DC arc smelting of silicon: Is it technically feasible? - saimm

DC arc smelting of silicon: Is it technically feasible? - saimm

DC arc smelting of silicon: Is it technically feasible? - saimm

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

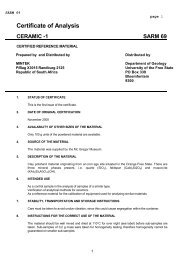

The furnace consisted <strong>of</strong> a refractory-lined cylindrical shell, a domed base, anda conical ro<strong>of</strong>. The furnace shell had an unlined internal diameter <strong>of</strong> 980 mm.The facil<strong>it</strong>y was designed for the <strong>smelting</strong> <strong>of</strong> various ferro-alloys, and nomodifications were undertaken in preparation for the current testwork as <strong>it</strong> wasexploratory in nature.Figure 1: Layout <strong>of</strong> the 200 kW <strong>DC</strong> <strong>arc</strong> furnace facil<strong>it</strong>yThe furnace ro<strong>of</strong> contained three ports for feeding, bath inspection, and acentral port for a 100 mm graph<strong>it</strong>e electrode (cathode). The furnace shell waslined w<strong>it</strong>h Verokast-1800 (Vereeniging Refractories, Table I), and had a graph<strong>it</strong>ecrucible w<strong>it</strong>h an internal diameter <strong>of</strong> about 400 mm and a height <strong>of</strong> 800 mm (seeFigure 2). The base and the furnace ro<strong>of</strong> were lined w<strong>it</strong>h alumina castable(Verokast-1800, Vereeniging Refractories).Table I: Chemical analysis <strong>of</strong> the Verokast 1800, mass %Component SiO 2 Al 2 O 3 Fe 2 O 3 CaO MgO TiO 2 Na 2 O + K 2 OVerokast-1800 5.3 94.2 0.1 0.1 0.1 0.1 0.3The return electrode, or anode, consisted <strong>of</strong> a 100 mm graph<strong>it</strong>e rod bolted to asteel plate that was attached to the hearth dome and was connected to theanode busbars. The electrode and feed pipe were electrically insulated from thefeed system. No water-cooling was provided to the shell (natural air-cooling).The conical ro<strong>of</strong> was cooled by means <strong>of</strong> pressurised water-cooled panels.104