1981-87 CHEV PICK-UP - Vintage Air

1981-87 CHEV PICK-UP - Vintage Air

1981-87 CHEV PICK-UP - Vintage Air

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

FOR MAXIMUM SYSTEM PERFORMANCE VINTAGE AIR RECOMMENDS THE FOLLOWING:THIS KIT DOES NOT CONTAIN HEATER HOSE. YOU MUST PURCHASE 12 FEET OF 5/8” DIA.HEATER HOSE FROM VINTAGE AIR (31800-VUD) OR FROM YOUR LOCAL PARTS RETAILERSAFETY SWITCHES:SERVICE INFO:IMPORTANT NOTICE-PLEASE READYOUR VINTAGE AIR SYSTEM IS EQUIPPED WITH A BINARY PRESSURE SAFETY SWITCH. A BINARY SWITCH(11078-VUS) DISENGAGES THE COMPRESSOR CLUTCH IN CASE OF EXTREME LOW PRESSURE CONDITION(REFRIGERANT LOSS) OR EXCESSIVELY HIGH HEAD PRESSURE (406 PSI), TO PREVENT COMPRESSOR DAMAGEOR HOSE R<strong>UP</strong>TURE. A TRINARY SWITCH (11076-VUS) COMBINES HI/LO PRESSURE PROTECTION WITH ANELECTRIC FAN OPERATION SIGNAL AT 254 PSI., AND MAY BE SUBSTITUTED FOR USE WITH ELECTRICCONDENSER FANS. COMPRESSOR SAFETY SWITCHES ARE EXTREMELY IMPORTANT SINCE AN A/C SYSTEMRELIES ON REFRIGERANT TO CARRY LUBRICATION THROUGH THE SYSTEM.ATTENTION: SYSTEM COMPONENTS: THE COMPRESSOR, EVAPORATOR, CONDENSER & DRIER ARE CAPPED.CAPS MAY BE UNDER PRESSURE WITH DRY NITROGEN; BE CAREFUL REMOVING CAPS. DO NOT REMOVE CAPSPRIOR TO INSTALLATION. REMOVING CAPS PRIOR TO INSTALLATION WILL CAUSE COMPONENTS TO COLLECTMOISTURE AND LEAD TO PREMATURE FAILURE AND REDUCED PERFORMANCE.EVACUATE THE SYSTEM FOR 35-45 MINUTES WITH SYSTEM COMPONENTS (DRIER, COMPRESSOR, EVAPORATORAND CONDENSER) AT A TEMPERATURE OF AT LEAST 85° F. ON A COOL DAY THE COMPONENTS CAN BE HEATEDWITH A HEAT GUN OR BY RUNNING THE ENGINE WITH THE HEATER ON BEFORE EVACUATING. LEAK CHECKAND CHARGE TO SPECIFICATIONS.VINTAGE AIR SYSTEMS ARE DESIGNED TO OPERATE WITH R134aREFRIGERANT ONLY! USE OF ANY OTHER REFRIGERANTS RISKS A DANGER OF FIREAND COULD DAMAGE EITHER YOUR AIR CONDITIONING SYSTEM OR YOUR VEHICLE.USE OF ANY OTHER REFRIGERANTS WILL VOID ALL WARRANTIES OFTHE AIR CONDITIONING SYSTEM AND COMPONENTS. USE OF THE PROPERTYPE AND AMOUNT OF REFRIGERANT IS CRITICAL TO PROPER SYSTEMOPERATION. VINTAGE AIR RECOMMENDS OUR SYSTEMS BE CHARGED BYWEIGHT WITH A QUALITY CHARGING STATION OR SCALE.REFRIGERANT CAPACITY FOR VINTAGE AIR SYSTEMS(FOR OTHER SYSTEMS, CONSULT MANUFACTURER GUIDELINES)134a SYSTEMCHARGE WITH 1.8 lbs.(1lbs. 12ozs) OF REFRIGERANTLUBRICANT CAPACITIES:NEW COMPRESSOR - NO ADDITIONAL OIL NEEDED901182 REV A 6/13/11, INST 81-<strong>87</strong> <strong>CHEV</strong> P-<strong>UP</strong> wo AC EVAP KIT PG 4 OF 274

IMPORTANT WIRING NOTICE-PLEASE READSOME VEHICLES MAY HAVE HAD SOME OR ALL OF THEIR RADIO INTERFERENCE CAPACITORSREMOVED. THERE SHOULD BE A CAPACITOR FOUND AT EACH OF THE FOLLOWING LOCATIONS:1. ON THE POSITIVE TERMINAL OF THE IGNITION COIL2. IF THERE IS A GENERATOR, ON THE ARMATURE TERMINAL OF THE GENERATOR3. IF THERE IS A GENERATOR, ON THE BATTERY TERMINAL OF THE VOLTAGE REGULATORMOST ALTERNATORS HAVE A CAPACITOR INSTALLED INTERNALLY TO ELIMINATE WHAT IS CALLED'WHINING' AS THE ENGINE IS REVVED. IF WHINING IS HEARD IN THE RADIO, OR JUST TO BE EXTRACAUTIOUS, A RADIO INTERFERENCE CAPACITOR CAN BE ADDED TO THE BATTERY TERMINAL OFTHE ALTERNATOR.IT IS ALSO IMPORTANT THAT THE BATTERY LEAD IS IN GOOD SHAPE AND THAT THE GROUNDLEADS ARE NOT COMPROMISED. THERE SHOULD BE A HEAVY GROUND FROM THE BATTERY TOTHE ENGINE BLOCK, AND ADDITIONAL GROUNDS TO THE BODY AND TO THE CHASSIS.IF THESE PRECAUTIONS ARE NOT OBSERVED, IT IS POSSIBLE FOR VOLTAGE SPIKES TO BE PRESENTON THE BATTERY LEADS. THESE SPIKES COME FROM IGNITION SYSTEMS, CHARGING SYSTEMS,AND FROM TURNING SOME OF THE VEHICLE'S OTHER SYSTEMS ON AND OFF. MODERNCOMPUTER OPERATED EQUIPMENT CAN BE SENSITIVE TO VOLTAGE SPIKES ON THEIR POWERLEADS, WHICH CAN CAUSE UNEXPECTED RESETS, STRANGE BEHAVIOR, AND MAY ALSO CAUSEPERMANENT DAMAGE.VINTAGE AIR STRIVES TO HARDEN THEIR PRODUCTS AGAINST THESE TYPES OF ELECTRICAL NOISE,BUT THERE IS A POINT WHERE A VEHICLE'S ELECTRICAL SYSTEM CAN BE DEGRADED SO MUCHTHAT NOTHING CAN HELP.RADIO INTERFERENCE CAPACITORS SHOULD BE AVAILABLE AT MOST AUTO & TRUCK PARTSS<strong>UP</strong>PLIERS. THEY TYPICALLY ARE CYLINDRICAL IN SHAPE, A LITTLE OVER AN INCH LONG, A LITTLEOVER A HALF INCH IN DIAMETER, THEY HAVE A SINGLE LEAD COMING FROM ONE END OF THECYLINDER WITH A TERMINAL ON THE END OF THE WIRE, AND THEY WILL HAVE A MOUNTING CLIPWHICH IS SCREWED INTO A GOOD GROUND ON THE VEHICLE. THE SPECIFIC VALUE OF THECAPACITANCE IS NOT TOO SIGNIFICANT, IN COMPARISON TO IGNITION CAPACITORS THAT AREMATCHED WITH THE COIL TO REDUCE PITTING OF THE POINTS.CARE MUST BE TAKEN WHEN INSTALLING THE COMPRESSOR LEAD, NOT TO SHORTIT TO GROUND. THE COMPRESSOR LEAD MUST NOT BE CONNECTED TO A CONDENSERFAN OR ANY OTHER AUXILIARY DEVICE. SHORTING TO GROUND OR CONNECTINGTO A CONDENSER FAN OR ANY OTHER AUXILIARY DEVICE WILL CAUSE SEVERE DAMAGETO THE ECU.WHEN INSTALLING GROUND LEADS ON GEN IV SYSTEMS, THE BLOWER CONTROL GROUNDAND ECU GROUND MUST BE CONNECTED DIRECTLY TO THE NEGATIVE BATTERY POST.5THE HEATER CONTROL VALVE IS A NORMALLY OPEN VALVE. IT MUST BE CONNECTED TOTHE ECU TO BLOCK WATER FLOW IN MAX AC MODE.901182 REV A 6/13/11, INST 81-<strong>87</strong> <strong>CHEV</strong> P-<strong>UP</strong> wo AC EVAP KIT PG 5 OF 27

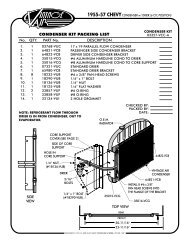

ENGINE COMPARTMENTBEFORE STARTING THE INSTALLATION, CHECK THE FUNCTIONOF THE VEHICLE (HORN, LIGHTS,ETC.) FOR PROPER OPERATIONS.STUDY THE INSTRUCTIONS, ILLUSTRATIONS, & DIAGRAMS.REMOVE THE FOLLOWINGDISCONNECT BATTERY.DRAIN RADIATOR, REMOVE RADIATOR (RETAIN)HEATER BLOWER ASSEMBLY AND OEM HEATER HOSES (DISCARD)NOTE: TO REMOVE THE OEM HEATER BLOWER ASSEMBLY (UNDER HOOD) AND THE AIRDISTRIBUTION SYSTEM (UNDER DASH). THE FACTORY MANUAL RECOMMENDS THAT YOU REMOVERIGHT INNER FENDER FOR ACCESSIBLITY.FIGURE 1OEM HEATERBLOWERASSEMBLYCONDENSER ASSEMBLY & INSTALLATIONREFER TO SEPARATE INSTRUCTIONS INCLUDED WITH THE CONDENSER KIT TO INSTALL THE CONDENSER.BINARY SWITCH INSTALLATION (REFER TO CONDENSER INSTRUCTIONS)COMPRESSOR & BRACKETSREFER TO SEPARATE INSTRUCTIONS INCLUDED WITH THE BRACKET KIT TO INSTALL THE COMPRESSORAND BRACKET.901182 REV A 6/13/11, INST 81-<strong>87</strong> <strong>CHEV</strong> P-<strong>UP</strong> wo AC EVAP KIT PG 6 OF 276

PASSENGER COMPARTMENTREMOVE THE FOLLOWING:GLOVE BOX DOOR AND GLOVE BOX ASSEMBLY (RETAIN) (SEE FIGURE 2 BELOW)UNDER DASH STEERING COLUMN COVER (RETAIN) (SEE FIGURE 2)INSTRUMENT PANEL BEZEL (RETAIN)DASH PAD (RETAIN) (SEE FIGURE 2)DISCONNECT ALL WIRES AND CABLES FROM CONTROL PANEL.REMOVE CONTROL PANEL (DISCARD) REFER TO CONTROL PANEL CONVERSION KIT INSTRUCTIONS.ASH TRAY (RETAIN)OEM HEATER ASSEMBLY (DISCARD) (SEE FIGURE 2a).DEFROST DUCT ASSEMBLY (DISCARD) (SEE FIGURE 2a.)NOTE: FOR EASE OF INSTALLING EVAPORATOR UNDER DASH, IT MAYBE HELPFULL TO REMOVE THE(2) OEM BOLTS UNDER THE DASH ON THE PASSENGER SIDE DOOR PILLAR AND PULL BACK DASH.DASHPADUNDER DASHINTSTRUMENTCOVERPANELBEZELCONTROLPANELFIGURE 2ASHTRAYGLOVE BOXDOOR &GLOVE BOXDEFROST DUCTASSEMBLY(2) OEMBOLTSFIGURE 2aOEM HEATERASSEMBLYDASHBRACE7901182 REV A 6/13/11, INST 81-<strong>87</strong> <strong>CHEV</strong> P-<strong>UP</strong> wo AC EVAP KIT PG 7 OF 27

DEFROST DUCT INSTALLATIONINSTALL (4) #8 U-NUTS IN OEM DEFROST DUCT OPENINGS AS SHOWN BELOW IN FIGURE 3.INSTALL DRIVER AND PASSENGER SIDE DEFROST DUCTS USING (4) #8 x 1/2” PH PAN HEAD SCREWSAS SHOWN BELOW. (2) DEFROSTDUCT623219(4) #8 x 1/2”PH PAN HEADSCREWS(4) #8 U-NUT189801FIGURE 3FRESH AIR CAP AND FIREWALL MODIFICATIONAPPLY A 1/4” BEAD OF SILICONE AROUND THE BACK SIDE OF THE FRESH AIR CAP AS SHOWN IN FIGURE 4,BELOW.ATTACH FRESH AIR CAP TO FIREWALL USING A 1/4-20 x 1” BOLT AND WASHER, SEE FIGURE 4 BELOW.PLACE FIREWALL COVER ON FIREWALL AND SCURE USING #14 x 3/4“ SHEET METAL SCREW AND(2) 1/4-20 x 3/4” HEX BOLT w/ 1/4” NUT w/ STAR WASHER AS SHOWN BELOW.USING FIREWALL COVER AS TEMPLATE, MARK THE HOLES ON FIREWALL AS SHOWN BELOW.REMOVE FIREWALL COVER.SILICONEBACK SIDE OFFRESH AIR CAP1/4-20 x 1”BOLT1/4” FLATWASHERFRESH AIRCAPFIGURE 4MARKHOLEMARKHOLEMARKHOLES1/4-20 x 3/4”BOLT1/4-20 x 3/4”BOLT 1/4” NUT w/STAR WASHEROEMHOLEMARKHOLES1/4” NUT w/STAR WASHERMARKHOLE#14 x 3/4”SHEET METALSCREWMARKHOLEOEMHOLE901182 REV A 6/13/11, INST 81-<strong>87</strong> <strong>CHEV</strong> P-<strong>UP</strong> wo AC EVAP KIT PG 8 OF 278

FIREWALL MODIFICATION CONT.DRILL HOLES AS SHOWN BELOW IN FIGURE 5DRILL 3/16”HOLEOEMHOLEDRILL 9/32”HOLEDRILL 3/8”HOLEOEMHOLEDRILL 3/16”HOLEFIGURE 5FIREWALL COVER INSTALLATIONOEMHOLEDRILL 3/16”HOLEDRILL 3/16”HOLEAPPLY A 1/4” BEAD OF SILICONE AROUND THE BACK SIDE OF THE FIREWALL COVER AS SHOWN BELOW.INSTALL FIREWALL COVER TO FIREWALL USING 1/4-20 x 3/4” HEX BOLT, 1/4“ FLAT WASHER, 1/4” NUTw/ STARWASHER AND (7) #14 x 3/4“ SHEET METAL SCREWS AS SHOWN BELOW.INSTALL GROMMETS AS SHOWN BELOW.SILICONE1/4-20 x 3/4”BOLT1/4” FLATWASHER1/4” NUT w/STAR WASHER9BACK SIDE OFFIREWALL COVER644086LARGEGROMMET33137-VUIGROMMET33135-VUI1/4-20 x 3/4”BOLT1/4” FLATFIGURE 6WASHER1/4” NUT w/STAR WASHER901182 REV A 6/13/11, INST 81-<strong>87</strong> <strong>CHEV</strong> P-<strong>UP</strong> wo AC EVAP KIT PG 9 OF 27(7) #14 x 3/4”SHEET METALSCREW

BRACKET & EVAPORATOR HARDLINE INSTALLATIONON A WORK BENCH INSTALL EVAPORATOR REAR BRACKET USING (4) 1/4-20 x 1/2” HEX BOLTS.(SEE FIGURE 8, PAGE 11)INSTALL #6 EVAP HARDLINE AND (2) HEATER HARDLINES WITH PROPERLY LUBRICATED O-RINGS.(SEE FIGURE 8, PAGE 11 AND FIGURE 11, PAGE 13.)INSTALL EVAPORATOR FRONT BRACKET ON EVAPORATOR USING (2)1/4-20 x 1/2” HEX BOLTS ANDTIGHTEN AS SHOWN IN FIGURE 7 BELOW.(2)1/4-20 x ½”HEX BOLTEVAP FRONTBRKT6440<strong>87</strong>FIGURE 7901182 REV A 6/13/11, INST 81-<strong>87</strong> <strong>CHEV</strong> P-<strong>UP</strong> wo AC EVAP KIT PG 10 OF 2710

BRACKET & EVAPORATOR HARDLINE INSTALLATION CONT.ECU MODULE(2) 1/4-20 x ½”HEX BOLTHOLD WITHTHIS WRENCH(2) 1/4-20 x ½”HEX BOLTTWIST WITHTHISREAR WREN<strong>CHEV</strong>APORATORBRACKET644083LUBRICATE O-RING(SEE FIGURE 11,PAGE 13.)FIGURE 8#6 O-RING(33857-VUF)#10 O-RING(33859-VUF)11#6 LIQUID LINE091153HEATER LINE(EVAP TO WATER PUMP)091151HEATER LINE(EVAP TO INTAKE)091151901182 REV A 6/13/11, INST 81-<strong>87</strong> <strong>CHEV</strong> P-<strong>UP</strong> wo AC EVAP KIT PG 11 OF 27

EVAPORATOR INSTALLATIONLIFT EVAPORATOR UNIT <strong>UP</strong> UNDER THE DASHBOARD. SECURE LOOSELY TO THE FIREWALL USING(2) 1/4-20 x 1¼” HEX BOLTS, (2) FLAT WASHERS AND (2) .563 L SPACERS. (SEE FIGURE 9.)NOTE: TO ENSURE PROPER DRAINAGE, IT IS VERY IMPORTANT THAT THE EVAPORATOR IS LEVEL, BOTH LEFT-RIGHTAND FORE-AFT. CHECK FOR LEVEL ON THE FLAT PORTIONS OF THE CASE AROUND THE DRAIN, BLOCK THE UNIT<strong>UP</strong>, THEN DRILL FOR FRONT BRACKET SCREWS.SECURE THE FRONT EVAPORATOR MOUNTING BRACKET TO COWL USING (2) #14 x 3/4” HEX SHEETMETAL SCREWS SEE FIGURE 9a BELOW.VERIFY THAT EVAPORATOR UNIT IS LEVEL AND SQUARE TO THE DASH, THENTIGHTEN ALL MOUNTING BOLTS.(NOTE: TIGHTEN THE BOLT ON FIREWALL FIRST, THEN THE FRONTMOUNTING BRACKET.)INSTALL #10 SUCTION LINE AS SHOWN IN FIGURE 9b BELOW.NOTE: WRAP THE #10 FITTING CONNECTIONSWITH PRESS TAPE. SEE FIGURE 9b BELOW.RE-INSTALL (2) OEM BOLTS UNDER DASH ONPASSENGER SIDE DOOR PILLAR.(2)1/4-20 x 1¼”HEX BOLT(2) 1/4” FLATWASHERINNERCOWLDRILL (2)3⁄16” HOLES (2)#14 x ¾”SHEET METALSCREWSFIGURE 9aVIEW FROMPASSENGER SIDEINSIDE OF CAB(2) .563 LSPACERSNOTE: AFTER INSTALLING#10 SUCTION LINEWRAP ALL EXPOSED METAL(FITTINGS & TUBE) WITHS<strong>UP</strong>PLIED PRESS TAPEFIGURE 9#10 O-RING33859-VUFPRESS TAPE#10 SUCTIONLINE091152FIGURE 9b901182 REV A 6/13/11, INST 81-<strong>87</strong> <strong>CHEV</strong> P-<strong>UP</strong> wo AC EVAP KIT PG 12 OF 2712

DRAIN HOSE INSTALLATIONLOCATE EVAPORATOR DRAIN ON BOTTOMOF EVAPORATOR CASE.IN-LINE WITH DRAIN, LIGHTLY MAKE A MARKON THE FIREWALL MEASURE 1” DOWN ANDDRILL A 5/8” HOLE THROUGH THE FIREWALL.INSTALL DRAIN HOSE TO BOTTOM OFEVAPORATOR UNIT AND ROUTE THROUGHFIREWALL. INSTALL 1/2” 90° DRAIN ELBOWON DRAIN HOSE.1”1”LUBRICATING O-RINGSO-RINGEVAPORATORCASEMALEINSERTFEMALENUTDRAINHOSEFIGURE 10FOR A PROPER SEAL OF FITTINGS:INSTALL S<strong>UP</strong>PLIED O-RINGS AS SHOWNAND LUBRICATE WITH S<strong>UP</strong>PLIED OIL.#6 O-RINGO -RINGS<strong>UP</strong>PLIED OILFOR O -RINGSO-RING, INSTALLESOVER MALE INSERTTO SWAGED LIP# 8 O -RING #10 O -RINGA/C HOSE INSTALLATIONSTANDARD HOSE KITFIGURE 11LOCATE THE #8 COMPRESSOR A/C HOSE. LUBRICATE (2) #8 O-RINGS (SEE FIGURE 11, ABOVE) AND CONNECTTHE 90° FEMALE FITTING TO THE #8 DISCHARGE PORT ON THE COMPRESSOR. ROUTE THE STRAIGHT FEMALEFITTING w/ 134a SERVICE PORT TO THE #8 CONDENSER HARDLINE COMING THROUGH CORE S<strong>UP</strong>PORT.SEE FIGURE 13, PAGE 15. TIGHTEN EACH FITTING CONNECTION AS SHOWN.LOCATE THE #10 COMPRESSOR A/C HOSE. LUBRICATE (2) #10 O-RINGS (SEE FIGURE 11, ABOVE) ANDCONNECT THE #10 135° FEMALE FITTING w/134a SERVICE PORT TO THE #10 SUCTION PORT ON THECOMPRESSOR. ROUTE THE STRAIGHT FEMALE FITTING TO THE #10 EVAPORATOR. SEE FIGURE 12, PAGE 14AND FIGURE 13, PAGE 15. TIGHTEN EACH FITTING CONNECTION AS SHOWN.INSTALL #6 A/C LIQUID LINE AS SHOWN IN FIGURE 13, PAGE 15.HOLD WITHTHIS W RENCHTWIST WITHTHIS WRENCH13MODIFIED A/C HOSE KITREFER TO SEPARATE INSTRUCTIONS INCLUDED WITH MODIFIED HOSE KIT.901182 REV A 6/13/11, INST 81-<strong>87</strong> <strong>CHEV</strong> P-<strong>UP</strong> wo AC EVAP KIT PG 13 OF 27

HEATER HOSE & HEATER CONTROL VALVE INSTALLATIONROUTE HEATER HOSE FROM WATER PUMP TO THE HEATER LINE COMING THROUGH THE FIREWALL ASSHOWN IN FIGURE 12, BELOW. SECURE USING HOSE CLAMPS. NOTE: A SMALL AMOUNT OF SILICONESPRAY WILL EASE HEATER HOSE INSTALLATION.ROUTE HEATER HOSE FROM THE INTAKE TO THE HEATER LINE COMING THROUGH THE FIREWALL AS SHOWNBELOW. NOTE: INSTALL HEATER CONTROL VALVE IN-LINE WITH INTAKE MANIFOLD (PRESSURE SIDE) HEATERHOSE, SECURE USING HOSE CLAMPS AS SHOWN. NOTE PROPER FLOW DIRECTION.HOSE SHOULD PROTRUDE THROUGH THE FIREWALL COVER SLIGHTLY TO CLOSE THE GAP BETWEEN THEALUMINUM LINE AND THE FIREWALL COVER. SEAL ANY REMAINING GAP WITH RTV SILICONE.FROM HEATER CORETO WATER PUMPHEATERHOSEO-RINGS#10 SUCTIONLINEFROM HTR CNTRL VLVTO HEATER CORE FROM INTAKEHEATERHOSEMANIFOLD#6 LIQUIDLINENOTE: FLOW ARROW DECALON HEATER CONTROL VALVE.FIGURE 12901182 REV A 6/13/11, INST 81-<strong>87</strong> <strong>CHEV</strong> P-<strong>UP</strong> wo AC EVAP KIT PG 14 OF 2714

NOTE: VINTAGE AIR SYSTEMS REQUIRE(2) 5/8” HOSE NIPPLES (NOT S<strong>UP</strong>PLIED)15AC & HEATER HOSE ROUTINGTIEWRAP#6 LIQUIDHARDLINE091150HEATER HOSE(HEATER CNTRLVALVE/INTAKE)#10 ADELCLAMP31601-VUD#8 DISCHARGEHOSE096004#10 SUCTIONHOSE096005FROM HTR CNTRL VLVTO HEATER CORE#6 COND/ DRIERHARDLINE091154OUT#6 CORE/ EVAPLIQUIDHARDLINE091149#8 CONDHARDLINE091156INHEATERHOSE#6 DRIER/CORE S<strong>UP</strong>PORTHARD LINE091155COMPRESSORSAFETY SWITCH(BINARY TYPE)SCREW ON DRIER(REFER TOCONDENSERINSTRUCTIONS)#2 ADELCLAMP31600-VUDFROM INTAKEMANIFOLD901182 REV A 6/13/11, INST 81-<strong>87</strong> <strong>CHEV</strong> P-<strong>UP</strong> wo AC EVAP KIT PG 15 OF 27(NOTE FLOW DIRECTION SPECIFIEDON HEATER CONTROL VALVE LABEL)FLOW SHOULD BE OPPOSITEDIRECTION OF MOLDED ARROWON VALVEFIGURE 13

PASSENGER SIDE LOUVER DASH PANEL INSTALLATIONREMOVE PASSENGER SIDE DASH TRIM FROM DASH PAD. (SEE FIGURE 14)INSTALL PASSENGER SIDE LOUVER DASH PANEL USING (7) NUTS. (SEE FIGURE 14)OEM PASSENGER SIDEDASH TRIMFIGURE 14PASSENGER SIDELOUVER DASH PANEL49176-VCLDRIVER SIDE/ CENTER LOUVER INSTALLATIONUSING DRIVER SIDE LOUVER TEMPLATE PROVIDED ON PAGE 25, MARK AND CUT INSTRUMENT PANEL BEZELAS SHOWN IN FIGURE 15 BELOW.CUT AND REMOVE PACKAGE TRAY AS SHOWN IN FIGURE 15a.INSTALL DRIVER SIDE LOUVER AND CENTER LOUVER AS SHOWN IN FIGURE 15b.DRILL (4) 3/32” HOLES IN DRIVER SIDE LOUVER AND SECURE USING (4) #4 PH PAN HEAD SCREWS.(SEE FIGURE 15c.)DRILL (4) 3/32” HOLES IN DRIVER SIDE CENTER LOUVER AND SECURE USING (4) #4 PH PAN HEAD SCREWS.(SEE FIGURE 15c.)1973-<strong>87</strong><strong>CHEV</strong>Y TRUCKNON AIRDRIVER SIDE VENTTEMPLATEPLACE DRIVER-SIDELOUVER TEMPLATE LOCATEDON PAGE 25 HEREFIGURE 15PACKAGETRAYDASHINSTRUMENTBEZELCUT ALONGEDGEAS SHOWNLOUVERPLATE ADAPTER49180-VCL CENTERLOUVER49179-VCLPACKAGETRAYFIGURE 15aDRIVER SIDECENTER LOUVER49179-VCLDRILL (4)3/32” HOLES(4) #4PH PAN HEADSCREWSFIGURE 15bDRIVER SIDELOUVER49178-VCL(4) #4DRILL (4)PH PAN HEAD3/32” HOLESSCREWS901182 REV A 6/13/11, INST 81-<strong>87</strong> <strong>CHEV</strong> P-<strong>UP</strong> wo AC EVAP KIT PG 16 OF 27FIGURE 15c16

FINAL STEPSINSTALL DUCT HOSES AS SHOWN IN FIGURE 18, PAGE 19.ROUTE A/C WIRES THROUGH 3/8” GROMMET AS SHOWN ON FIGURE 16(12 VOLT/GROUND/BINARY SWITCH/HEATER VALVE).INSTALL CONTROL PANEL ASM.PLUG THE WIRING HARNESS IN THE ECU MODULE ON SUB CASE AS SHOWN IN FIGURE 18, PAGE 19(WIRE ACCORDING TO WIRING DIAGRAM ON PAGE 20 AND 21.)MODIFY GLOVE BOX AS SHOWN ON PAGE 18.REINSTALL GLOVE BOX.REINSTALL ALL PREVIOUSLY REMOVED ITEMS, INNER FENDER.FILL RADIATOR WITH AT LEAST A 50/50 MIXTURE OF APPROVED ANTIFREEZE AND DISTILLED WATER. IT IS THEOWNER'S RESPONSIBILITY TO KEEP THE FREEZE PROTECTION AT THE PROPER LEVEL FOR THE CLIMATE INWHICH THE VEHICLE IS OPERATED. FAILURE TO FOLLOW ANTIFREEZE RECOMMENDATIONS WILL CAUSEHEATER CORE TO CORRODE PREMATURELY AND POSSIBLY BURST IN AC MODE AND/OR FREEZING WEATHER,VOIDING YOUR WARRANTY.DOUBLE CHECK ALL FITTINGS, BRACKETS AND BELTS FOR TIGHTNESS.VINTAGE AIR RECOMMENDS THAT ALL AC SYSTEMS BE SERVICED BY A CERTIFIED AUTOMOTIVE AIRCONDITIONING TECHNICIAN.EVACUATE THE SYSTEM FOR A MINIMUM OF 45 MINUTES PRIOR TO CHARGING AND LEAK CHECK PRIORTO SERVICING.CHARGE THE SYSTEM TO THE CAPACITIES STATED ON THE INFORMATION PAGE (PAGE 4) OF THISINSTRUCTION MANUAL.SEE OPERATION OF CONTROLS PROCEDURES PAGE 22.3/8” GROMMET33144-VUIFIGURE 1617901182 REV A 6/13/11, INST 81-<strong>87</strong> <strong>CHEV</strong> P-<strong>UP</strong> wo AC EVAP KIT PG 17 OF 27

GLOVE BOX MODIFICATIONUSE GLOVE BOX MODIFICATION TEMPLATE PROVIDED ON PAGE 26.PLACE TEMPLATE ON THE OUTSIDE OF THE GLOVE BOX. MARK THE OUTSIDE OF THE GLOVE BOX ALONGTHE FRONT OF THE TEMPLATE AS SHOWN IN FIGURE 17 BELOW.PLACE THE SAME TEMPLATE ON THE OUTSIDE OF THE GLOVE BOX ON THE OPPOSITE SIDE. MARK THE OUTSIDEOF THE GLOVE BOX ALONG THE FRONT OF THE TEMPLATE AS SHOWN BELOW.MARK THE BOTTOM OF THE BOX CONNECTING EACH END OF TEMPLATE.CUT THE BOX ON THE LINES YOU HAVE MARKED. DISCARD THE FRONT PORTION OF THE BOX.INSTALL THE NEW S<strong>UP</strong>PLIED GLOVE BOX BY PRESSING THE S-CLIPS ONTO THE OEM PORTION OF THE BOX.AS SHOWN IN FIGURE 17a BELOW.OEM wo ACGLOVE BOXDISCARD FRONTPORTION OFBOXDISCARD FRONTPORTION OFBOXOEM wo ACGLOVE BOXFACTORY AIRGLOVE BOXTEMPLATEFACTORY AIRGLOVE BOXTEMPLATECUT BOX WITH AHACK SAW BLADEON THESE THREEFRONT LINES ONLYFIGURE 17CUT BOX WITH AHACK SAW BLADEON THESE THREEFRONT LINES ONLYMODIFIED GLOVEBOXFIGURE 17a901182 REV A 6/13/11, INST 81-<strong>87</strong> <strong>CHEV</strong> P-<strong>UP</strong> wo AC EVAP KIT PG 18 OF 2718

CONTROL PANEL & DUCT HOSE ROUTINGHIDEFOFFFLRCOLDA/CDASHHOTPASS. SIDEDEF. DUCT2” x 12”PASS SIDELOUVER2 ½” x 45”DRIVER SIDEDEF DUCT2” x 28”PLUGFROMCONTROLWIRINGHARNESS232007-VURPLUGFROMWIRINGHARNESS232001-VURCENTER DRIVERSIDE LOUVER2 ½” x 28”FIGURE 1819DRIVER SIDELOUVER2 ½” x 26”CENTER PASSSIDE LOUVER2 ½” x 15”901182 REV A 6/13/11, INST 81-<strong>87</strong> <strong>CHEV</strong> P-<strong>UP</strong> wo AC EVAP KIT PG 19 OF 27

WIRING DIAGRAM232007-VURJF8TANORABLKWHTREDWHT/REDWHT/YELWHT/GRNAC ANNUNCIATORBACKLIGHT POSBACKLIGHT NEGGND5V-SWTEMP WIPERMODE WIPERFAN WIPERVIEWED FROM WIRE SIDEPRE-WIRED232002-VUAA/C(IF USED)GEN IV ECUGEN IV WIRING DIAGRAMREV C, 11/24/2009TEMPMODEFAN*** WIDE OPENTHROTTLESWITCH(OPTIONAL)PROGRAM* DASH LAMP(IF USED)** CIRCUITBREAKER30 AMP* DASH LAMP IS ONLY USED WITH TYPE 232007-VUR HARNESS** WARNING: ALWAYS MOUNT CIRCUIT BREAKER UNDER THE HOOD IN THE ENGINE COMPARTMENTAND AS CLOSE TO THE BATTERY AS POSSIBLE.*** WIDE OPEN THROTTLE SWITCH CONTACTS CLOSE ONLY AT FULL THROTTLE, WHICH DISABLES ACCOMPRESSOR.901182 REV A 6/13/11, INST 81-<strong>87</strong> <strong>CHEV</strong> P-<strong>UP</strong> wo AC EVAP KIT PG 20 OF 2720

BACK SIDEOF EVAPORATORCONNECTNOTE:MOUNT RELAYSIN DESIREDLOCATIONUNDER DASHHEATERCONTROLVALVE RELAYHEATERCONTROLVALVECONNECT(S<strong>UP</strong>PLIEDGROUNDWIRE, NOTPART OFHARNESS)CIRCUIT BREAKER30 AMPCONNECTCONNECTGEN IV WIRINGCONNECTIONINSTRUCTIONSREFER TO CONTROLPANEL INSTRUCTIONSAND PLUG IN ACCORDINGLYCONTROLWIRINGHARNESSCONNECTWIRINGHARNESSFRONT SIDEOF EVAPORATORVIO LE TWHTA/CCOMPRESSORRELAYCHASSISGROUND+CONNECTCONNECT(IGNITION HOTTERMINAL)+BLACKBLUERUNBATCOMPRESSORBINARYSAFETYSWITCHCONNECT-NOTE: CONNECT WHITEWIRES DIRECTLY TO( ) BATTERY TERMINALNOTE: IF USING TRINARYSAFETY SWITCH- REFER TOWIRING SCHEMATIC S<strong>UP</strong>PLIEDWITH TRINAY SAFETY SWITCHFOR PROPER WIRING INSTRUCTIONSBATTERYWH TW HTREDWHTRE DW H TBLUEGRNWHTR EDW H T W H TR EDRE DWARNING:ALWAYS MOUNT CIRCUITBREAKER UNDER THE HOODIN THE ENGINE COMPARTMENTAND AS CLOSE TO THEBATTERY AS POSSIBLE.NOTE:YELLOW & ORANGEWIRE COMING FROMHARNESS ARE NOTUSED FOR PROGRAMMINGCONTROLS IF APPLICABLEIGNITIONSWITCH12 VTANDASHBACK LIGHT+0-12V21901182 REV A 6/13/11, INST 81-<strong>87</strong> <strong>CHEV</strong> P-<strong>UP</strong> wo AC EVAP KIT PG 21 OF 27

OPERATION OF CONTROLSNOTE: WHEN BATTERY POWER IS FIRST CONNECTED TO THE ECU, THE MICRO PROCESSOR GOES THROUGH AN INITIALIZATIONSEQUENCE.THIS INITIALIZATION MAY TAKE <strong>UP</strong> TO 30 SECONDS. DURING INITIALIZATION THE BLOWER WILL NOT OPERATE,BUT THE DOORS INSIDE THE UNIT WILL BE OPERATING. A LOW BATTERY OR DISCONNECTING THE BATTERY MAY ALSOTRIGGER A RE-INITIALIZATION. DURING START <strong>UP</strong>, A LOW BATTERY MAY DROP BELOW 7 VOLTS, TRIGGERINGRE-INITIALIZATION.AC MODEMODELEVEROFF HI BLOWERSPEEDDASH FLR DEFHOTCOLDA/CBLOWER SPEEDADJUST TO DESIREDSPEEDMODE LEVERSLIDE THE LEVER TOTHE LEFT POSITIONHEAT MODETEMPERATURE LEVERIN A/C MODE SLIDE THETEMPERATURE LEVER ALLTHE WAY TO THE RIGHTTO ENGAGE COMPRESSOR.(SLIDE LEVER LEFT OR RIGHTTO ADJUST DESIREDTEMPERATURE)TEMPERATURELEVEROFFHIDASH FLR DEFHOTCOLDA/CBLOWER SPEEDADJUST TO DESIREDSPEEDMODE LEVERSLIDE THE LEVER TOTHE CENTER POSITIONTEMPERATURE LEVERSLIDE THE TEMPERATURELEVER ALL THE WAY LEFTTO THE HOT POSITION.(SLIDE LEVER LEFT OR RIGHTTO DESIRED TEMPERATURE)DEFROST/ DE-FOG MODEOFFHIDASH FLR DEFHOTCOLDA/CBLOWER SPEEDADJUST TO DESIREDSPEEDMODE LEVERSLIDE THE LEVER TOTHE RIGHT POSITIONTEMPERATURE LEVERADJUST LEVER TODESIRED TEMPERATURE.(COMPRESSOR ISAUTOMATICALLYENGAGED)901182 REV A 6/13/11, INST 81-<strong>87</strong> <strong>CHEV</strong> P-<strong>UP</strong> wo AC EVAP KIT PG 22 OF 2722

23TROUBLE SHOOTING INFORMATIONSYMPTOM CONDITION CHECKS ACTIONS NOTESVERIFY ALL PINS ARE INSERTED INTO PLUG. INSURE NOPINS ARE BENT OR DAMAGES IN ECU.NO OTHER FUNCTIONS WORK1. BLOWER STAYS ON HIGHSPEED WHEN IGNITION IS ONLOSS OF GROUND ON THIS WIRE RENDERCONTROL HEAD IN OPERABLEVERIFY CONTINUITY TO CHASSIS GROUND WITH WHITECONTROL HEAD WIRE AT VARIOUS POINTSSEE BLOWER SWITCH CHECK PROCEDURECHECK FOR DAMAGED PINS OR WIRES IN CONTROLHEAD PLUG.CHECK FOR DAMAGED GROUND WIRE (WHITE) INCONTROL HEAD HARNESS.CHECK FOR DAMAGED BLOWER SWITCH OR POTAND ASSOCIATED WIRING.ALL OTHER FUNCTIONS WORKBE SURE SMALL, 20 GA WHITE GROUND WIRE ISCONNECTED TO THE BATTERY GROUND POST. IF IT IS,REPLACE ECU.UNPLUG 3 WIRE BSC CONTROL CONNECTORFROM ECU. IF BLOWER SHUTS OFF, ECU IS EITHERIMPROPERLY WIRED, OR DAMAGED.BLOWER STAYS ON HIGHSPEED WHEN IGNITION IS ONOR OFFCHECK TO INSURE THAT NO BSC WIRING IS DAMAGEDOR SHORTED TO VEHICLE GROUND. THE BSC OPERATESTHE BLOWER BY GROUND SIDE PWM SWITCHING. THEPOSITIVE WIRE TO THE BLOWER WILL ALWAYS BE HOT.IF THE “GROUND” SIDE OF THE BLOWER IS SHORTED TOCHASSIS GROUND, THE BLOWER WILL RUN ON HI.UNPLUG 3 WIRE BSC CONTROL CONNECTORFROM ECU. IF BLOWER STAYS RUNNING, THE BSCIS EITHER IMPROPERLY WIRED, OR DAMAGED.NO OTHER PART REPLACEMENTS SHOULD BENECESSARYREPLACE BSC. (THIS WILL REQUIRE EVAPORATOR TO BEREMOVED FROM VEHICLE.)DANGER- NEVER BYPASS SAFETY SWITCH WITHENGINE RUNNING, SERIOUS INJURY CANRESULT.SYSTEM IS NOT CHARGED SYSTEM MUST BE CHARGED FOR COMP. TOENGAGE2. COMPRESSOR WILL NOT TURNON (ALL OTHER FUNCTIONSWORK)901182 REV A 6/13/11, INST 81-<strong>87</strong> <strong>CHEV</strong> P-<strong>UP</strong> wo AC EVAP KIT PG 23 OF 27CHARGE SYSTEM OR BYPASS PRESSURE SWITCH.TO CHECK FOR PROPER POT FUNCTION, CHECKVOLTAGE AT WHITE/ BLUE WIRE. VOLTAGESHOULD BE BETWEEN 0 AND 5V, AND WILL VARYWITH POT LEVER POSTION.CHECK CONTINUITY TO GROUND ON WHITE CONTROLHEAD WIRE. CHECK FOR 5V ON RED CONTROL HEADWIRE.CHECK FOR FAULTY A/C POT OR ASSOC. WIRING(NOT APPLICABLE TO 3 POT CONTROLSDISCONNECTED OR FAULTY THERMISTOR WILLCAUSE COMPRESSOR TO BE DISABLED.CHECK TWO PIN CONNECTOR AT ECU HOUSINGCHECK FOR DISCONNECTED OR FAULTYTHERMISTOR.RED WIRE @ A/C POT SHOULD HAVE APPROX. 5VWITH IGNITION ON. WHITE WIRE WILL HAVECONTINUITY TO CHASSIS GROUND, WHITE/ BLUEWIRE SHOULD VARY BETWEEN 0V AND 5V WHENLEVER IS MOVED <strong>UP</strong> AND DOWN.CHECK FOR FAULTY A/C POT OR ASSOC. WIRING REPAIR/REPLACE POT/ CONTROL WIRING3. COMPRESSOR WILL NOT TURNOFF (ALL OTHER FUNCTIONSWORK)REPLACE RELAYCHECK FOR FAULTY A/C RELAY

TROUBLE SHOOTING INFORMATION CONT.4. SYSTEM WILL NOT TURN ON ORRUNS INTERMITTENLYWORKS WHN ENGINE IS NOTRUNNING, SHUTS OFF WHENENGINE IS STARTED.(TYPICALLY EARLY GEN 4, BUTPOSSIBLE ON ALL VERSIONS)WILL NOT TURN ON UNDER ANYCONDITIONSNO MODE CHANGE AT ALLPARTIAL FUNCTION OF MODEDOORS5. LOSS OF MODE DOORFUNCTIONBATTERY VOLTAGE IS AT LEAST12V.BATTERY VOLTAGES IS LESSTHAN 12VNOISE INTERFERENCE FROM EITHER IGNITION ORALTERNATORINSTALL CAPACITORS ON IGN. COIL, AND ALTERNATOR.ENSURE GOOD GROUND AT ALL POINTS. RELOCATE COILAND ASSOCIATED WIRING AWAY FROM ECU AND ECUWIRING. CHECK FOR BURNED OR LOOSE PLUG WIRES.IGNITION NOISE (RADIATED OR CONDUCTED)WILL CAUSE THE SYSTEM TO SHUT DOWN DUETO HIGH VOLTAGE SPIKES. IF THIS IS SUSPECTED,CHECK WITH A QUALITY OSCILISCOPE. SPIKESGREATER THAN 16V WILL SHUT DOWN ECU.INSTALL A RADIO CAPACITOR AT THE POSITIVEPOST OF THE IGNITION COIL (SEE RADIOCAPACITOR INSTALLATION BULLETEN). A FAULTYALTERNATOR OR WORN OUT BATTERY CAN ALSORESULT IN THIS CONDITION FOR ALTERNATORREGULATOR TO FUNCTION PROPERLY.VERIFY CONNECTIONS ON POWER LEAD, IGNITIONLEAD, AND BOTH WHITE GROUND WIRESVERIFY BATTERY VOLTAGE IS GREATER THAN 10VOLTS AND LESS THAN 16.CHECK FOR POSITIVE POWER AT HEATER VALVE GREENWIRE. AND BLOWER RED WIRE. CHECK FOR GROUNDON CONTROL HEAD WHITE WIREVERIFY PROPER METER FUNCTION BY CHECKING AKNOWN GOOD BATTERYS VOLTAGE.CHECK FOR DAMAGED MODE SWITCH OR POT ANDASSOCIATED WIRINGCHECK FOR OBSTRUCTED OR BINDING MODEDOORSCHECK FOR DAMAGED STEPPER MOTOR ORWIRINGTYPICALLY CAUSED BY EVAPORATOR HOUSINGINSTALLED IN A BLIND IN THE VEHICLE. BE SUREALL MOUNTING LOCATIONS LINE <strong>UP</strong> AND DON’THAVE TO BE FORCED INTO POSITION.CHECK FOR AT LEAST 12V BETWEEN GREENHEATER VALVE WIRE AND CHASSIS GROUND.CHECK FOR FAULTY BATTERY OR ALTERNATORINSURE ALL SYSTEM GROUNDS AND POWERCONNECTION ARE CLEAN AND TIGHT.CHARGE BATTERYSYSTEM SHUTS OFF BLOWER AT 10V. POORCONNECTIONS OR WEAK BATTERY CAN CAUSESHUT DOWN AT <strong>UP</strong> TO 11VCHECK FOR DAMAGED SWITCH OR POT ANDASSOCIATED WIRINGREPAIR OR REPLACETHIS IS AN INDICATOR THAT THE SYSTEM HASBEEN RESET. BE SURE THE RED POWER WIRE IS ONTHE BATTERY POST AND NOT ON A SWITCHEDSOURCE. ALSO, IF THE SYSTEM IS PULLED BELOW7V EVEN FOR A SPLIT SECOND, THE SYSTEM WILLRESET.RUN RED POWER WIRE DIRECTLY TO BATTERY6. BLOWER TURNS ON AND OFFRAPIDLY901182 REV A 6/13/11, INST 81-<strong>87</strong> <strong>CHEV</strong> P-<strong>UP</strong> wo AC EVAP KIT PG 24 OF 277. ERATIC FUNCTIONS OFBLOWER, MODE , TEMP, ETC.8. WHEN THE IGNITION IS TURNEDON, THE BLOWER MOMENTARILYCOMES ON, THEN SHUTS OFF.THIS IS WITH THE BLOWERSWITCH IN THE OFF POSITION24

DRIVER SIDE LOUVER TEMPLATE(DO NOT EXCEED DIMENSIONS GIVEN)3 ⅛”CUT ALONGDOTTED LINE2 15⁄16”1973-<strong>87</strong><strong>CHEV</strong>Y TRUCKNON-AIRDRIVER SIDE LOUVERTEMPLATE2 13⁄16”CUT ALONGDOTTED LINE25901182 REV A 6/13/11, INST 81-<strong>87</strong> <strong>CHEV</strong> P-<strong>UP</strong> wo AC EVAP KIT PG 25 OF 27

GLOVE BOX MODIFICATION TEMPLATE73-<strong>87</strong> <strong>CHEV</strong> P-<strong>UP</strong>GLOVE BOXMODIFICATIONTEMPLATECUT ALONGDOTTED LINE901182 REV A 6/13/11, INST 81-<strong>87</strong> <strong>CHEV</strong> P-<strong>UP</strong> wo AC EVAP KIT PG 26 OF 2726

O FDASHHOTFLRHIDEFCOLDA/CNO. QTY. PART NO. DESCRIPTION1.2.EVAPORATOR KIT PACKING LIST11744004-VUE791181GEN IV 4 VENT EVAP. SUB CASE w/ 204 ECUACCESSORY KIT 81-<strong>87</strong> <strong>CHEV</strong> P-<strong>UP</strong> wo ACEVAPORATOR KIT751181CHECK BY:PACKED BY:DATE:1GEN IV 4 VENTEVAP SUB CASEw/204 ECU744004-VUE2ACCESSORY KIT791181NOTE: IMAGES MAY NOT DEPICT ACTUAL PARTS AND QUANTITIES.REFER TO PACKING LIST FOR ACTUAL PARTS AND QUANTITIES.901182 REV A 6/13/11, INST 81-<strong>87</strong> <strong>CHEV</strong> P-<strong>UP</strong> wo AC EVAP KIT PG 27 OF 27