Stora Enso Annual Report 2011 - Rethink Volume 2 - Innovation ...

Stora Enso Annual Report 2011 - Rethink Volume 2 - Innovation ...

Stora Enso Annual Report 2011 - Rethink Volume 2 - Innovation ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

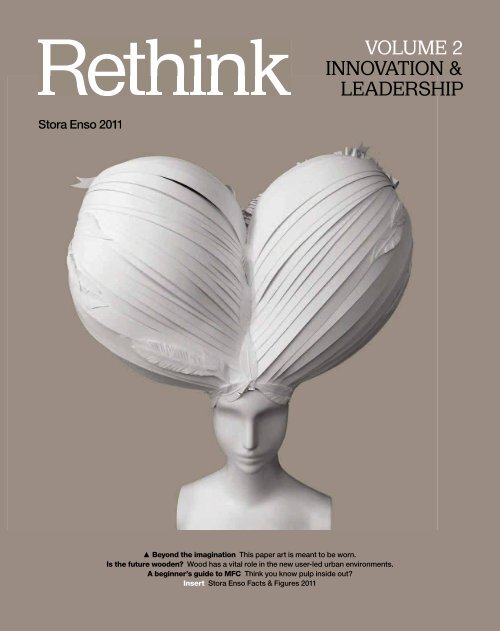

<strong>Rethink</strong> LEADERSHIP<br />

<strong>Stora</strong> <strong>Enso</strong> <strong>2011</strong><br />

VOLUME 2<br />

INNOVATION &<br />

LEADERSHIP<br />

Beyond the imagination This paper art is meant to be worn.<br />

Is the future wooden? Wood has a vital role in the new user-led urban environments.<br />

A beginner’s guide to MFC Think you know pulp inside out?<br />

Insert <strong>Stora</strong> <strong>Enso</strong> Facts & Figures <strong>2011</strong>

Certified<br />

excellence.<br />

This annual report has been printed on LumiArt and LumiSilk art printing papers. The Lumi product family is developed<br />

for applications that require exceptionally high quality in text printing and image reproduction. In art print business,<br />

Lumi translates to excellence in all languages.<br />

The Lumi products have been awarded with the EU Ecolabel – the most prominent environmental accolade in Europe.<br />

This accolade joins Forest Stewardship Council’s (FSC) and Programme for the Endorsement of Forest Certification<br />

Scheme’s (PEFC) environmental accolades, which had already been awarded to Lumi. The Lumi products are rethinking<br />

the business in terms of sustainability and quality.<br />

Image from the<br />

LUMI PHOTOGRAPHIC<br />

ART AWARDS<br />

by honorary award winner<br />

Wawi Navarroza<br />

From the series “Dominion”<br />

rethink<br />

Editorial Jump the curve 4<br />

Phenomenon Recycling the city 6<br />

News <strong>Innovation</strong> and inspiration 8<br />

Rewind Regards from Langerbrugge Mill 11<br />

From juice carton to car parts 12<br />

Time to wake up 18<br />

Agile and future-focused 22<br />

Interview Beyond the imagination 24<br />

A beginner’s guide to MFC 26<br />

Rewind Bomb clearance work continues 29<br />

LeADersHIP<br />

Leadership 3.0 30<br />

New paths ahead 33<br />

Building the backbone of leadership 34<br />

The way forward 36<br />

Column More than words 37<br />

Milk power! 38<br />

Gallup What was your way of rethinking during <strong>2011</strong>? 41<br />

Is the future wooden? 42<br />

Passion for safety 48<br />

Safety fi rst Towards zero accidents 51<br />

Unique recipe 52<br />

Living in the year 2030 56<br />

Phenomenon Wanderer of the seas 58<br />

Fresh perspectives 66<br />

A new beginning 68<br />

Uruguay diary 72<br />

Point of view Five insights to creative packaging 74<br />

Insert <strong>Stora</strong> <strong>Enso</strong> Facts & Figures <strong>2011</strong><br />

Cover stock: LumiArt 170 g/m 2 <strong>Stora</strong> <strong>Enso</strong>, Oulu Mill (ISO 14001 certi ed)<br />

Text stock: LumiArt 115 g/m 2 and LumiSilk 100 g/m 2 <strong>Stora</strong> <strong>Enso</strong>, Oulu Mill (ISO 14001 certi ed)<br />

From juice carton to car parts<br />

A new life begins for Spanish beverage cartons<br />

after dropping them in the recycling bin. 12<br />

unique recipe<br />

PrimaPress has become the fi rst true uncoated<br />

alternative to coated magazine papers. 52<br />

It should be noted that certain statements herein which are not historical facts, including, without limitation those regarding expectations for market growth and<br />

developments; expectations for growth and pro tability; and statements preceded by “believes”, “expects”, “anticipates”, “foresees”, or similar expressions, are forwardlooking<br />

statements within the meaning of the United States Private Securities Litigation Reform Act of 1995. Since these statements are based on current plans, estimates<br />

and projections, they involve risks and uncertainties, which may cause actual results to materially differ from those expressed in such forward-looking statements. Such<br />

factors include, but are not limited to: (1) operating factors such as continued success of manufacturing activities and the achievement of ef ciencies therein, continued<br />

InsTITuTo bALeIA JubArTe<br />

success of product development, acceptance of new products or services by the Group’s targeted customers, success of the existing and future collaboration<br />

arrangements, changes in business strategy or development plans or targets, changes in the degree of protection created by the Group’s patents and other intellectual<br />

property rights, the availability of capital on acceptable terms; (2) industry conditions, such as strength Wanderer of product demand, of intensity the of seas competition, prevailing and future<br />

global market prices for the Group’s products and the pricing pressures thereto, price uctuations in raw materials, nancial condition of the customers and the competitors<br />

of the Group, the potential introduction of competing products and technologies by competitors; and Pulp (3) general barges economic evade conditions, humpback such whales as rates as of economic they each growth<br />

in the Group’s principal geographic markets or uctuations in exchange and interest rates.<br />

year migrate to reproduce in the Brazilian coast. 58<br />

<strong>Stora</strong> <strong>Enso</strong> <strong>Rethink</strong> <strong>2011</strong><br />

Editor-in-chief Lauri Peltola<br />

Concept & design Miltton Oy<br />

Printing Libris Oy<br />

Cover photo Courtesy of Paper-Cut-Project<br />

<strong>Stora</strong> <strong>Enso</strong> Oyj P.O. Box 309, FI-00101 Helsinki, Finland<br />

Visiting address Kanavaranta 1, tel. +358 2046 131<br />

<strong>Stora</strong> <strong>Enso</strong> AB Box 70395, SE-107 24 Stockholm, Sweden<br />

Visiting address World Trade Center, Klarabergsviadukten 70, tel. +46 1046 46000<br />

storaenso.com, group.communications@storaenso.com<br />

DAnIeL LoeWe<br />

LAsse ArVIDson<br />

VoLume 2<br />

InnoVATIon &<br />

LeADersHIP<br />

<strong>Stora</strong> <strong>Enso</strong>—3

Editorial<br />

Jump the curve<br />

JennI-JusTIInA nIemI<br />

CEO Jouko Karvinen<br />

challenges every one<br />

of us to rethink.<br />

4—<strong>Rethink</strong><br />

Dear reader of <strong>Rethink</strong> <strong>2011</strong>, thank you for taking<br />

the time to read this magazine.<br />

Another exciting, challenging year is behind<br />

us. For us at <strong>Stora</strong> <strong>Enso</strong>, it was first and<br />

foremost another year of learning! What, then, did<br />

we learn?<br />

Firstly, we were reminded that, even if we<br />

think we have changed a lot and done a lot in<br />

<strong>Stora</strong> <strong>Enso</strong> in the past few years, we must wake<br />

up every morning ready to start fresh. The past<br />

does not matter. Whether it is the obvious and<br />

severe weakness of most European economies<br />

that we will face for the foreseeable future or the<br />

digital transformation that is not just forecasted<br />

but already has changed our markets and more<br />

importantly the consumer markets we serve<br />

together with our customers, there is no time to<br />

rest.<br />

I<br />

believe the report for last year is mixed. Operationally,<br />

we were able to respond early to the<br />

first signals of a turn to the weaker in our markets,<br />

spearheaded by the Fine Paper May structural<br />

cost improvement programme and followed<br />

by others with capacity curtailments, cost<br />

controlling efforts and inventory controls. And to<br />

be frank with you, I am not that happy about our<br />

working capital performance in <strong>2011</strong> – we can<br />

and must do better. At the same time, each day<br />

we must <strong>Rethink</strong> how we improve our costs, our<br />

flexibility and our demand chain. We are not there<br />

yet – we have just started our journey.<br />

In the early days of 2012, we changed our<br />

Business Area structure and renamed the<br />

areas. Our underlying thought was and is to<br />

simplify, focus, clarify responsibilities and make<br />

everyone focus on external customers rather than<br />

internally divided captive supply chains.<br />

We have started a global Biomaterials<br />

Business Area, a business that most<br />

long-time industry insiders call Pulp but which for<br />

us means the promise of many new ideas beyond<br />

traditional paper and board raw material markets.<br />

The extraordinary efforts to complete our joint<br />

venture Montes del Plata in 2013 – with thousands<br />

of people working at the Punta Pereira site in<br />

Uruguay to build something that we, our partner<br />

Arauco and the local community can be proud<br />

of – is obviously at the top of this agenda. In the<br />

future, though, there is more to come. Whether it<br />

is nanotechnology innovations on top of what we<br />

already have in Micro Fibrillated Cellulose (MFC)<br />

or something else that will make a difference, a<br />

real difference is what I have asked this team to<br />

deliver.<br />

Packaging, now Renewable Packaging, the<br />

one area that tends to be the easiest to<br />

explain, is also perhaps the most challenging of<br />

our businesses. Selected packaging segments<br />

are growing at 25% a year in the markets we<br />

call growth markets – not emerging markets, for<br />

example, with 1.5 billion more consumers in 2020<br />

wanting renewably and cost-efficiently packaged<br />

food and liquid. That is a race we want to win.<br />

When one third or in some countries half of the<br />

food produced gets thrown away every day, I am<br />

sure you agree there is a true need to improve. The<br />

business case is strong. We, not only us at <strong>Stora</strong><br />

<strong>Enso</strong> but also you, the reader, have to get serious<br />

about the 100 million tonnes of plastics going<br />

into landfills and oceans every year. We may not<br />

worry about it but our children do, and rightfully<br />

so. There is today a floating garbage island in the<br />

I strongly believe Asia will not<br />

follow the West, but has instead<br />

already jumped the curve!<br />

Pacific called the Pacific Plastic Ocean. We do not<br />

want to leave that to our kids, do we?<br />

In the Building and Living Business Area,<br />

formerly Wood Products, we have the same<br />

logic: if we do good for the consumer, it will<br />

do good for all of our stakeholders. Is this just<br />

dreaming? Absolutely not. The first proof point,<br />

now followed by several others across Europe,<br />

is an eight-storey building based on cross<br />

laminated timber (CLT) in Hackney in London UK.<br />

You might say meeting the costs of traditional<br />

concrete or even clearly beating the construction<br />

time of a concrete equivalent is not such a big<br />

deal. But how about being able to build twice the<br />

number of storeys due to close to 50% weight<br />

reduction? Or if that is not so important, how<br />

about – as estimated by the Centre of Sustainable<br />

development at Cambridge University – the<br />

expectation that, with the carbon sink benefit<br />

<strong>Stora</strong> <strong>Enso</strong> CLT offers, this building can be<br />

heated and lit for 29 years with the positive CO2 impact alone. I say, “very cool”. What do you say?<br />

And your kids?<br />

The paper business is now called Printing<br />

and Reading to signal that our focus is again<br />

on the ultimate market, the consumer. Several<br />

other changes which have already taken place in<br />

the consumer behaviour of news consumption,<br />

mobile eMedia, demographics and social media<br />

have impacted the North American and European<br />

markets for the past ten years. I strongly believe<br />

Asia will not follow the West but has instead<br />

already jumped the curve! And yet you see many<br />

people arguing whether the change will happen<br />

or not. It will not because it already did. We feel<br />

we are up to the challenge to win in that scenario<br />

too. It will be different, economies of scale and<br />

size will mean a lot less, and winning and keeping<br />

customer loyalty – as already demonstrated<br />

by <strong>Rethink</strong> and measured by our Net Promoter<br />

Score – will mean so much more.<br />

We have repeatedly faced criticism on<br />

how local communities experience our<br />

development actions, and interestingly enough<br />

most of the critics seem to come from the<br />

Nordics. I find it really sad, especially as I have<br />

had the honour myself to visit, talk with and listen<br />

to such local people. I hope that some of the<br />

articles in this magazine will open a few more<br />

eyes to the positive impact of what we do. And it<br />

is by doing, not talking, that we will continue to<br />

improve further and demonstrate to all stakeholders<br />

that we are there to stay and we are also<br />

there to share value with the local communities.<br />

Not perfect, never perfect, but learning every day.<br />

Let me finish with an issue that is personal<br />

and crucial to all of us at <strong>Stora</strong> <strong>Enso</strong>. Many of<br />

our colleagues work with large machines, heavy<br />

products and difficult environments. With that we<br />

have had for years, even with safety training and<br />

equipment, way too many accidents, even fatal<br />

ones. That we must change and can change, and<br />

you can read how in the enclosed article from<br />

one of our colleagues at Arapoti Mill, who has<br />

demonstrated how 347 people can operate more<br />

than four years with zero accidents. And that is<br />

the goal we all must now have, not a percentage<br />

reduction, but zero. I am sure we all want to go,<br />

and want our colleagues to go, back home to<br />

their families healthy. Every day of the year.<br />

Dear reader, jump to the future with us!<br />

<strong>Stora</strong> <strong>Enso</strong>—5

Phenomenon<br />

Recycling the city<br />

Every hour some 10 000 Chinese citizens<br />

permanently relocate from rural areas to cities.<br />

Of all the emerging economies, it is China that<br />

is becoming urbanised at the quickest pace.<br />

By 2020, the number of Chinese urban dwellers<br />

is estimated to increase to 800 million. By that<br />

time, China is also expected to have become the<br />

world’s biggest economy.<br />

Urbanisation forces China to develop its<br />

infrastructure in a new way. Life that is resettled<br />

to urban areas, together with the strong<br />

economic boost, means modern lifestyles,<br />

growing consumption and increased amounts<br />

of litter. Food is brought home daily in billions<br />

of packages. Luckily, fully recyclable and<br />

biodegradable alternatives for food packages are<br />

available in increasing quantities.<br />

These alternatives benefit both the Chinese<br />

and the whole planet.<br />

CorbIs<br />

6—<strong>Rethink</strong><br />

<strong>Stora</strong> <strong>Enso</strong>—7

news<br />

Compiled by Niina Streng<br />

80 million<br />

euro is the amount<br />

that <strong>Stora</strong> <strong>Enso</strong> spent<br />

on research and<br />

development in <strong>2011</strong>.<br />

sTorA enso<br />

Meet InnoMould<br />

Think about a yoghurt or dessert pot. Like many similar products, it is for the<br />

most part made of polypropylene. The purpose of the pot is to protect the<br />

content and be attractive. Pots made of <strong>Stora</strong> <strong>Enso</strong>’s InnoMould paper do all<br />

this and more, while reducing the amount of non-renewable material used for<br />

packaging.<br />

“InnoMould is a new product innovation in paper that makes plastic<br />

containers lighter and eco-friendlier by replacing the plastic fi lm label with<br />

a paper label,” says Eckhard Kallies, who is responsible for the sales of<br />

<strong>Stora</strong> <strong>Enso</strong>’s Speciality Papers.<br />

The potential of InnoMould paper is enormous, as it is suitable for all polypropylene<br />

packages that are produced using the injection moulding process<br />

– meaning millions of packages every day. Replacing plastic fi lm labels that<br />

contain brand and product information with InnoMould paper reduces the<br />

use of fossil-based material while also making the package stiffer. Thanks to<br />

the improved strength properties, the walls of the pots can be produced with<br />

up to 50% less material.<br />

Outstanding printing results are a further important benefi t, making<br />

InnoMould ideal for creating the kind of realistic visuals that catch<br />

consumers’ attention.<br />

8—<strong>Rethink</strong><br />

sTorA enso<br />

Say no to toxic wood<br />

Did you know that until now the most used type of<br />

wood with long-term outdoor durability has been<br />

hazardous to nature? <strong>Stora</strong> <strong>Enso</strong> Building and<br />

Living has developed a new wood modifi cation<br />

method that enables good longevity outdoors,<br />

but in a safe, non-toxic and eco-friendly way. The<br />

new treatment, called Q-Treat, makes wood hard,<br />

fi re-resistant, decay-resistant and weatherproof.<br />

The characteristics of the treated wood make<br />

Q-Treat products ideal for garden and outdoor use,<br />

for example cladding, decking, marine docks and<br />

piers, children’s playground equipment, outdoor<br />

light poles, fences, electricity poles – and even for<br />

under the railroad tracks. The treated wood can<br />

also be used to manufacture beautiful solid wood<br />

fl ooring, panelling and fi re-safe staircases for the<br />

interiors of buildings and homes.<br />

The Q-Treat wood products will be available for<br />

sale in spring 2012.<br />

storaenso.com/buildingandliving<br />

our papers<br />

in three clicks<br />

<strong>Stora</strong> <strong>Enso</strong>’s web pages will offer easier<br />

access to the company’s fi ne papers’<br />

sales representatives, sustainability<br />

issues and certifi cates from summer<br />

2012 onwards.<br />

storaenso.com/printingandreading<br />

Tracking the water footprint<br />

Water scarcity is beginning to rival climate<br />

change as an issue of global concern. The<br />

concept of a product’s water footprint was<br />

originally developed for agriculture to examine<br />

how much water is consumed during all stages of<br />

the production of foodstuffs. Consumers are also<br />

becoming interested in the water footprints of<br />

packaging materials.<br />

<strong>Stora</strong> <strong>Enso</strong>’s Skoghall Mill in Sweden has<br />

started to trace the water footprint of its liquid<br />

packaging board using a methodology devised<br />

by the Water Footprint Network. The fi rst water<br />

footprint study, prepared in collaboration with the<br />

Alliance for Beverage Cartons and the WWF, was<br />

published in <strong>2011</strong>.<br />

Read more about the water footprint study in<br />

<strong>Stora</strong> <strong>Enso</strong>’s Global Responsibility stakeholder<br />

magazine on storaenso.com.<br />

sHuTTersToCk<br />

LAsse ArVIDson<br />

Taking over<br />

the supply chain<br />

news<br />

1 100<br />

is the number of<br />

patents <strong>Stora</strong> <strong>Enso</strong><br />

has in total.<br />

<strong>Stora</strong> <strong>Enso</strong> is strengthening its leading position in<br />

corrugated packaging in Central and Eastern Europe<br />

by renewing containerboard capacity at Ostrołęka<br />

Mill in Poland. The production of high-performance<br />

containerboard with the new recycled fi bre-based<br />

containerboard machine is expected to begin early in<br />

2013.<br />

The company will take a more active role in the<br />

whole supply chain of corrugated packaging, starting<br />

from the collection of recovered fi bres. “The present<br />

collection rate is only at around 40% in Poland,<br />

so there is a lot of potential to increase collection.<br />

With this investment, we can competitively secure<br />

a containerboard fl ow to <strong>Stora</strong> <strong>Enso</strong>’s corrugated<br />

packaging units,” explains Anna-Maria Tuominen-<br />

Reini, who is responsible for Supply Chain and<br />

Business Development in Corrugated Packaging.<br />

For <strong>Stora</strong> <strong>Enso</strong>, high-performance containerboard<br />

represents effective package performance in terms<br />

of supply chain functionality and printability, as well<br />

as the sustainability advantages. Demand for high<br />

performance corrugated packaging is increasing<br />

rapidly, and customers storing goods, for example in<br />

cold storage, particularly appreciate lasting strength<br />

values and cost effi ciency.<br />

<strong>Stora</strong> <strong>Enso</strong>—9

news<br />

30<br />

is the number<br />

of patents and<br />

patent applications<br />

<strong>Stora</strong> <strong>Enso</strong> made and<br />

received approval for<br />

during <strong>2011</strong>.<br />

TAIsTo sAArI<br />

Machines in shipshape<br />

Condition monitoring carried out by the machine and equipment<br />

operators themselves has, in recent years, been successfully tested<br />

at <strong>Stora</strong> <strong>Enso</strong>’s Varkaus and Veitsiluoto paper mills. Operator Driven<br />

Reliability is a method of operating in which operators regularly collect<br />

data from various production measurement points using not only their<br />

sense perception but also user-friendly palm computers acquired for<br />

the purpose.<br />

Operators who are very familiar with the process are the fi rst<br />

to notice changes in machines that are regularly monitored, and<br />

through their actions they can prevent unexpected production breaks.<br />

Preventing production breaks results in considerable cost savings and<br />

simultaneously diversifi es the job description of the operators.<br />

sTorA enso<br />

10—<strong>Rethink</strong><br />

Grow a ticket to Brazil<br />

<strong>Stora</strong> <strong>Enso</strong> in Sweden has launched a<br />

seedling competition for Swedish university<br />

students. The student with the tallest spruce<br />

seedling after three months of growing<br />

wins a trip to Brazil, including a visit to<br />

<strong>Stora</strong> <strong>Enso</strong>’s operations.<br />

facebook.com/<strong>Stora</strong><strong>Enso</strong>Sverige<br />

Using diamonds to save energy<br />

Producing mechanical pulp by grinding requires a lot<br />

of energy. In August <strong>2011</strong>, <strong>Stora</strong> <strong>Enso</strong>’s Maxau Mill<br />

implemented a new grinding process that requires<br />

25% less energy to produce the same amount of pulp.<br />

These considerable energy savings are gained by<br />

replacing the traditional ceramic grinder stone with<br />

a steel cylinder with industrial diamonds attached<br />

precisely on its surface, forming a homogeneous<br />

pattern.<br />

After the rebuild, the grinding process is better<br />

controlled, as individual differences between<br />

machines disappear and the machines’ use can be<br />

optimised. The machines’ higher production capacity<br />

corresponds with a boost to energy effi ciency. In<br />

addition, the end product is more uniform in quality,<br />

as the diamonds keep grinding wood precisely and<br />

tirelessly.<br />

<strong>Stora</strong> <strong>Enso</strong> was involved in developing this new<br />

grinding process in co-operation with four other<br />

companies in the industry.<br />

sTorA enso<br />

Better packaging for chocolate<br />

<strong>Stora</strong> <strong>Enso</strong> Renewable Packaging has launched<br />

enhanced versions of the Performa carton boards.<br />

Thanks to several reforms made at Fors Mill in Sweden<br />

in <strong>2011</strong>, these products, used in chocolate and<br />

confectionery packages, now come with excellent<br />

smoothness, increased strength and an enhanced<br />

visual appearance.<br />

“By listening to printing houses and brand owners<br />

and by focusing on the capabilities of the rebuilt board<br />

machine, we focused our development work on the<br />

key properties of strength and printability,” says Eva<br />

Lundqvist, Product Manager at Fors Mill, discussing<br />

the successful development work.<br />

Rewind What has happened since <strong>Rethink</strong> 2010?<br />

Regards from<br />

Langerbrugge Mill<br />

Langerbrugge Mill in Belgium, along with two<br />

German mills, Maxau and Sachsen, puts a<br />

lot of energy into improving recovered paper<br />

sourcing. <strong>Stora</strong> <strong>Enso</strong> began a project in <strong>2011</strong><br />

with the aim of reminding local citizens that local<br />

recycling means more than just separating waste.<br />

“In an ideal world, locally recovered paper (RCP) is<br />

used as raw material for making new paper products<br />

at the closest paper mill. That is defi nitely the most<br />

sustainable way of using RCP. Today however, RCP is<br />

routinely transported across Europe – distances which<br />

are far too large – even to and from Langerbrugge.<br />

What worries me the most is that 20% of the RCP<br />

collected in Europe ends up in other territories, for<br />

instance in China. That defi nitely puts the future<br />

of local mills at risk,” says Mill manager Chris De<br />

Hollander.<br />

The project includes lobbying and communications<br />

actions from advertising campaigns to social<br />

media presence. Its goal is to share knowledge about<br />

the importance and sustainability of locally used<br />

recovered paper and convince inhabitants that local<br />

recycling really does matter.<br />

“People who deposit their waste paper in local<br />

paper recycling bins deserve to know that they are<br />

doing more than just recycling – and that their actions<br />

make a difference,” De Hollander continues.<br />

storaenso.com/rethink<br />

youtube.com/storaenso<br />

Teemu kuusImurTo<br />

Taste for waste<br />

Last year’s <strong>Rethink</strong><br />

magazine profi led the<br />

<strong>Stora</strong> <strong>Enso</strong> Langerbrugge<br />

Mill, which<br />

is one of the world’s<br />

top mills in terms of<br />

recycled paper usage.<br />

<strong>Stora</strong> <strong>Enso</strong>—11

It is a late Friday morning in Barcelona. We<br />

join Olga Roger on her balcony, overlooking<br />

a courtyard in the chic neighbourhood of<br />

Eixample. In her late 40s, Roger epitomises<br />

the busy, modern woman who has a lot going on.<br />

A professional in communications, she has two<br />

jobs, one in Barcelona and one in Madrid. On top<br />

of this, she recently submitted her doctoral thesis<br />

and now regularly lectures at the university.<br />

We have come to meet Olga Roger to discuss<br />

her consumption and recycling habits. Due to<br />

her busy schedule, she consumes plenty of<br />

packaged food and drinks. She also represents<br />

the eco-conscious consumer who knows what<br />

she buys and why.<br />

“In the morning I eat like this,” Roger says,<br />

“Toast, cheese and jam with orange juice.” She<br />

picks up a juice brick off the table and sticks a<br />

straw in it. “These single-packed carton juices<br />

are my favourites. When you’re in a hurry, you just<br />

take one with you.”<br />

The fact that Olga Roger likes things to be<br />

practical does not mean that she makes purely<br />

rational choices. Marketing research tells us<br />

that the act of shopping is loaded with feelings,<br />

desires and habits, many of which we are unaware<br />

of. “I want my orange juice and vegetable soup<br />

packaged in carton and my Coca-Cola in an<br />

aluminium tin,” Roger says, “I always buy them<br />

like that.” She studies the juice brick in her hand<br />

and squeezes it gently. “I think many people have<br />

clear preferences in packaging, even if they never<br />

think about it. People just buy what feels right. I<br />

do, anyway.”<br />

A private issue<br />

For a growing number of consumers, what feels<br />

right is what can be recycled. For Roger, this is<br />

a decisive factor. “The packaging I buy, I always<br />

recycle. There are recycling bins just next to my<br />

house, so it’s easy to take out the recycling when<br />

I walk my dog,” she says.<br />

What sounds like a simple personal habit is<br />

no minor issue when looked at on a larger scale.<br />

Together, European consumers use over a million<br />

tonnes of beverage cartons per year. Whether<br />

these beverage cartons get recycled is a serious<br />

matter for the environment and the climate. Olga<br />

Roger, though a rigorous recycler herself, does<br />

not see it exactly in that way.<br />

“Sure, I care about climate change. But to be<br />

honest, it feels distant and global to me. What<br />

really drive me are things that are close by,”<br />

she says. Roger, a born and bred Barcelonian,<br />

glances anxiously at the courtyard. “You may<br />

think that Barcelona is a nice city, and it is, but it<br />

is also a polluted one. There is a lot of noise and,<br />

12—<strong>Rethink</strong><br />

A 21st century proverb: The quickest<br />

way to know a woman is to go<br />

shopping with her. Too bad that Olga<br />

Roger has just been to the grocery<br />

store.<br />

Text Eeva Taimisto Photos Daniel Loewe<br />

From<br />

juice carton<br />

to car parts<br />

A busy day ahead<br />

For Olga Roger,<br />

breakfast is a time to<br />

recharge.<br />

<strong>Stora</strong> <strong>Enso</strong>—13

in many places, litter. When I leave my house, it<br />

is all just there in front of me,” Roger frowns, “It’s<br />

about my life, about my city. Recycling is a private<br />

issue, really.”<br />

Like Olga Roger, many consumers living in big<br />

cities all over the world have come to realise the<br />

problem. Litter in cities and growing mountains<br />

of waste in landfills on their outskirts are not a<br />

pretty sight. The collection rate for used beverage<br />

cartons in Spain is 55% and growing. Yet the<br />

global waste problem has to do with much more<br />

than that.<br />

According to the European Commission and<br />

the OECD, the way we use our natural resources<br />

is the key question in today’s world where nature<br />

cannot keep up with the growing consumption.<br />

Policymakers are calling for resources to be used<br />

in the most efficient way possible.<br />

What matters to shoppers are the materials<br />

they choose to buy: whether they are renewable<br />

and how efficiently they can be recycled.<br />

Trash secrets<br />

A new life begins for Olga Roger’s cartons after<br />

she drops them in the recycling bin. The carton<br />

waste is picked up and brought to a municipal<br />

sorting plant. After sorting, the used beverage<br />

cartons are sold and transported to <strong>Stora</strong> <strong>Enso</strong>’s<br />

Barcelona Mill. The waste does not have to travel<br />

far as the mill is conveniently located only 20<br />

kilometres from the city centre.<br />

We approach the mill alongside trucks that<br />

seem to be in a hurry to unload their cargo.<br />

Nearing the mill yard, you begin to understand<br />

the impact recyclers like Olga Roger have. The<br />

volume of waste in view is jaw-dropping.<br />

“Every year, we receive about two billion<br />

used beverage cartons from a radius of 1 200<br />

kilometres,” says Mill manager Juan Vila. He<br />

stands in the yard, looking content as he watches<br />

the trucks enter and leave. The carton bales<br />

they leave at the plant look dirty, some of them<br />

hosting hordes of flies. “For consumers that is<br />

14—<strong>Rethink</strong><br />

garbage. For us it is raw material,” he declares,<br />

smiling.<br />

There is good reason for Vila’s contentment.<br />

The way in which Barcelona recycles used<br />

beverage cartons is unique globally. With the<br />

help of specialised technology, all parts of the<br />

carton can be reused at the plant. With no waste,<br />

the cartons are given a new life as energy or raw<br />

material.<br />

“Let me first tell you the basic facts,” says<br />

Vila, as we walk across the yard. “The cartons<br />

are made of fibre, plastic and aluminium. About<br />

75% is fibre, 20% plastic and 5% aluminium.” He<br />

picks a carton from the ground and tears it open.<br />

“There is plastic and aluminium here on the inside<br />

layer of a juice carton. Recycling all of these – the<br />

fibres, plastics and aluminium – requires a few<br />

tricks.”<br />

Vila walks us to a conveyor belt that transports<br />

the packaging, along with other paper waste,<br />

into a big pulper. “This is where it all starts,” he<br />

explains, “Here the fibres in the beverage cartons<br />

are washed away from the plastic and aluminium.<br />

The fibres are cleaned, and then we make new<br />

board out of them. The board will be used for<br />

example in food packaging, like cereal boxes.<br />

It isn’t used for packages with direct contact to<br />

groceries though, such as juice or milk cartons.”<br />

Juan Vila points at a pile of dirty-looking<br />

waste plastic and aluminium lying next to the<br />

pulper. “The revolutionary part, however, is what<br />

happens to that aluminium and plastic once the<br />

fibres are removed,” he explains, continuing, “All<br />

of that used to go to the landfill. Nowadays we are<br />

able to reuse everything. Out of the plastic, we<br />

make energy. The aluminium we recover as bricks<br />

and sell it to aluminium companies.”<br />

Heat and aluminium<br />

Explained by Vila, the recycling of beverage<br />

carton layers sounds perfectly simple and<br />

effortless. History, however, reveals some difficulties<br />

along the way. <strong>Stora</strong> <strong>Enso</strong> experimented with<br />

Tero PAJukALLIo<br />

Tero PAJukALLIo<br />

Innovative concept<br />

Mill manager Juan<br />

Vila takes pride in<br />

the unique recycling<br />

process.<br />

Raw material<br />

in bales<br />

The Barcelona Mill<br />

sources its raw<br />

material from a radius<br />

of 1 200 kilometres.<br />

From garbage to<br />

raw material<br />

The used beverage<br />

packages will be<br />

processed into new<br />

carton material, heat<br />

and aluminium bricks.<br />

the process for years at Varkaus Mill, Finland, but<br />

was not able to recover the aluminium unoxidised<br />

despite great research efforts. It might not have<br />

worked in Barcelona either, not without the<br />

innovative use of a technology called pyrolysis.<br />

This technology was awarded by the European<br />

Union last year for bringing great environmental<br />

benefits. Barcelona Mill is the first mill in the<br />

world to use the pyrolysis technology on a large<br />

scale.<br />

“Pyrolysis works by heating up the plastic<br />

and aluminium to a temperature of 500°C, but<br />

without oxygen. This way, the plastics do not<br />

burn. Instead they transform into gas and oil,<br />

which are used to generate energy for the mill,”<br />

Vila explains.<br />

He walks over to a pile of perfectly-shaped<br />

aluminium bricks that glitter in the sun. “And<br />

this is what becomes of the aluminium in your<br />

beverage carton after being treated in the heat<br />

of pyrolysis. It comes back to life in good shape.”<br />

He picks up a brick, and passes it over. “These<br />

bricks will now be sold to aluminium companies.<br />

They will make new aluminium products, such as<br />

car bumpers, out of them.”<br />

We stop here for a while to reflect on the<br />

life cycle of a juice carton. Once, it was a tree<br />

growing somewhere in Sweden or Finland. Then<br />

it was turned into the orange juice package in<br />

your fridge. After recycling, it became another<br />

package, perhaps a box for corn flakes or a<br />

perfume bottle. But it also became energy for<br />

a mill and aluminium for new products. Juan<br />

Vila grins and adds: “Yes. The orange juice you<br />

bought yesterday can, in a few short weeks, be<br />

part of a car. Just think about it next time you<br />

have a drink of juice!”<br />

Changing the game<br />

Judging by the amount of cartons the mill<br />

treats, it has a very real positive impact on the<br />

environment. We walk into Juan Vila’s office, and<br />

he lays the figures out. “By recycling plastic and<br />

aluminium, we save about 20 000 tonnes of waste<br />

annually. Without pyrolysis, all that waste would<br />

end up in the dump.” This sounds like a fantastic<br />

outcome, but we doubt the mill puts in all this<br />

effort solely to save the environment. “It’s not just<br />

that,” interrupts Vila, “We also make business<br />

out of it.” He grabs a pen and a piece of paper to<br />

demonstrate.<br />

“First of all, we avoid the dumping fees.<br />

Second, we produce aluminium and get to<br />

sell it. Third, we produce gas and oils that can<br />

be converted into energy in the form of steam<br />

or even electricity.” Vila shows us a graph.<br />

“Currently, we cover around 20% of our steam<br />

<strong>Stora</strong> <strong>Enso</strong>—15

needs with the energy we retain from used<br />

beverage carton plastic. That’s quite a lot.”<br />

<strong>Innovation</strong>s rarely fall from the skies, so how<br />

did the mill come up with pyrolysis? “We worked<br />

hard on it with Alucha,” Vila says. He explains<br />

that the origins of the innovation are with Alucha<br />

Recycling Technologies, a company set up by a<br />

group of students to develop the use of pyrolysis.<br />

Together with <strong>Stora</strong> <strong>Enso</strong>, Alucha tested and<br />

developed the technology on an industrial scale.<br />

Vila calls Hans Cool, one of the founders<br />

of Alucha, asking him to stop by at his offi ce.<br />

Cool, of Dutch origin, arrives after a few minutes,<br />

looking busy but full of energy. He tells us how<br />

Alucha got started, “Me and my friend Gijs<br />

Jansen studied together in an MBA programme<br />

here in Barcelona. Another friend had a contact<br />

at Cambridge, Carlos Ludlow, who was studying<br />

pyrolysis as the subject of his PhD. We teamed up<br />

with Ludlow and founded the company together.”<br />

The students had a business plan for<br />

separating plastics from aluminium but were not<br />

sure how it would work. They contacted Juan<br />

Vila, who got interested in their idea. As a result,<br />

<strong>Stora</strong> <strong>Enso</strong> and Alucha ended up testing and<br />

modifying the technology for six years, hoping<br />

that it would eventually yield results. All the while,<br />

the young entrepreneurs of Alucha were gambling<br />

their future prospects.<br />

“That’s the thing with innovation,” Cool says<br />

and continues, “The world is full of nice ideas.<br />

But will they work in real life? Can you make them<br />

happen on an industrial scale? Will they really<br />

change the game?” Cool scratches his forehead,<br />

thinking, “We were not sure about pyrolysis<br />

Tero PAJukALLIo<br />

16—<strong>Rethink</strong><br />

ALuCHA<br />

Long path<br />

“It is not easy to put<br />

innovation into an<br />

industrial process. It<br />

took us almost eight<br />

years to get here,”<br />

says Hans Cool, one<br />

of the developers of<br />

the pyrolysis.<br />

Back to the<br />

breakfast table<br />

“The carton board<br />

produced from the<br />

old beverage cartons<br />

is used for making<br />

cereal boxes, for<br />

example,” explains<br />

Juan Vila.<br />

and cartons. We were graduates fresh out of<br />

university with all our eggs in one basket, and we<br />

had to work hard before it all came together.”<br />

Vila nods, “I am proud of the perseverance<br />

that we had with this project, both Alucha and<br />

<strong>Stora</strong> <strong>Enso</strong>. We were doing something completely<br />

new, and we had to push for it.” He stops to look<br />

out of his offi ce window. “I think that’s the key to<br />

everything in life. Never say that you would like<br />

to do something. You will have to simply make it<br />

happen without giving up. Never give up.”<br />

Electricity out of plastics<br />

Seen from Barcelona Mill, Olga Roger’s breakfast<br />

set-up starts to look a little different. The way<br />

she consumes does not only make a difference<br />

to the environment but it also contributes to<br />

innovation: the choices people like Roger make<br />

at the grocery store and at the recycling bin have<br />

a real impact. It is astounding how much value<br />

can be created out of something as simple and<br />

unattractive as waste.<br />

“The possibilities of carton are almost infi nite,”<br />

says Vila, “and there’s still so much we could do.”<br />

The process at Barcelona Mill, for one, could be<br />

developed further. “We could still improve the<br />

quality of the aluminium to make foil out of it.<br />

And maybe one day the aluminium from used<br />

beverage cartons could go back to be reused in<br />

beverage cartons.”<br />

Juan Vila is also thinking about energy. “You<br />

could produce electricity out of the plastics in the<br />

beverage cartons. Or you could make car fuel out<br />

of it.” Pyrolysis could also be used to generate<br />

energy out of making paper. “With it, you could<br />

separate organic matter and minerals from paper<br />

sludge and make bioenergy from the organic<br />

stuff,” Vila explains, “Alucha is already testing it.”<br />

Looking to the future, Vila’s dreams fl y even<br />

higher. “Society will have to learn to recycle and<br />

to recover what cannot yet be recovered,” he<br />

says. “Everything we take from nature will have to<br />

be recycled. We still don’t have all those technologies,<br />

but one day we will.” Vila leans forward<br />

in his chair, a glint of inspiration in his eyes.<br />

“Remember that we are making business out of<br />

waste that until recently had very little value, and<br />

which many did not even know how to recycle.<br />

And here we are,” Vila grins, “This is one damned<br />

exciting business.”<br />

A new life of pyrolysis<br />

Pyrolysis (‘Pyros’ is Greek for ‘fi re’) of an element means<br />

heating up the material in the absence of oxygen at temperatures<br />

above 300–400°C. The process itself has been around for<br />

centuries and is commonly used in the oil industry. In the case of<br />

Barcelona Mill, it is an existing idea applied in a new context.<br />

At Barcelona Mill, pyrolysis is used as a recycling technology<br />

to treat plastic and aluminium laminates. During the<br />

process, the long chains of polyethylene are being broken<br />

at random, thus generating gases such as butane, methane<br />

and heavier oils, which can be used as energy at the mill. The<br />

technology renders the aluminum unoxidised, and therefore it<br />

can be recycled and remelted without diffi culty.<br />

<strong>Stora</strong> <strong>Enso</strong>’s Barcelona Mill is the fi rst and only one in the<br />

world running an industrial-scale pyrolysis system for recy-<br />

cling polyethylene and aluminium. It is, however, not the fi rst<br />

technology to separate aluminium from plastics. <strong>Stora</strong> <strong>Enso</strong>’s<br />

Varkaus Mill experimented with a similar process for about ten<br />

years using a different technology. The technology at Varkaus<br />

Mill required higher amounts of oxygen in the process, which<br />

oxidised the aluminium. This lowered the value of recovered<br />

aluminium and made its recycling more diffi cult.<br />

<strong>Stora</strong> <strong>Enso</strong> and Alucha Recycling Technologies received<br />

the European Commission’s ‘Best of the Best’ LIFE environment<br />

award in <strong>2011</strong> for this project. The award is granted by<br />

the European Commission and it recognises Europe’s very<br />

best environmental projects.<br />

<strong>Stora</strong> <strong>Enso</strong>—17

18—<strong>Rethink</strong><br />

Time to<br />

wake up<br />

The media arena is changing. As yet, there is no consensus on<br />

the speed of that change, but the direction is clear: towards<br />

digital content. In the most extreme case, paper consumption<br />

could be cut in half by 2020.<br />

Text Jarno Forssell Illustration Shutterstock/Miltton<br />

In the fi rst scene of a YouTube video viewed<br />

over three three million times, a baby enthusiastically<br />

pushes an iPad iPad screen: “This one<br />

works!” Then she desperately tries to make<br />

a a magazine work in the same way. She can can<br />

turn the pages and crinkle them, but the<br />

pictures just won’t won’t get bigger or open up.<br />

“Is it broken, or what?” At the end of the video, the<br />

child dumps the magazine and goes back to the<br />

interface she can work with her fi ngers.<br />

Is this the future for print media, as twenty years<br />

from now these children born into a digital world will<br />

be adults?<br />

The change may happen even sooner than we<br />

think. The migration of media companies towards<br />

producing digital content started already a long time<br />

ago. Now, online media has gained a strong foothold<br />

alongside print: online publications, mobile content<br />

and, most recently, applications for tablets such as<br />

the iPad are becoming more and more popular.<br />

“Most consumers never really warmed up to the<br />

experience of reading text on a computer screen.<br />

Tablets, however, have changed the situation: many<br />

users consider reading on a tablet just as pleasant,<br />

if not more so, than reading print materials,” says<br />

consultant Alex Bhak, who has been following the<br />

media and technology sectors for 15 years.<br />

Bhak is a partner at the London-based global<br />

consultancy Bain & Company. According to him, the<br />

transformation we are seeing in the world of media<br />

is most apparent in mature markets.<br />

“The digital shift began in markets like the USA.<br />

We are talking about a long-term development with<br />

wide-ranging effects. The power has shifted to<br />

consumers, who can now choose when, how and<br />

where they consume information,” Bhak explains.<br />

Newspapers feel<br />

the biggest impact<br />

Transition to digital media is most apparent in the<br />

printed press. press. A report report published in autumn <strong>2011</strong><br />

by the the World Association of of Newspapers and News<br />

Publishers (WAN-IFRA) described how newspaper<br />

circulation circulation in in North America as as well as in Central,<br />

Eastern and Western Europe has dropped notably<br />

over over the past few years.<br />

“The value of basic news has decreased, since<br />

consumers have have access to to various news sources at<br />

<strong>Stora</strong> <strong>Enso</strong>—19

no cost. Print publishers have had to develop a<br />

combination of news, editorial commenting and<br />

analysis,” says Bhak.<br />

Newspapers are also moving to the digital<br />

world at a fast rate. In the UK, for example, most<br />

national newspapers offer, in addition to their<br />

online services, applications for tablets. And<br />

for their advertising customers, many also offer<br />

packages that combine print and digital media<br />

advertising.<br />

According to Bhak, “Some publishers have<br />

successfully combined print and online media.<br />

They don’t simply reproduce printed content on<br />

the web. Instead, they offer added value on top<br />

of print. Publishers who have taken an integrated<br />

approach are experiencing greater success than<br />

those who haven’t.”<br />

The digital transition has also affected<br />

magazines but to a somewhat lesser extent than<br />

newspapers. Glossy lifestyle magazines have a<br />

high-end look and feel, and they offer a reading<br />

experience more diffi cult to replicate using digital<br />

media than the news fl ow offered by newspapers,<br />

which is perceived to be a basic commodity.<br />

Nevertheless, digital content has managed<br />

to come up on the heels of print in the magazine<br />

world, as well. According to a study released<br />

at the end of <strong>2011</strong>, approximately a third of<br />

consumers of magazine brands published by<br />

Time Inc., the biggest magazine publisher in the<br />

USA, read both print and digital content. 55% of<br />

consumers relied exclusively on print, and 15%<br />

on digital media. (American Magazine Study,<br />

autumn <strong>2011</strong>.)<br />

Printed forms of direct mail, such as brochures<br />

and product catalogues, have fared better than<br />

20—<strong>Rethink</strong><br />

magazines. In this area the digital transition<br />

has been subdued, as the paradigms of digital<br />

advertising have not developed far enough.<br />

“Effi ciency in digital marketing is about the<br />

ability to target consumers effectively and having<br />

the right measurement capabilities in place.<br />

These elements are emerging today, but they are<br />

still nascent and immature. Until that changes,<br />

the demand for paper in push marketing will<br />

remain relatively better than it will in other print<br />

forms,” Bhak believes.<br />

Cycles speeding up<br />

New media have always been expected to<br />

displace existing ones. Television was supposed<br />

to edge out radio and cinema, but the opposite<br />

occurred. The death of printed media has been<br />

declared at least since PC and internet use<br />

became widespread. For now, however, online<br />

media merely supplement printed media.<br />

“At some stage, there may be a turning<br />

point where digital forms begin to replace or<br />

‘cannibalise’ non-digital media consumption,”<br />

states Bhak.<br />

And that scenario might not be far in the future.<br />

Earlier, consumer behaviour changed rather<br />

slowly, lagging behind technological development.<br />

Recently, however, cycles of adopting new<br />

technology have been picking up speed.<br />

“It took around 20 years until half of the<br />

American population had a personal computer.<br />

For mobile devices, it took some 15 years, while<br />

the estimate for touch screens is only 5 to 7 years.<br />

And in future, such cycles of adoption might be<br />

even shorter.”<br />

In Western europe paper consumption<br />

could decrease 15–20% by 2020.<br />

Social media adopted faster than any other<br />

device / media<br />

% of U.S. population using technology / service<br />

80<br />

60<br />

40<br />

20<br />

0<br />

0 5 10<br />

bAIn & ComPAnY<br />

DVD player<br />

Television<br />

Radio<br />

Cellphone<br />

PC<br />

Telephone<br />

Years after<br />

product launch<br />

Global shipment<br />

Units<br />

60M<br />

40<br />

20<br />

0<br />

Apple iPad<br />

Apple iPhone<br />

+ iTouch<br />

Nintendo Wii<br />

Nintendo DS<br />

Sony PSP<br />

Apple iPod<br />

RIM Blackberry<br />

0 1 2 3 4 5 6 7 8 9 10 Quarters after<br />

Apple estimate<br />

Actual<br />

product launch<br />

The future depends on what people do with their<br />

tablets – will they end up as an experiment, or<br />

will consumers use them as a daily news source?<br />

For the time being, however, consumers still<br />

favour print. A study conducted by the Two Sides<br />

initiative, which works to promote the use of<br />

print and paper, revealed that 80% of European<br />

consumers prefer to read print rather than on a<br />

screen. In younger age groups, the percentage is<br />

even slightly higher.<br />

Paper consumption cut in<br />

half?<br />

Bain & Company has compiled two scenarios that<br />

foresee a media revolution and the development<br />

of paper demand on the basis of three infl uential<br />

factors. These factors are the development of<br />

technology, in particular the growing popularity of<br />

tablets; a change in consumer behaviour towards<br />

favouring digital media; and the development of<br />

advertising paradigms involving an ad spending<br />

shift towards digital media.<br />

In a moderate, evolution-based scenario<br />

for Western Europe, paper consumption could<br />

decrease 15–20% per cent by 2020. In this<br />

scenario, tablets become like televisions, a<br />

regular household item, and consumer behaviour<br />

changes slowly.<br />

“In a more aggressive change scenario, each<br />

consumer would have their own personal tablet,<br />

and ‘digitality’ would become a natural part<br />

of their world. In this case paper consumption<br />

would be cut nearly in half in Western Europe,”<br />

Alex Bhak says, “Globally, we see a worst-case<br />

scenario of a 25% reduction in paper demand for<br />

newspapers, magazines and fi ne papers by 2020.”<br />

The future of print and digital media depends<br />

on what people do with their tablets. Will they<br />

end up nothing more than an experiment, or will<br />

consumers use them as their daily news source?<br />

But it’s not just about tablets. Bhak expects also<br />

other new ways of consuming information, with<br />

even better interfaces, to emerge over the next 10<br />

years. The pace of change may accelerate both in<br />

technological trends and in consumer behaviour.<br />

“I believe that once consumers have had a<br />

taste of the freedom of choice, the change will be,<br />

to some extent, permanent,” says Bhak.<br />

In addition to technology, consumer behaviour<br />

and advertising paradigms, there is a fourth factor<br />

infl uencing the consumption of print media: the<br />

social media, which have signifi cant coverage.<br />

Facebook, with its 750 million users, is already<br />

being called the world’s ‘third biggest nation’.<br />

The social media’s direct impact on print<br />

media consumption is, however, diffi cult to<br />

predict. A key question is how will the social<br />

media affect online advertising? Will they enable<br />

marketing that is better and more effectively<br />

targeted than online advertising thus far?<br />

Print growing in the East<br />

Although the digital shift has hit newspapers hard<br />

in mature markets, on a global level print media is<br />

not a sunset industry. According to WAN-IFRA’s<br />

report, newspaper circulation has increased<br />

in the last fi ve years in Africa, Asia and South<br />

America. Today the largest newspaper markets<br />

are in India, China and Japan.<br />

What the future holds is another story. It is<br />

entirely possible that consumers in emerging<br />

markets skip a phase of media evolution, “jump<br />

the curve” and move directly to digital services.<br />

There have been signs of this at least in China,<br />

where wall-newspaper readers have become<br />

smartphone users, bypassing the print phase<br />

altogether.<br />

“Consumers in China have both the technological<br />

opportunity and the readiness to quickly<br />

change their behaviour. This is partly because<br />

there was no previous behavioural phase and<br />

partly because online they have access to a much<br />

better offering than now,” Bhak concludes.<br />

<strong>Stora</strong> <strong>Enso</strong>—21

In the beginning of 2012, <strong>Stora</strong> <strong>Enso</strong> renewed its Business Area structure and<br />

renamed the Business Areas. Product orientation was replaced with a focus on<br />

end uses, and from now on the four business areas are known as Biomaterials,<br />

Printing and Reading, Renewable Packaging and Building and Living.<br />

Text Lauri Peltola Photos <strong>Stora</strong> <strong>Enso</strong><br />

Agile and<br />

future-focused<br />

22—<strong>Rethink</strong><br />

As a part of this renewal, the paper<br />

businesses were put under one<br />

area because they have much in<br />

common compared to the other<br />

Business Areas. At the same time,<br />

the company wanted to increase the transparency<br />

of the pulp business and make sure that,<br />

from the financial reporting point of view, all<br />

stakeholders can see the impact of market pulp<br />

in the company’s financial results. Furthermore,<br />

in the new setup, the different nature and focus<br />

of the various businesses becomes clearer than<br />

before.<br />

“We now organise our businesses based<br />

on the different markets and customers they<br />

serve. The aim is to increase our organisation’s<br />

competitiveness, flexibility, speed and accountability,<br />

and to minimise dependencies between<br />

the businesses to ensure that we have the ability<br />

and agility to seize the opportunities arising from<br />

the changes in the global economy,” says CEO<br />

Jouko Karvinen.<br />

The names of the Business Areas were<br />

changed because the old titles were very<br />

product-orientated. The world is changing rapidly,<br />

and these businesses are better described as<br />

having diversified missions and visions rather<br />

than merely products. The company therefore<br />

decided to rename its Business Areas in a more<br />

future-focused and consumer-related manner.<br />

Biomaterials with<br />

opportunities<br />

One of <strong>Stora</strong> <strong>Enso</strong>’s strategically defined growth<br />

areas is pulp from sustainably-managed tree<br />

plantations. The new Biomaterials Business<br />

Area will focus on this growth and the innovative<br />

possibilities of fibre as a renewable raw material.<br />

The new Business Area will also increase<br />

transparency in financial reporting, as earlier the<br />

renewed<br />

<strong>Stora</strong> <strong>Enso</strong> has renewed its Business Area and reporting<br />

segment structure. The Group combined the paper<br />

reporting segments Newsprint and Book Paper, Magazine<br />

Paper and Fine Paper into one Business Area and<br />

reporting segment called Printing and Reading.<br />

The reporting segments Consumer Board and<br />

Industrial Packaging now form the Renewable Packaging<br />

market pulp sales figures were included in several<br />

reporting segments.<br />

The Biomaterials Business Area contains the<br />

joint venture pulp mills in Brazil (Veracel) and<br />

Uruguay (Montes del Plata) and their related<br />

plantations, the Skutskär Pulp Mill in Sweden,<br />

and the Enocell and Sunila pulp mills in Finland.<br />

The plantations in Rio Grande do Sul in Brazil and<br />

the trial plantations in Laos and Thailand also<br />

form part of the new Business Area.<br />

“The overall demand for pulp is growing<br />

worldwide, especially in Asia. Even though the<br />

market is volatile and price changes are common,<br />

demand continues to increase. Pulp is a very<br />

sustainable raw material. It can be used for many<br />

purposes, many of which are hard to imagine<br />

today, so we believe that there is a lot of potential.<br />

Establishing these operations as its own business<br />

area will give us better possibilities to develop the<br />

business and serve our customers,” says Juan<br />

Bueno, head of the Biomaterials Business Area.<br />

Seizing<br />

opportunities<br />

The aim is to increase<br />

our organisation’s<br />

competitiveness,<br />

flexibility, speed and<br />

accountability to<br />

ensure that we have<br />

the ability and agility<br />

to seize the opportunities<br />

arising from the<br />

changes in the global<br />

economy.<br />

Business Area and reporting segment. A new Business<br />

Area and reporting segment called Biomaterials was<br />

established chiefly comprising the company’s jointventure<br />

pulp mills, stand-alone pulp mills and wood<br />

plantations.<br />

The Wood Products Business Area was renamed as<br />

Building and Living.<br />

<strong>Stora</strong> <strong>Enso</strong>—23

Interview<br />

24—<strong>Rethink</strong><br />

Yes. The heart-shaped wig on the cover is indeed made of paper. Amy Flurry<br />

and Nikki Nye’s custom-made paper art installations are fueled by an appreciation<br />

of the grace and nuance inherent in this seemingly humble material. We<br />

met with Amy Flurry to discuss their work.<br />

Text Niina Streng Photo Caroline Petters<br />

Telling stories<br />

“We realised we<br />

shared a love of<br />

fashion and fantasy<br />

in storytelling,” say<br />

Nikki Nye (left) and<br />

Amy Flurry holding a<br />

cockatiel mask.<br />

beyond<br />

the imagination<br />

You create paper art through your own<br />

company called Paper-Cut-Project.<br />

How did you get started?<br />

Our original idea was simply to create a great<br />

window display together, something we were not<br />

seeing in Atlanta. Nikki, working with paper in her<br />

own art since college, already knew the material<br />

well, and we decided that our signature would be<br />

to make three-dimensional sculptures of paper<br />

that carried the styling concepts. We debuted<br />

our first window installation in January 2010,<br />

and Hermès reached out to us already a month<br />

later. Work opportunities have been presenting<br />

themselves to us since! Today, we create art<br />

for window installations, fashion runways,<br />

catalogues and advertising campaigns.<br />

What is it in paper that intrigues you?<br />

Unlike other materials, paper has an amazing<br />

ability to retain shapes. Using glue, water or<br />

other means, we are able to reach end results far<br />

beyond flat-cut paper surfaces.<br />

To date, we have exclusively worked with<br />

Bristol papers: heavy, uncoated paperboards<br />

which are often used in painting, drawing or the<br />

production of postcards. But I imagine we will<br />

expand our range of raw materials in the near<br />

future, just as we previously branched out from<br />

white and have introduced some black pieces<br />

into the collection.<br />

Where did the inspiration for paper wigs come<br />

from?<br />

Wigs are small, contained pieces that, as a group,<br />

make a serious statement. Hairstyles are often<br />

quite artful and cool to study. Paper wigs solved a<br />

dilemma for many stores, too: how to cover a bald<br />

mannequin head without making it look ridiculous<br />

or cheap.<br />

Are your wigs comfortable enough to be worn<br />

by people?<br />

All parts are well sealed, and the wigs are<br />

certainly meant to be worn! Models have walked<br />

down runways and hosts have greeted guests<br />

at lavish fêtes wearing them. For mannequin<br />

displays, we are able to custom the fit for various<br />

head sizes. All in all, our wigs are quite functional,<br />

whether as large pieces or smaller accessories.<br />

Paper wigs is not all you do. What else have<br />

you done?<br />

We can make whatever we are able to imagine<br />

and sketch! We have made crowns, cuffs, capes,<br />

tutus and masks, for example. In the future, we<br />

hope to create a jewelry line in paper: items would<br />

be worn once and then put on display as pieces<br />

of sculpture!<br />

Are all your pieces unique?<br />

Yes, they are all one of a kind. We may make<br />

something twice, like an owl mask, but it will be<br />

styled differently and have a slightly different look.<br />

Due to the simple fact that each piece is cut by<br />

hand by Nikki and me, they will always be unique!<br />

Any advice for people interested in working<br />

with paper design?<br />

You must experiment and play with the material<br />

to discover the variety of ways paper can be<br />

manipulated. Oh, and always work with a sharp<br />

blade!<br />

paper-cut-project.com<br />

<strong>Stora</strong> <strong>Enso</strong>—25

26—<strong>Rethink</strong><br />

A beginner’s<br />

guide to mFC<br />

Text Eeva Taimisto Photos Shutterstock<br />

Exciting<br />

possibilities<br />

Micro Fibrillated<br />

Cellulose opens<br />

up completely<br />

new applications<br />

for wood fi bre.<br />

Think you know pulp inside out? Prepare to rethink your<br />

preconceptions.<br />

until recently, pulp and innovation<br />

were words words rarely seen seen in the<br />

same sentence. Pulp producers<br />

were constantly criticised for for their their<br />

lack of creativity, and few people<br />

would have predicted this to change. Behind the<br />

curtains, however, research and development<br />

was going on, which came as<br />

a surprise to many when<br />

<strong>Stora</strong> <strong>Enso</strong> announced<br />

a pre-commercial<br />

production plant<br />

investment into an<br />

innovation called Micro<br />

Fibrillated Cellulose (MFC) in <strong>2011</strong>.<br />

To fi gure out what the innovation was all<br />

about, one had to make an effort. There was<br />

talk of revolutionary new opportunities, but few<br />

concrete examples of what those would be.<br />

The complex vocabulary surrounding things –<br />

nanotechno logies, micro fi brils – didn’t help much.<br />

To get to the bottom of this, we talked to two<br />

MFC pioneers, <strong>Stora</strong> <strong>Enso</strong>’s Vice President of<br />

Biorefi nery Mikael Hannus and<br />

Jan Lif, Head<br />

of R&D and <strong>Innovation</strong> at <strong>Stora</strong> <strong>Enso</strong> Renewable<br />

Packaging. The pilot-scale production of MFC<br />

started in late <strong>2011</strong> at <strong>Stora</strong> <strong>Enso</strong>’s Imatra Mills in<br />

Finland.<br />

Introducing fi brils<br />

To understand what Micro Fibrillated Cellulose is<br />

all about, you have to start with the basics. “First<br />

you will need to know what a a fi bre is,” says Lif,<br />

who knows the development process behind the<br />

innovation. “When making MFC, cellulose fi bres<br />

are disintegrated into their their components, fi brils,”<br />

Lif says. “The fi fi brils are very small and invisible<br />

to the the naked eye. Whereas a cellulose fi bre is is 1–3<br />

mm long, the the length length of a a fi bril ranges from a few few<br />

to several hundred micrometres,” he explains.<br />

“By processing fi bres into these these tiny fi fi brils, we<br />

get get MFC.”<br />

Is this a nanotechnology product then?<br />

“No,” answers Lif. Lif. “Not according according to the the<br />

common defi nition. Micro is a length scale<br />

1 000 times larger than nano. Fibrils are the<br />

natural micro-sized components of fi bres.” The<br />

innovation, however, is based on nanotechnology.<br />

“MFC was discovered as a by-product during<br />

research on nanotechnology,” says Lif. “So yes,<br />

you could say that we have nanotechnology to<br />

thank for this.”<br />

MFC, then, is made of wood pulp by disintegrating<br />

fi bres into their micro-sized building<br />

blocks, fi brils. But what is so special about the<br />

product? What are the properties of MFC that<br />

differentiates it from traditional pulp?<br />

“MFC has similar properties to traditional<br />

pulp – and more besides,” says Lif. He shows<br />

a photograph of the product. Compared to<br />

traditional pulp which is white and resembles<br />

snow, MFC is transparent and looks like gel.<br />

“It’s a great material that comes with a variety<br />

of possible uses,” Lif says. “It is currently being<br />

tested in some of our packaging and media<br />

products, and in the future it has the potential<br />

to be used in a variety of entirely new products.<br />

MFC can also be used as a substitute for nonrenewable<br />

materials such as plastics, metals and<br />

chemicals. For <strong>Stora</strong> <strong>Enso</strong> it creates a range of<br />

new opportunities.”<br />

Revolution in a milk carton?<br />

Some of those new possibilities are now being<br />

realised at <strong>Stora</strong> <strong>Enso</strong>. “With “With MFC, you can make<br />

a a more durable, durable, lighter, lighter, high-quality packaging<br />

product out of less raw material,” says Lif. Lif.<br />

“It makes packaging solutions more effi cient<br />

materially.”<br />

Material effi ciency means the degree to which<br />

one is capable of producing a given amount of<br />

product out of a a given amount of raw material.<br />

According to the European European Commission and the<br />

OECD, resource effi ciency is crucial in a world<br />

with with a growing growing population population and restricted material material<br />

resources. For a a company like <strong>Stora</strong> <strong>Enso</strong>, it<br />

also also brings signifi cant cant cost cost savings. “We save save in<br />

raw materials, as as less is needed for us and our<br />

customers,” customers,” Lif Lif explains. explains. “This is a real sustainability<br />

improvement, too.”<br />

In the packaging business, the development<br />

of material effi ciency has been phenomenal. To<br />

make make a milk carton in the 1970s, 1970s, you needed<br />

more than than double the amount of raw material you<br />

do today. today. Now with with MFC, the resource effi ciency<br />

of packaging is taking another big leap. “MFC<br />

has brought along the kind of results that enable<br />

a step forward in reducing raw material usage<br />

that would normally take 10 years of research and<br />

development,” Lif says.<br />

You could call it a revolution inside a milk<br />

carton. But if it is a revolution, it’s a silent one. The<br />

shrinking amount of raw material in the carton<br />

is unnoticeable for consumers. “If you take a<br />

<strong>Stora</strong> <strong>Enso</strong>—27

28—<strong>Rethink</strong><br />

MFC-based carton and tear it up, you cannot see<br />

a difference,” Jan Lif says. “This is very important.<br />

You are getting more with less, but it does not<br />

compromise the quality – it only enhances it.”<br />

The enhanced properties that MFC brings<br />

to packaging are numerous. “You could, for<br />

instance, improve the mechanical properties of<br />

packages such as grip stiffness,” Lif explains. “It<br />

means that the package deforms less when held<br />

in your hands. For our customers, MFC is a great<br />

tool in our toolbox when we look for the best ways<br />

to enhance their product and their business.”<br />

Rubber tyres and muffi ns<br />

In addition to its packaging potential, MFC has<br />

brought along other completely new opportunities.<br />

For <strong>Stora</strong> <strong>Enso</strong>, the new applications of<br />

MFC are not a future fantasy, but part of the<br />

company’s business as we speak.<br />

Jan Lif and Mikael Hannus are reluctant to<br />

talk about ongoing projects, but admit that they<br />

do exist and are top secret. “We are still in the<br />

beginning of our journey, but there are segments<br />

that are highly interesting for MFC,” says<br />

Hannus, who has worked with the research and<br />