Commercial Cement Plaster (CCP) 5 Data Sheet ... - Dryvit

Commercial Cement Plaster (CCP) 5 Data Sheet ... - Dryvit

Commercial Cement Plaster (CCP) 5 Data Sheet ... - Dryvit

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

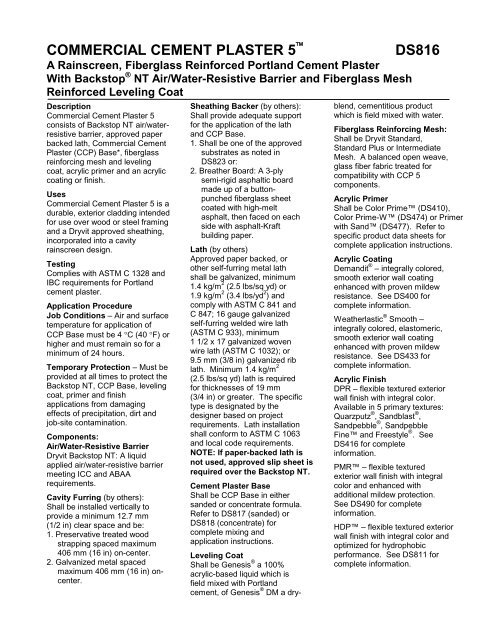

COMMERCIAL CEMENT PLASTER 5 A Rainscreen, Fiberglass Reinforced Portland <strong>Cement</strong> <strong>Plaster</strong>With Backstop ® NT Air/Water-Resistive Barrier and Fiberglass MeshReinforced Leveling CoatDescription<strong>Commercial</strong> <strong>Cement</strong> <strong>Plaster</strong> 5consists of Backstop NT air/waterresistivebarrier, approved paperbacked lath, <strong>Commercial</strong> <strong>Cement</strong><strong>Plaster</strong> (<strong>CCP</strong>) Base*, fiberglassreinforcing mesh and levelingcoat, acrylic primer and an acryliccoating or finish.Uses<strong>Commercial</strong> <strong>Cement</strong> <strong>Plaster</strong> 5 is adurable, exterior cladding intendedfor use over wood or steel framingand a <strong>Dryvit</strong> approved sheathing,incorporated into a cavityrainscreen design.TestingComplies with ASTM C 1328 andIBC requirements for Portlandcement plaster.Application ProcedureJob Conditions – Air and surfacetemperature for application of<strong>CCP</strong> Base must be 4 °C (40 °F) orhigher and must remain so for aminimum of 24 hours.Temporary Protection – Must beprovided at all times to protect theBackstop NT, <strong>CCP</strong> Base, levelingcoat, primer and finishapplications from damagingeffects of precipitation, dirt andjob-site contamination.Components:Air/Water-Resistive Barrier<strong>Dryvit</strong> Backstop NT: A liquidapplied air/water-resistive barriermeeting ICC and ABAArequirements.Cavity Furring (by others):Shall be installed vertically toprovide a minimum 12.7 mm(1/2 in) clear space and be:1. Preservative treated woodstrapping spaced maximum406 mm (16 in) on-center.2. Galvanized metal spacedmaximum 406 mm (16 in) oncenter.Sheathing Backer (by others):Shall provide adequate supportfor the application of the lathand <strong>CCP</strong> Base.1. Shall be one of the approvedsubstrates as noted inDS823 or:2. Breather Board: A 3-plysemi-rigid asphaltic boardmade up of a buttonpunchedfiberglass sheetcoated with high-meltasphalt, then faced on eachside with asphalt-Kraftbuilding paper.Lath (by others)Approved paper backed, orother self-furring metal lathshall be galvanized, minimum1.4 kg/m 2 (2.5 lbs/sq yd) or1.9 kg/m 2 (3.4 lbs/yd 2 ) andcomply with ASTM C 841 andC 847; 16 gauge galvanizedself-furring welded wire lath(ASTM C 933), minimum1 1/2 x 17 galvanized wovenwire lath (ASTM C 1032); or9.5 mm (3/8 in) galvanized riblath. Minimum 1.4 kg/m 2(2.5 lbs/sq yd) lath is requiredfor thicknesses of 19 mm(3/4 in) or greater. The specifictype is designated by thedesigner based on projectrequirements. Lath installationshall conform to ASTM C 1063and local code requirements.NOTE: If paper-backed lath isnot used, approved slip sheet isrequired over the Backstop NT.<strong>Cement</strong> <strong>Plaster</strong> BaseShall be <strong>CCP</strong> Base in eithersanded or concentrate formula.Refer to DS817 (sanded) orDS818 (concentrate) forcomplete mixing andapplication instructions.Leveling CoatShall be Genesis ® a 100%acrylic-based liquid which isfield mixed with Portlandcement, of Genesis ® DM a dry-DS816blend, cementitious productwhich is field mixed with water.Fiberglass Reinforcing Mesh:Shall be <strong>Dryvit</strong> Standard,Standard Plus or IntermediateMesh. A balanced open weave,glass fiber fabric treated forcompatibility with <strong>CCP</strong> 5components.Acrylic PrimerShall be Color Prime (DS410),Color Prime-W (DS474) or Primerwith Sand (DS477). Refer tospecific product data sheets forcomplete application instructions.Acrylic CoatingDemandit ® – integrally colored,smooth exterior wall coatingenhanced with proven mildewresistance. See DS400 forcomplete information.Weatherlastic ® Smooth –integrally colored, elastomeric,smooth exterior wall coatingenhanced with proven mildewresistance. See DS433 forcomplete information.Acrylic FinishDPR – flexible textured exteriorwall finish with integral color.Available in 5 primary textures:Quarzputz ® , Sandblast ® ,Sandpebble ® , SandpebbleFine and Freestyle ® . SeeDS416 for completeinformation.PMR – flexible texturedexterior wall finish with integralcolor and enhanced withadditional mildew protection.See DS490 for completeinformation.HDP – flexible textured exteriorwall finish with integral color andoptimized for hydrophobicperformance. See DS811 forcomplete information.

<strong>Commercial</strong> <strong>Cement</strong> <strong>Plaster</strong> 5E Finish – lightweight, highlyflexible textured exterior wallfinish with integral color.Available in 4 textures:Quarzputz E, Sandpebble E,Sandpebble Fine E, andMojave E (with recycled content).See DS468 (E Finishes) orDS706 (Mojave E) for completeinformation.Weatherlastic – elastomerictextured exterior wall finish withintegral color. Available in 5textures: Adobe, Quarzputz,Sandpebble, Sandpebble Fineand Mojave. See DS418 forcomplete information.All of the above coatings andfinishes are available in asiliconized (Si) formula uponrequest.Application – <strong>Commercial</strong><strong>Cement</strong> <strong>Plaster</strong> 5 must beapplied in accordance with localand national code requirementsand ASTM C 926. Refer to<strong>Commercial</strong> <strong>Cement</strong> <strong>Plaster</strong> 5Specifications (DS823) and<strong>Commercial</strong> <strong>Cement</strong> <strong>Plaster</strong> 5Details (DS828).DS816Warranty<strong>Dryvit</strong> Systems, Inc. shallprovide a limited warrantyagainst defective material.Warranty length will bedetermined by coating or finishselected. <strong>Dryvit</strong> shall make noother warranties, expressed orimplied. <strong>Dryvit</strong> does notwarrant workmanship. Fulldetails are available from <strong>Dryvit</strong>Systems, Inc.Technical and Field ServicesAvailable on request.*Other approved scratch andbrown coats may beacceptable. Consult <strong>Dryvit</strong>Systems, Inc. for specifics.<strong>Dryvit</strong> Systems, Inc.One Energy WayWest Warwick, RI 02893800-556-7752www.dryvit.comThis information conforms to the standard detail recommendationsand specifications for the installation of <strong>Dryvit</strong> Systems, Inc.products as of the date of publication of this document and ispresented in good faith. <strong>Dryvit</strong> Systems, Inc. assumes no liability,expressed or implied, as to the architecture, engineering orworkmanship of any project. To ensure that you are using the latest,most complete information, contact <strong>Dryvit</strong> Systems, Inc.Printed in U.S.A. R2:7-20-10 visit these links. 2©<strong>Dryvit</strong> Systems, Inc. 2010For more information on <strong>Dryvit</strong> Systems or Continuous Insulation,