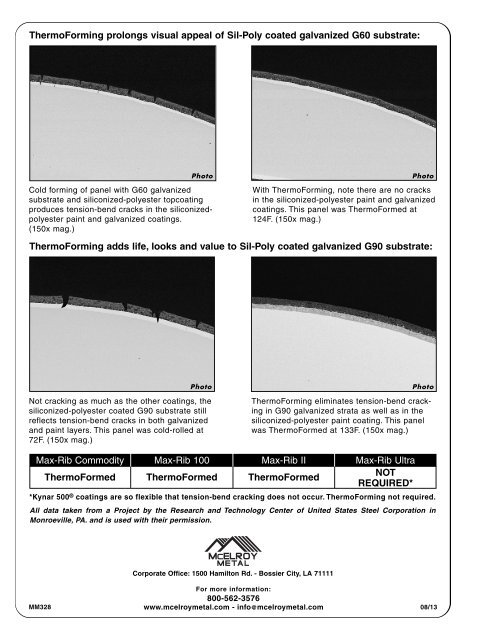

ThermoForming prolongs visual appeal of Sil-Poly coated galvanized G60 substrate:PhotoCold forming of panel with G60 galvanizedsubstrate and siliconized-polyester topcoatingproduces tension-bend cracks in the siliconizedpolyesterpaint and galvanized coatings.(150x mag.)PhotoWith ThermoForming, note there are no cracksin the siliconized-polyester paint and galvanizedcoatings. This panel was ThermoFormed at124F. (150x mag.)ThermoForming adds life, looks and value to Sil-Poly coated galvanized G90 substrate:PhotoNot cracking as much as the other coatings, thesiliconized-polyester coated G90 substrate stillreflects tension-bend cracks in both galvanizedand paint layers. This panel was cold-rolled at72F. (150x mag.)PhotoThermoForming eliminates tension-bend crackingin G90 galvanized strata as well as in thesiliconized-polyester paint coating. This panelwas ThermoFormed at 133F. (150x mag.)Max-Rib CommodityThermoFormedMax-Rib 100ThermoFormedMax-Rib IIThermoFormedMax-Rib UltraNOTREQUIRED**Kynar 500 ® coatings are so flexible that tension-bend cracking does not occur. ThermoForming not required.All data taken from a Project by the Research and Technology Center of United States Steel Corporation inMonroeville, PA. and is used with their permission.Corporate Office: 1500 Hamilton Rd. - Bossier City, LA 71111For more information:800-562-3576MM328 www.mcelroymetal.com - info@mcelroymetal.com08/13