Why does Fibre Cement Matter? - ENGINEERED ASSEMBLIES

Why does Fibre Cement Matter? - ENGINEERED ASSEMBLIES

Why does Fibre Cement Matter? - ENGINEERED ASSEMBLIES

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

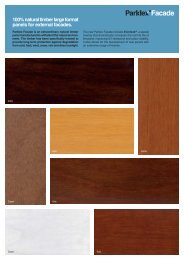

High Density vs. Medium Density We consider fibre cement products with a density of 1650 gr/m³ or more to be high density. Medium density fibre cement, which means it has less density than High density cladding panels, has been developed for the residential marketplace, the most common of those being Hardipanel. The difference is in durability, resistance to water that can cause cyclical freeze thaw failure, dimensional tolerance and other factors that affect longterm performance and design freedom. Because of these properties; • Medium density panels can’t be used in high rise buildings • Medium density panels need to be coated, on both sides • Medium density panels need more supporting structure, for example on one recent job the girt and fastener spacing with medium density panels was 16” on centre, while in high density fastener and girt spacing are typically 24”. That is why the majority of uses are for residential applications. One might ask why residential buildings can accept less quality products when they must last as long as any institutional building. Surfaces and colours The natural, untreated surface of fibre cement is velvety and open-‐pored. Products for external use are coated or treated with a hydrophobic coating so that efflorescence and dirt do not become a problem. The rear side is treated in a similar way to balance the forces. <strong>Fibre</strong> cement surfaces are smooth, sanded or textured. The most used panels are smooth. Innovation occurs in the colour availability, the thru coloured aspect combined with a pigmented transparent top-‐coating. Some manufacturers even provide an extra anti-‐graffiti layer! Colours can provide the cement look, or be a fully covering surface coating. Colour-‐thru panels are created by including pigments, in the cement slurry, during manufacturing. They provide colour while maintaining the natural cement aesthetic. Some panels can have slight irregularities and imperfections that allow the wall to have some variability. This is desired in order to give the wall some ‘life’. If a more homogeneous look is desired, panels are available that have a coating that makes the panels identical. Colour fastness or durability is dependent upon the manufacturer and the choice of pigments. Dark colours can fade, and some manufacturers design with this in mind. Others have spent research and development to reduce fading and differentiate their products by their colour durability. This can be measured by objective tests. Freeze thaw testing of EN 12467 for distribution, please contact EA 10 at 905 816 2218