Phoenix

Phoenix

Phoenix

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

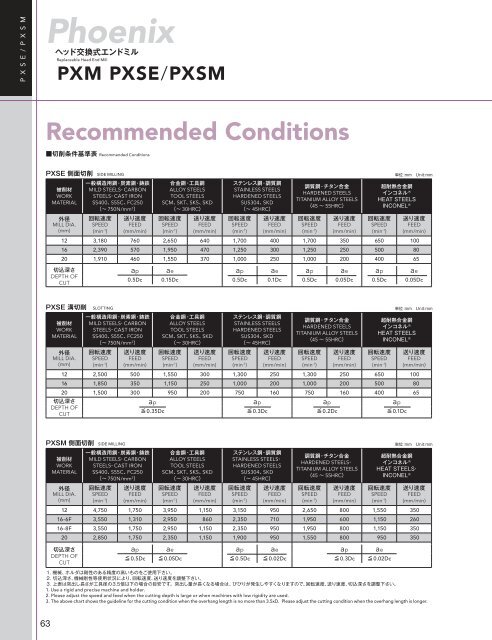

PXSE/PXSM<strong>Phoenix</strong>Replaceable Head End MillPXM PXSE/PXSMRecommended ConditionsRecommended ConditionsSIDE MILLINGWORKMATERIALMILL DIA.(mm)MILD STEELSCARBONSTEELSCAST IRONSS400 S55C FC250 750N/mm 2 SPEED(min -1 )FEED(mm/min)ALLOY STEELSTOOL STEELSSCM SKT SKS SKD 30HRCSPEED(min -1 )FEED(mm/min)STAINLESS STEELSHARDENED STEELSSUS304 SKD 45HRCSPEED(min -1 )FEED(mm/min)HARDENED STEELSTITANIUM ALLOY STEELS45 55HRCSPEED(min -1 )FEED(mm/min) SPEED(min -1 )FEED(mm/min)12 3,180 760 2,650 640 1,700 400 1,700 350 650 10016 2,390 570 1,950 470 1,250 300 1,250 250 500 8020 1,910 460 1,550 370 1,000 250 1,000 200 400 65DEPTH OFCUTap ae ap ae ap ae ap ae0.5Dc 0.15Dc 0.5Dc 0.1Dc 0.5Dc 0.05Dc 0.5Dc 0.05DcSLOTTINGWORKMATERIALMILL DIA.(mm)MILD STEELSCARBONSTEELSCAST IRONSS400 S55C FC250 750N/mm 2 SPEED(min -1 )FEED(mm/min)ALLOY STEELSTOOL STEELSSCM SKT SKS SKD 30HRCSPEED(min -1 )FEED(mm/min)STAINLESS STEELSHARDENED STEELSSUS304 SKD 45HRCSPEED(min -1 )FEED(mm/min)HARDENED STEELSTITANIUM ALLOY STEELS45 55HRCSPEED(min -1 )FEED(mm/min) SPEED(min -1 )FEED(mm/min)12 2,500 500 1,550 300 1,300 250 1,300 250 650 10016 1,850 350 1,150 250 1,000 200 1,000 200 500 8020 1,500 300 950 200 750 160 750 160 400 65ap ap ap apDEPTH OFCUT0.35Dc 0.3Dc 0.2Dc 0.1DcSIDE MILLINGWORKMATERIALMILL DIA.(mm)MILD STEELSCARBONSTEELSCAST IRONSS400 S55C FC250 750N/mm 2 SPEED(min -1 )FEED(mm/min)ALLOY STEELSTOOL STEELSSCM SKT SKS SKD 30HRCSPEED(min -1 )FEED(mm/min)STAINLESS STEELSHARDENED STEELSSUS304 SKD 45HRCSPEED(min -1 )FEED(mm/min)HARDENED STEELSTITANIUM ALLOY STEELS45 55HRCSPEED(min -1 )FEED(mm/min) SPEED(min -1 )FEED(mm/min)12 4,750 1,750 3,950 1,150 3,150 950 2,650 800 1,550 35016-6F 3,550 1,310 2,950 860 2,350 710 1,950 600 1,150 26016-8F 3,550 1,750 2,950 1,150 2,350 950 1,950 800 1,150 35020 2,850 1,750 2,350 1,150 1,900 950 1,550 800 950 350DEPTH OFCUTap ae ap ae ap ae0.5Dc 0.05Dc 0.5Dc 0.02Dc 0.3Dc 0.02Dc1. Use a rigid and precise machine and holder.2. Please adjust the speed and feed when the cutting depth is large or when machines with low rigidity are used.3. The above chart shows the guideline for the cutting condition when the overhang length is no more than 3.5xD. Please adjust the cutting condition when the overhang length is longer.63