Stak System Brochure - Lista

Stak System Brochure - Lista

Stak System Brochure - Lista

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

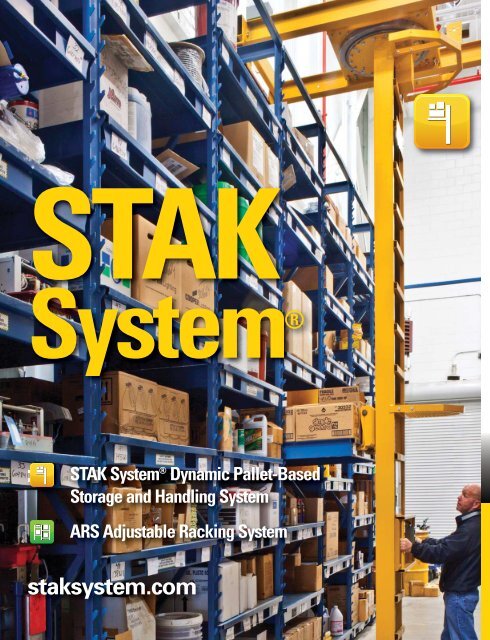

STAK<strong>System</strong> ®; STAK <strong>System</strong> ® Dynamic Pallet-BasedStorage and Handling <strong>System</strong>ARS Adjustable Racking <strong>System</strong>staksystem.com

STAK SYSTEM ®LARGE CAPACITY.SMALL FOOTPRINT.ERGONOMICSAFETY.The storage and retrieval of heavy, bulky itemshas never been easier! With the STAK <strong>System</strong> ® ,one operator can efficiently manage loads weighingup to 4,000 lbs. – all in a footprint that’s as much as70% smaller than fixed horizontal beam rack storage.No forklift needed!Based on a system of dynamically adjustable pallets(rather than fixed shelves) and a captive lifting andhandling device, the STAK <strong>System</strong> helps maximizestorage density by minimizing the vertical spacerequirements of each stored pallet and its contents.Saves valuable floor space, saves time, andboosts productivity... SAFELY!2Introduction 2Features 4Applications 52K STAK <strong>System</strong> ® 6Pallets 8Options & Accessories 9Add-Ons/Features 104K STAK <strong>System</strong> ® 12HazMat STAK <strong>System</strong> ® 13STAK Max 13ARS Adjustable Rack <strong>System</strong> 14Color Choices 16

DYNAMIC PALLET-BASED STORAGEAND HANDLING SYSTEMStore or retrieve loads more quickly –regardless of size, shape, or weight!• Space savings – Squeeze wasted air out of your vertical storage and make use ofevery cubic foot! Free up floor space for other uses.• Value – Maximize the use of your cubic space, and get more productivity from yourentire facility.• Manpower efficiency – Retrieve items weighing up to 2 tons with just one person.• Ergonomic safety – Lifting and handling device is engineered for maximum ease of use.• Ease of retrieval and inventory control – Stored items are easily located, positionedand repositioned.• Precise load positioning – Pallets are positioned in the STAK <strong>System</strong> ® at verticalincrements of 4", so items can be stored exactly where you want them, on the fly.• Reduced use of fork trucks – Fewer fork trucks means greater savings, greatersafety on your shop floor and less wear and tear to floor. Operation of the STAK<strong>System</strong> lifting and handling device doesn’t require certification.• Product protection and security – Store large items on safe, protected pallets,off the floor.• Ideal for work-in-process, maintenance, tooling and fixturing, and supply and distribution.• Available as 2K STAK <strong>System</strong> (2,000-lb. capacity), 4K STAK <strong>System</strong> (4,000-lb. capa city),or HazMat STAK <strong>System</strong> (2,000-lb. capacity). Consult factory for capacities above 4,000 lbs., extendedheight systems, or oversized pallets.The STAK <strong>System</strong> is designed to be easily expanded incrementally as your storage needs grow. And with along list of available accessories, your STAK <strong>System</strong> can be designed to your facility’s exact requirements.For more information or a free site analysis, visit www.staksystem.com.Store a wide range of items of varyingsizes, shapes and heights, with a minimumof wasted space!Aisle space requirements are narrowerthan those required whenusing a conventional forklift.The system can be configured in a numberof ways, and can incorporate mid-aisleaccess. See page 7 for more.3

FEATURESThe STAK <strong>System</strong> ® is loaded with features to save space and maximize productivity.Add on bays to allow your STAK <strong>System</strong> to grow as yougrow. You can even add sections of mixed widths inthe same system!The STAK <strong>System</strong> ® is fully modular. Rack capacity is 25,000 lbs. per section and 50,000 lbs. per bay(seismic zones 1 and 2).Easy-to-learn and easy-to-usecontrols don’t require license orcertification.Loaded pallets are easily extractedand positioned.Pallets are placed in vertical increments of 4 ", soitems can be stored just where you want them, andare positioned via a positive engagement system.Mast hovers over floor for easeof use on uneven surfaces.4Unique handling device is completely ergonomic,which makes removing even large loads easy.Pallets are removed and replaced by guiding themast to the new position. Handling device man -euvers on four axes, creating total 360° flexibility.Simple, intuitive positioning enables the operatorto relocate a pallet quickly, accurately and safely.

APPLICATIONSWhether you need it for motors, pumps,dies and fixtures, molds, barrels, orwork-in-process, the STAK <strong>System</strong> ® canbe conveniently positioned in a centrallocation, where it’s needed most.Work-in-process.Work-in-Process/Buffer StorageThe STAK <strong>System</strong> helps reduce work cycle time by locatingwork-in-process close to the next station. Component damageis also minimized, since parts are kept off the plant floor.As a result, the STAK <strong>System</strong> boosts operator and departmentalproductivity.Maintenance and MROThe STAK <strong>System</strong> is ideal for bulky spare parts, motors,valves and pumps, making these hard-to-handle maintenanceitems easily accessible andorganized. A single operator can locateand retrieve critical inventory, helpingreduce production interruptions. In addition,the STAK <strong>System</strong> eliminates disposalproblems posed by oil-soakedwooden pallets.Tool and Die StorageThe STAK <strong>System</strong>’s hefty weight capacity makesit a natural for the storage of tools, dies andplastic injection molds, bringing much-neededorganization, efficiency, and expediency to thestorage of these expensive items. With theSTAK <strong>System</strong>, your entire inventory is visibleand reachable at all times, reducing downtime.The STAK <strong>System</strong> ® isideal for storing motors,valves and pumps.The STAK <strong>System</strong> is idealfor a number of applications,including:• Manufacturing• Service• Agriculture• Heavy equipment• MRO/Maintenance• Transportation• Warehouse• Utilities• Government5

2K STAK SYSTEM ®• An integrated storage and retrieval system,2K STAK <strong>System</strong> ® is designed to accommodatestorage items up to 2,000 lbs. in weight.• Consists of three main elements:1 mast and bridge assembly with liftingforks mounted on top of2 variable-location racks which accept3 removable steel pallets• Available with a variety of accessories.DE2K STAK Elements:MastRackingBCAPalletsOther available heightsPALLET DIMENSIONS CENTER-TO-CENTER OVERALL WIDTH AISLE WIDTH OVERALL HEIGHT OVERALL RACK HEIGHTW D A B C D E26 1 ⁄2" 30" 31 1 ⁄2" 11'11" 6' 6" 15'5" 13'36" 30" 41" 11'11" 6' 6" 15'5" 13'36" 36" 41" 13'7" 7' 2" 15'5" 13'42" 36" 47" 13'7" 7' 2" 15'5" 13'42" 42" 47" 15'3" 7'10" 15'5" 13'52" 42" 57" 15'3" 7'10" 15'5" 13'60" 42" 65" 16'3" 7'10" 15'5" 13'72" 42" 78" 16'3" 7'10" 15'5" 13'42" 48" 47" 16'3" 7'10" 15'5" 13'48" 48" 53" 16'3" 7'10" 15'5" 13'52" 48" 57" 16'3" 7'10" 15'5" 13'60" 48" 65" 16'3" 7'10" 15'5" 13'72" 48" 78" 16'3" 7'10" 15'5" 13'OVERALL HT. RACK HT. AVG. LOAD HT. OF 14" PALLETS18'5" 16' 817'5" 15' 716'5" 14' 615'5" 13' 614'5" 12' 613'5" 11' 512'6" 10'1" 411'6" 9'1" 310'6" 8'1" 3For additional available heights, contact your STAK<strong>System</strong> representative.Allow a minimum of 6" overhead clearance betweenoverall system height and ceiling.Length*To estimate overall length, multiply the center-to-center section width (A) x the number of bays + 28". For example,(3) sections with 48" x 48" pallets and (3) sections with 60" x 48" pallets: 53" x 3 = 159" + 65" x 3 = 195"159" + 195" + 28" = 382" (31'10")*For detailed dimentions for your application, contact your STAK ystem representative.6

The STAK <strong>System</strong> ® is available in a variety of configurations to suit your specific needs.Double-sided standardSingle-sidedDouble-sided with single mid-aisle accessDouble-sided with pair of mid-aisle accessDouble-sided with walk-through only accessDouble-sided with half cantileverWALLMACHINEMACHINETOOL STORAGECURINGWIPTOOL STORAGEDouble-sided with full cantileverFlexible solutions to meet unique needs. Above layout is just an exampleof the configurations we can design to solve your tough problems.7

PALLETSDesigned with two fork guides in front, STAK <strong>System</strong> ® pallets are offered in a variety of styles and sizes.Front engagement detailRear engagement detailThe back of the pallet is open to accommodate a variety of materialhandling devices when the pallet has been removed from the system.Plain PalletRear Lip Pallet• Plain Pallet: Available in a variety of standard sizes,6 widths and 4 depths (see page 6). Perfect for a widerange of uses.• Rear Lip Pallet: Centered on pallet, 1 1 ⁄4" high rear lipprovides added security by preventing items from extendingbeyond pallet.• Pallet Support Frame: Used to store loads on skids (onepiece).• Tub Kit: Four sidewalls.Available in three heights: 4 7 ⁄8",8 3 ⁄4" and 12 5 ⁄8".• Tub Kit Dividers & Partitions:Sidewall and front-to-back partitionsplus dividers. Allowscompartment alization of pallets. Contact your STAK<strong>System</strong> ® representative for size availability.• Tub Kit with Drop Front: Items can be easily removedwhen front wall is dropped. Available in three heights:4 7 ⁄8", 8 3 ⁄4" and 12 5 ⁄ 8".• Flow-Through Pallet:Allows sprinkler systemwater to flow throughpallet.8

OPTIONS & ACCESSORIES• Tire Storage Pallet: Cross bars secure up to six standardtires or four oversized tires. Tire storage pallet can beloaded directly to and from delivery truck, eliminating atransport step.• Wire Basket:Easy-to-seestorage forsmall or irregularitems.• Work-in-ProcessCart: Cradles entirepallet for easy, fast delivery. Utilizes two fixed and twoswivel casters with locks. Available for five pallet widths:26 1 ⁄2", 36", 42", 48" and 52". 2,000 lb. capacity.• Reel Storage: Steel brackets are attached to pallet forstorage of wire rope, cable, tubing, hosing, etc.• Instant-ID Pallet Labels (not pictured): Affix andremove labels quickly and easily with magneticallyattached ID labels.• Toolholder (not pictured): Heavy-duty tool storagepallet for machining centers.• Barrel Storage: Barrels and heavy drums can be storedhorizontally in our steel cradles, orstored vertically as shown.Barrel storage9

ADD-ONS/ FEATURESWhether you work with spare parts, motors,dies, pumps, tires, computer equipment, or55-gallon drums, we have the accessories youneed to make your STAK <strong>System</strong> ® work for you.Cantilever OverhangAllows lifting device to travel beyond racking(provides 4' of overhang). Ideal for parts stagingor transfer. Available for pallet sizes 26 1 ⁄2", 36",42", 48", 52", 60" and 72".Mast Rotation RestraintAutomatically positions mast at 90° intervals(parallel and perpendicular to aisle). Can bedisengaged to provide 360° continuous rotation.Safety MeshRecommended for STAK <strong>System</strong> ® bays on ornear traffic aisles or operations areas. Flushmountednylon mesh or expanded metal, safetyratedup to 1,000 lbs. per square foot for 2KSTAK <strong>System</strong>s and up to5,000 lbs. per square footfor 4K STAK <strong>System</strong>s.Nylon mesh10 10Expanded metal

Mast/Column Pallet LocatorAllows operator to place forks in exact position required toeasily remove and replace pallets in their numbered locations.Rear Column BracketsBolt to rear columns to convert unused space into manualstorage space. Available in 6", 8" and 12" depths.Mast/Floor LockHolds mast in place while items are being transferred frompallet. Will compensate for up to 6" variation in floor level.Trolley LockSecures lifting device in the middle of aisle for ease of useon longer systems.Mast/Floor LockMotorized BridgeTravels at 135 feet per minute.Recommended on systems with longruns and high activity.11

4K STAK SYSTEM ®• The ultimate single-operator storage solution, 4K STAK <strong>System</strong> ® is designedfor the storage of larger and heavier items (up to 4,000 lbs.).• From one convenient operator’s position, 4K STAK <strong>System</strong> keeps hard-tohandleitems accessible and organized.• Same main elements as 2K STAK <strong>System</strong>, with all directional movements fullymotorized.4K Operator’s Cab: Ergonomically designed, operator’s cab has all controls onboard and provides clear sight lines. Safety is further enhanced by platform controlpedal, protective canopy, hand guards, and cab back.4K Controls: Two types of control stations are available for operation, a cage or awalk-behind with detachable controls. Cage pendant controls direct movement onall four axes and are mounted on themast. Walk-behind allows operator tostand off to the side to increase visibility.For safety, control pendant has a removablekey switch and e-stop emergencybutton.Pallet and hook12

HAZMAT STAK SYSTEM ®Designed specifically for the storage, staging, and retrieval of 55-gallonhazardous material drums, the HazMat STAK <strong>System</strong> ® gets your drums offthe floor and into their own dedicated storage system – withouthaving to use a forklift.Every detail of the HazMat STAK <strong>System</strong> is designed for safetyand ergonomic operation, from its pneumatic operation to its brightyellow color. Drums are stored one deep, so they’re always visibleand potential problems can be easily detected.The HazMat STAK <strong>System</strong> can efficiently manage loads up to2,000 lbs. with pallets specifically designed to allow sprinkler sys -t em water to flow through the pallets (must specify flow-throughpallet – see page 8). All HazMat STAK <strong>System</strong> storage units carryfactory mutual system approval.STAK MAXThe STAK Max has all the features and benefits of the STAK<strong>System</strong> ® taken to the next level.• Build up to 24 feet high.• Each pallet can accommodate loads up to 2,500 lbs.• Six additional pallet widths available (19 sizes total).STAK Max 5000 is our top-of-the-line system, combining allthe features and benefits of STAK Max but with even greaterload capacities.• Pallet load capacity up to 5,000 lbs. each, with verticalheights up to 24 feet.• Six additional pallet widths available (19 sizes total).13

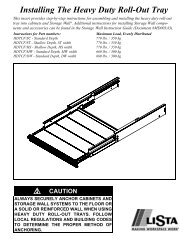

ARS – ADJUSTABLE RACKA completely flexible heavy-duty storage solution, the ARSAdjustable Racking <strong>System</strong> allows super-efficient storage ofitems of varying size and weight. Like the STAK <strong>System</strong> ® , theARS is based on a system of removable, positionable pallets,but does not include the STAK <strong>System</strong>’s mast and bridgeassembly. ARS pallets are moved by means of fork trucks.The ARS Adjustable Racking <strong>System</strong> helps maximize storagedensity by minimizing the vertical space requirements of eachstored pallet and its contents.• Removable, fully adjustable pallets that can change andgrow with your storage requirements.• Racking is available up to 16' high for maximum verticalstorage space.• <strong>System</strong>s can be broken up to fit around unavoidablebuilding structures like columns.• Array of convenient storage accessories is available(same accessories as STAK <strong>System</strong> ® ).• Consult factory for capacities above 4,000 lbs., extendedheight systems, or oversized pallets.ADJUSTABLE RACKING FEATURESColumns and PalletsAdjustable racking system roll-formed columns providedouble-strength rest hooks. Pallets are reinforced withdouble-layer steel surfaces.Pallet Fork GuidesAdjustable racking system pallet fork guides insure properengagement and provide additional structural support.Opposing cross members provide total surface supportstability.Pallet Racking <strong>System</strong>Heavy-duty columns provide 25,000-lb. capacity per storagesection (seismic zones 1 and 2). Double-strength rest hookson 7 3 ⁄4" centers allow maximum-density pallet positions.14

HEIGHT/PALLETSELECTION GUIDETo determine the height of the adjustableracking system that will fit your building andthe number of pallets per section based onload heights, follow these steps:1. Measure from the floor to the lowestoverhead obstruction. To account for variationsin the floor level, check this measurementat several locations within thearea of the storage system.2. The standard rack height is 152" (12' 8").If your ceiling will not accept the standardheight, select the height that will clear allobstructions from the other available heights below.3. Match the height you selected for your rack height withthe average pallet load height in the table below. Theintersection will determine the number of pallets persection. Multiply this number by the number of sectionsof racking to obtain the total number of pallets for yourstorage system.Height/Pallet Selection GuidePALLETOTHER AVAILABLE RACK HEIGHTS STD RACK HT OTHER AVAILABLE RACK HEIGHTSLOAD HT. 190" 183" 175" 167" 159" 152" 144" 136" 128" 121" 113" 105" 97" 90" 82"6" 11 11 10 10 9 9 8 8 7 7 6 6 5 5 410" 8 7 7 7 6 6 6 5 5 5 4 4 4 3 314" 7 7 7 6 6 6 5 5 5 4 4 4 3 3 318" 6 5 5 5 5 4 4 4 4 3 3 3 3 2 222" 5 5 5 5 4 4 4 4 3 3 3 3 2 2 226" 4 4 4 4 3 3 3 3 3 3 2 2 2 2 230" 4 4 4 4 3 3 3 3 3 2 2 2 2 2 1PALLETS PER SECTION15

STAK <strong>System</strong> ® and ARS Color ChoicesRacks and palletsOff-WhiteS22570BeigeS20100GreenS20606Light BlueS22577STAK BlueS22447<strong>Lista</strong> Bright BlueS1010Dark BlueS22578GrayS23321Light GrayS1075BlackS20106Bridge and mast assemblySafety YellowContact your STAK SYSTEM® representative for more details, specifications and warranty,or visit staksystem.com.Designed to be Rack Manufacturers Institute (RMI) and American National Standards Institute (ANSI) compliant.©2012 <strong>Lista</strong> International Corp. Printed in U.S.A. 04-12 5M