G:\Government\Document Files\Handbook ... - Granta Design

G:\Government\Document Files\Handbook ... - Granta Design

G:\Government\Document Files\Handbook ... - Granta Design

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

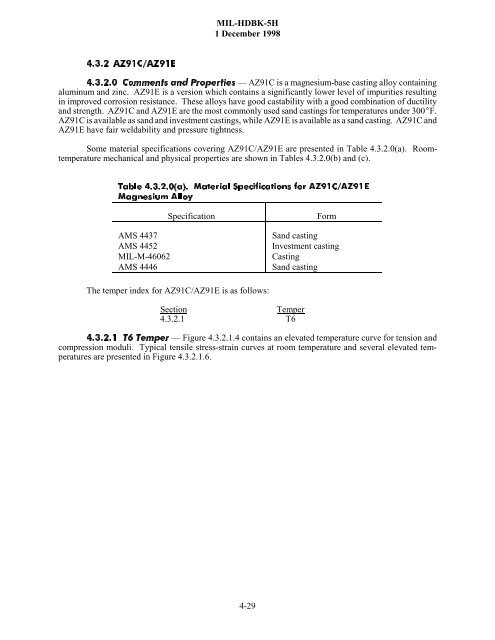

MIL-HDBK-5H1 December 1998 — AZ91C is a magnesium-base casting alloy containingaluminum and zinc. AZ91E is a version which contains a significantly lower level of impurities resultingin improved corrosion resistance. These alloys have good castability with a good combination of ductilityand strength. AZ91C and AZ91E are the most commonly used sand castings for temperatures under 300F.AZ91C is available as sand and investment castings, while AZ91E is available as a sand casting. AZ91C andAZ91E have fair weldability and pressure tightness.Some material specifications covering AZ91C/AZ91E are presented in Table 4.3.2.0(a). Roomtemperaturemechanical and physical properties are shown in Tables 4.3.2.0(b) and (c). %!" ## $7 1$7 ) AMS 4437AMS 4452MIL-M-46062AMS 4446SpecificationFormSand castingInvestment castingCastingSand castingThe temper index for AZ91C/AZ91E is as follows:SectionTemper4.3.2.1 T6 — Figure 4.3.2.1.4 contains an elevated temperature curve for tension andcompression moduli. Typical tensile stress-strain curves at room temperature and several elevated temperaturesare presented in Figure 4.3.2.1.6.4-29

MIL-HDBK-5H1 December 1998 %!" #'# ('# ( $7 Specification ..........Form ................AMS4437SandcastingAMS 4452InvestmentcastingMIL-M-46062Casting (any method)Temper .............. T6 T6 T6Locationwithin casting..........Any area<strong>Design</strong>ated areaClass 1 b Class 2 b Class 3 bNondesignated areaBasis................. S S S S S SMechanical Properties a :F tu , ksi...............F ty , ksi ..............F cy , ksi ..............F su , ksi ..............F bru , ksi:(e/D = 1.5) ..........(e/D = 2.0) ..........F bry , ksi:(e/D = 1.5) ..........(e/D = 2.0) ..........e, percent ...........E, 10 3 ksi ............E c , 10 3 ksi ...........G, 10 3 ksi ............µ ...................Physical Properties:, lb./in. 3 ...........C,Btu/(lb)(F) ........K, Btu/[(hr)(ft 2 )(F)/ft], 10 -6 in./in./F ......17 c12 c12...............0.75 c 17 c12 c12...............1 c 351818...............4291616...............36.56.52.40.350.06520.25 d41 (212F to 572F)14 (65F to 212F)271414...............2171212...............0.75a Reference should be made to the specific requirements of the procuring or certificating agency with regard to the use of theabove values in the design of castings.b Class of properties attainable depends on location specified and casting design and should be coordinated with the producer.c When specified on drawing, conformance to tensile property requirements is determined by testing specimens cut fromcastings.d Estimated.4-30

MIL-HDBK-5H1 December 1998 %!"# #'# ('# ( $7 ) Specification .......................... AMS 4446Form.................................Sand castingCondition .............................T6Location within casting ..................Any areaBasis.................................SMechanical Properties a :F tu , ksi ..............................17 bF ty , ksi ..............................12 bF cy , ksi .............................. 12F su , ksi .............................. ...F bru , ksi:(e/D = 1.5) .......................... ...(e/D = 2.0) .......................... ...F bry , ksi:(e/D = 1.5) .......................... ...(e/D = 2.0) .......................... ...e, percent............................ ...E, 10 3 ksi ............................ 6.5E c , 10 3 ksi ........................... 6.5G, 10 3 ksi............................ 2.4µ .................................. 0.35Physical Properties:, lb/in. 3 ............................ 0.0652C, Btu/(lb)(F) ....................... 0.25 cK, Btu/[(hr)(ft 2 )(F)/ft] ................. 41 (212F to 572F), 10 -6 in./in./F ....................... 14 (65F to 212F)abcReference should be made to the specific requirements of the procuring or certificating agency with regard to the use of theabove values in the design of castings.When specified on drawing, conformance to tensile property requirements is determined by testing specimens cut fromcastings.Estimated.4-31

.MIL-HDBK-5H1 December 1998100Percentage of Room Temperature Modulus80604020Modulus at temperatureExposure up to 1/2 hrTYPICALE & E c00 100 200 300 400 500 600 700 800Temperature, F* %! )# ' #. ) ) # $7 +-1$7 )+-251/2 -hr exposureRT20300 F400 FStress, ksi1510Ramberg - Osgoodn (RT) = 4.5n (300 F) = 3.9n (400 F) = 5.3TYPICAL500 2 4 6 8 10 12Strain, 0.001 in./in.* %! - # + #. # $7 +-1$7 )+- . 4-32