Phoenix

Phoenix

Phoenix

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

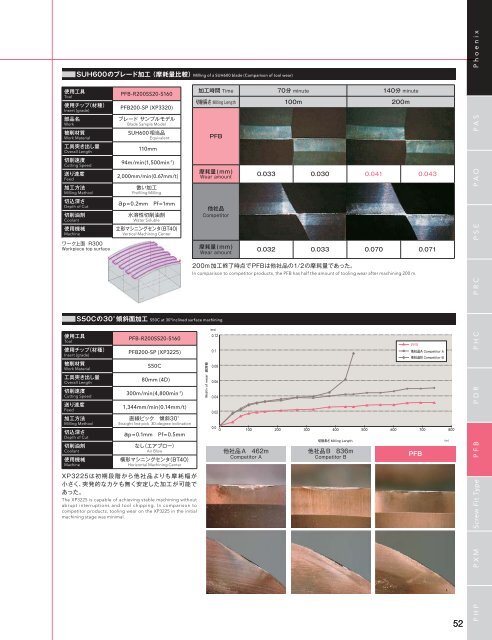

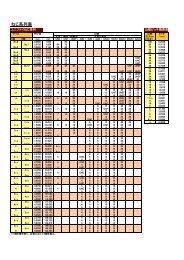

Milling of a SUH600 blade (Comparison of tool wear)ToolInsert (grade)PFB-R200SS20-S160PFB200-SP(XP3320) WorkWork MaterialBlade Sample ModelSUH600 EquivalentPASOverall Length110mmCutting SpeedFeedMilling Method94m/min(1,500min -1 )2,000mm/min(0.67mm/t)Profi ling Milling PAODepth of CutCoolantap=0.2mmPf=1mmWater SolubleMachineVertical Machining Center PSE In comparison to competitor products, the PFB has half the amount of tooling wear after machining 200 m.S50C at 30°inclined surface machiningToolInsert (grade)Work MaterialPFB-R200SS20-S160PFB200-SP (XP3225)S50C0.120.10.08PHCOverall LengthCutting SpeedFeedMilling MethodDepth of CutCoolantMachine80mm (4D)300m/min(4,800min -1 )1,344mm/min(0.14mm/t)Straight line pick 30-degree inclinationap=0.1mmPf=0.5mmAir BlowHorizontal Machining Center0.060.040.020.00 100 200 300 400 500 600700800 The XP3225 is capable of achieving stable machining withoutabrupt interruptions and tool chipping. In comparison tocompetitor products, tooling wear on the XP3225 in the initialmachining stage was minimal.PXMPRC<strong>Phoenix</strong>PDRPFBScrew Fit Type52PHP