Phoenix

Phoenix

Phoenix

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

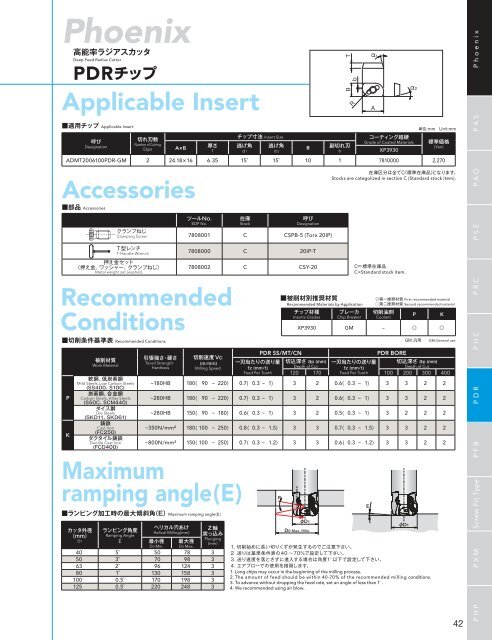

<strong>Phoenix</strong>Deep Feed Radius CutterPDRApplicable InsertApplicable InsertDesignationNumber of CuttingEdgesA×BTInsert Size12RbGrade of Coated MaterialsADMT2006100PDR-GM 2 24.18×16 6.35 15˚ 15˚ 10 1 7810000 2,270AccessoriesAccessories XP3930 (Yen)Stocks are categolized in section C (Standard stock item).<strong>Phoenix</strong>PASPAOClamping ScrewT-Handle WrenchEDP No.StockDesignation7808001 C CSPB-5 (Torx 20IP)7808000 C 20IP-TPSE Metal weight set (washer)RecommendedConditionsRecommended ConditionsPKWork MaterialMild SteelsLow Carbon SteelsCarbon SteelsAlloy SteelsDie SteelsCast IronDuctile Cast IronTensil StrengthHardness7808002 C CSY-20 Milling SpeedMaximum ramping angle(E)D1Ramping AngleE C=Standard stock item.PDR SS/MT/CNPDR BOREDepth of CutDepth of CutFeed Per Tooth 120 170 Feed Per Tooth 100 200 300 400~180HB 180( 90 ~ 220) 0.7( 0.3 ~ 1) 3 2 0.6( 0.3 ~ 1) 3 3 2 2~280HB 180( 90 ~ 220) 0.7( 0.3 ~ 1) 3 2 0.6( 0.3 ~ 1) 3 3 2 2~280HB 150( 90 ~ 180) 0.6( 0.3 ~ 1) 3 2 0.5( 0.3 ~ 1) 3 2 2 2~350N/mm² 180( 100 ~ 250) 0.8 ( 0.3 ~ 1.5) 3 3 0.7( 0.3 ~ 1.5) 3 3 2 2~800N/mm² 150( 100 ~ 250) 0.7( 0.3 ~ 1.2) 3 3 0.6 ( 0.3 ~ 1.2) 3 3 2 2Maximumramping angle(E)Helical Milling(mm)D0 Min.D0 Max.Plunging(mm)40 5˚ 50 78 350 3˚ 70 98 363 2˚ 96 124 380 1˚ 130 158 3100 0.5˚ 170 198 3125 0.5˚ 220 248 3PRecommended Materials by ApplicationInserts GradesD1D0 Max./Min.Chip BreakerEFirst recommended materialSecond recommended materialP KCoolantXP3930 GM D1 GM:General use 1. Long chips may occur in the beginning of the milling process.2. The amount of feed should be within 40-70% of the recommended milling conditions.3. To advance without dropping the feed rate, set an angle of less than 1˚ .4. We recommended using air blow.PXM Screw Fit Type PFBPDRPHCPRC42PHP