On the Design and Test of a Low Noise Propeller - CAFE Foundation

On the Design and Test of a Low Noise Propeller - CAFE Foundation

On the Design and Test of a Low Noise Propeller - CAFE Foundation

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

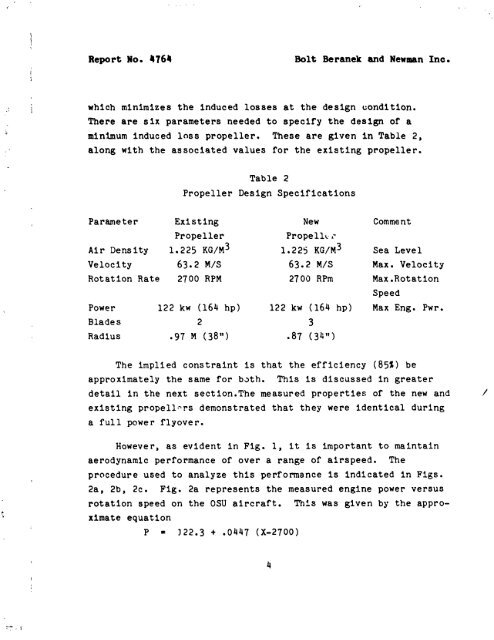

Report No. 1761Bolt Beranek <strong>and</strong> Newman Inc.which minimizes <strong>the</strong> induced losses at <strong>the</strong> design condition.There are six parameters needed to specify <strong>the</strong> design <strong>of</strong> aminimum induced loss propeller. These are given in Table 2,along with <strong>the</strong> associated values for <strong>the</strong> existing propeller.Table 2<strong>Propeller</strong> <strong>Design</strong> SpecificationsParameter Ex1 s t ing<strong>Propeller</strong>AirDensity 1.225 KG/M~Velocity 63.2 M/SRotation Rate 2700 RPMPower 122 kw (164 hp)Blades 2Radlus .97 M (38")NewPropellc A-Comment1.225 KG/M~ Sea Level63.2 M/S Max. Velocity2700 RPm Max .RotationSpeed122 kw (164 hp) Max Eng. Pwr.3-87 (34")The implied constraint is that <strong>the</strong> efficiency (85%) beapproximately <strong>the</strong> same for bath.This is discussed in greaterdetail in <strong>the</strong> next section.The measured properties <strong>of</strong> <strong>the</strong> new <strong>and</strong> ./existing propellnrs demonstrated that <strong>the</strong>y were identical duringa full power flyover.However, as evident in Fig. 1, it is important to maintainaerodynamic performance <strong>of</strong> over a range <strong>of</strong> airspeed.procedure used to analyze this performance is indicated in Figs.2a, 2b, 2c. Fig. 2a represents <strong>the</strong> measured engine power versusrotation speed on <strong>the</strong> OSU aircraft.ximate equationP122.3 + .0447 (X-2700)TheThis was given by <strong>the</strong> appro-