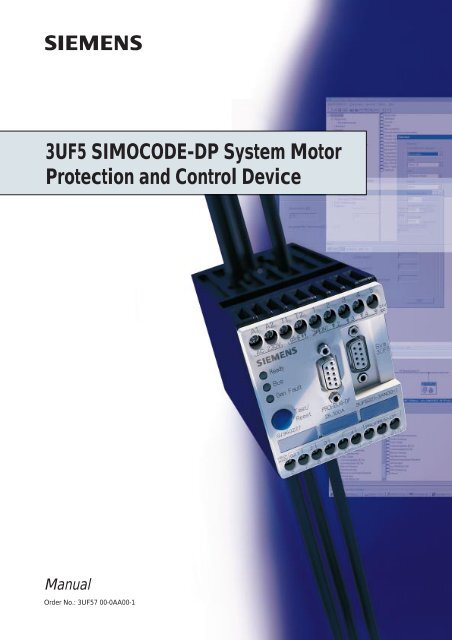

3UF5 SIMOCODE-DP System Motor Protection and Control Device

3UF5 SIMOCODE-DP System Motor Protection and Control Device

3UF5 SIMOCODE-DP System Motor Protection and Control Device

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

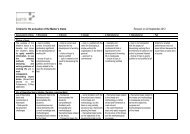

ContentsA Tables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1A.1 Assignment table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2A.2 Active <strong>Control</strong> Stations, Contactor <strong>Control</strong>s, Lamp <strong>Control</strong>s <strong>and</strong> status messagesfor the <strong>Control</strong> Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4A.3 <strong>Control</strong>, signalling <strong>and</strong> diagnostic data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5A.4 Acknowledgement <strong>and</strong> Fault h<strong>and</strong>ling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-10A.5 Sketch of <strong>SIMOCODE</strong>-<strong>DP</strong> circuit diagram with basic elements . . . . . . . . . . . . . . . . A-15A.6 Block diagram of the assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-17A.7 Parameter table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-19B Data Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1B.1 Data formats <strong>and</strong> data records . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2B.2 Cyclical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4B.2.1 Basic Types. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4B.2.2 Assignment of cyclical messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6B.3 Diagnosis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-8B.3.1 St<strong>and</strong>ard diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-8B.3.2 <strong>Device</strong>-specific diagnosis according to <strong>DP</strong> st<strong>and</strong>ard . . . . . . . . . . . . . . . . . . . . . . . B-9B.3.3 <strong>Device</strong>-specific diagnosis according to <strong>DP</strong>V1 . . . . . . . . . . . . . . . . . . . . . . . . . . . B-11B.3.4 Alarms (only as S7 slave) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-14B.4 Reading/writing data records acyclically . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-17B.4.1 Reading data record 130 - signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-17B.4.2 Reading data record 131 - display/diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-19B.4.3 Writing data record 133 - statistical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-19B.4.4 Writing data record 132 - control comm<strong>and</strong>s. . . . . . . . . . . . . . . . . . . . . . . . . . . . B-20B.4.5 Data record 138 - device parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-20C Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1C.1 General data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2C.2 Auxiliary circuit / control circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-4C.3 Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-5C.3.1 Number of inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-5C.3.2 Simultaneity for Basic Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-5C.3.3 Simultaneity for Expansion Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-5C.3.4 Input currents / cable lenghts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-5C.4 Communications interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-6C.5 Behaviour in the event of supply-voltage failure . . . . . . . . . . . . . . . . . . . . . . . . . . C-6C.6 Short-circuit protection for motor branches for short-circuit currents up to 50 kA at 690 V C-7C.7 <strong>System</strong> reaction times (typical values) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-8C.8 New system functions as of product status E10 . . . . . . . . . . . . . . . . . . . . . . . . . C-9C.9 Description of DMD <strong>and</strong> type data files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-9C.10 Source of supply for DMD <strong>and</strong> type data files. . . . . . . . . . . . . . . . . . . . . . . . . . . C-9D Dimension Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1D.1 Basic Unit <strong>3UF5</strong>00./<strong>3UF5</strong>01. /Expansion Module <strong>3UF5</strong>1. . . . . . . . . . . . . . . . . . . . . D-2D.2 Basic Unit <strong>3UF5</strong>02. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-3D.3 Basic Unit <strong>3UF5</strong>03. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-4D.4 Basic Unit <strong>3UF5</strong>04. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-5D.5 Basic Unit <strong>3UF5</strong>05. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-6D.6 Operator Panel <strong>3UF5</strong>2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-7GWA 4NEB 631 4286-02aiii

ContentsE Typical Circuits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-1E.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-2E.2 Parameter Table Default Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-3E.3 Overload . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-11E.3.1 Circuit diagram of Overload <strong>Control</strong> Function . . . . . . . . . . . . . . . . . . . . . . . . . . . E-11E.3.2 Block diagram of Overload <strong>Control</strong> Function . . . . . . . . . . . . . . . . . . . . . . . . . . . E-12E.3.3 Parameters of Overload <strong>Control</strong> Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-13E.4 Direct Starter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-14E.4.1 Circuit diagram of Direct Starter <strong>Control</strong> Function . . . . . . . . . . . . . . . . . . . . . . . . E-14E.4.2 Block diagram of Direct Starter <strong>Control</strong> Function . . . . . . . . . . . . . . . . . . . . . . . . . E-15E.4.3 Parameters of Direct Starter <strong>Control</strong> Function . . . . . . . . . . . . . . . . . . . . . . . . . . E-16E.5 Reversing Starter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-17E.5.1 Circuit diagram of Reversing Starter <strong>Control</strong> Function . . . . . . . . . . . . . . . . . . . . . . E-17E.5.2 Block diagram of Reversing Starter <strong>Control</strong> Function . . . . . . . . . . . . . . . . . . . . . . E-18E.5.3 Parameters of Reversing Starter <strong>Control</strong> Function . . . . . . . . . . . . . . . . . . . . . . . . E-19E.6 Star Delta Starter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-20E.6.1 Circuit diagram of Star Delta Starter <strong>Control</strong> Function . . . . . . . . . . . . . . . . . . . . . . E-20E.6.2 Block diagram of Star Delta Starter <strong>Control</strong> Function . . . . . . . . . . . . . . . . . . . . . . E-21E.6.3 Parameters of Star Delta Starter <strong>Control</strong> Function . . . . . . . . . . . . . . . . . . . . . . . . E-22E.7 Pole Changing Starter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-23E.7.1 Circuit diagram of Pole Changing Starter <strong>Control</strong> Function . . . . . . . . . . . . . . . . . . . E-23E.7.2 Block diagram of Pole Changing Starter <strong>Control</strong> Function . . . . . . . . . . . . . . . . . . . . E-24E.7.3 Parameters of Pole Changing Starter <strong>Control</strong> Function . . . . . . . . . . . . . . . . . . . . . E-25E.8 Dahl<strong>and</strong>er Starter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-26E.8.1 Circuit diagram of Dahl<strong>and</strong>er Starter <strong>Control</strong> Function . . . . . . . . . . . . . . . . . . . . . . E-26E.8.2 Block diagram of Dahl<strong>and</strong>er Starter <strong>Control</strong> Function . . . . . . . . . . . . . . . . . . . . . . E-27E.8.3 Parameters of Dahl<strong>and</strong>er Starter <strong>Control</strong> Function . . . . . . . . . . . . . . . . . . . . . . . . E-28E.9 Solenoid Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-29E.9.1 Circuit diagram of Solenoid Valve <strong>Control</strong> Function . . . . . . . . . . . . . . . . . . . . . . . . E-29E.9.2 Block diagram of Solenoid Valve <strong>Control</strong> Function . . . . . . . . . . . . . . . . . . . . . . . . E-30E.9.3 Parameters of Solenoid Valve <strong>Control</strong> Function . . . . . . . . . . . . . . . . . . . . . . . . . . E-31E.10 Positioner <strong>Control</strong> Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-32E.10.1 Circuit diagram of Positioner <strong>Control</strong> Function . . . . . . . . . . . . . . . . . . . . . . . . . . E-32E.10.2 Block diagram of Positioner <strong>Control</strong> Function . . . . . . . . . . . . . . . . . . . . . . . . . . . E-34E.10.3 Parameters of Positioner <strong>Control</strong> Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-35E.11 Soft Starter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-36E.11.1 Circuit diagram of Soft Starter <strong>Control</strong> Function. . . . . . . . . . . . . . . . . . . . . . . . . . E-36E.11.2 Block diagram of Soft Starter <strong>Control</strong> Function . . . . . . . . . . . . . . . . . . . . . . . . . . E-38E.11.3 Parameters of Soft Starter <strong>Control</strong> Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-39F Order Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-1G Frequently asked questions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-1G.1 General reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-2G.2 Win-<strong>SIMOCODE</strong>-<strong>DP</strong> fault situations in online operation. . . . . . . . . . . . . . . . . . . . . G-3H Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . H-1Glossaryiv GWA 4NEB 631 4286-02a

FiguresPage1 Simplified structure of the system . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-22 Layout of a motor branch (Direct Starter) using conventional technology . . . . . . . . . 1-33 Future-oriented circuit diagram with <strong>SIMOCODE</strong>-<strong>DP</strong> . . . . . . . . . . . . . . . . . . . 1-44 Reducing the amount of wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-55 Data traffic over the PROFIBUS-<strong>DP</strong> between the PLC <strong>and</strong> <strong>SIMOCODE</strong>-<strong>DP</strong> . . . . . . . . 1-66 <strong>SIMOCODE</strong>-<strong>DP</strong> modular system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-97 Win-<strong>SIMOCODE</strong>-<strong>DP</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-98 <strong>System</strong> configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-109 Summary of functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1110 Structural design of the <strong>SIMOCODE</strong>-<strong>DP</strong> system . . . . . . . . . . . . . . . . . . . . . 1-1311 Front of Basic Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-212 Summary of functions performed by the Basic Unit . . . . . . . . . . . . . . . . . . . . 2-313 Diagram of Output Relays for Basic Unit . . . . . . . . . . . . . . . . . . . . . . . . . 2-414 Diagram of the Inputs for Basic Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-515 Diagram of input circuitry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-616 Method of assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-817 Push-through <strong>and</strong> loop-through openings on the <strong>3UF5</strong>001 Basic Unit . . . . . . . . . . . 2-918 Circuit diagram with external current transformer . . . . . . . . . . . . . . . . . . . . . 2-1019 Tripping characteristics (cold) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1120 <strong>Protection</strong> of motors in potentially explosive atmospheres . . . . . . . . . . . . . . . . 2-1321 Cooling behaviour with <strong>and</strong> without Idle Time . . . . . . . . . . . . . . . . . . . . . . . 2-1422 Diagram of Earth Fault Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1823 Diagram for Thermistor <strong>Motor</strong> <strong>Protection</strong> . . . . . . . . . . . . . . . . . . . . . . . . . 2-2024 <strong>Control</strong> <strong>and</strong> motor protection block . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2125 Diagram of information data block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2226 Diagram of <strong>Control</strong> Stations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2327 Function diagram of Torque <strong>and</strong> Limit Switches in the control of Positioners . . . . . . . 2-3528 Torque or Limit Switch as a changeover contact . . . . . . . . . . . . . . . . . . . . . . 2-4229 Interrelationship of UVO, UVO-Time, Grading Time <strong>and</strong> QE . . . . . . . . . . . . . . . . 2-4930 Diagram of Signal Matching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5231 Diagram of signal types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5232 Diagram of Non-Reseting Elements on Power Loss . . . . . . . . . . . . . . . . . . . . 2-5333 Diagram of Truth Tables 3I / 1O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5434 Example of a Truth Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-54GWA 4NEB 631 4286-02av

35 External circuitry / parameters for the Truth Table example . . . . . . . . . . . . . . . . . 2-5536 Diagram of the Truth Table 5I / 2O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5737 Diagram of Flash / Flicker components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5938 Diagram of Timers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6039 Output behaviour of Timers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6040 Diagram of the Counters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6141 Front of Expansion Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-242 Summary of functions performed by the Expansion Module . . . . . . . . . . . . . . . . 3-243 Diagram of Inputs for Expansion Module . . . . . . . . . . . . . . . . . . . . . . . . . . 3-344 Diagram of Input circuitry for Expansion Module . . . . . . . . . . . . . . . . . . . . . . 3-345 Diagram of Output Relays for Expansion Module . . . . . . . . . . . . . . . . . . . . . . 3-446 Operator Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-247 Summary of the Operator Panel's functions . . . . . . . . . . . . . . . . . . . . . . . . 4-248 Diagram of control buttons <strong>and</strong> indicator LEDs of the Operator Panel . . . . . . . . . . . 4-349 Fast fault analysis with the "<strong>Control</strong>/Report" mask . . . . . . . . . . . . . . . . . . . . . 5-250 Possibilities of data transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-351 Setting parameters for <strong>DP</strong> st<strong>and</strong>ard . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1352 Enabling diagnosis according to <strong>DP</strong>V1 . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1653 Selecting <strong>SIMOCODE</strong>-<strong>DP</strong> as a <strong>DP</strong>V1 slave with HW Config (hardware configuration) . . . 6-2554 Selecting <strong>SIMOCODE</strong>-<strong>DP</strong> as an S7 slave from the hardware catalog . . . . . . . . . . . . 6-2555 Specifying operating parameters for <strong>SIMOCODE</strong>-<strong>DP</strong> . . . . . . . . . . . . . . . . . . . . 6-2656 Parameterizing <strong>SIMOCODE</strong>-<strong>DP</strong> via a DMD file . . . . . . . . . . . . . . . . . . . . . . . 6-2757 Parameterizing <strong>SIMOCODE</strong>-<strong>DP</strong> with Win-<strong>SIMOCODE</strong>-<strong>DP</strong>/Professional . . . . . . . . . . 6-2858 Enabling diagnosis according to <strong>DP</strong>V1 in HW Config . . . . . . . . . . . . . . . . . . . . 6-3159 Bus segment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3660 Bus termination module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3861 Setting parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-462 Connecting free elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-463 Example for establishing connections . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-564 Symbols used: sockets <strong>and</strong> plugs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-565 Layout of a motor branch (Direct Starter) using conventional technology . . . . . . . . . . 8-366 Step 2: Drawing the elements in the <strong>SIMOCODE</strong>-<strong>DP</strong> circuit diagram . . . . . . . . . . . 8-467 Step 3: Deleting elements from the <strong>SIMOCODE</strong>-<strong>DP</strong> circuit diagram . . . . . . . . . . . . 8-568 Step 4: Deleting elements from the <strong>SIMOCODE</strong>-<strong>DP</strong> circuit diagram . . . . . . . . . . . . 8-669 Step 5: Drawing the elements in the <strong>SIMOCODE</strong>-<strong>DP</strong> circuit diagram . . . . . . . . . . . 8-770 Step 6: Deleting elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-871 Step 7: Deleting elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-972 Step 8: Drawing the auxiliary contact of the fuse-disconnector fortest operation in the <strong>SIMOCODE</strong>-<strong>DP</strong> circuit diagram . . . . . . . . . . . . . . . . . . . . 8-10vi GWA 4NEB 631 4286-02a

viii GWA 4NEB 631 4286-02a

TablesSeite1 Summary of topics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv2 Detection of motor currents below 1.25 A . . . . . . . . . . . . . . . . . . . . . . . . . 2-93 Factors for tripping times when the motor is warm . . . . . . . . . . . . . . . . . . . . 2-124 Description of the settings for current-dependent motor protection . . . . . . . . . . . . 2-155 Description of the settings for Current Limit Values / Blocking <strong>Protection</strong> . . . . . . . . . 2-166 Description of the settings for Earth Fault Detection . . . . . . . . . . . . . . . . . . . 2-187 Types of detector for Thermistor <strong>Motor</strong> <strong>Protection</strong> . . . . . . . . . . . . . . . . . . . . 2-198 Description of the settings for Thermistor <strong>Motor</strong> <strong>Protection</strong> . . . . . . . . . . . . . . . . 2-209 Operating modes of <strong>Control</strong> Stations . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2410 Determining Operator Enabling signals . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2611 Active <strong>Control</strong> Stations, Contactor <strong>Control</strong>s, Lamp <strong>Control</strong>s <strong>and</strong> status messages withDirect Starter, Reversing Starter, Star Delta Starter, Dahl<strong>and</strong>er starter,Pole Changing Starter <strong>and</strong> Soft Starter . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2712 Active <strong>Control</strong> Stations, Contactor <strong>Control</strong>s, Lamp <strong>Control</strong>s<strong>and</strong> status messages for Positioner . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3313 Variants for Positioner control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3614 Check-Back Signals for Positioner 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3715 Check-Back Signals for Positioner 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3916 Check-Back Signals for Positioner 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4017 Check-Back Signals for Positioner 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4218 Check-Back Signals for Positioner 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4319 Active <strong>Control</strong> Stations, Contactor <strong>Control</strong>s, Lamp <strong>Control</strong>s<strong>and</strong> status messages for a Solenoid Valve. . . . . . . . . . . . . . . . . . . . . . . . . 2-4420 Check-Back Signals for Solenoid Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4521 Description of the settings for motor control . . . . . . . . . . . . . . . . . . . . . . . 2-4922 States of the status LEDs / Contactor <strong>Control</strong>s during a test . . . . . . . . . . . . . . . 2-5123 Status LEDs on the Basic Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5124 NOR function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5325 Description of the settings for types of signal . . . . . . . . . . . . . . . . . . . . . . . 2-5326GWA 4NEB 631 4286-02aix

27 Description of the settings for Truth Tables . . . . . . . . . . . . . . . . . . . . . . . . . 2-5528 Description of the settings for Timers . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6029 Description of the settings for the upper limit of Counters . . . . . . . . . . . . . . . . . 2-6130 Status LEDs on the Operator Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-431 Fault Diagnosis, Fault H<strong>and</strong>ling, Warning . . . . . . . . . . . . . . . . . . . . . . . . . . 5-832 Parameter Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-933 Description of settings for fault behaviour . . . . . . . . . . . . . . . . . . . . . . . . . 5-1134 Slave operating modes for <strong>SIMOCODE</strong>-<strong>DP</strong> on master class 1 . . . . . . . . . . . . . . . 6-435 Necessary settings for bus communication with <strong>SIMOCODE</strong>-<strong>DP</strong> . . . . . . . . . . . . . 6-636 Setting the Basic Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-737 Data block (y) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1738 Parameter FCT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1839 Parameter FCT=DW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1940 Assignment of the S5 memory area for FCT =DW . . . . . . . . . . . . . . . . . . . . . 6-1941 Parameter FCT=CW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2042 Parameter FCT=DR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2143 Parameter FCT=CR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2244 Assignment of the S5 memory area for FCT = CR . . . . . . . . . . . . . . . . . . . . . 6-2245 Basic data for a bus segment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3646 Distance between two stations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3747 Length of the spur lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3748 Wiring <strong>and</strong> connecting the T-clamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3849 Parameter channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-350 Active <strong>Control</strong> Stations, Contactor <strong>Control</strong>s, Lamp <strong>Control</strong> <strong>and</strong> status messages . . . . . A-451 Writing control data to <strong>SIMOCODE</strong>-<strong>DP</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . A-552 Reading signalling <strong>and</strong> diagnostic data from <strong>SIMOCODE</strong>-<strong>DP</strong> . . . . . . . . . . . . . . . . A-953 Assignment of control data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-654 Assignment of process data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-755 Assignment of device-specific diagnostic bytes . . . . . . . . . . . . . . . . . . . . . . B-956 <strong>Device</strong>-specific diagnosis according to <strong>DP</strong>V1 . . . . . . . . . . . . . . . . . . . . . . . B-1157 Process alarm in the event of a fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1558 Process alarm in the event of a warning . . . . . . . . . . . . . . . . . . . . . . . . . . B-1659 Data record 130 - signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-17x GWA 4NEB 631 4286-02a

60 Data record 131 - display / diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1961 Writing data record 133 - statistical data . . . . . . . . . . . . . . . . . . . . . . . . . B-1962 Data record 132 - control comm<strong>and</strong>s . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2063 Data record 138 - device parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2064 General Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-265 Auxiliary circuit / control circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-466 Number of inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-567 Simultaneity for Expansion Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-568 Input currents / cable lenghts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-569 Communications interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-670 Behaviour of the contactor control circuits in the event of supply-voltage failure . . . . . C-671 Behaviour of the functions in the event of supply-voltage failure . . . . . . . . . . . . . C-672 Program cycle times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-873 Description of DMD <strong>and</strong> type data files . . . . . . . . . . . . . . . . . . . . . . . . . . C-974 Order numbers for Basic Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-275 Order numbers for expansion components . . . . . . . . . . . . . . . . . . . . . . . . F-2GWA 4NEB 631 4286-02axi

xii GWA 4NEB 631 4286-02a

Introduction <strong>and</strong> Notes on the ManualPurpose of the manualTopics coveredConfiguration exampleTablesTypical CircuitsNotesThis manual is intended to be used as a reference book. The information inthe manual enables you to operate <strong>SIMOCODE</strong>-<strong>DP</strong>.The manual consists of chapters providing instructions for use <strong>and</strong> referencechapters. The topics it covers include the following:• Philosophy <strong>and</strong> overview of the <strong>SIMOCODE</strong>-<strong>DP</strong> system• Parameterization• <strong>System</strong> componenets• Description of the parameterizing <strong>and</strong> diagnosis softwareWin-<strong>SIMOCODE</strong>-<strong>DP</strong>• Error h<strong>and</strong>ling, diagnosis• Communication, data transmission• Data structure• Technical data <strong>and</strong> conductor cross sectionsA complete configuration example is included in the manual. This exampleexplains to you, step by step, how to configure a Direct Starter with<strong>SIMOCODE</strong>-<strong>DP</strong>.In Appendix A you will find tables <strong>and</strong> partly predrawn circuit diagrams forthe purpose of configuration, diagnosis etc.. If you are already familiar withhow to operate the <strong>SIMOCODE</strong>-<strong>DP</strong>, the tables are sufficient for workingwith the system.You can enter your selected parameter settings in the tables in order to facilitatesubsequent parameterization. At the same time, this also gives you arecord of how you have parameterized the system.In the Appendix E you will find a summary of Typical Circuits which you canuse for the individual control functions.Notes which are of special importance are enclosed by two straight lines.Correction pageOthersystem manualsA correction page is to be found at the end of this book. Please use thispage to report your suggestions for improvements, additional information orcorrections <strong>and</strong> send the page back to us. In this way, you will help usimprove the next edition of this manual.If you are working with IM308C <strong>and</strong> COM PROFIBUS, you will additionallyrequire the system manual• "Decentralized Peripheral <strong>System</strong> ET 200"If you are working with STEP 7, you will additionally require thesystem manual• "<strong>System</strong> Software for S7 300/400 <strong>System</strong> <strong>and</strong> St<strong>and</strong>ard FunctionsReference Manual"If you want to use <strong>SIMOCODE</strong>-<strong>DP</strong> as an S7 slave, refer to the latest informationon the Internet athttp://www.ad.siemens.de/ans/2/support/downloadGWA 4NEB 631 4286-02axiii

Basic ContentsThe following table provides a summary of the topics with their basiccontents:Section / Topic1 A Description of the<strong>System</strong>Basic contents- Performance criteria- Philosophie- <strong>System</strong> configurations2 Basic Unit - <strong>Protection</strong> functions- Branch control- Signal processing3 Expansion Module - Inputs-Outputs4 Operator Panel - Freely assignable buttons- Freely assignable LEDs-Test / Reset5 Fault H<strong>and</strong>ling - Acknowledgements- Table of the individual fault messages6 Communication /Data transmission7 Parameterization /Observation8 Configuration exampleDirect StarterAppendix AAppendix BAppendix CAppendix DAppendix EAppendix FAppendix G- PROFIBUS-<strong>DP</strong>- Parameterizing via the bus- Basics- Win-<strong>SIMOCODE</strong>-<strong>DP</strong>- COM PROFIBUS- Circuit diagram- Block diagram- Parameterizing with Win-<strong>SIMOCODE</strong>-<strong>DP</strong>- Assignment table- Tables <strong>Control</strong>, Signaling, Diagnosis- Block diagram of assignments- Parameter table- Data structure- Technical data- Dimension drawings- Circuit examples- Order numbers- Frequenty asked questionsGlossaryIndexTable 1: Summary of topicsxiv GWA 4NEB 631 4286-02a

A Description of the <strong>System</strong>1Secion Topic Page1.1 Philosophy behind the<strong>SIMOCODE</strong>-<strong>DP</strong> <strong>3UF5</strong> system1-21.2 Overview 1-71.3 Components of the <strong>SIMOCODE</strong>-<strong>DP</strong> system 1-91.4 <strong>System</strong> configurations 1-101.5 Summary of functions 1-111.6 Structural design of the <strong>SIMOCODE</strong>-<strong>DP</strong> system 1-12GWA 4NEB 631 4286-02a 1-1

A Description of the <strong>System</strong>1.1 Philosophy behind the <strong>SIMOCODE</strong>-<strong>DP</strong> <strong>3UF5</strong> system<strong>Protection</strong><strong>Control</strong>Current as the centralreference value<strong>SIMOCODE</strong>-<strong>DP</strong> <strong>3UF5</strong> (Siemens <strong>Motor</strong> <strong>Protection</strong> <strong>and</strong> <strong>Control</strong> <strong>Device</strong> -Decentralized Periphery) is a motor protection <strong>and</strong> control device with aPROFIBUS-<strong>DP</strong> interface.The microprocessor is the central element of the system. All motor protection<strong>and</strong> control functions are implemented with the microprocessor, as wellas interlocking functions, the calculation of operating, diagnosis <strong>and</strong> statisticaldata <strong>and</strong> high-performance communication (PROFIBUS-<strong>DP</strong>) between theautomation level <strong>and</strong> the motor branch.The integrated current transformers serve the purpose of detecting themost important measured variable, electric current. Whether for Overload<strong>Protection</strong>, Overload Warning, the current thresholds, the On/Off Check-Back Signal, calculation of the Number of Operating Hours, etc.,<strong>SIMOCODE</strong>-<strong>DP</strong> always takes the electric current as the central referencevalue.Structure The structure of the system is shown in greatly simplified form in Fig. 1:<strong>SIMOCODE</strong>-<strong>DP</strong>PROFIBUS-<strong>DP</strong>DIAGNOSISCONTROLMOTOR PROTECTIONMicroprocessorCurrent detectionFig. 1: Simplified structure of the system1-2 GWA 4NEB 631 4286-02a

A Description of the <strong>System</strong>What distinguishes the <strong>SIMOCODE</strong>-<strong>DP</strong> system from conventional motorprotection <strong>and</strong> control equipment?Great simplificationLayout usingconventionaltechnology<strong>SIMOCODE</strong>-<strong>DP</strong> <strong>3UF5</strong> greatly simplifies the motor branch. This becomesapparent after examining Fig. 2 "Layout of a motor branch (Direct Starter)using conventional technology" <strong>and</strong> Fig. 3 "Future-oriented circuit diagramwith <strong>SIMOCODE</strong>-<strong>DP</strong>".The figure below shows a layout using conventional technology:3/N/PE ~ 50/60Hz 400/230VL1L2L3NPEQ11 3 51L1-F4-Q1-F2--F3OnOffAutomation level / I/O moduleCheck-Back SignalOverloadThermistor-Q1 openCurrent<strong>Control</strong> comm<strong>and</strong>sMan. / AutoOn / Off2 4 6-X1- K11 3 52 4 6-K11ManualAutoPE- F21 3 52 4 6U VM3~Wϑ 1Local stopS1Local start24 to 20 mAS21N-K1-X2-K1PLCStart/Stop-X3-K12-F3Thermistorevaluation1-K1 -K1 -F2 -F3Switchgear-Q1DA-K11 -K12N2Fig. 2: Layout of a motor branch (Direct Starter) using conventional technologyGWA 4NEB 631 4286-02a 1-3

A Description of the <strong>System</strong>Layout with<strong>SIMOCODE</strong>-<strong>DP</strong>Future-orientedcircuit diagramThe <strong>SIMOCODE</strong>-<strong>DP</strong> system alone is used for all control <strong>and</strong> monitoring functions,up to <strong>and</strong> including signal preprocessing. In this way there is no needfor additional overload relays, thermistor evaluation devices, current transformers,analog-to-digital converters etc.. The wiring of the control circuit isdispensed with entirely. The Start <strong>and</strong> Stop switches are wired directly tothe inputs of the <strong>3UF5</strong>0 Basic Unit. The contactor coil is controlled via theoutput of the <strong>3UF5</strong>0 Basic Unit - an auxiliary contact for latching is unnecessary.The "<strong>Motor</strong> On/Off" Check-Back Signal, which in the past was sent viaan auxiliary contact of the contactor, is implemented using the current with<strong>SIMOCODE</strong>-<strong>DP</strong>. This means that when an On comm<strong>and</strong> applies <strong>and</strong> currentis flowing, <strong>SIMOCODE</strong>-<strong>DP</strong> returns the Check-Back Signal "<strong>Motor</strong> On", or inthe event of an Off comm<strong>and</strong> <strong>and</strong> when current is not flowing,<strong>SIMOCODE</strong>-<strong>DP</strong> returns the Check-Back Signal "<strong>Motor</strong> Off".The figure below shows a layout with <strong>SIMOCODE</strong>-<strong>DP</strong>:L1L2L3NPE3/N/PE ~ 50Hz 400/230V1L11NPEPROFIBUS-<strong>DP</strong>2L12NF11Q11 3 5Local <strong>Control</strong> Station2 4 6K11 3 52 4 6S2StartS1StopA1 A2 PE A B61 2 3 4 5Overload protectionCurrent asymmetryPhase failureBlocking protectionCurrent detection<strong>3UF5</strong>0 Basic UnitPE T1 T278 910 11M3~ϑA1-K1A22NRCFig. 3: Future-oriented circuit diagram with <strong>SIMOCODE</strong>-<strong>DP</strong>1-4 GWA 4NEB 631 4286-02a

A Description of the <strong>System</strong>Data transmissionPROFIBUS-<strong>DP</strong>The start/stop signal is transmitted from the automation system (PLC) viathe PROFIBUS-<strong>DP</strong>, as are the Check-Back Signals for on, off, fault overload,fault thermistor, the current etc.All parallel wiring between the automation system <strong>and</strong> the motor branch isomitted. In the example used here, this amounts to 23 clamping points <strong>and</strong>10 cores. Because as many as 122 slaves (<strong>SIMOCODE</strong>-<strong>DP</strong>) can be connectedto the PROFIBUS-<strong>DP</strong> when the system is fully exp<strong>and</strong>ed, the twowirePROFIBUS-<strong>DP</strong> cable replaces 2806 clamping points <strong>and</strong> 1220 cores,<strong>and</strong> therefore also the I/O modules required in the automation system (PLC).Reducing the amountof wiringAs a result of the enormous reduction in the amount of wiring <strong>and</strong> clampingpoints, there are also fewer potential sources of faults.Point-to-point wiringWiring with PROFIBUS-<strong>DP</strong>PLCPROFIBUS-<strong>DP</strong><strong>SIMOCODE</strong>-<strong>DP</strong><strong>Motor</strong> 1 <strong>Motor</strong> 2<strong>Motor</strong> 1 <strong>Motor</strong> 1Fig. 4: Reducing the amount of wiringOmission ofsupplementarycomponentsLogic modulesFast modificationby softwareIf coupling devices <strong>and</strong> terminal boards are used in addition, these can alsobe omitted. Details of how to convert a conventional circuit diagram into afuture-oriented circuit diagram <strong>and</strong> which parameters need to be set areexplained in the chapter on "Configuration".The <strong>SIMOCODE</strong>-<strong>DP</strong> system additionally makes various logic modules available,such as Truth Tables, timers, counters <strong>and</strong> Signal Matching modules.This openness enables you to translate your own installation-specificrequirements into practice with <strong>SIMOCODE</strong>-<strong>DP</strong>.Using the logic modules you can quickly change the functionality via the softwareduring commissioning or during operation. There is no need for complexrewiring.GWA 4NEB 631 4286-02a 1-5

A Description of the <strong>System</strong>AutonomousoperationPROFIBUS-<strong>DP</strong>As all motor protection <strong>and</strong> <strong>Control</strong> Functions are processed according to adecentralized principle in the <strong>SIMOCODE</strong>-<strong>DP</strong> <strong>3UF5</strong> system, the motorbranch can continue to be controlled even in the event of failure of the automationsystem (PLC) or of disturbances on the communication path. Fromthis it also follows that <strong>SIMOCODE</strong>-<strong>DP</strong> can be operated without a connectionto the PROFIBUS-<strong>DP</strong>. The PROFIBUS-<strong>DP</strong> can then be retrofitted as necessary.The non-proprietary PROFIBUS-<strong>DP</strong> (Process Fieldbus - DecentralizedPeriphery), st<strong>and</strong>ardized in DIN (E) 19245 Part 3 EN 50170, establishes thehigh-performance communication link between <strong>SIMOCODE</strong>-<strong>DP</strong> <strong>3UF5</strong>0 <strong>and</strong>the automation system (PLC).<strong>Control</strong> comm<strong>and</strong>s <strong>and</strong> operating, diagnostic <strong>and</strong> statistical data are thereforetransmitted via the two-wire PROFIBUS-<strong>DP</strong> cable.PLC or process control systemUp to 4 bytesCyclical data:• Comm<strong>and</strong> on• Comm<strong>and</strong> off• Manual, automatic• Emergency start• Fault acknowledgement• PLC-CPU monitoringetc.213 bytesAcyclical parameter data:• Set current• CLASS• Current limit values• <strong>Control</strong> functions• Timers• Truth TablesUp to 12 bytesCyclical data:• Check-Back Signal On• Check-Back Signal Off• Warning• Fault• Phase current as %etc.20 bytesDiagnosis:• Overload, thermistor, earth fault, ineach case warning <strong>and</strong>/ortripping• Number of overload trips• Operating hoursetc.<strong>SIMOCODE</strong>-<strong>DP</strong>Fig. 5: Data traffic over the PROFIBUS-<strong>DP</strong> between the PLC <strong>and</strong> <strong>SIMOCODE</strong>-<strong>DP</strong>The communication processor (CP/IM) plugged into the programmable controllertakes care of management of the <strong>SIMOCODE</strong>-<strong>DP</strong> devices connectedto the PROFIBUS-<strong>DP</strong> <strong>and</strong> acts as the interface to the application program.Further processing of the <strong>SIMOCODE</strong>-<strong>DP</strong> data, i.e. integration into thecross-plant control system <strong>and</strong> subsequent data preparation, is performedby the application program.In parallel with this, all <strong>SIMOCODE</strong>-<strong>DP</strong> units can be parameterized, controlled<strong>and</strong> monitored via PROFIBUS-<strong>DP</strong> from a second "central station". Fordetailed information refer to the chapter entitled "Communication <strong>and</strong> DataTransmission".On the following pages you can familiarize yourself with the scope of functions<strong>and</strong> with the available components.1-6 GWA 4NEB 631 4286-02a

A Description of the <strong>System</strong>1.2 OverviewCurrent-dependentmotor protectionThermistor<strong>Motor</strong> <strong>Protection</strong>Earth FaultDetection<strong>Control</strong> FunctionsThe Basic Unit consists of several protective mechanisms for currentdependentmotor protection:• Overload <strong>Protection</strong>• Current Asymmetry• Phase Failure• Blocking <strong>Protection</strong>• Current limit-valuesVersions <strong>3UF5</strong>0.1-A enable Thermistor Detectors to be connected in order tomonitor the motor temperature. You can choose between the followingtypes of detector:• PTC Binary• PTC Analog / KTY• NTC AnalogThe Basic Unit has• an internal Earth Fault Detection component. For motors with three-conductortermination, the unit can determine a possible Earth Fault current from thecurrent balance at a particular time.• an external Earth Fault Detection component for versions <strong>3UF5</strong>0.1-B. Here,the Basic Unit evaluates rated fault currents via an externally connected summation-currenttransformer (3UL22, NSK Catalogue, Part 4).The following parameterizable <strong>Control</strong> Functions are implemented in the system:• Direct Starter• Reversing Starter• Star Delta Starter• Pole Changing Starter• Dahl<strong>and</strong>er Starter• Positioner• Solenoid Valve• Softstarter SIKOSTART 3RW22CommunicationThe system is equipped with the st<strong>and</strong>ard interfaces:• PROFIBUS-<strong>DP</strong>• PROFIBUS-<strong>DP</strong>V1• RS 232 for connecting the PCGWA 4NEB 631 4286-02a 1-7

A Description of the <strong>System</strong>Signal processingin the branchSt<strong>and</strong>ard FunctionBlocksOperatingstatistics <strong>and</strong>diagnostic dataThe system incorporates several supplementary functions which can be setas required:• Signal Matching• Truth Table• Timer• CounterSt<strong>and</strong>ard function blocks are self-contained units, implementing for exampletime-graded restarting of the drives after a mains failure.• Check-Back Signal Test• Operating <strong>Protection</strong> Off• Ready to Start• Undervoltage Off• Graded Restart• External Fault• External Warning• Emergency Start• External Diagnosis• External Check-Back Signal• Test 1 with shutdown• Test 2 without shutdown• Reset• PLC-CPU Fault• <strong>DP</strong> FaultThe <strong>SIMOCODE</strong>-<strong>DP</strong> supplies data such as• <strong>Motor</strong> On / Off / Left / Slow / Close etc.• Fault: Overload / Thermistor / etc.• Warning: Overload / Threshold for upper current exceeded etc.• Operating Current• Operating Hours• Number of switching cycles• Number of Overload Trips• Current for last Overload Trip1-8 GWA 4NEB 631 4286-02a

A Description of the <strong>System</strong>1.3 Components of the <strong>SIMOCODE</strong>-<strong>DP</strong> systemModular system<strong>SIMOCODE</strong>-<strong>DP</strong> is a modular system, the building blocks in the system comprisinga <strong>3UF5</strong>0 Basic Unit, the <strong>3UF5</strong>1 Expansion Module, the <strong>3UF5</strong>2 OperatorPanel, connecting cables <strong>and</strong> the Win-<strong>SIMOCODE</strong>-<strong>DP</strong> <strong>3UF5</strong>7 st<strong>and</strong>ardsoftware for parameterization <strong>and</strong> diagnosis.<strong>3UF5</strong>0 Basic Unit<strong>3UF5</strong>1 Expansion ModuleFig. 6: <strong>SIMOCODE</strong>-<strong>DP</strong> modular system<strong>3UF5</strong>2 Operator Panel<strong>3UF5</strong>7 softwareWin-<strong>SIMOCODE</strong>-<strong>DP</strong><strong>3UF5</strong>7Software for the parameterization, control, diagnosis <strong>and</strong> testing of<strong>SIMOCODE</strong>-<strong>DP</strong>, online via PROFIBUS-<strong>DP</strong> or via the RS232 interface<strong>SIMOCODE</strong>-<strong>DP</strong>. Runs under Windows 95 or Windows NT, switchablebetween German <strong>and</strong> English.Win-<strong>SIMOCODE</strong>-<strong>DP</strong>/Professional <strong>3UF5</strong>710:online via PROFIBUS-<strong>DP</strong> or RS232Win-<strong>SIMOCODE</strong>-<strong>DP</strong>/Smart <strong>3UF5</strong>711:via RS232Fig. 7: Win-<strong>SIMOCODE</strong>-<strong>DP</strong>OM-<strong>SIMOCODE</strong>-<strong>DP</strong>Connecting cables/connectorsBus connection block/bus terminationmoduleStep 7 Object Manager for calling Win-<strong>SIMOCODE</strong>-<strong>DP</strong>/Professional inSIMATIC S7/STEP 7, Version 4.0 or higher.Connection between the Basic Unit, Expansion Module <strong>and</strong>/or OperatorPanel.If the PROFIBUS-<strong>DP</strong> is connected to the 9-pole Sub-D socket of the BasicUnit, st<strong>and</strong>ardized 9-pole Sub-D plugs can be used. Otherwise there is a T-clamp available for connection to terminals A <strong>and</strong> B. The bus terminationmodule with integrated power supply ensures that data traffic is carriedproperly even if the last slave is removed from the bus line(see page1-13).GWA 4NEB 631 4286-02a 1-9

A Description of the <strong>System</strong>1.4 <strong>System</strong> configurations<strong>System</strong> configuration 1: Minimum configurationThe minimum configuration issufficient to enable you to implementall available control functions.Basic Unit (BU)PC / Programming Unit (PU)<strong>System</strong> configuration 2:Basic Unit (BU)Expansion Module (EM)PC / Programming Unit (PU)<strong>System</strong> configuration 3:Operator Panel (OP)Basic Unit (BU)PC / Programming Unit (PU)<strong>System</strong> configuration 4:Operator Panel (OP)Basic Unit (BU)Expansion Module (EM)PC / Programming Unit (PU)Fig. 8: <strong>System</strong> configurations1-10 GWA 4NEB 631 4286-02a

A Description of the <strong>System</strong>1.5 Summary of functionsDiagramBasic Unit<strong>Protection</strong> functionsSummary of functions <strong>SIMOCODE</strong>-<strong>DP</strong> system:Current-dependentmotor protectionCurrent limit valueEarth Fault DetectionThermistor<strong>Motor</strong> <strong>Protection</strong>Blocking <strong>Protection</strong>Branch control<strong>Motor</strong> control 4 Inputs 4 OutputsTest / Status-LEDsSignal processingSignal Matching Truth Table TimerCounterFlickerFlashSt<strong>and</strong>ard Function BlocksCheck-Back Signal Test Operating <strong>Protection</strong> Off Ready to Start Undervoltage OffCST OPO RTS UVOExternal Fault 1 External Fault 2 External Warning Emergency StartExt.Fault1 Ext.Fault2 Ext.Warn.Em.StartExternal Diagnosis Prog. controller CPU Ext. Check-Back Signal 1Ext.Diag PLC-CPU Ext.CS1Ext. Check-Back Signal 2Ext.CS2Ext. Check-Back Signal 3Ext.CS3Test 1 Test 2Reset 1Reset 2Reset 3Communication / Data TransmissionPROFIBUS-<strong>DP</strong> RS 232ExpansionModule8 Inputs 4 outputsOperatorPanel3 <strong>Control</strong> buttons 6 signal LEDs Test / status-LEDsFig. 9: Summary of functionsGWA 4NEB 631 4286-02a 1-11

A Description of the <strong>System</strong>1.6 Structural design of the <strong>SIMOCODE</strong>-<strong>DP</strong> systemFree elementsWhat does free mean?Structural designAs the motor branches differ in terms of protection <strong>and</strong> control functionsfrom one set of switchgear to another, all elements in the <strong>SIMOCODE</strong>-<strong>DP</strong>system are free.Free means that the inputs <strong>and</strong> outputs can be assigned to the various elementssuch as– the <strong>Control</strong> <strong>and</strong> motor protection block,– the Function Blocks,– the Logic Modules etc.This occurs in accordance with the requirements of the installation-specificmotor branch.The figure on page1-13 shows the structural design of the system with itsfree elements in the form of a block diagram:1. The four outputs of the <strong>3UF5</strong>0 Basic Unit.2. The process data (signal bits) that are transmitted from the <strong>SIMOCODE</strong>-<strong>DP</strong> tothe PROFIBUS-<strong>DP</strong> master. There are three different base types.3. The logic modules for Signal Matching, Truth Tables, Timers <strong>and</strong> Counters.4. The <strong>Control</strong> Stations, Auxiliary <strong>Control</strong> inputs, Contactor <strong>Control</strong>s,Function Blocks.5. The four buttons, the three green <strong>and</strong> three yellow LEDsof the <strong>3UF5</strong>2 Operator Panel.6. The four inputs of the <strong>3UF5</strong>0 Basic Unit.7. The process data (control bits) that are transmitted from the PROFIBUS-<strong>DP</strong>master to the <strong>SIMOCODE</strong>-<strong>DP</strong>.8. The eight inputs <strong>and</strong> four outputs of the <strong>3UF5</strong>1 Expansion Module.Plugs <strong>and</strong> sockets You will see that all of the elements have plugs <strong>and</strong> sockets : you canconnect the individual free elements to each other by parameterization.A socket can be used as many times are required, a plug just once.1-12 GWA 4NEB 631 4286-02a

St<strong>and</strong>ard Function BlocksAuxiliary <strong>Control</strong> InputsA Description of the <strong>System</strong>1. 2.3.OutSignal120Matching 1InResetInOut121SignalMatching 2Out122ResetInResetInResetSignalMatching 3OutIn1In2In3In1In2In3In1In2In3In1In2In3In4123SignalMatching 4OutTruthTable 1134OutTruthTable 2135OutTruthTable 3136In5Out1TruthTable 4132InOut2133OutFlashing 1 137OutFlashing 2 138OutFlashing 3 139Out140Flickering 1Out141Flickering 2Out142Flickering 3InInInInInInInInResetInReset144145146147148149150151InInNon-Reset. OutReset Element on126Power Loss 1Non-Reset. OutReset Element on127Power Loss 2Process data PROFIBUS-<strong>DP</strong><strong>SIMOCODE</strong>-<strong>DP</strong> --> <strong>DP</strong>-MasterOutTimer 1 128Basic Type 1, Byte 0...11Basic Type 2, Byte 0...3Basic Type 3, Byte 0...3OutTimer 2 129Out1Out2OutCounter 1 130Out3Out4BU OutputsOutCounter 2 1314.<strong>Control</strong> <strong>and</strong> motor protection blockGroup<strong>Control</strong><strong>Control</strong> StationsLocalQE1229QE2230QE3231<strong>Control</strong> Function<strong>Motor</strong> protection functionsOn1232Off233On2234Operator Enabling<strong>DP</strong>C+MOPPCPOTCTOCSTOPOInformationdata blockRTSUVOExt.Fa1QLE1Ext.Fa2Ext.Warn224225226QLAQLE2QLSOperatingdataEm.StartExt.Diag.PLC-CPU6063Ext.CS1227Overload244Signals(Assignmenttable)Ext.CS2Ext.CS3Test1Test2Thermistor.592762Reset1Reset2Reset330Expansion ModuleOperator PanelGreen1-OPGreen2-OPGreen3-OPYellow1-OPYellow2-OPYellow3-OPButtons T/REM OutputsButtons1Buttons2Buttons3Out1Out2Out3Out489101112131415In1In2In3In4In5In6In7In845675.8.6.Basic Unit <strong>3UF5</strong>0BU InputsLC-On1LC-OffLC-On2In1In2In3In40123<strong>DP</strong>-On1<strong>DP</strong>-Off<strong>DP</strong>-On2565758C+M-On1C+M-OffC+M-On2242526OP-On1OP-OffOP-On2PCS1S261254Process data PROFIBUS-<strong>DP</strong><strong>DP</strong>-Master --> <strong>SIMOCODE</strong>-<strong>DP</strong>Byte 0...3 PROFIBUS-<strong>DP</strong>8072645657 65 73 8158 66 74 8259 67 75 8360 68 76 8461 69 77 8562 70 78 8663 71 79 8732Byte 0...1 <strong>DP</strong>V1247.33343525262736283738EM Inputs29303931Fig. 10: Structural design of the <strong>SIMOCODE</strong>-<strong>DP</strong> systemGWA 4NEB 631 4286-02a 1-13

A Description of the <strong>System</strong>1-14 GWA 4NEB 631 4286-02a

The <strong>3UF5</strong>0 Basic Unit2Section Topic Page2.1 Description 2-22.2 Summary of functions 2-32.3 Outputs 2-42.4 Inputs 2-52.5 <strong>Protection</strong> functions 2-72.5.1 Current-dependent motor protection 2-72.5.2 Current Limit Value / Blocking <strong>Protection</strong> 2-162.5.3 Earth Fault Detection 2-172.5.4 Thermistor <strong>Motor</strong> <strong>Protection</strong> 2-192.6 Branch control 2-212.6.1 <strong>Control</strong> <strong>and</strong> motor protection block 2-212.6.2 Information data block 2-222.6.3 Description of the <strong>Control</strong> Stations 2-232.6.4 Description of the <strong>Control</strong> Functions 2-272.6.5 Description of the Function Block Inputs 2-472.6.6 Test / status LEDs 2-502.7 Logic modules 2-522.7.1 Signal Matching 2-522.7.2 Non-Reseting Elements on Power Loss 2-532.7.3 Truth Table 3I / 1O 2-542.7.4 Truth Table 5I / 2O 2-572.7.5 Flash /Flicker 2-592.7.6 Timers 2-602.7.7 Counters 2-61GWA 4NEB 631 4286-02a 2-1

The <strong>3UF5</strong>0 Basic Unit2.1 DescriptionFrontThe following diagram shows the front of the Basic Unit,e.g. a 230 V version.Connection of a thermistor detector formotor protection or a summation currenttransformer for Earth Fault Detection,depending on the version of the unit.Connection of thesupply voltage• 24 V DC• 115 V AC• 230 V ACA1 A2 T1 T2 1 2 3 4 5AC230VIN1 .2 .3 .44 opto-coupler inputs• 24 V DC,internally supplied• External 24 V DCpossible3 LED displaysUnit test, manual reset• Automatic reset parameterizable• Remote reset via bus orinput4 Output RelaysReadyBusGen.Fault6,3...25ATest/ResetPROFIBUS-<strong>DP</strong>G/9542 <strong>3UF5</strong>011-3AN00-1OUT 16 7.2.3.4 PROFIBUS-<strong>DP</strong>Sys.<strong>3UF5</strong>8 9 10 11 B A SPE/E<strong>System</strong> interfaceincl. RS 232• For connection ofExpansion Module,Operator Panel <strong>and</strong> PCBus terminal forPROFIBUS-<strong>DP</strong>• 9-pole SUB-D socket• Terminal, provided forplug-in unitsFig. 11: Front of Basic Unit2-2 GWA 4NEB 631 4286-02a

The <strong>3UF5</strong>0 Basic Unit2.2 Summary of functionsDiagramBasic Unit<strong>Protection</strong> functionsThe following diagram contains a summary of the functions performed bythe <strong>3UF5</strong>0 Basic Unit:Current-dependentmotor protectionCurrent limit valueEarth Fault DetectionThermistor<strong>Motor</strong> <strong>Protection</strong>Blocking <strong>Protection</strong>Branch control<strong>Motor</strong> control 4 Inputs 4 OutputsTest / Status-LEDsSignal processingSignal Matching Truth Table TimerCounterFlickerFlashSt<strong>and</strong>ard Function BlocksCheck-Back Signal Test Operating <strong>Protection</strong> Off Ready to Start Undervoltage OffCST OPO RTS UVOExternal Fault 1 External Fault 2 External Warning Emergency StartExt.Fault1 Ext.Fault2 Ext.Warn.Em.StartExternal Diagnosis Prog. controller CPU Ext. Check-Back Signal 1Ext.Diag PLC-CPU Ext.CS1Ext. Check-Back Signal 2Ext.CS2Ext. Check-Back Signal 3Ext.CS3Test 1 Test 2Reset 1Reset 2Reset 3Communication / Data TransmissionPROFIBUS-<strong>DP</strong> RS 232Fig. 12: Summary of functions performed by the Basic UnitGWA 4NEB 631 4286-02a 2-3

The <strong>3UF5</strong>0 Basic Unit2.3 OutputsDescription of functionsThe Basic Unit has 4 Output Relays with which, for example, you can operatecontactors or lamps.BistablebehaviourDiagramIf the status of the Output Relays is to be retained when the supply voltageis cut off, you have to select the 3UF..-3.10-1 version of the unit (bistablebehaviour).Then, you have to set the parameters for• "Response - <strong>3UF5</strong>0 CPU Fault" <strong>and</strong>• "Response - <strong>Control</strong> Voltage Fault"to "Retain Status".The following diagram shows the Output Relays.InternalinputsOut1Out2Out3Out4Circuit OutputBU Outputsterminal No.67891011Fig. 13: Diagram of Output Relays for Basic Unit2-4 GWA 4NEB 631 4286-02a

The <strong>3UF5</strong>0 Basic Unit2.4 InputsDescription of functionsThe Basic Unit has 4 inputs with which you can interrogate mechanical contactsor detectors.ExamplesIf you wish, you can wire up the START <strong>and</strong> STOP keys of the Local <strong>Control</strong>to the inputs, <strong>and</strong> assign the internal control to "local".With the signals, you can, for example, activate Function Blocks such as"Reset" or "Ready to Start (RTS)" by appropriate assignment of the inputs.SchemaInputterminal No 1234BU InputsIn1In2In3In4InternalOutputs0123Fig. 14: Diagram of the Inputs for Basic UnitInput delayFor reasons of interference immunity, you can set a debounce time for theinputs.GWA 4NEB 631 4286-02a 2-5

The <strong>3UF5</strong>0 Basic UnitVoltage supply• internal 24 V DC supply, if you are using mechanical contacts• external 24 V DC supply, if you are using solid-state sensors (e.g. limit switchesfor level measurements). Input 1 is the reference potential, i.e. threeinputs are available to you.• external 24 V DC, if you are using mechanical contacts. A2 is the referencepotential, i.e. there are four inputs available (only 24 V DC versions of theunit).In1 .2 .3 .41 2 3 4 5Possible input circuitryfor all AC / DC versions of the unitInput circuitry with internal24 V DC (pulsed)Buffering 20 ms+_In1 .2 .3 .41 2 3 4Input circuitry with external24 V DC.+_A1A2In1 .2 .3 .41 2 3 4Possible input circuitryfor 24 V DC versionsInput circuitry with external24 V DC (pulsed)All four inputs can therefore beused.Fig. 15: Diagram of input circuitryNoteThe internal 24 V DC voltage supply must be used for the inputs of the BasicUnit only.Cable lengthsFurther information about cable lengths is given in the appendix,page C-5.2-6 GWA 4NEB 631 4286-02a

The <strong>3UF5</strong>0 Basic UnitCurrent detectionbelow 1.25 AYou can also detect motor currents of less than 1.25 A with <strong>SIMOCODE</strong>-<strong>DP</strong>.To do this you must run the motor supply leads through the push-throughopenings <strong>and</strong> form an appropriate number of loops. This has the effect ofamplifying the primary signal.Proceed as follows:1. Insert the motor supply leads phase by phase through thepush-through openings X2. Guide them back through the loop-through opening Y3. Push them through the push-through openings X again. This gives you twoloops.YXFig. 17: Push-through <strong>and</strong> loop-through openings on the <strong>3UF5</strong>001 Basic UnitThe table below shows the number of loops for the corresponding levels ofmotor rated current.Number of loops n 5 4 3 2<strong>Motor</strong> rated current I N [A] 0.25 to 0.31 to 0.42 to 0.63 to0.3 0.41 0.62 1.24Current to be set Is [A]Table 2: Detection of motor currents below 1.25 A1.25 to1.51.25 to1.641.26 to1.821.26 to2.48The Set Current for the unit I s is calculated thus: I s = n x I NExample I N = 0.5 A; n = 3;Current to be set: I s = 1.5 AGWA 4NEB 631 4286-02a 2-9

The <strong>3UF5</strong>0 Basic UnitTripping classes, specified times, thermal memoryClassThe class (tripping class) indicates the maximum tripping time in which aprotection device has to trip from cold at 7.2 times the Set Current (motorprotection according to IEC 60947). The tripping characteristics show thetripping time in relation to the tripping current.1201005012010050Deratings min201052150201051510CLASS 52x I s10,7 1 2 5 83-pole symmetrical loadt ACLASS 302520Fig. 19: Tripping characteristics (cold)s min1015510CLASS 52x I s10,7 1 2 5 82-pole load(failure of a phase or currentasymmetry > 40 %)Bear in mind that, for starts > Class 10, the permissible AC3 current of themotor contactor has to be reduced (derating). The data (rated operatingcurrents Is [A] /AC-3) are given in Appendix D.5.20105215020t ACLASS 302520GWA 4NEB 631 4286-02a 2-11

The <strong>3UF5</strong>0 Basic UnitWarm tripping"thermal memory"When the motor is warm, the tripping times are reduced by the factors listedin the table. These factors apply to 3-pole symmetrical loads, Class 5 toClass 30:x I sPre-loading in % of the Set Current I s0 20 40 60 80 1001.15 1 1 1 1 1 12 1 0.88 0.74 0.58 0.40 0.194 1 0.85 0.69 0.52 0.35 0.168 1 0.84 0.67 0.51 0.33 0.15Table 3: Factors for tripping times when the motor is warmExampleFailure ofsupply voltageYou have operated the motor with a Set Current of 100 % I s <strong>and</strong> turned it off.You turn the motor on again immediately. Tripping due to overload with 2 xI s , Class 10, occurs.Tripping time when cold: approx. 40 s (tripping characteristic).Factor for tripping time in the event of pre-loading 100 % I s : 0.19 (table).Reduced tripping time: 0.19 x 40 s = 7.6 sIf the supply voltage to the <strong>3UF5</strong>0 Basic Unit fails for longer than 200 ms,the thermal memory is lost. In the event of an overload, the remaining coolingtime is stored.2-12 GWA 4NEB 631 4286-02a

The <strong>3UF5</strong>0 Basic UnitType of protectionEEX eExampleThe <strong>SIMOCODE</strong>-<strong>DP</strong> <strong>3UF5</strong> system conforms to the regulations for the overloadprotection of explosion-protected motors of the "increased safety" typeof protection EEx e DIN EN 50 0019 / DIN VDE 0165, DIN VDE 0170/0171 <strong>and</strong>to the PTB test regulations.In the case of tripping units with DC operation, electrical isolation must beensured by a battery or safety isolating transformer conforming toDIN VDE 0551.Separate monitoring of the control supply voltage is recommended if the<strong>SIMOCODE</strong>-<strong>DP</strong> <strong>3UF5</strong> system is used with parameterized bistable behaviourof the output relays (Order No. <strong>3UF5</strong>0..-3..10-1) for the protection of motorswith increased safety.PTB test report no. 3.53-14605/96.<strong>Protection</strong> of motors in potentially explosive atmospherest E12010050201052150201051510CLASS 5CLASS 302520Example:<strong>Motor</strong> 400 V, 50/60 Hz, 1.5 kW, 3.3 At E time where T3 = 21 sI A / I N = 6.5Critical firing point,selected: Class 102t A10,7x I e1 2 5 8I A / I NFig. 20: <strong>Protection</strong> of motors in potentially explosive atmospheresOriginal trippingcharacteristicsYou can request the original tripping characteristics (precision ± 10 %), especiallyfor EEexe applications, fromSiemens AGA&D CD SV TGP 2Tel.: ++49-9621-80-2127Fax: ++49-9621-80-3141GWA 4NEB 631 4286-02a 2-13

The <strong>3UF5</strong>0 Basic UnitCooling TimeEmergencyStartIdle TimeThe Cooling Time is the specified time after which the unit can be reset followingtripping due to overload.Voltage failures during this time lengthen the specified time accordingly.The Cooling Time after Overload Trip is at least 5 minutes. You can set theCooling Time <strong>and</strong>, if necessary, extend it.A way of deleting the thermal memory <strong>and</strong> bypassing the Cooling Time, thusallowing a restart. (Reset <strong>and</strong> Switch-On comm<strong>and</strong>s also necessary!). TheEmergency Start is only activated by edges. A new overload trip can neverbe prevented.The Idle Time is the time specified for cooling when the motor at operatingtemperature is turned off by <strong>Control</strong> Functions (not due to overload!).After this time, the thermal memory is deleted <strong>and</strong> a cold start is possible.This allows frequent starting.The following diagram shows cooling behaviour with <strong>and</strong> without Idle Time:<strong>Motor</strong>OnOfftWithout Idle TimeυTripping limitOverload TriptυWith Idle TimeTripping limitNo Overload TriptIdle Time.Thermal memory deleted after the Idle TimeFig. 21: Cooling behaviour with <strong>and</strong> without Idle Time2-14 GWA 4NEB 631 4286-02a

The <strong>3UF5</strong>0 Basic UnitSettingsThe following table contains a description of the settings.Designation Range CommentsSet Current Is1 1.25 A to 820 A Set Current 1.Range depends onversion*Set Current Is2 1.25 A to 820 A Set Current 2. Rangedepends on version.Only for "Fast" operatingmode when Dahl<strong>and</strong>er /Pole Changing Starter isused, otherwise 0.Tripping class / Class 5, 10, 15, 20, 25, 30Behaviour in the eventof overloadShutdownWarningCooling Time 0.5 s to 60 min At least 5 min.,even when lower valuesare set. Example:Cooling Time:6 min required; time tobe set: 6 minIdle TimeSingle-phase motor0.5 s to 60 minNoYesOnly one conductingpath may be connectedthrough/to the first currenttransformer. InternalEarth FaultDetection has to bedeactivated.Table 4: Description of the settings for current-dependent motor protectionThe parameters are summarized in the parameter table (Appendix A.2).* With Star Delta Starter:I s 1 = I n------1 3Example: motor with I n =100 A. I s 1 = 57.7 A.GWA 4NEB 631 4286-02a 2-15

The <strong>3UF5</strong>0 Basic Unit2.5.2 Current Limit Value / Blocking <strong>Protection</strong>Descriptions of functionsYou can enter a lower <strong>and</strong>/or an upper Current Limit.Example:"Stirring mass too thick", i.e. the upper Current Limit has been exceeded."Idling as drive belt torn", i.e. the level has fallen below the lower limit.The Current Limit Values <strong>and</strong> the Blocking <strong>Protection</strong> function are - for startbypassing purposes - only active after the class time has expired, z.B. Class10 nach 10 Sekunden. If a current limit is exceeded or if the current fallsbelow a limit, the <strong>SIMOCODE</strong>-<strong>DP</strong> reacts• by turning off the Contactor <strong>Control</strong>s QE1 / QE2 / QE3 or• with a warning,depending on the setting you have entered.The Blocking <strong>Protection</strong> function always turns off the Contactor <strong>Control</strong>sQE1 / QE2 / QE3 instantaneously.SettingsThe following table contains a description of the settings:Designation Range CommentsResponse threshold forlower Current LimitBehaviour if the currentfalls below the lowerCurrent LimitResponse threshold forupper Current LimitBehaviour if the upperCurrent Limit isexceeded20% to 1000%of the Set CurrentWarningShutdown20% to 1000%of the Set CurrentWarningShutdownin steps of 5%in steps of 5%Blocking 20% to 1000%of the Set CurrentIn steps of 5%Always shutdownTable 5: Description of the settings for Current Limit Values / Blocking <strong>Protection</strong>The parameters are summarized in the parameter table (Appendix A.2).2-16 GWA 4NEB 631 4286-02a

The <strong>3UF5</strong>0 Basic Unit2.5.3 Earth Fault DetectionDescription of functionInternalfunctionNoteThe internal Earth Fault Detection function is only suitable for motors with a3-conductor connection <strong>and</strong> for earthed power systems! You can activatethe internal Earth Fault Detection function by means of parameterization. Itcovers two sets of circumstances during operation:• normal operation at up to 2 x I s . The operating current has to be less than doublethe Set Current I s . Fault currents amounting to > 30 % of the Set CurrentI s are detected.• starting or overload at above 2 x I s . The operating current is greater than doublethe Set Current I s . Fault currents amounting to > 15 % of the motor currentare detected.If you are using internal Earth Fault Detection with a Star Delta Starter connection,spurious tripping may occur. In delta operation the net current is notequal to zero because of harmonic waves.ExternalfunctionYou can operate internal Earth Fault Detection in parallel with Thermistor<strong>Motor</strong> <strong>Protection</strong>.With the 3UL22 summation current transformer, rated fault currents of 0.3A, 0.5 A <strong>and</strong> 1 A are evaluated. Response delay time: > 200 ms.If the earth-fault limit is exceeded, a signal is emitted. You can specify additionaltripping circumstances by means of parameterization.NoteThe external Earth Fault Detection function is an alternative to Thermistor<strong>Motor</strong> <strong>Protection</strong> (version of unit).If the rated fault currents are exceeded,<strong>SIMOCODE</strong>-<strong>DP</strong> responds either• with shutdown of the Contactor <strong>Control</strong>s QE1 / QE2 / QE3 or• with a warningdepending on what you have set.GWA 4NEB 631 4286-02a 2-17

The <strong>3UF5</strong>0 Basic UnitDiagramThe following diagram shows an example of Earth Fault Detection:L1L2L3NOnly unit versions <strong>3UF5</strong>0.1-3B...-1External3UL22C1C2A1A2SPE/PE6101235InternalOVERLOADCURRENT ASYMMETRYPHASE FAILUREBLOCKING PROTECTIONCURRENT DETECTION<strong>3UF5</strong>0 Basic Unit789114M3~Fig. 22: Diagram of Earth Fault DetectionSettingsThe following table contains a description of the settings:Designation Range CommentsInternalEarth Fault DetectionExternalEarth Fault DetectionBehaviour in the eventof an earth-faultYesNoYesNoWarningShutdownActiveNot activeActiveNot activeTable 6: Description of the settings for Earth Fault DetectionThe parameters are summarized in the parameter table (Appendix A.2).2-18 GWA 4NEB 631 4286-02a

The <strong>3UF5</strong>0 Basic Unit2.5.4 Thermistor <strong>Motor</strong> <strong>Protection</strong>Description of functionsOperationA Thermistor-detector circuit can be connected to versions <strong>3UF5</strong>0.1 to 3A...for direct temperature detection. Thermistor <strong>Motor</strong> <strong>Protection</strong> is an alternativeto external Earth Fault Detection.If the resistance values are exceeded (PTC) or fall below a certain value(NTC), the <strong>SIMOCODE</strong>-<strong>DP</strong> reacts either• by turning off the Contactor <strong>Control</strong>s QE1 / QE2 / QE3 or• with a warning,depending on the setting you have entered.NoteThermistor <strong>Motor</strong> <strong>Protection</strong> is an alternative to the external Earth FaultDetection function (version of unit).Types of detectorThree types of detector can be evaluated:Type Behaviour Characteristic Comments1 PTCBinaryRWarning or shutdown can be set.2 PTCAnalogKTY3 NTCAnalog1 2 υTable 7: Types of detector for Thermistor <strong>Motor</strong> <strong>Protection</strong>RR1 2υυTwo thresholds can be evaluated.1. Warning <strong>and</strong>2. ShutdownTwo thresholds can be evaluated.1. Warning <strong>and</strong>2. ShutdownGWA 4NEB 631 4286-02a 2-19

The <strong>3UF5</strong>0 Basic UnitDiagramThe following diagram shows an example of Thermistor <strong>Motor</strong> <strong>Protection</strong>:L1L2L3NOnly device versions <strong>3UF5</strong>0.1-3A..T1T2A1A2SPE/PE1235OVERLOADCURRENT AYMMETRYPHASE FAILUREBLOCKING PROTECTIONCURRENT DETECTION<strong>3UF5</strong>0 Basic Unit789116104M3~ϑFig. 23: Diagram for Thermistor <strong>Motor</strong> <strong>Protection</strong>SettingsThe following table contains a description of the settings.Designation Range CommentsPTC BinaryBehaviour PTC BinaryPTC Analog/KTYNTC AnalogYesNoWarningShutdownYesNoYesNoActiveNot activeActiveNot activeActiveNot activeAnalog trippingthresholdAnalog warningthreshold0..5,1 km Increment 20 m0...5,1 km Increment 20 mShort-circuit in detectorlineYes / NoOnly indicatedTable 8: Description of the settings for Thermistor <strong>Motor</strong> <strong>Protection</strong>The parameters are summarized in the parameter table (Appendix A.2.).2-20 GWA 4NEB 631 4286-02a

Function Block InputsAuxiliary control inputsThe <strong>3UF5</strong>0 Basic Unit2.6 Branch control2.6.1 <strong>Control</strong> <strong>and</strong> motor protection blockDescription of functionsIn order to provide reliable protection of the motor branch, you must assignthe control comm<strong>and</strong>s to the control <strong>and</strong> motor protection block.NoteOtherwise Operator Enabling signals, <strong>Control</strong> Functions <strong>and</strong> protection functionshave no effect.DiagramThe principle is illustrated in the following diagram:<strong>Control</strong> <strong>and</strong> motor protection blockLOC-On1LOC-OffLOC-On2<strong>DP</strong>-On1<strong>DP</strong>-Off<strong>DP</strong>-On2C+M-On1C+M-OffC+M-On2<strong>Control</strong> StationsLocal<strong>DP</strong>C+MOperator EnablingGroupcontrolStationOn1232Off233On2234<strong>Control</strong> Function<strong>Motor</strong> protection functionsQE1QE2QE3229230231OP-On1OP-OffOP-On2OPPCS1S2CSTOPORTSUVOExt.Fa1Ext.Fa2Ext.WarnEm.StartExt.Diag.PLC-CPUExt.CS1Ext.CS2Ext.CS3Test1Test2Reset1Reset2Reset3PCPOTCTOFig. 24: <strong>Control</strong> <strong>and</strong> motor protection blockGWA 4NEB 631 4286-02a 2-21

The <strong>3UF5</strong>0 Basic Unit<strong>Control</strong> Stations<strong>Control</strong> Function<strong>Motor</strong> protectionfunctionThe set Operator Enabling signals are processed in the <strong>Control</strong> Stationsblock, <strong>and</strong> the <strong>Control</strong> Function, for example reversing starter, in the nextblock. Depending on which <strong>Control</strong> Function is selected, all interlocks, logicoperations <strong>and</strong> delays are implemented here. If Function Blocks are requiredor Auxiliary <strong>Control</strong> Inputs need to be used, for example for actuator/Positionercontrol, these have an effect on the <strong>Control</strong> Function.The motor protection function acts as the last block in this chain. The Contactor<strong>Control</strong>s QE1/QE2/QE3 switch in accordance with the <strong>Control</strong> Functionbeing used, see Table 11: on page 2-27.The Contactor <strong>Control</strong>s QE1/QE2/QE3 have a high signal after an "On" comm<strong>and</strong><strong>and</strong> a low signal after an "Off" comm<strong>and</strong> or if a fault applies, in otherwords the motor branch is reliably switched on <strong>and</strong> off even in the event of afault.Reliable on/offswitchingThe Contactor <strong>Control</strong>s QE1/QE2/QE3 reliably switch the motor branch on<strong>and</strong> off.2.6.2 Information data blockDescription of functionsThe information data block makes important operating data <strong>and</strong> signals available,such as On, Off, Left, Right, Slow, Fast, Close, Open, warnings, faultsetc. (see also assignment table, Appendix A.1). You can connect these signalsto the outputs of the system, transmit them via PROFIBUS-<strong>DP</strong> or displaythem on the Operator Panel.DiagramThe principle is shown in the following diagram:Informationdata blockQLE1QLAOperating dataQLE2QLS224225226227244signals(assignmenttable A.1)Overload.ThermistorFig. 25: Diagram of information data block2-22 GWA 4NEB 631 4286-02a

The <strong>3UF5</strong>0 Basic Unit2.6.3 Description of the <strong>Control</strong> Stations<strong>Control</strong> Stations are points from where switching comm<strong>and</strong>s (for example<strong>Motor</strong> On or <strong>Motor</strong> Off) are issued. Possible <strong>Control</strong> Stations include:1. Local <strong>Control</strong> Station, which is situated in the immediate vicinity of the motor<strong>and</strong> is operated via pushbuttons, for example.2. PROFIBUS-<strong>DP</strong>, switching comm<strong>and</strong>s from the automation system (PLC).3. HMI, as an additional option for control via an operator control <strong>and</strong> monitoringstation (human-machine interface)or via PROFIBUS-<strong>DP</strong>V1 with theWin-<strong>SIMOCODE</strong>-<strong>DP</strong>/Professional software.4. <strong>3UF5</strong>2 Operator Panel, which is fitted in the switchgear cubicle door.The <strong>SIMOCODE</strong>-<strong>DP</strong> system provides these <strong>Control</strong> Stations internally. The<strong>Control</strong> Stations each have three internal inputs: On1, On2, Off.NoteThe internal input LOC-Off is inverted <strong>and</strong> 0 is therefore active. As a resultthe Contactor <strong>Control</strong>s QE1/QE2/QE3 are deactivated in the event of a wirebreak in the supply lead to the external stop button, for example, <strong>and</strong> canonly be reactivated when the fault has been rectified.LOC-On1LOC-OffLOC-On2<strong>DP</strong>-On1<strong>DP</strong>-Off<strong>DP</strong>-On2C+M-On1C+M-OffC+M-On2OP-On1OP-OffOP-On2<strong>Control</strong> StationsLocal<strong>DP</strong>C+MOPOperator EnablingThe options for assignment to the internalinputs of the <strong>Control</strong> Stations include, forexample:• the external Local <strong>Control</strong> Station (start <strong>and</strong>stop buttons, which are wired to the inputsof the <strong>3UF5</strong>0 Basic Unit)• the buttons of the Operator Panel• the PROFIBUS-<strong>DP</strong> control bits• the PROFIBUS-<strong>DP</strong>V1 control bitsS1S2PCFig. 26: Diagram of <strong>Control</strong> StationsGWA 4NEB 631 4286-02a 2-23