NOxBOXi Operating Instructions - Bedfont Scientific

NOxBOXi Operating Instructions - Bedfont Scientific

NOxBOXi Operating Instructions - Bedfont Scientific

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

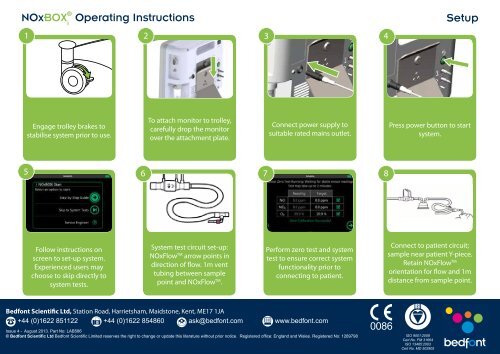

®NOxBOX i<strong>Operating</strong> <strong>Instructions</strong>1 2 3Cylinder setup4Engage trolley brakes tostabilise system prior tochanging cylinder.Check cylinder concentrationmatches the setting for thesystem.Load cylinders onto trolley.Secure with straps.Check regulator surfacesare damage free. Do not usedamaged equipment.56 78Attach regulator to cylinder.Screw firmly by hand. Attachsupply line to regulator.Perform a leak test: open the cylinder valve Apply then supply close. line to port onObserve gauge for rear 30 of monitorseconds, needle should remain sta>onary. Slowly open cylinder valve.Read gauge. If needle in redzone, replace cylinder beforestarting treatment.Perform a leak test: open thecylinder valve then close.Observe gauge for 30seconds, needle shouldremain stationary.Re-open cylinder.2www.bedfont.com

®NOxBOX i<strong>Operating</strong> <strong>Instructions</strong>System tests1 2 3 4The system automaticallyruns the zero test. Nospecial connectionsrequired.System test circuit set-up:NOxFlow arrow points indirection of flow. 1m venttubing between samplepoint and NOxFlow.Connect O 2supply toNOxFlow TM inlet. Set O 2flowto 10 L/min. Press “Next” onsystem screen to run test.System test takes approx.5 minutes to run. This purgesNO2 and ensures correctNOxBOX ioperation.5 6 7 8System test takes approx.5 minutes to run. This purgesNO 2and ensures correctNOxBOX ioperation.System test failed. Check:NOxFlow orientation; O 2flow at 10 L/min, NO cylinderconnected and valve open.Re-run test.If not using in next 10 mins:Prevent NO 2forming. Turnoff NO, disconnect supplylines, depressurise system.Connect to patient circuit.Enter dose and check alarmlevels before commencingtreatment.3www.bedfont.com

®NOxBOX i<strong>Operating</strong> <strong>Instructions</strong>1 2 3Ventilator connections4The NOxFlow TM is singlepatient use. Unwrap andcarefully uncoil the lines.Push and click-to-lock twinsensor line to unit.Twist dose line luer to unit.Patient sample line is singlepatient use. Unwrap andconnect female luer to watertrap inlet on unit.Select a vent connector withluer port from the NOXKIT TM .Connect the male luer of thesample line.5NOxFlow TM is situated in the inspiratory limb, before thehumidifier.The sample line is situated in the inspiratory limb just priorto the patient Y-piece. A non-return valve should be placedbetween the sample point and the patient Y-piece toprevent back-flow affecting the monitored readings.NOxFlow should be approx. 1 metre back from the samplepoint. Ideal range 0.7 m – 1.3 m.For system test, high frequency and manual bagging circuitdiagrams please refer to Technical Guide.4www.bedfont.com

®NOxBOX i<strong>Operating</strong> <strong>Instructions</strong>Dose setting & main screen featuresTo set or change dose press ‘editdose’ . The NOxBOX iwill thenguide you through setting thedose and high/low alarms. Onceconfirmed the delivery andmonitoring will adjustaccordingly.Maximum dose - 60ppmMinimum dose - 0.1ppmThe navigation tabs access the alarm history and user settings screens.Alarm history: shows last 10 alarms for current treatment. Openalarms are listed at the top.User settings: change user settings, access Emergency Overridecalculator, Sensor Zero and Service Engineer area.5www.bedfont.com

®NOxBOX i<strong>Operating</strong> <strong>Instructions</strong>1 23 4Cylinder replacementEngage trolley brakes tostabilise system prior tochanging cylinder.Fully close cylinder valve.Detach hose from monitor anddepressurise on purge needle.Remove regulator from emptycylinder.5678Remove empty cylinder fromtrolley and replace with newsupply cylinder. Check theconcentration matches thevalue displayed on-screen.Attach regulator to newcylinder.Perform a leak test slowly.Perform a leak test: open the cylinder valveOpen thenthe close.cylindervalve thenclose. Observe gauge for 30Observe gauge for 30 seconds, needle should remainseconds, needle should stationary.remain sta>onary. Purge pressure from hose,then reconnect the hose toinlet port monitor. Open valveon cylinder fully.6www.bedfont.com

®NOxBOX i<strong>Operating</strong> <strong>Instructions</strong>Shutdown12 3 4When ready to shutdownthe system, briefly press thepower button on themonitor .Confirm on-screen thatshutdown is required. Followon-screen instructions.Fully close each cylinder anddepressurise the supply linesusing the purge needle.Remove regulator fromeach cylinder and stow onsystem trolley.5 6 78Remove all single patientuse devices from monitorand dispose of according tolocal regulations.Drain water trap and disposeof drainage syringe. Cleaninside water trap withinstrument wipes priorto storage.On completion of lastinstruction screen, systemwill purge and shutdownsafely ready for storage.Remove power supply andstore on trolley for transport.Ensure system is attached tosuitable mains supply whilstin storage.7www.bedfont.com

®NOxBOX i<strong>Operating</strong> <strong>Instructions</strong>High alarmsAlarmNO LowNO HighAction<strong>NOxBOXi</strong> delivery system cannot maintain correct dose setting.Check sample line is correctly attached to ventilator circuit, the <strong>NOxBOXi</strong> inlet and is free from leakages.Ensure no ventilator circuit breaks or leakages have occurred.<strong>NOxBOXi</strong> delivery system cannot maintain the correct dose setting.Ensure the NO supply cylinder concentration matches the system settings. If possible, change the NO supply cylinder for thecorrect concentration. If not, call Service Engineer.Check no ventilator stagnation has occurred that may cause build up of NO concentration due to lack of ventilator flow.NO2 HighO2 LowWater Trap FullMonitored levels of NO2 gas being delivered to the patient have risen above the alarm setting boundary.NO2 is extremely toxic and poses risk to patient health. High NO dose settings on low ventilator flows may cause higher NO2build-up. Increase ventilator bias flow to help reduce stagnation in delivery circuit.Monitored levels of O2 gas being delivered to the patient have fallen below the alarm setting boundary.The NO gas added to the ventilator circuit will dilute the O2 levels. High NO doses using low cylinder concentration (400 ppm)will create a larger dilution to O2 % v/v. Adjust O2 settings at the ventilator to compensate.Water trap is filled with condensate from sample line. If allowed to overflow this will damage the <strong>NOxBOXi</strong> sensors.Use disposable male luer lock syringe to empty fluid from water trap via the self-sealing drain located at the bottom of thewater trap. Dispose of entire syringe and contents according to local directives.Sample Line BlockVisually inspect sample line for any crush, pinch or knots along length and remedy if present. If none visible, replace sample lineas internal blockage may have occurred.Battery Critical<strong>NOxBOXi</strong> is running on battery and the charge level is low. System power failure imminent. Reconnect <strong>NOxBOXi</strong> to mainspower. If unable to do so, set-up Emergency Override and prepare to engage. Prepare a second system to continue treatment.NO Supply CriticalNO gas supply is running low and no alternative supply cylinder is detected by the system.Install a new gas cylinder supply and connect to the alternate gas inlet port at rear of <strong>NOxBOXi</strong>. If already installed, ensurecylinder valve is open to continue supply.Vent Flow IdleNOxFlow has not detected any ventilator flow for over 30 seconds. Ensure NOxFlow is correctly orientated in inspiratory limb,green arrow points to patient. Ensure NOxFlow twin sensor line is correctly inserted and locked to <strong>NOxBOXi</strong> socket.8www.bedfont.com

®NOxBOX i<strong>Operating</strong> <strong>Instructions</strong>Medium alarmsAlarmCylinder LowActionAppears when two cylinders are attached to system, but one is detected to have low pressure.Check regulator gauge to confirm cylinder fill pressure. If in red zone, close cylinder valve, remove supply line from unit andpurge pressure on purge needle at rear of unit.Ensure pressure gauge reads “zero” before removing regulator from cylinder by hand.Stow regulator and supply line on system trolley.Replace cylinder with a new cylinder.Zero CalibrationSystem needs a zero calibration performed once every 24 hours during use. System prompts user when this is due.Zero calibration takes approximately 2 minutes during which monitoring is offline, delivery remains unaffected.Only perform when dose delivery and vent settings are stable.High Calibration OverdueFor best operational function, the <strong>NOxBOXi</strong> requires a high calibration for the gas sensors once every 30 days. This is to beperformed by a qualified Systems Engineer.If calibration is allowed to lapse, the system will remind user during use.To resolve, the system sensors must be calibrated by the appointed Systems Engineer using calibration gases.Sensor calibration may be performed whilst the system is in use, however <strong>Bedfont</strong> strongly recommend that the sensorcalibrations are performed as part of routine maintenance in a systems engineering lab to minimise risk to the patient.Each sensor calibration will take approx. 3 minutes to run. During this time, patient gas monitoring is offline, but delivery willremain unaffected.Only perform in use when dose delivery and vent settings are in a stable condition.Do not alter ventilator settings during the calibration period.<strong>Bedfont</strong> reccomend that environmental monitoring is used at all times with <strong>NOxBOXi</strong>.9www.bedfont.com

NO400ppm®NOxBOX i<strong>Operating</strong> <strong>Instructions</strong>Emergency override1 2 3A65AB1423If Emergency Override is required:First check suitable flow rate is set.Then engage mode selection valve to theposition seen on right hand side image.B651423Using On-screen CalculatorAccess the emergencyoverride calculator fromSettings.4 5NO400ppmAdjust vent flow to bestmatch patient settings. Tabledisplays approx. dose pervalve setting.To set flow rateNOTE: all dose information for the EmergencyOverride are approximations. Monitoring mustbe used to ensure the patient is receiving thecorrect dose.Use the look-up tables inthis guide. To set flow rate,find the table matching NOsupply concentration.Find the vent flow setting tobest match patient settings.The column lists the approx.dose per valve setting.10www.bedfont.com

®NOxBOX i<strong>Operating</strong> <strong>Instructions</strong>Cylinder Concentration (ppm)Flow Valve SettingMinute Flow VolumeDose look-up table 1000ppm,800ppm & 600ppmWARNING: Dose >40 ppmDose over 20 ppm1000 Vent Flow (L/Min)Dial 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 5.5 6 6.5 7 7.5 8 8.5 9 9.5 10 10.5 11 11.5 12 12.5 13 13.5 14 14.5 15 15.5 16 16.5 17 17.5 18 18.5 19 19.5 201 180 99 68 52 42 35 30 27 24 22 20 18 17 15 14 14 13 12 11 11 10 10 9 9 9 8 8 8 8 7 7 7 7 6 6 6 6 6 6 52 231 130 91 70 57 48 41 36 32 29 27 24 23 21 20 18 17 16 16 15 14 13 13 12 12 11 11 11 10 10 10 9 9 9 8 8 8 8 8 73 286 167 118 91 74 63 54 48 43 38 35 32 30 28 26 24 23 22 21 20 19 18 17 16 16 15 15 14 14 13 13 12 12 12 11 11 11 10 10 104 338 203 145 113 93 78 68 60 54 49 44 41 38 35 33 31 29 28 26 25 24 23 22 21 20 19 19 18 17 17 16 16 15 15 14 14 14 13 13 135 379 234 169 132 109 92 80 71 63 57 53 48 45 42 39 37 35 33 31 30 28 27 26 25 24 23 22 21 21 20 19 19 18 18 17 17 16 16 15 156 459 298 221 175 145 124 108 96 86 78 72 66 61 57 54 50 48 45 43 41 39 37 36 34 33 32 31 29 28 28 27 26 25 24 24 23 22 22 21 21800 Vent Flow (L/Min)Dial 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 5.5 6 6.5 7 7.5 8 8.5 9 9.5 10 10.5 11 11.5 12 12.5 13 13.5 14 14.5 15 15.5 16 16.5 17 17.5 18 18.5 19 19.5 201 144 79 55 42 34 28 24 21 19 17 16 14 13 12 12 11 10 10 9 9 8 8 8 7 7 7 6 6 6 6 6 5 5 5 5 5 5 5 4 42 185 104 73 56 45 38 33 29 26 23 21 20 18 17 16 15 14 13 12 12 11 11 10 10 9 9 9 8 8 8 8 7 7 7 7 7 6 6 6 63 229 133 94 73 59 50 43 38 34 31 28 26 24 22 21 20 18 17 16 16 15 14 14 13 13 12 12 11 11 11 10 10 10 9 9 9 9 8 8 84 270 163 116 90 74 63 54 48 43 39 35 33 30 28 26 25 23 22 21 20 19 18 17 17 16 15 15 14 14 13 13 13 12 12 11 11 11 11 10 105 303 187 135 106 87 74 64 57 51 46 42 39 36 33 31 29 28 26 25 24 23 22 21 20 19 18 18 17 16 16 15 15 15 14 14 13 13 13 12 126 368 239 177 140 116 99 87 77 69 63 57 53 49 46 43 40 38 36 34 33 31 30 29 27 26 25 24 24 23 22 21 21 20 20 19 18 18 18 17 17600 Vent Flow (L/Min)Dial 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 5.5 6 6.5 7 7.5 8 8.5 9 9.5 10 10.5 11 11.5 12 12.5 13 13.5 14 14.5 15 15.5 16 16.5 17 17.5 18 18.5 19 19.5 201 108 59 41 31 25 21 18 16 14 13 12 11 10 9 9 8 8 7 7 7 6 6 6 5 5 5 5 5 5 4 4 4 4 4 4 4 4 3 3 32 138 78 55 42 34 29 25 22 19 17 16 15 14 13 12 11 10 10 9 9 8 8 8 7 7 7 7 6 6 6 6 6 5 5 5 5 5 5 5 43 171 100 71 55 44 38 32 29 26 23 21 19 18 17 16 15 14 13 12 12 11 11 10 10 9 9 9 8 8 8 8 7 7 7 7 7 6 6 6 64 203 122 87 68 56 47 41 36 32 29 27 24 23 21 20 19 17 17 16 15 14 14 13 12 12 12 11 11 10 10 10 9 9 9 9 8 8 8 8 85 227 140 101 79 65 55 48 43 38 34 32 29 27 25 23 22 21 20 19 18 17 16 16 15 14 14 13 13 12 12 12 11 11 11 10 10 10 9 9 96 276 179 132 105 87 74 65 58 52 47 43 40 37 34 32 30 29 27 26 24 23 22 21 21 20 19 18 18 17 17 16 16 15 15 14 14 13 13 13 12All dose information shown in these tables is for guidance only. The patient monitored gas levels should be used for actual dose delivery information.All nitric oxide (NO) doses shown in parts per million (ppm) when introduced to continuous flow rates indicated.Doses of NO above 40 ppm are not recommended. Doses above 20 ppm are considered clinically high.11www.bedfont.com

®NOxBOX i<strong>Operating</strong> <strong>Instructions</strong>Dose look-up table 500ppm, 400ppm, 300ppm & 200ppmCylinder Concentration (ppm)Flow Valve SettingMinute Flow VolumeWARNING: Dose >40 ppmDose over 20 ppm500 Vent Flow (L/Min)Dial 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 5.5 6 6.5 7 7.5 8 8.5 9 9.5 10 10.5 11 11.5 12 12.5 13 13.5 14 14.5 15 15.5 16 16.5 17 17.5 18 18.5 19 19.5 201 90 50 34 26 21 18 15 13 12 11 10 9 8 8 7 7 6 6 6 5 5 5 5 5 4 4 4 4 4 4 4 3 3 3 3 3 3 3 3 32 115 65 45 35 28 24 21 18 16 15 13 12 11 10 10 9 9 8 8 7 7 7 6 6 6 6 5 5 5 5 5 5 5 4 4 4 4 4 4 43 143 83 59 45 37 31 27 24 21 19 18 16 15 14 13 12 11 11 10 10 9 9 9 8 8 8 7 7 7 7 6 6 6 6 6 5 5 5 5 54 169 102 73 57 46 39 34 30 27 24 22 20 19 18 16 15 15 14 13 12 12 11 11 10 10 10 9 9 9 8 8 8 8 7 7 7 7 7 6 65 189 117 84 66 54 46 40 35 32 29 26 24 22 21 20 18 17 16 16 15 14 13 13 12 12 11 11 11 10 10 10 9 9 9 9 8 8 8 8 86 230 149 110 88 73 62 54 48 43 39 36 33 31 29 27 25 24 23 21 20 19 19 18 17 16 16 15 15 14 14 13 13 13 12 12 12 11 11 11 10400 Vent Flow (L/Min)Dial 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 5.5 6 6.5 7 7.5 8 8.5 9 9.5 10 10.5 11 11.5 12 12.5 13 13.5 14 14.5 15 15.5 16 16.5 17 17.5 18 18.5 19 19.5 201 72 40 27 21 17 14 12 11 10 9 8 7 7 6 6 5 5 5 5 4 4 4 4 4 3 3 3 3 3 3 3 3 3 3 2 2 2 2 2 22 92 52 36 28 23 19 16 14 13 12 11 10 9 8 8 7 7 7 6 6 6 5 5 5 5 5 4 4 4 4 4 4 4 3 3 3 3 3 3 33 114 67 47 36 30 25 22 19 17 15 14 13 12 11 10 10 9 9 8 8 7 7 7 7 6 6 6 6 5 5 5 5 5 5 5 4 4 4 4 44 135 81 58 45 37 31 27 24 21 19 18 16 15 14 13 12 12 11 10 10 9 9 9 8 8 8 7 7 7 7 6 6 6 6 6 6 5 5 5 55 152 93 68 53 43 37 32 28 25 23 21 19 18 17 16 15 14 13 12 12 11 11 10 10 10 9 9 9 8 8 8 7 7 7 7 7 6 6 6 66 184 119 88 70 58 50 43 38 35 31 29 26 25 23 21 20 19 18 17 16 16 15 14 14 13 13 12 12 11 11 11 10 10 10 9 9 9 9 9 8300 Vent Flow (L/Min)Dial 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 5.5 6 6.5 7 7.5 8 8.5 9 9.5 10 10.5 11 11.5 12 12.5 13 13.5 14 14.5 15 15.5 16 16.5 17 17.5 18 18.5 19 19.5 201 54 30 20 16 13 11 9 8 7 6 6 5 5 5 4 4 4 4 3 3 3 3 3 3 3 3 2 2 2 2 2 2 2 2 2 2 2 2 2 22 69 39 27 21 17 14 12 11 10 9 8 7 7 6 6 6 5 5 5 4 4 4 4 4 4 3 3 3 3 3 3 3 3 3 3 2 2 2 2 23 86 50 35 27 22 19 16 14 13 12 11 10 9 8 8 7 7 7 6 6 6 5 5 5 5 5 4 4 4 4 4 4 4 3 3 3 3 3 3 34 101 61 44 34 28 24 20 18 16 15 13 12 11 11 10 9 9 8 8 7 7 7 7 6 6 6 6 5 5 5 5 5 5 4 4 4 4 4 4 45 114 70 51 40 33 28 24 21 19 17 16 15 13 13 12 11 10 10 9 9 8 8 8 7 7 7 7 6 6 6 6 6 5 5 5 5 5 5 5 56 138 89 66 53 44 37 32 29 26 24 22 20 18 17 16 15 14 14 13 12 12 11 11 10 10 9 9 9 9 8 8 8 8 7 7 7 7 7 6 6200 Vent Flow (L/Min)Dial 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 5.5 6 6.5 7 7.5 8 8.5 9 9.5 10 10.5 11 11.5 12 12.5 13 13.5 14 14.5 15 15.5 16 16.5 17 17.5 18 18.5 19 19.5 201 36 20 14 10 8 7 6 5 5 4 4 4 3 3 3 3 3 2 2 2 2 2 2 2 2 2 2 2 2 1 1 1 1 1 1 1 1 1 1 12 46 26 18 14 11 10 8 7 6 6 5 5 5 4 4 4 3 3 3 3 3 3 3 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 13 57 33 24 18 15 13 11 10 9 8 7 6 6 6 5 5 5 4 4 4 4 4 3 3 3 3 3 3 3 3 3 2 2 2 2 2 2 2 2 24 68 41 29 23 19 16 14 12 11 10 9 8 8 7 7 6 6 6 5 5 5 5 4 4 4 4 4 4 3 3 3 3 3 3 3 3 3 3 3 35 76 47 34 26 22 18 16 14 13 11 11 10 9 8 8 7 7 7 6 6 6 5 5 5 5 5 4 4 4 4 4 4 4 4 3 3 3 3 3 36 92 60 44 35 29 25 22 19 17 16 14 13 12 11 11 10 10 9 9 8 8 7 7 7 7 6 6 6 6 6 5 5 5 5 5 5 4 4 4 4All dose information shown in these tables is for guidance only. The patient monitored gas levels should be used for actual dose delivery information.All nitric oxide (NO) doses shown in parts per million (ppm) when introduced to continuous flow rates indicated.Doses of NO above 40 ppm are not recommended. Doses above 20 ppm are considered clinically high.12www.bedfont.com